Quick and efficient shaping method of super-abrasive grinding wheel

A super-hard abrasive and grinding wheel technology, used in abrasive surface adjustment devices, parts of grinding machine tools, and grinding/polishing equipment, etc., can solve the problems of high consumption of dressing wheels and low shaping efficiency, and improve shaping efficiency and save money. Dressing wheel, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

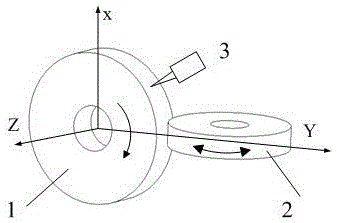

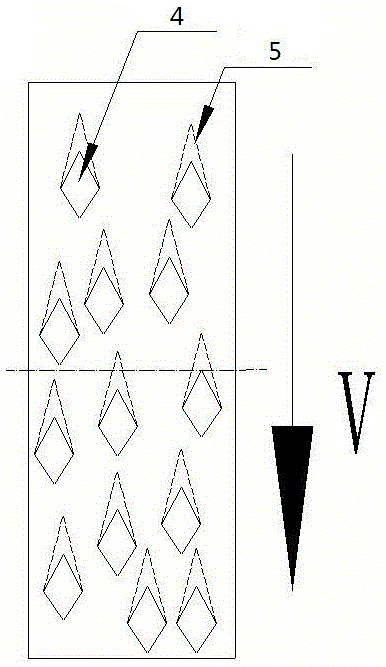

[0021] as attached Figure 1-5 As shown, a fast and efficient dressing method for superabrasive grinding wheels, the specific steps are: install the dressing wheel driver on the grinding machine, make the main shaft of the grinding machine and the main shaft of the driver perpendicular; install the grinding wheel 1 to be dressed on the main shaft of the grinding machine, and install it on the driver Dressing wheel 2, the axes of the dressed grinding wheel and the dressing wheel are arranged in a cross, so that the linear speed directions of the two are perpendicular; the grinding machine spindle motor and the drive motor are respectively connected to their frequency converters, and the frequency converter is connected to the PLC; and, the dressed grinding wheel The time-domain control of the rotational speed of the dressing wheel and the dressing wheel is periodic, and the period of the two is the same, with a phase difference of 180°. Dressing wheel 2 cooperates at high speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com