High-power semiconductor laser array fast and slow axis beam quality homogenization device

A laser array and semiconductor technology, applied in the field of laser technology applications, can solve the problems of poor control of precise positioning between prisms and difficult assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

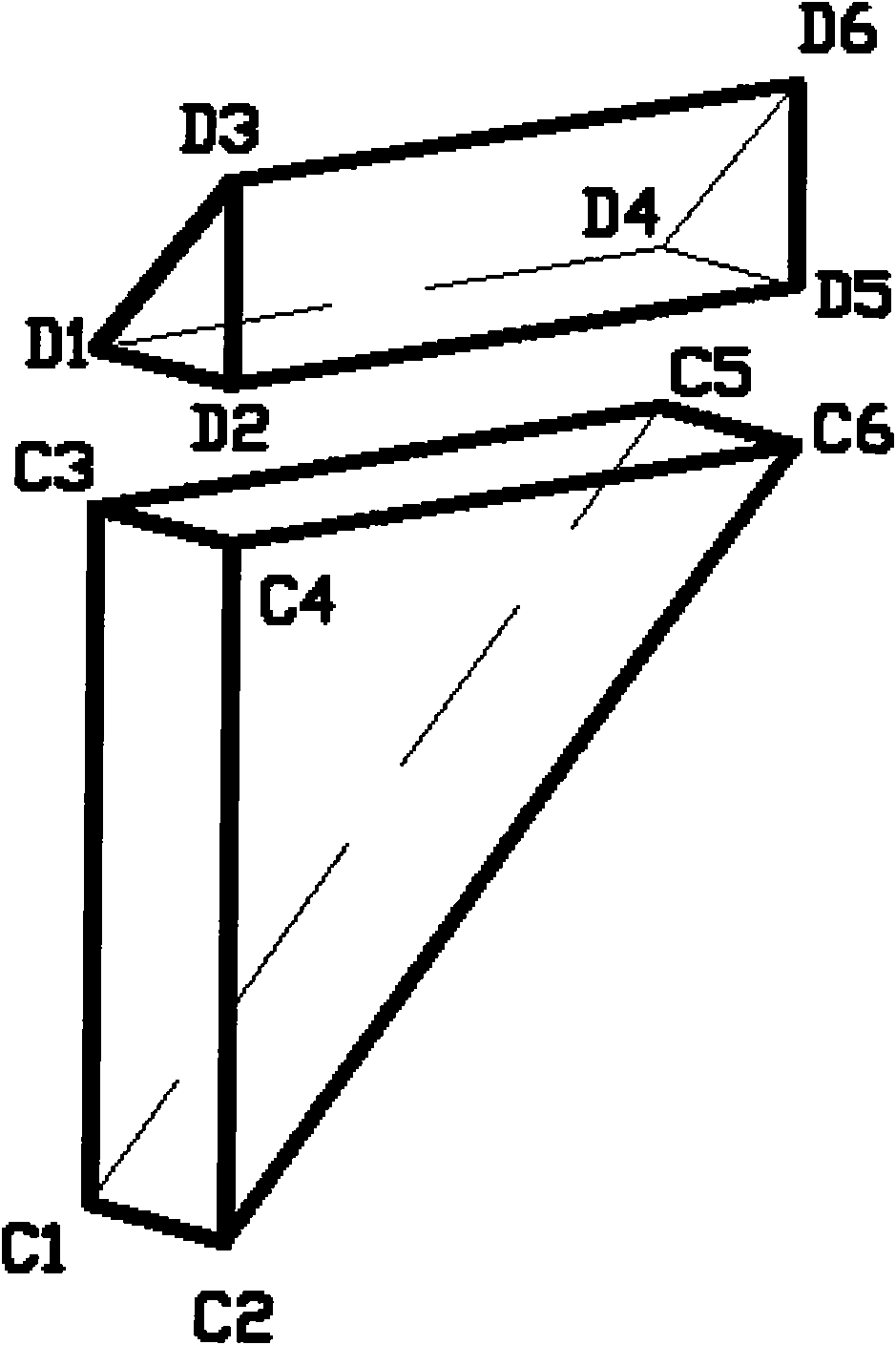

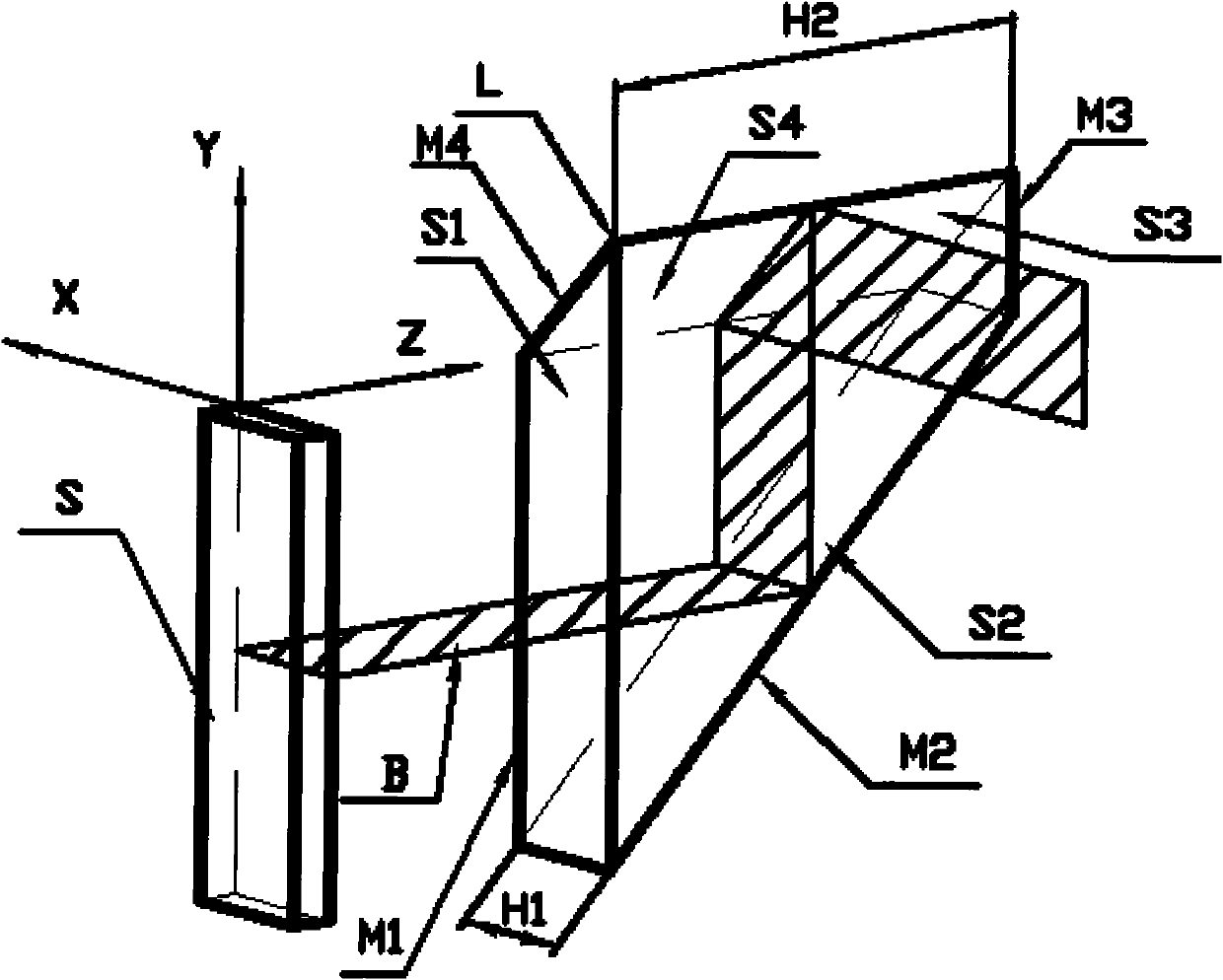

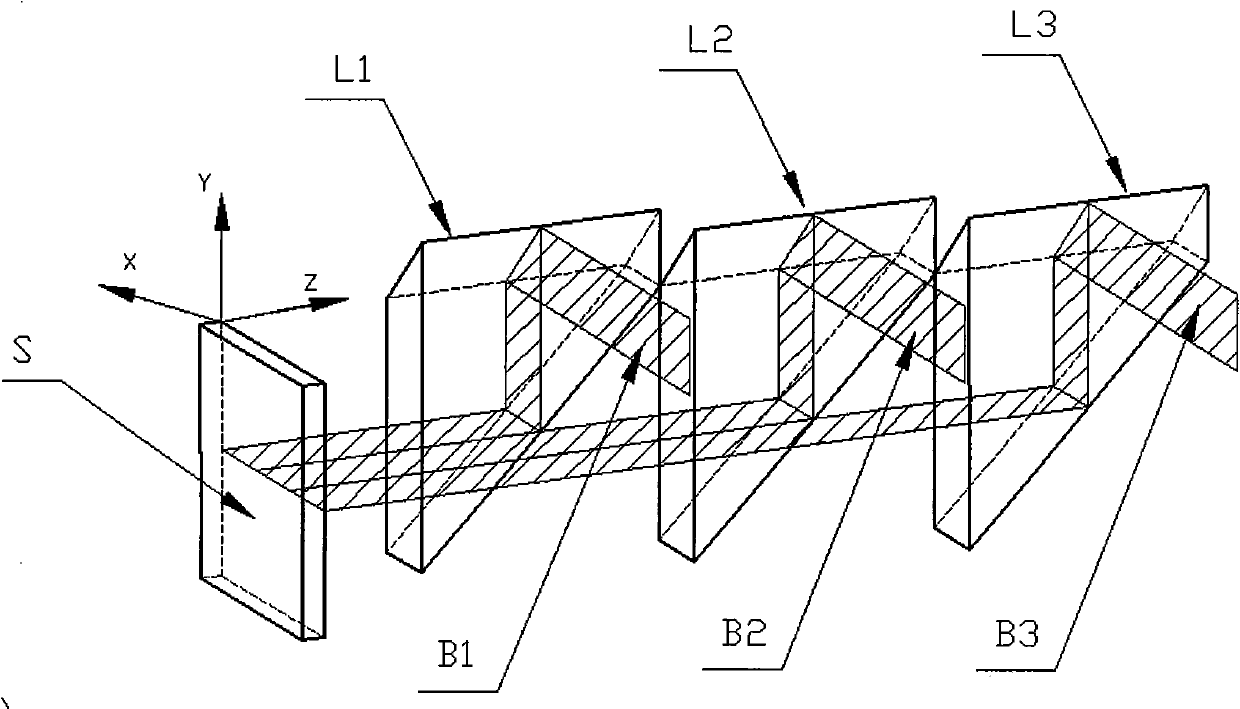

[0026] In this embodiment, the semiconductor laser beam is divided into three parts in the direction of the slow axis, and the structure of the shaping device is as follows: image 3As shown, it includes a semiconductor laser array S, an improved first isosceles right-angle prism L1, an improved second isosceles right-angle prism L2, and an improved third isosceles right-angle prism L3 placed in sequence along the light propagation direction. The structures of the improved isosceles right-angle prisms L1, L2 and L3 are exactly the same, but the placement positions are different. All the prisms are placed in parallel along the direction of the slow axis of the semiconductor laser array, staggered forward and backward by a certain distance, and distributed in a ladder shape. The first surface S1 of all prisms staggered forward and backward by a certain distance, that is, surface C1C2C4C3, performs beam cutting on the slow axis of the laser array, and passes through the second su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com