Strip steel surface deformation shaping apparatus

A surface deformation and strip steel technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems affecting the flatness of the strip steel surface, fine shaping of the strip steel surface, secondary damage to the strip steel quality, etc., to achieve High flatness, good shaping effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

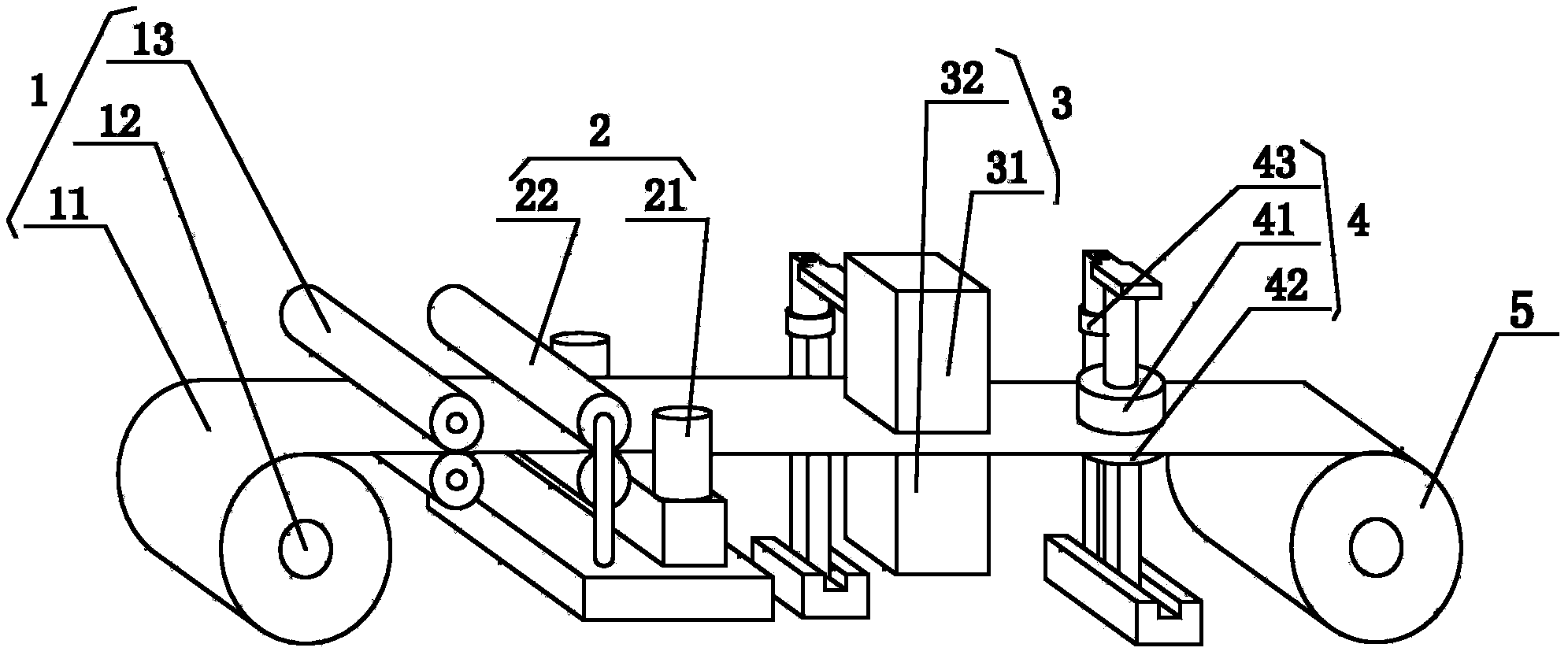

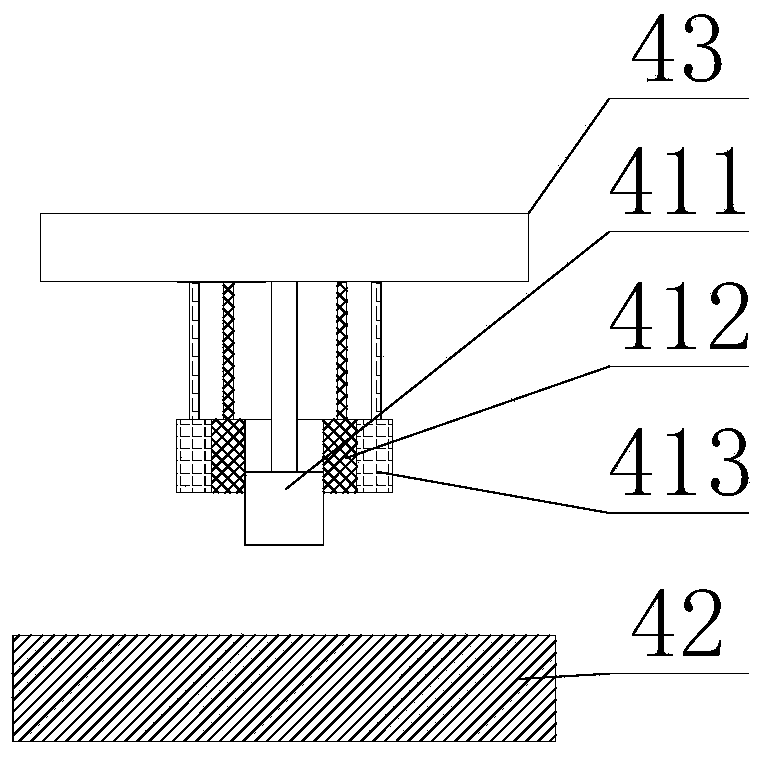

[0017] like figure 1 and 2 as shown, figure 1 It is a structural schematic diagram of a strip surface deformation shaping device proposed by the present invention, figure 2 for figure 1 Schematic cross-sectional view of the shaping mechanism shown.

[0018] refer to figure 1 and 2 , a strip surface deformation shaping equipment proposed by the present invention, comprising a feeding device 1, a limit device 2, a detection device 3, a micro-shaping device 4, and a winding device 5;

[0019] The feeding device 1 comprises a raw material rack 11, a first drive mechanism 12, and an uncoiling mechanism 13. The first driving mechanism 12 is used to drive the raw material rack 11 to rotate so as to send out the coiled steel strip. Flat steel strip;

[0020] The limit device 2 is used to limit the horizontal and vertical positions of the flat steel strip during the feeding process, and it includes a vertical limit mechanism 21 and a horizontal limit mechanism 22, and the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com