Automatic control method for surface defect shaping of strip steel

A technology of surface depressions and defects, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems affecting strip surface flatness, secondary damage to strip quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

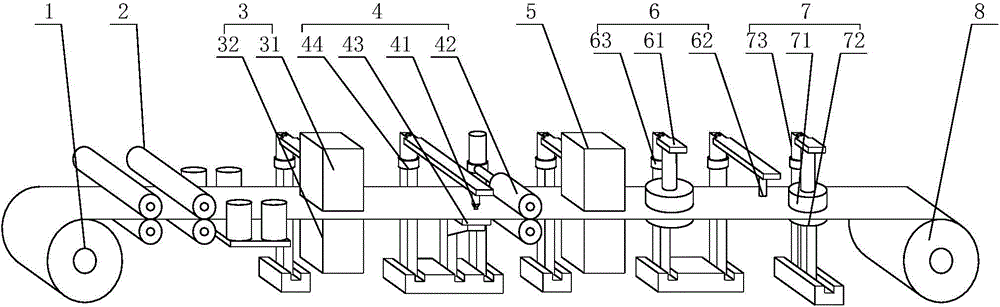

[0019] like figure 1 as shown, figure 1 A structural schematic diagram of an automatic control system for implementing an automatic control method for strip steel surface defect shaping proposed by the present invention.

[0020] An automatic control method for shaping the surface defects of the strip steel proposed by the present invention is used to detect the surface defects of the strip steel and carry out shaping of the surface defects, and is characterized in that it comprises the following steps:

[0021] Strip feeding: develop coiled strips into flat strips and feed them. During the flat strip feeding process, the feeding track of the flat strips is controlled by the horizontal limit mechanism set on the left and right and the vertical limit mechanism set up and down. Carry out limit;

[0022] Defect detection: the distance L1 from the detection probe to the upper surface of the flat steel strip is detected by the first detector, the distance L2 from the detection pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com