Shaping mechanism for powder metallurgy spacer products

A powder metallurgy and product technology, which is applied in the field of mechanical pressing and precision shaping mechanism, can solve the problems of inability to provide large pressure holding, low mechanical press pressure, and difficulty in correcting parallelism, so as to improve the shaping ability, avoid slow movements, and improve The effect of shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

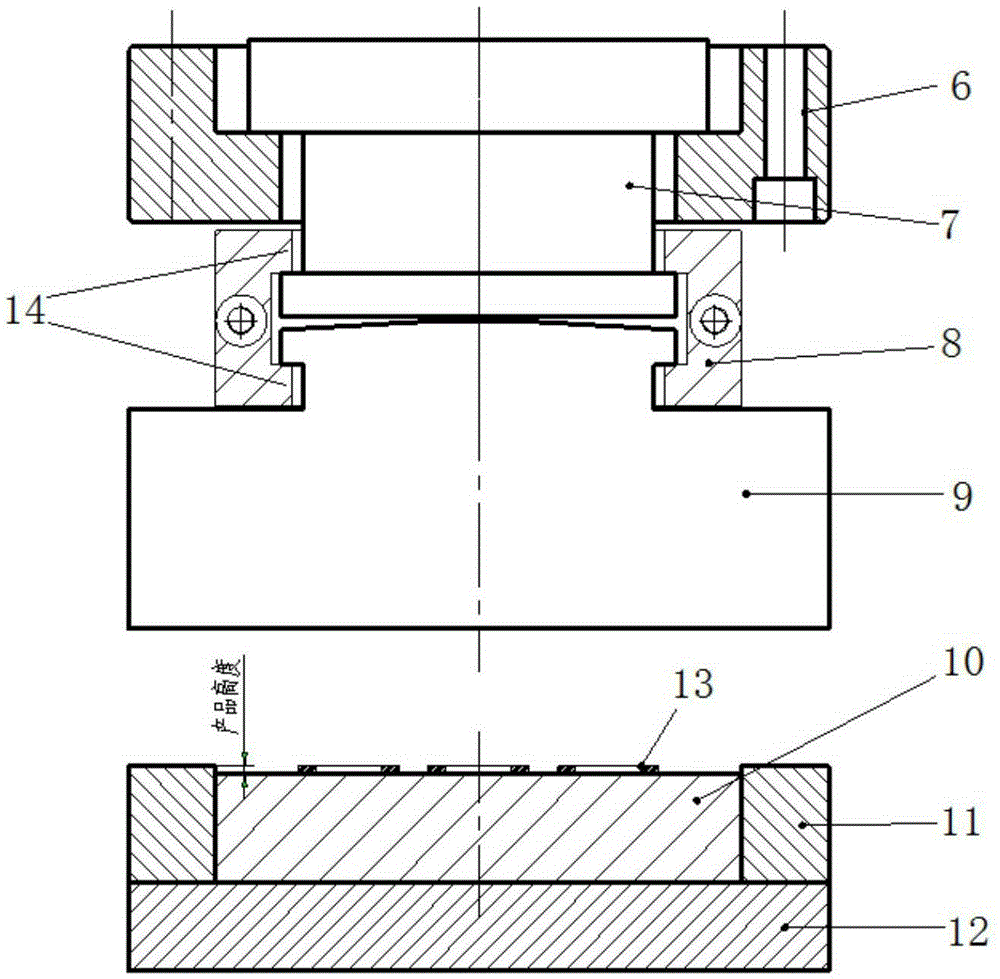

[0015] Such as image 3 As shown, a shaping mechanism for gasket-type powder metallurgy products includes an upper punch connected with an upper punch hanging block 7, and a punch cover 6 is arranged on the side of the upper punch hanging block. The upper punch hanging block 7 is movably connected with a floating punch 9, and the upper punch hanging block 7 and the floating punch 9 are connected by a Haval connecting block 8, and the upper punch hanging block 7 and the floating punch 9 are ladders at the joint shape, both ends of the Haval connecting block have protruding parts 14, and the protruding parts 14 buckle the upper punch hanging block 7 and the stepped part of the connection of the floating punch 9, so that the upper punch hanging, 7 It is connected with the floating punch 9; at the contact point with the upper punch hanging block 7, the floating punch 9 is arc-shaped, and this structure enables the floating punch 9 to have a degree of freedom of movement in the Har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com