Beam shaping of linear laser diode array and coupling system

A diode array and laser diode technology, applied in the coupling of optical waveguide, nonlinear optics, optics, etc., can solve the problem of difficult surface shape of step mirror processing, and achieve the effect of simple structure, convenient processing and high coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

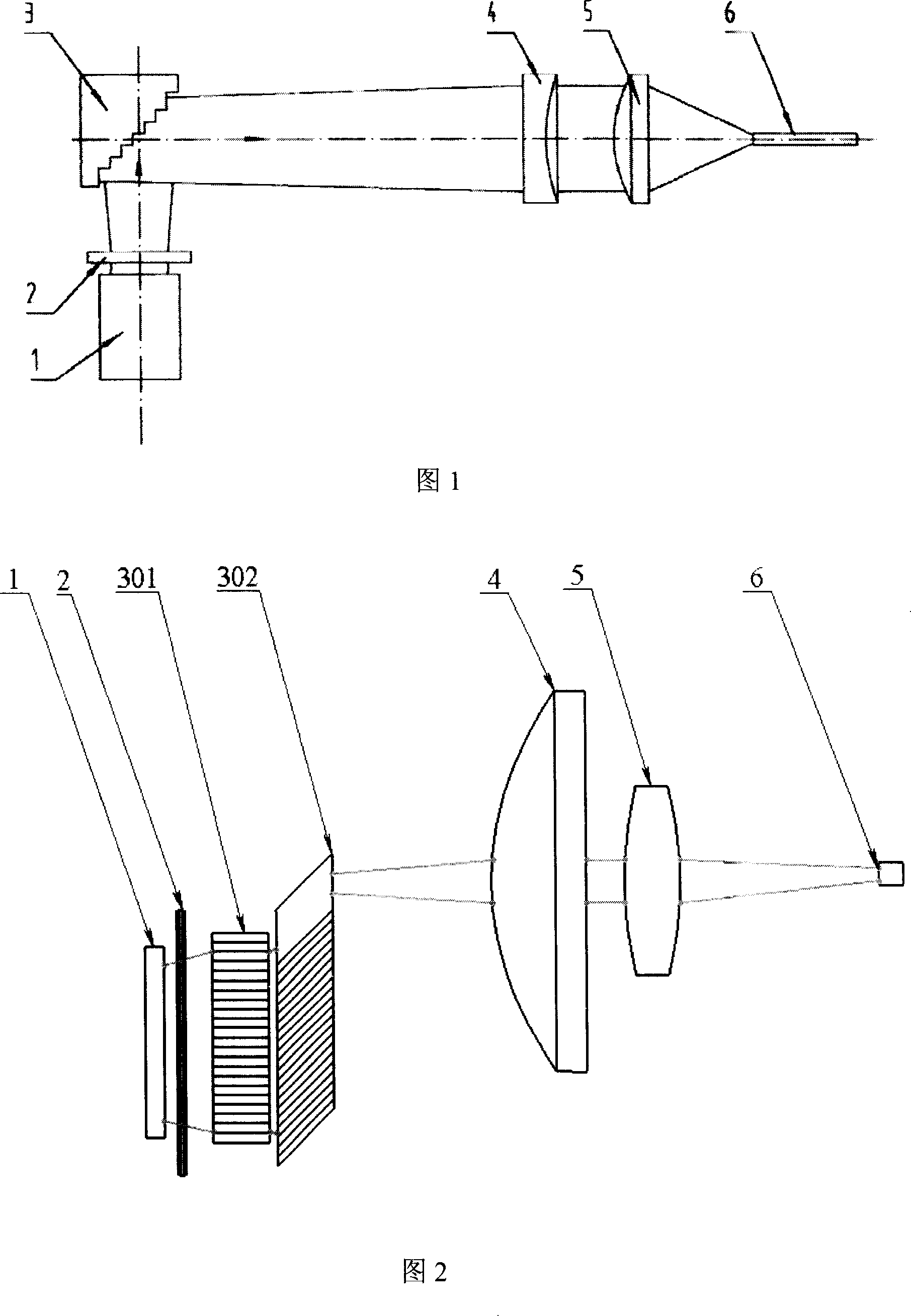

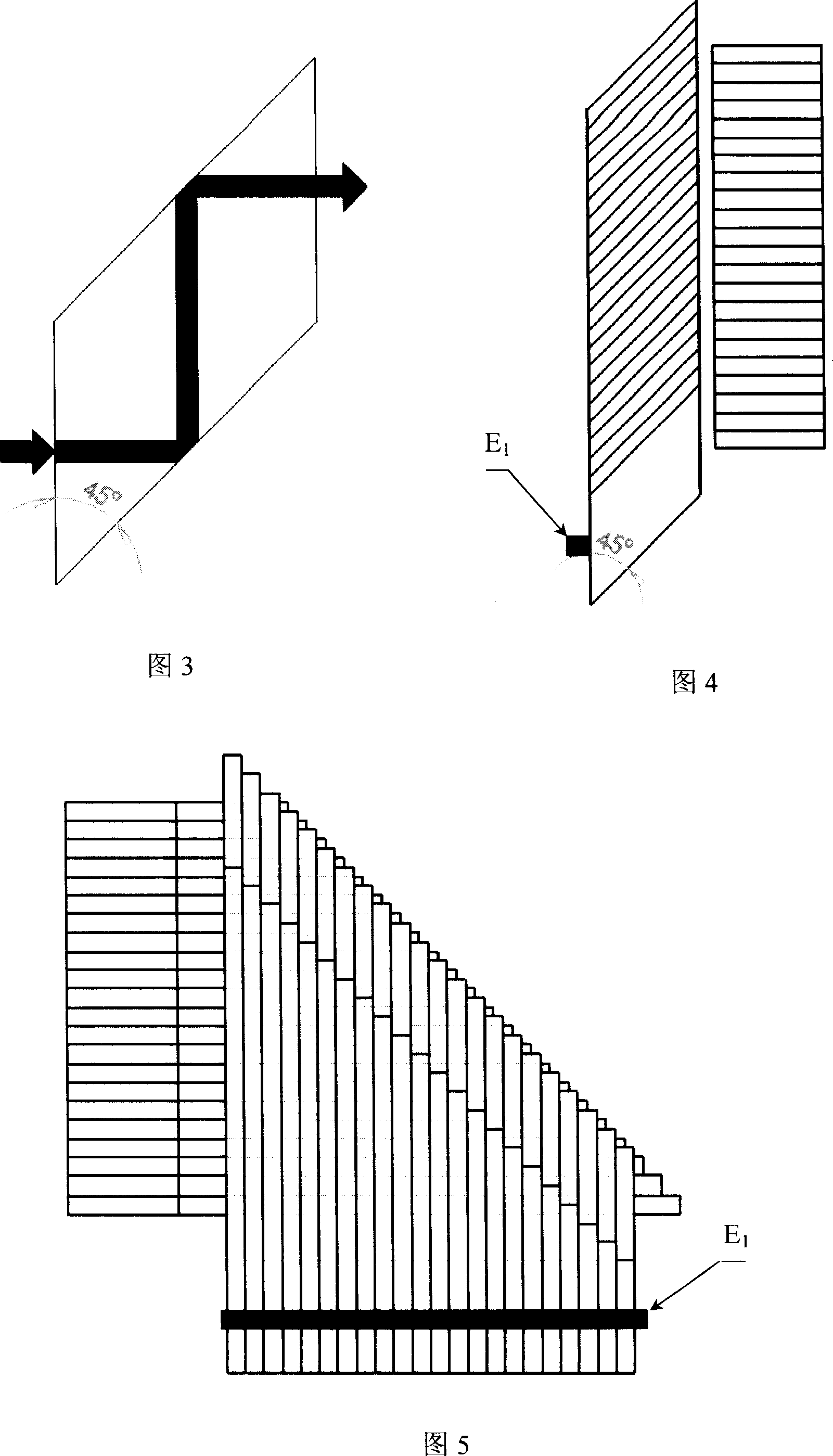

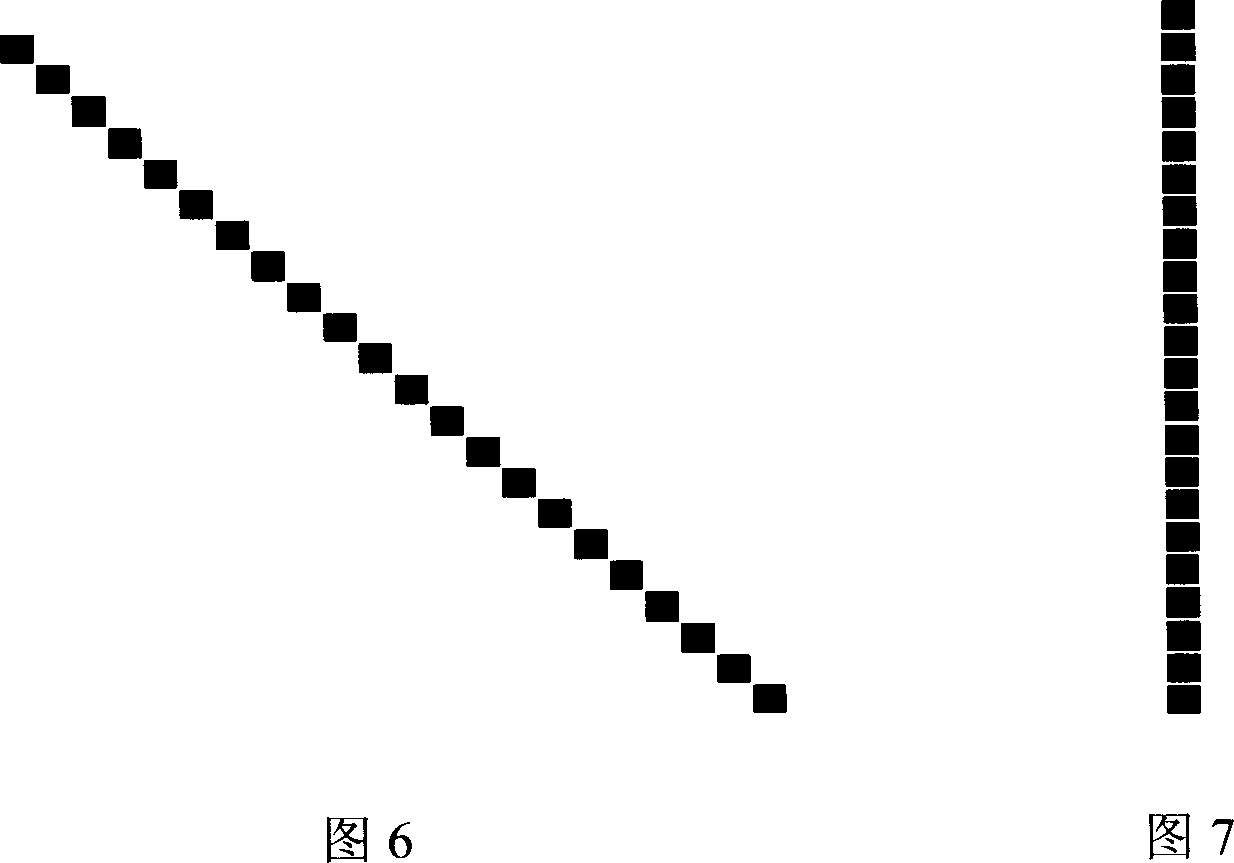

[0026] Use microcylindrical lens 2 to collimate a high-power laser diode array with a length of 1 cm to the direction of the fast axis, and adjust the distance between the microcylindrical lens 2 and the light-emitting surface. Usually, it is not difficult to make the divergence of the fast axis after collimation If the angle is less than 0.5 degrees, the divergence angle in the direction of the slow axis will remain unchanged at this time, about 10 degrees. Considering that the scale of the slow axis increases along with the propagation of the light beam, the distance between the shaper 3 and the microcylindrical lens 2 should be less than 3 millimeters to ensure that the shaper 3 does not need too many microchips to make the linear beam It all goes into the shaper. Shaper 3 is made up of two groups of microchip stacks. Considering that most of the current high-power laser diode arrays are composed of about 20 discontinuous light-emitting regions, each group of microchip stac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| divergence angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com