Radial stretching type concave pipe maintenance device

A technology of repairer and shaper, which is applied in the direction of special pipes, pipe components, pipes/pipe joints/fittings, etc. It can solve the problems of no deformed pipes, long working time, medium stoppage, etc., and achieve large shaping force and shaping effect Good and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

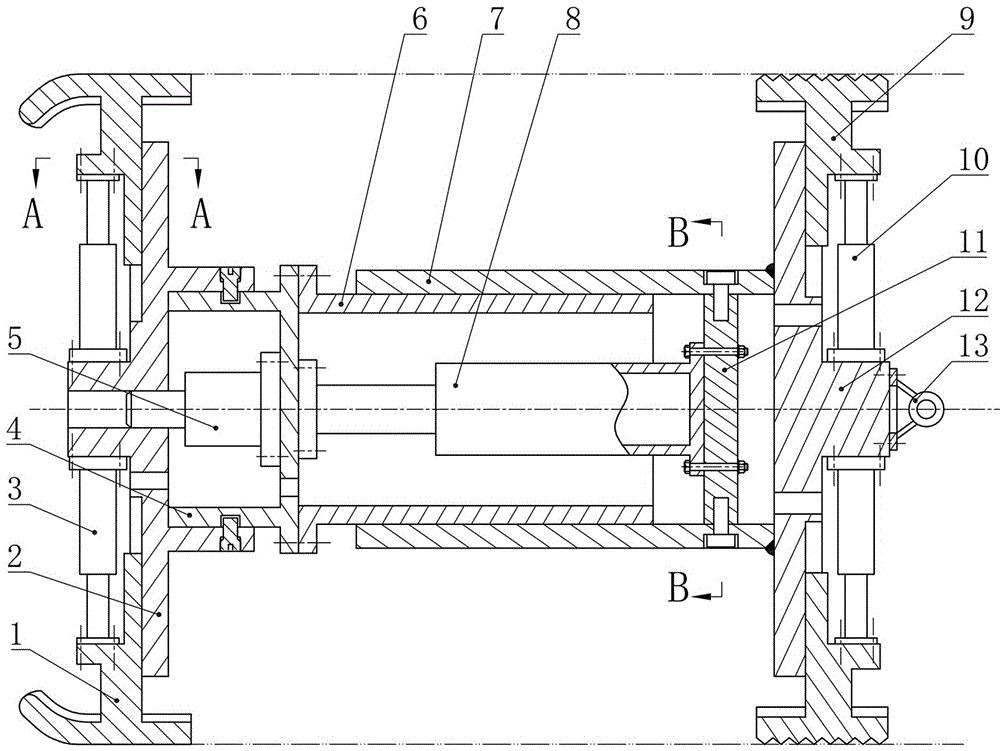

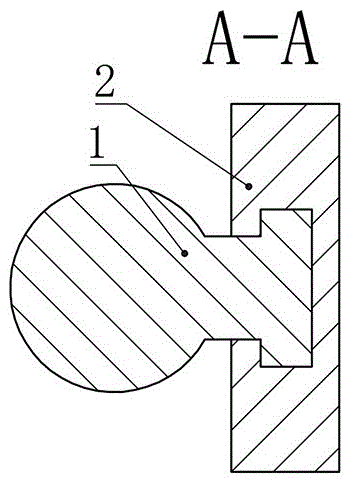

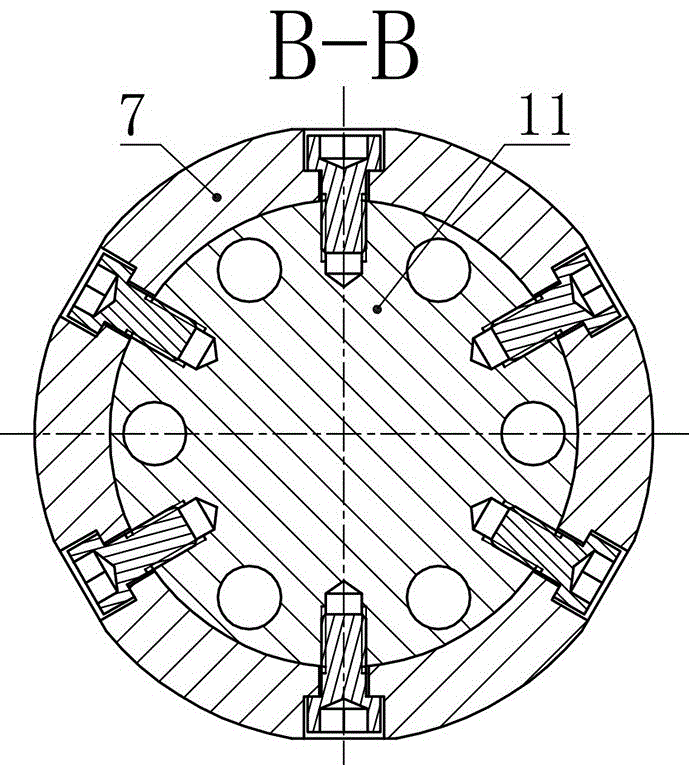

[0017] The present invention is not limited by the following implementation examples, and specific implementations can be determined according to the technical solutions and actual conditions of the present invention. Combine below figure 1 , figure 2 , image 3 The present invention will be described below. The positional relationship of up, down, left and right is based on the instructions attached figure 1 The layout direction is determined.

[0018] The front end cover 2 is in the shape of a disk as a whole and a cylinder is arranged in the middle position. The base 4 is in the shape of a cylinder with a bottom cover as a whole. The base 4 is buckled at the center of the front end cover 2 and fits with the cylinder of the front end cover 2. An outer ring groove is arranged at the middle position on the outside of the cylinder of the base 4, and the front end cover 2 is provided with a screw at the corresponding position and the front end cover 2 and the base 4 are axially f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com