Patents

Literature

30results about How to "Reduce compacted density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing lithium ion battery mixed positive electrode

ActiveCN108933242AExtend your lifeIncrease the output voltageElectrode carriers/collectorsSecondary cellsHigh rateHigh energy

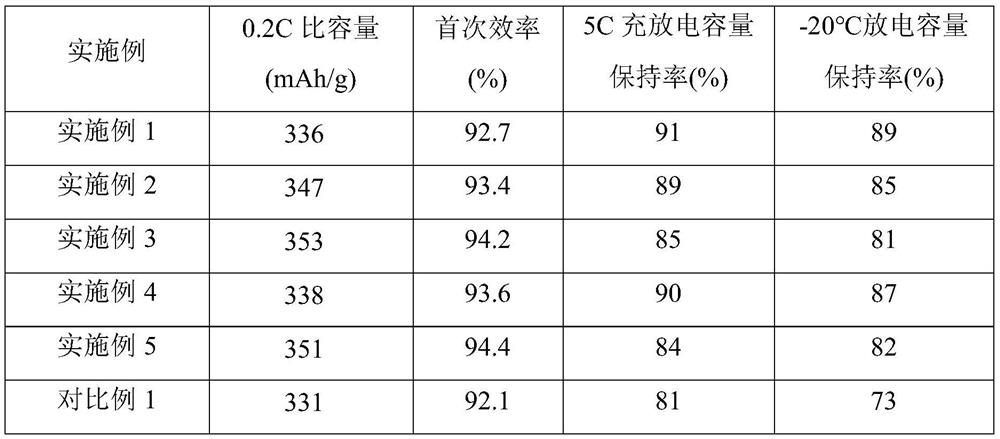

The invention provides a method for preparing a lithium ion battery mixed positive electrode. Slurries comprise different proportions of a first active material, a second active material and a third active material, wherein the molecular formula of the first active material is LiNi0.8Mn0.1Co0.1O2, the molecular formula of the second active material is LiNi0.3Mn0.4Co0.3O2, and the molecular formulaof the third active material is LiMnPO4, and particles with two particle sizes exist in the first active material; the average particle size of the second active material is 50-200 nm, the length-to-diameter ratio of the second active material is 1.1-1.3, and the D90 / D10 value of the second active material is 1.6-2.2; and the average particle size of the third active material is 0.5-1 [mu]m, thelength-to-diameter ratio of the third active material is 1.5-2, and the D90 / D10 value of the third active material is 1.2-1.5. The slurries are respectively prepared according to the different structures of the active materials, a current collector is respectively coated with the slurries to sequentially obtain a first active material layer, a first active material and second active material mixedlayer and a third active material layer along a direction from a position adjacent to the current collector to a position away from the current collector. The slurries obtained in the invention havegood dispersibility and good retention performances, and the positive electrode has good high-rate performances and a high energy density.

Owner:JIANGXI DIBIKE

Quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material and preparation method

InactiveCN105958038AImprove structural stabilityImprove securityCell electrodesSecondary cellsLithiumHigh voltage

The invention relates to a preparation method of a quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material. The preparation method comprises the following steps: preparing Li<2>CO<3> and Co<3>O<4> as raw materials, adding a doping element M, adding a grain refiner and a cosolvent, and performing first sintering; and adding a grain refiner and a coating compound into a firstly-sintered material serving as a raw material, and performing surface coating and second sintering, wherein the doping element M is one or more of Ti<4+>, Zr<4+>, Mn<4+>, Sn<4+>, Ce<4+>, Ir<3+>, Mg<2+>, Al<3+>, V<5+>, Nb<3+> and Co<2+>, a molecular formula of doped lithium cobaltate is LiCo<1-x>M<y>O<2-y>; and the grain refiner is one or more of oxides of Ti, Nb, V, Al and Zr. The prepared lithium cobaltate positive electrode material has the characteristics of rapid charging, high capacity, high voltage, high cycle and low cost, can be applied under a rapid-charging high-voltage condition, and has superior electrochemical performance.

Owner:湖南美特新材料科技有限公司 +1

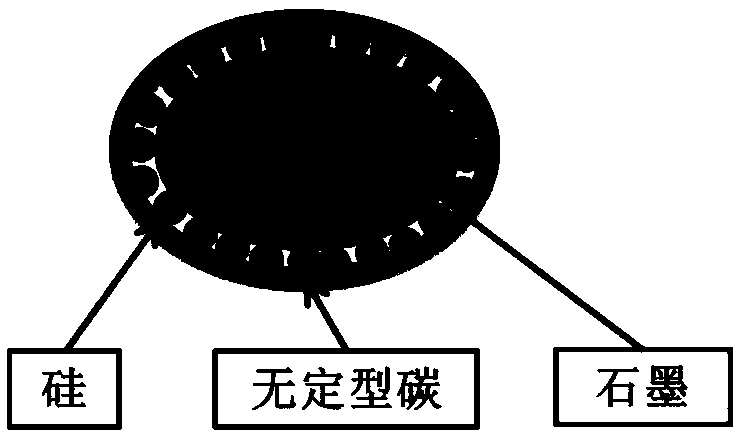

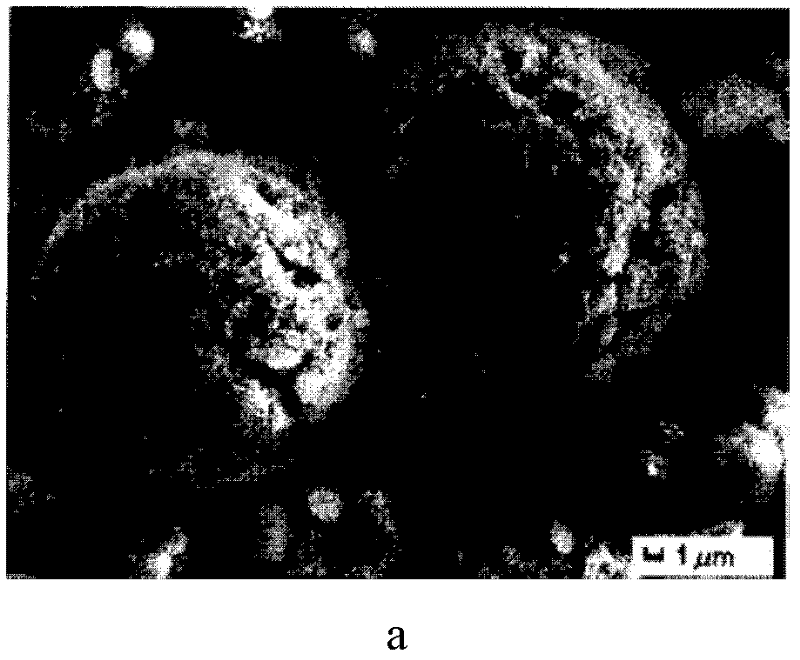

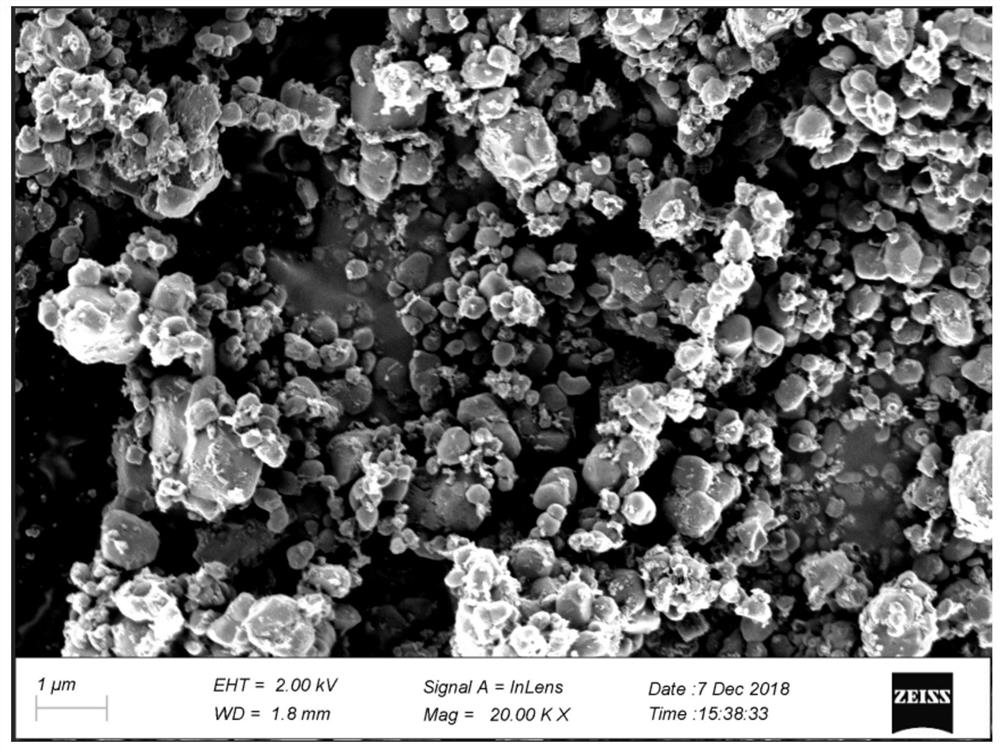

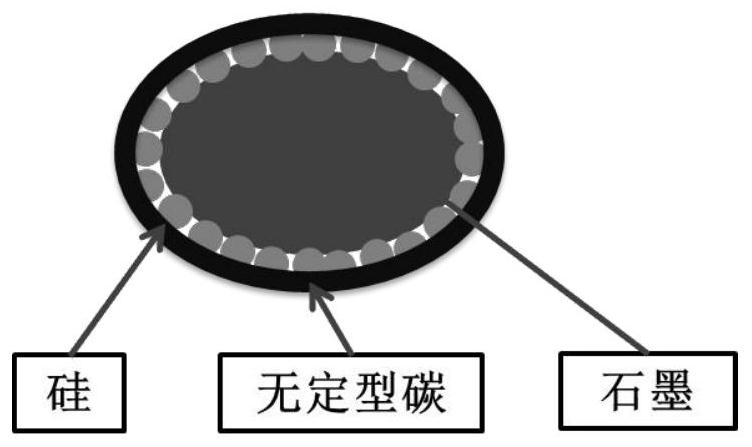

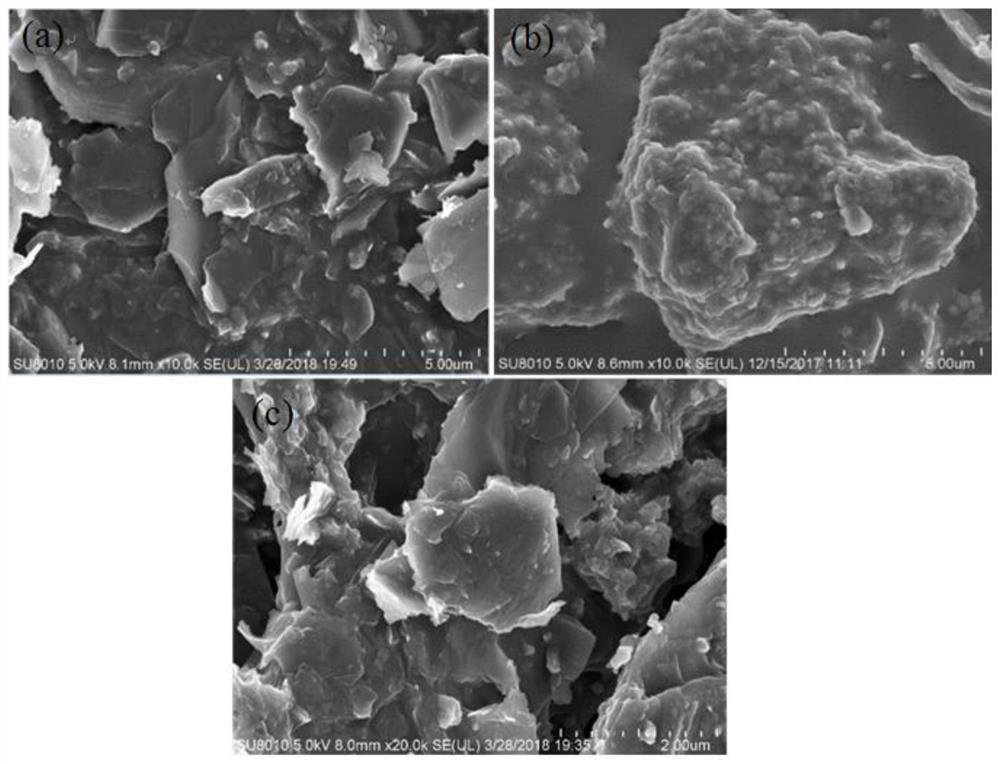

Preparation method of silicon-carbon anode material and lithium ion battery

The invention discloses a preparation method of a silicon-carbon anode material and a lithium ion battery. The preparation method includes: mixing nano-silicon with graphite solid phase, sieving the mixture, mixing the mixture with an amorphous carbon precursor solid phase, sieving the mixture, performing vibrating shaping, and sintering the product to obtain the silicon-carbon anode material. Bymeans of sieving, the graphite, nano-silicon and amorphous carbon precursor are dispersed, so that the surface of graphite can be uniformly coated with the nano-silicon and the surface of nano-siliconcan be uniformly coated with the amorphous carbon precursor; through the vibrating shaping, surface-to-surface contact between the amorphous carbon precursor and the nano-silicon and between the nano-silicon and the graphite is achieved without existence of a gap; through the sintering step, a volatile substance can be slowly volatilized from interior to exterior, so that a problem of forming pores since a huge gas pressure is generated from the volatile substance can be avoided. The silicon-carbon anode material, when being used for producing the lithium ion battery, shows excellent electrochemical cyclic stability.

Owner:湖北融通高科先进材料集团股份有限公司

A preparing method of a high-power high-energy density lithium ion battery

InactiveCN104766998ARegular shapeGood conductivityFinal product manufactureCell electrodesCarbon nanotubeLithium electrode

A preparing method of a high-power high-energy density lithium ion battery is provided. According to the lithium ion battery, the cathode material is Li(Ni<0.6>Co<0.2>Mn<0.2>)O2 / carbon nanotube composite ternary material, the inner core is hollow, the outer core is of a double-layer structure, the first layer is Li(Ni<0.6>Co<0.2>Mn<0.2>)O2, and the outer layer is carbon nanotubes. The preparing method includes following steps: 1) preparing the cathode material and 2) preparing an anode material. The ternary material prepared by the preparing method is structured and uniform in morphology, large in particles, irregular in morphology, and high in conductivity. A particle gap is reduced, and compaction density and conductivity of the ternary material are improved. By a chemical vapor deposition method, the carbon nanotubes with high conductivity are deposited on the surface of the ternary material, thus further improving conductivity and rate performance of the lithium ion battery.

Owner:JIANGSU LENENG BATTERY INC

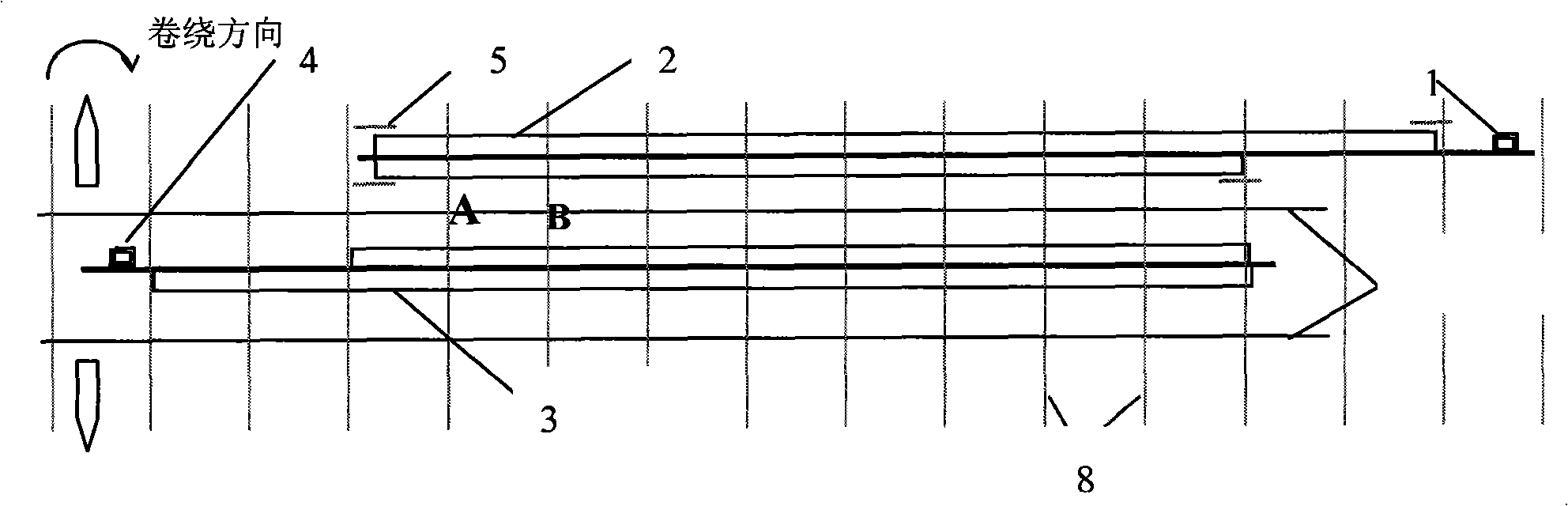

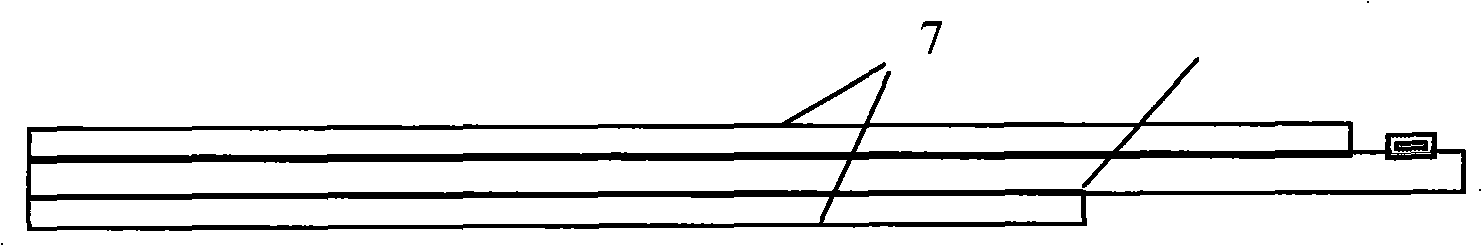

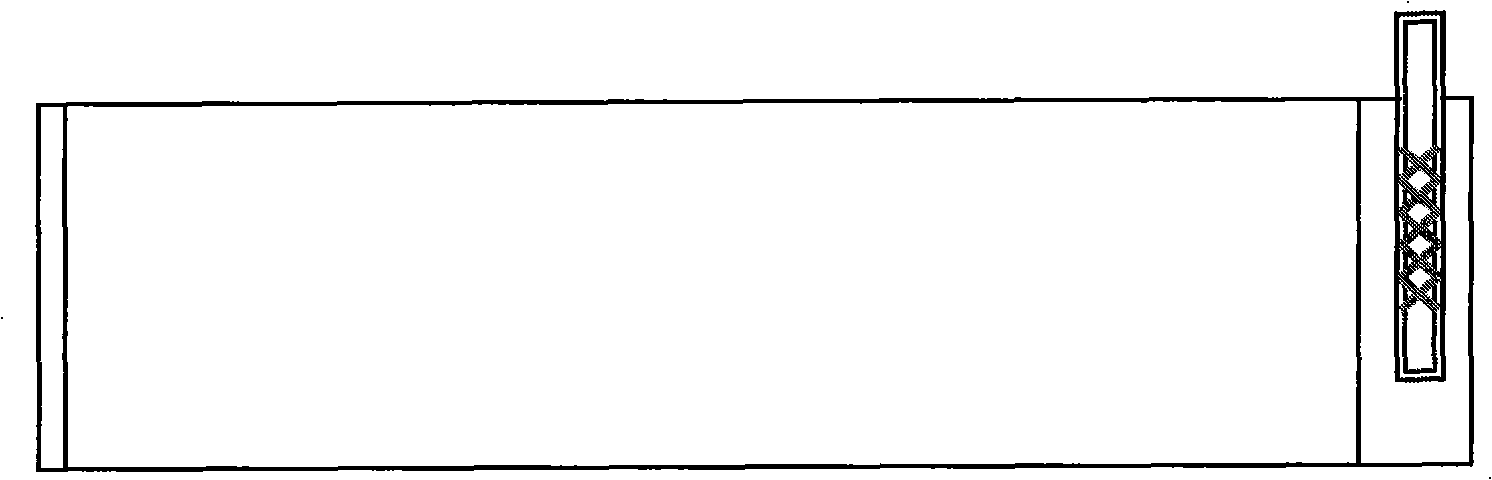

Coil type battery plate group and battery comprising the same

ActiveCN101339983AReduce compacted densityHigh tensile strengthFinal product manufacturePrimary cellsStress concentrationSpecific energy

The invention discloses a wound battery polar pack and a battery including the battery polar pack, which relate to the technical field of batteries. The wound battery polar pack comprises a positive plate and is characterized in that a winding head end of the positive plate is provided with a thin coated section. The battery comprises the wound battery polar pack which comprises the positive plate and the battery is characterized in that the positive plate is provided with the thin coated section close to the winding head end. In the invention, as the winding head end of the positive plate is provided with the thin coated section, compared with the battery which is not provided with the thin coated section and has the same volumetric specific energy, the battery can reduce the compaction density of the positive plate at the position, thus improving the tensile strength of the positive plate, reducing the stress concentration of the positive plate at the folding place of the section and avoiding possible fracture trouble of the positive plate at the position.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Granule-based wax sweating method

ActiveCN109810725AIncrease heat transfer areaIncreased flow poresPetroleum wax recoveryParaffin waxWarm water

A granule-based wax sweating method comprises the following steps: (1) filling water to the bottom part of a sweating device; (2) heating paraffin to a liquid state, adding sweating granules, and thenadding the mixture in the sweating device; (3) cooling the paraffin to be 10 to 20 DEG C lower than a melting point at the speed of 1 to 4 DEG C / h; (4) releasing the water, pumping warm water to a sweating tank, heating at the speed of 0.5 to 2 DEG C / h, and collecting the paraffin which can sweat at different melting points; (5) melting the paraffin after finishing heating, and enabling a moltenhigh-melting-point paraffin product to flow into an intermediate tank; (6) blowing residual sweating granules and the last one distillate in the sweating tank by using steam, filtering and separatingthe sweating granules and the distillate, and recycling the sweating granules. According to the granule-based wax sweating method disclosed by the invention, the compaction density of sweating raw materials is reduced, outflow of oil content and low-melting-point wax can be facilitated, the fluidity of sweating liquid is improved, and the separation effect is multiplied; meanwhile, the yield of asweating product is higher, a wax melting range is narrower, a wax product is concentrated in molecular weight, and the enthalpy value of a product is higher.

Owner:上海焦耳蜡业有限公司

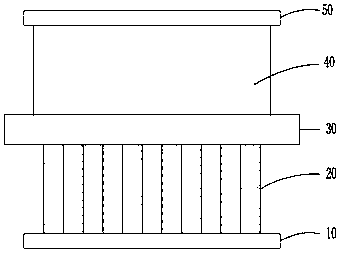

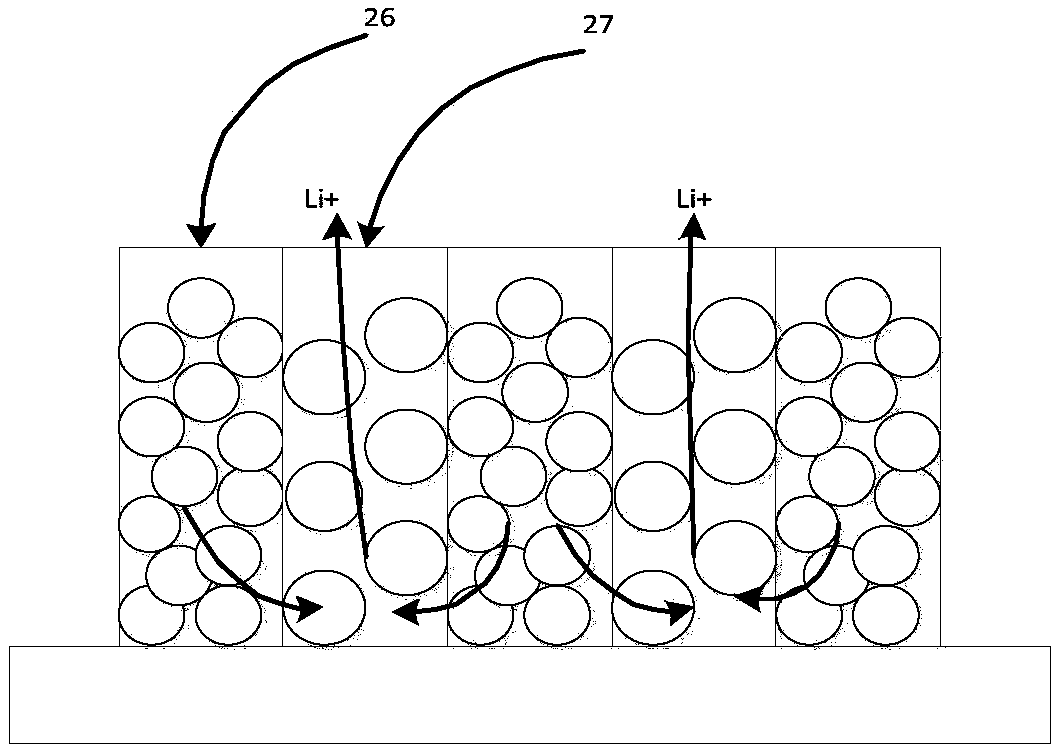

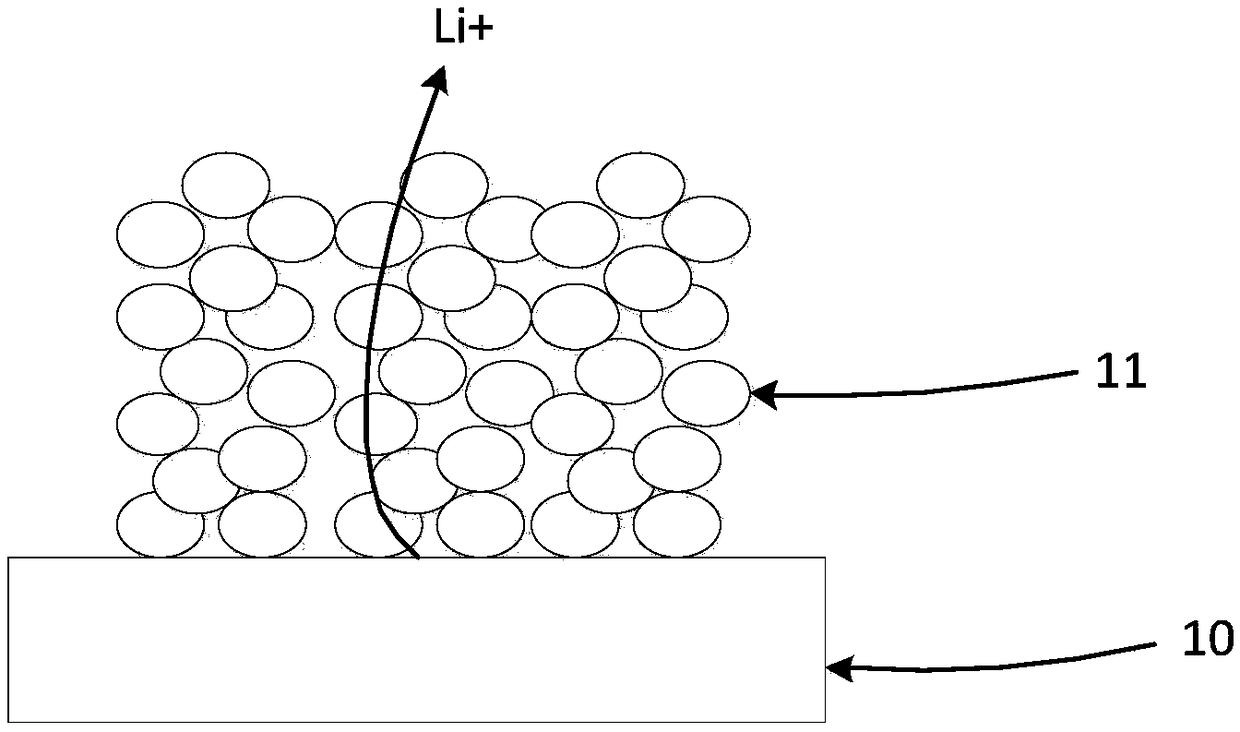

Lithium ion battery cathode plate and lithium ion battery

InactiveCN108832135AShorten the diffusion distanceGuaranteed thicknessElectrode carriers/collectorsSecondary cells servicing/maintenanceConductive polymerElectrical battery

The invention provides a lithium ion battery cathode plate. The lithium ion battery cathode plate comprises a current collector and a cathode material layer deposited on the surface of the current collector; the cathode material layer comprises a number of cathode material stripe units; the adjacent cathode material stripe units are contacted in a conductive manner; and in the adjacent cathode material stripe units, the types and / or contents of the cathode active materials and / or additives are different, wherein the additives are additives with foaming function.

Owner:SHENZHEN UTILITY POWER SOURCE CO LTD

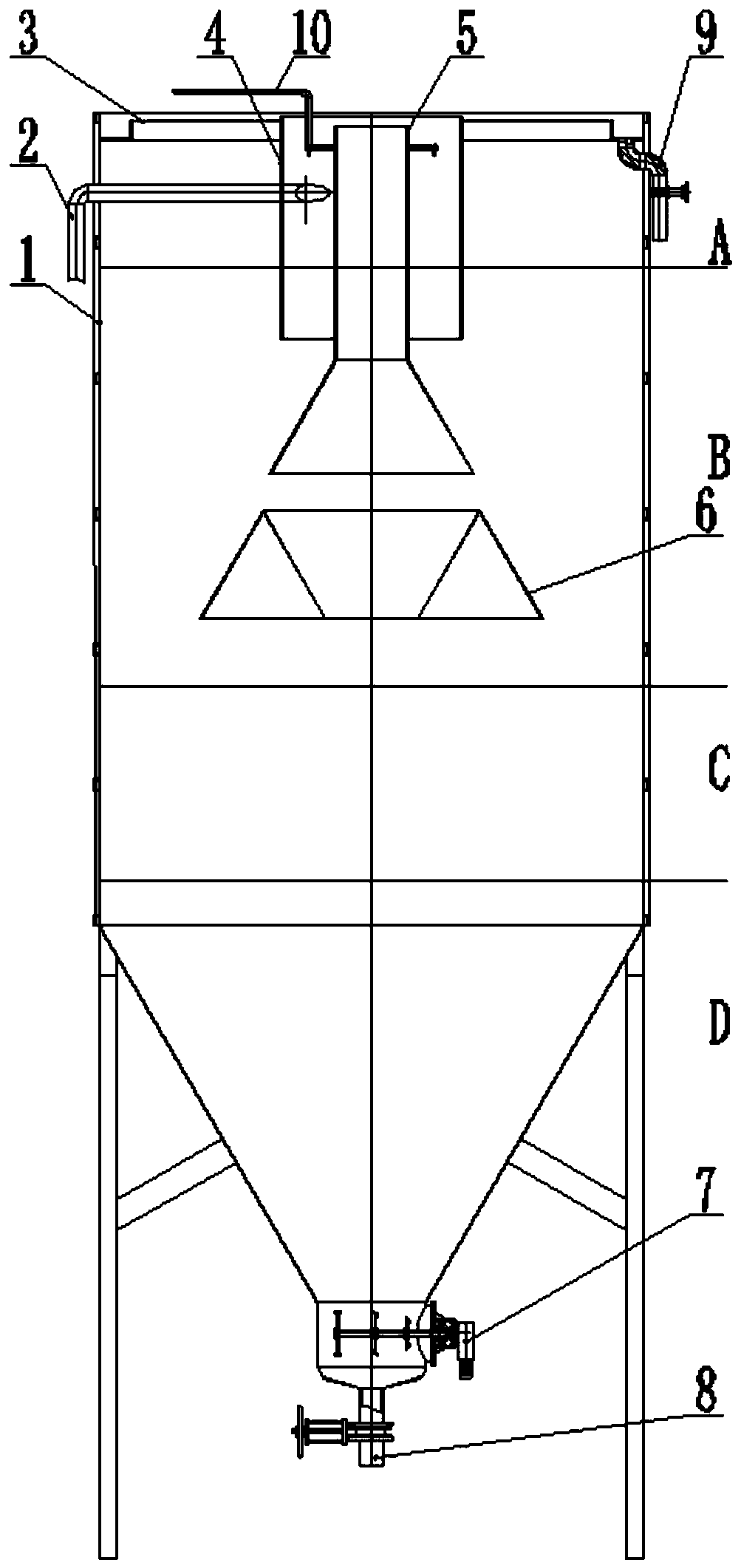

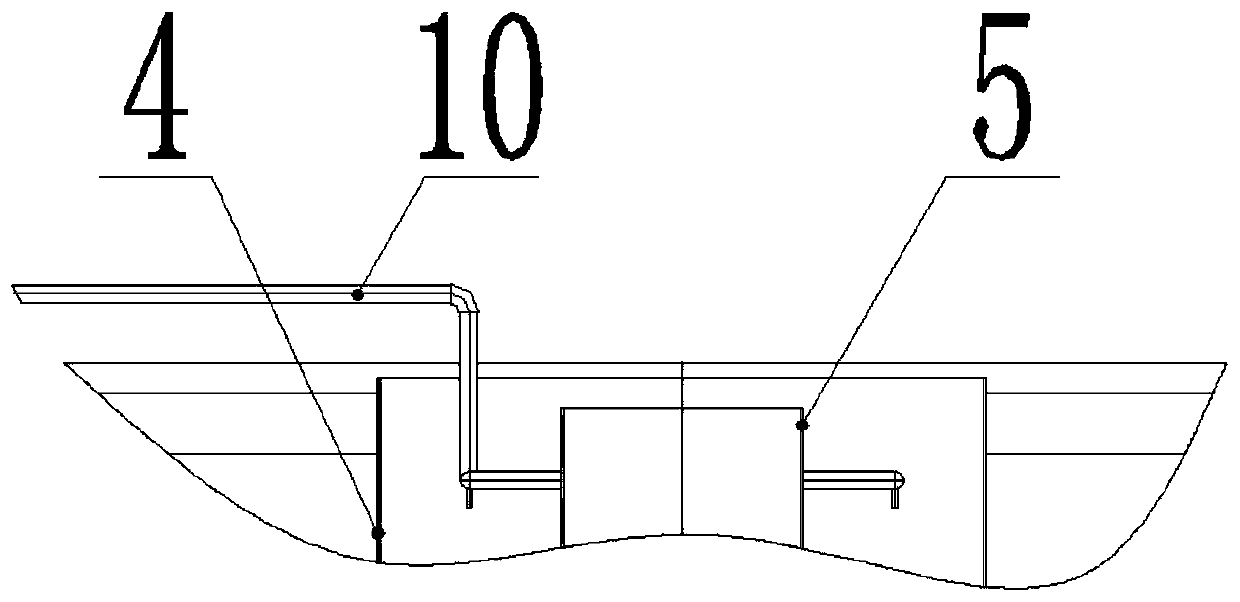

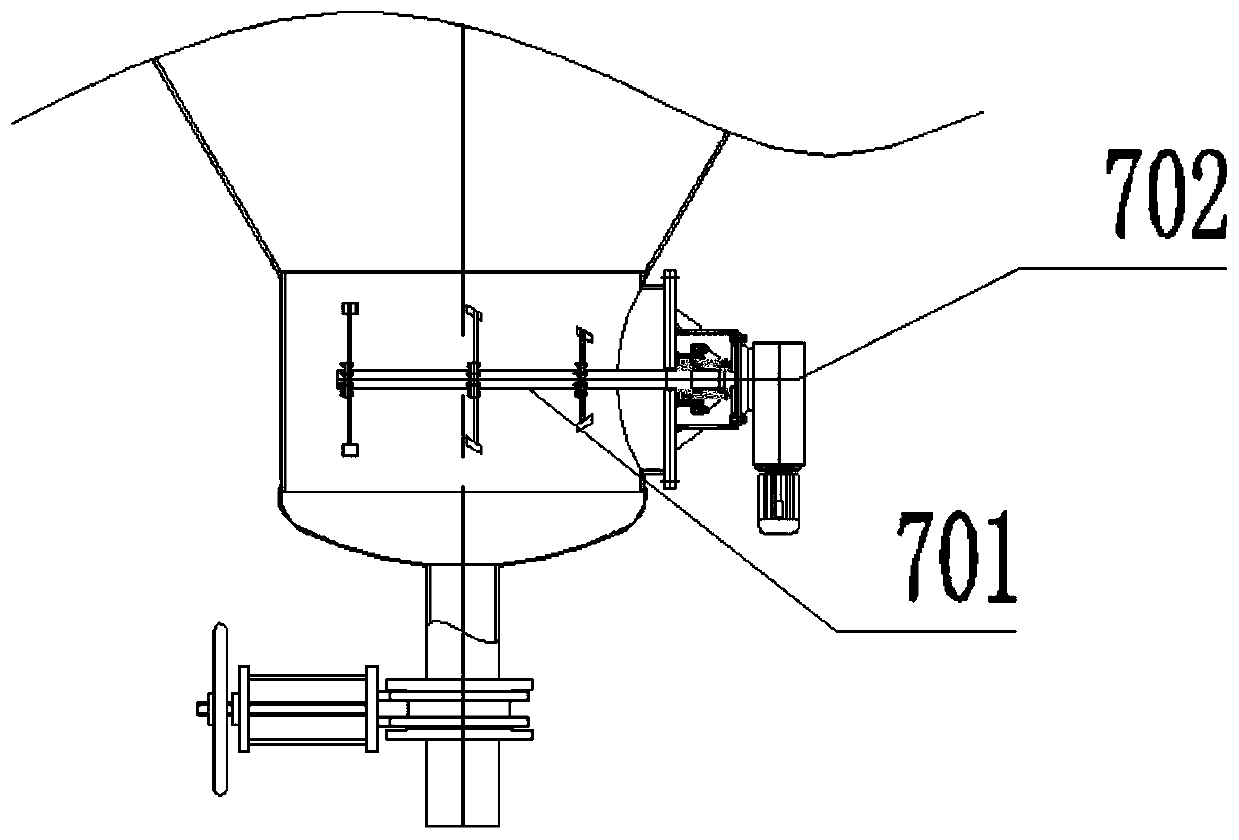

Deep-cone thickening sand bin with fluidized sand discharging device

PendingCN110152358AAccelerate the speed of flocculation and agglomerationReduce concentrationSettling tanks feed/dischargeCentrifugal force sediment separationEngineeringTailings

The invention relates to a deep-cone thickening sand bin with a fluidized sand discharging device. The deep-cone thickening sand bin with a fluidized sand discharging device comprises a sand bin body,a material feeding pipe, a flocculant inlet pipe, an overflow tank, a material feeding well, a circulation well, an annular guide cone and a stirring fluidization device, wherein the overflow tank isfixedly connected to the top of the inner wall of the sand bin body, and communicates with a supernatant return pipe, the material feeding well is disposed at the center of the top of the sand bin body, and is fixedly connected with the sand bin body, and the circulation well is disposed in the material feeding well, and is fixedly connected with the material feeding well; a material feeding zoneis formed between the material feeding well and the circulation well, the material feeding pipe communicates with the material feeding zone, and the annular guide cone is disposed directly below thecirculation well, and is fixedly connected with the inner wall of the sand bin body; and the diameter of the top of the annular guide cone is the same as the diameter of the circulation well, a material outlet is formed in the bottom of the sand bin body, and the stirring fluidization device is fixedly connected with the mouth outlet. A special flow field is formed after tailings is introduced into the sand bin, no consumption of waterpower and gas power is generated, the fluidization effect is good, and it is ensured that the mortar concentration and the thickening effect are not reduced.

Owner:金诚信矿山工程设计院有限公司

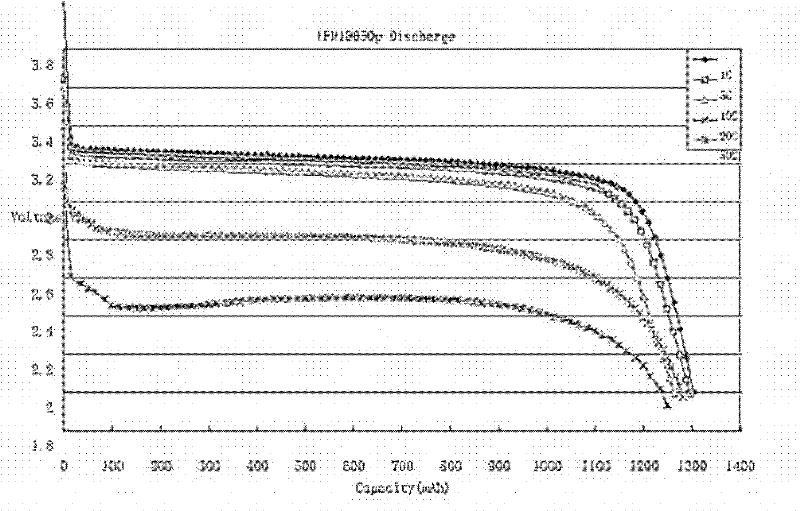

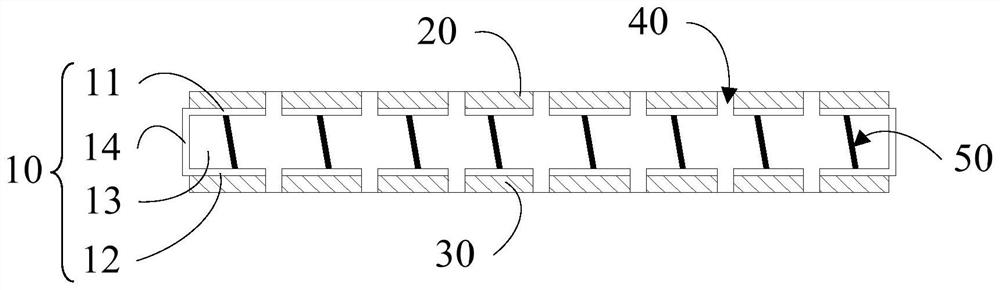

Lithium ion battery and preparation method thereof

PendingCN112864450ALow densityReduce compacted densityCell electrodesFinal product manufactureElectrolytic agentLithium iron phosphate

The invention belongs to the technical field of lithium ions, and particularly relates to a lithium ion battery. According to the lithium ion battery, a positive plate, a negative plate and a diaphragm are laminated in a Z shape and are subjected to hot pressing and assembling to form the lithium ion battery; the positive plate comprises positive slurry, and the positive slurry comprises 93-96 wt% of a positive active material, 2-3 wt% of a conductive agent and 2-4 wt% of a positive binder; and the negative plate comprises negative slurry, and the negative slurry comprises 94.5-96.5 wt% of a negative active material, 1-2 wt% of a conductive agent and 2.5-3.5 wt% of a negative binder. According to the invention, the coating surface density and compaction density of the positive and negative electrodes are reduced; and the glued diaphragm is subjected to hot pressing, so the electrolyte wettability and the electrolyte retention of the positive and negative plates and the diaphragm are improved, the lithium iron phosphate battery is kept in a rich liquid state in a long-term cycle process, and the cycle life of the lithium iron phosphate battery is prolonged.

Owner:TIANNENG SAFT ENERGY JOINT CO

Layered composite oxide coated positive electrode material and preparation method and application thereof

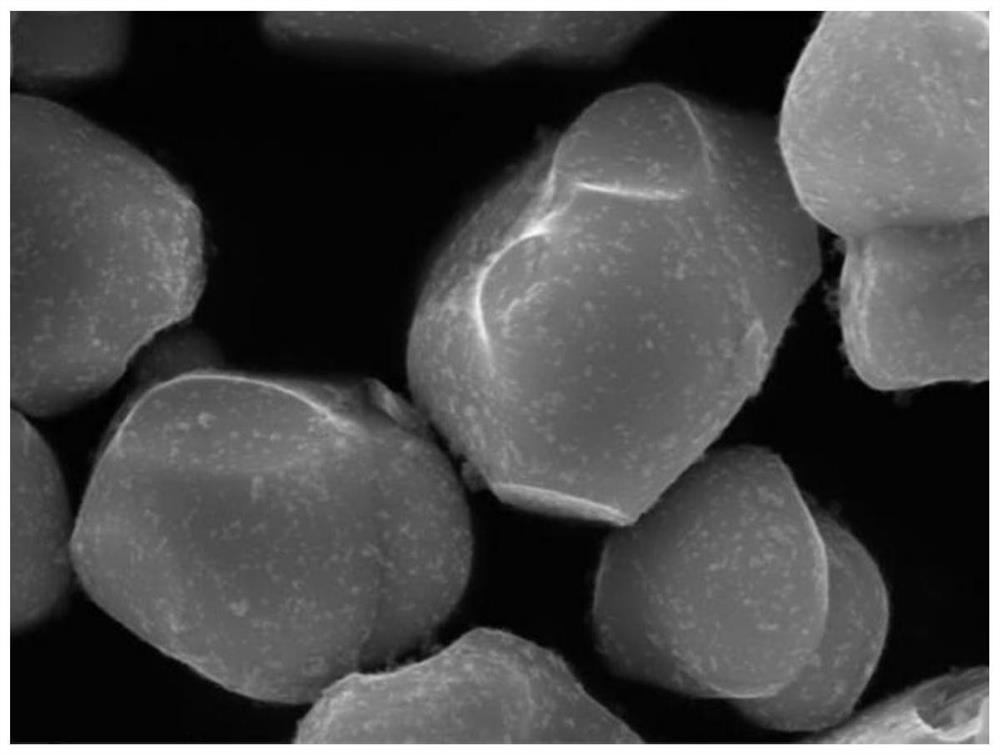

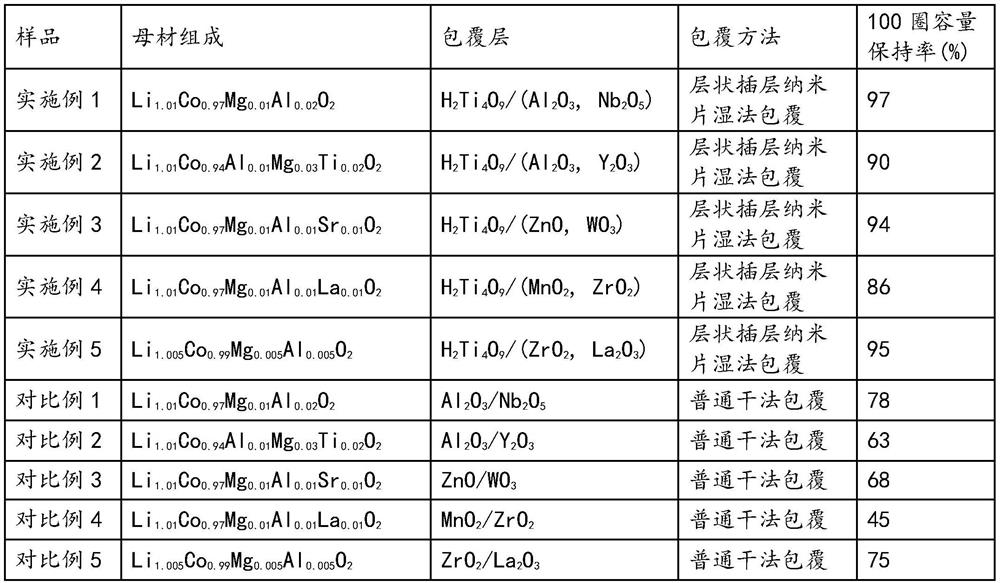

ActiveCN113443655AImprove cycle lifeReduce capacityMaterial nanotechnologyCell electrodesPhysical chemistryComposite oxide

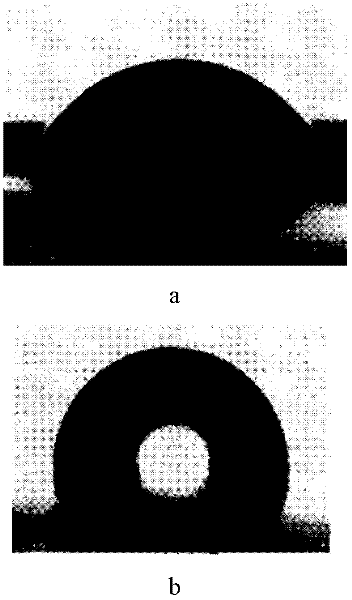

The invention relates to a layered composite oxide coated positive electrode material as well as a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing cobalt salt and M salt or oxide according to a ratio, conducting sintering to obtain a bulk phase material precursor, mixing the bulk phase material precursor with lithium salt and an additive according to a ratio, conducting sintering at a high temperature, and conducting crushing to obtain gradient-doped modified lithium cobalt oxide; ultrasonically dispersing layered protonated titanate nanosheets in a uniformly dispersed dispersion liquid containing a metal oxide, transferring the dispersion liquid to a high-pressure reaction kettle for reaction, and conducting washing after separation to obtain intercalated layered titanate; carrying out dispersion and ultrasonic treatment on the intercalated layered titanate to obtain a stripped intercalated layered titanate nanosheet colloidal solution; and adding the modified lithium cobalt oxide into the intercalated layered titanate nanosheet colloidal solution, carrying out rotary evaporation to remove the solvent, carrying out vacuum drying, and carrying out heat treatment on the dried material to form the intercalated layered titanate nanosheet-coated modified lithium cobalt oxide layered composite oxide-coated positive electrode material.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

A kind of additive for preparing lithium iron phosphate battery coating process

InactiveCN102299335AAvoid falling powderPrevent powder dropping process defectsCell electrodesLithium iron phosphatePolyvinylidene difluoride

The invention discloses an additive for a lithium iron phosphate battery coating process and a preparation method thereof, comprising the following steps: 1) mixing a polyvinylidene fluoride adhesive with nitrogen methylpyrrole; 2) adding the additive to the mixture and mixing 0.5-1 hour; 3) Add lithium iron phosphate powder to the mixture, gradually add it three times, and concentrate; 4) Add conductive carbon black to the concentrated mixture, stir evenly, and obtain lithium iron phosphate battery coating technology additive. The additive has good compatibility with the electrolyte, can reduce the surface activity of lithium iron phosphate and PVDF, improve the bonding performance of the material, and solve the problem of powder dropping of the lithium iron phosphate material during the coating process.

Owner:IRICO

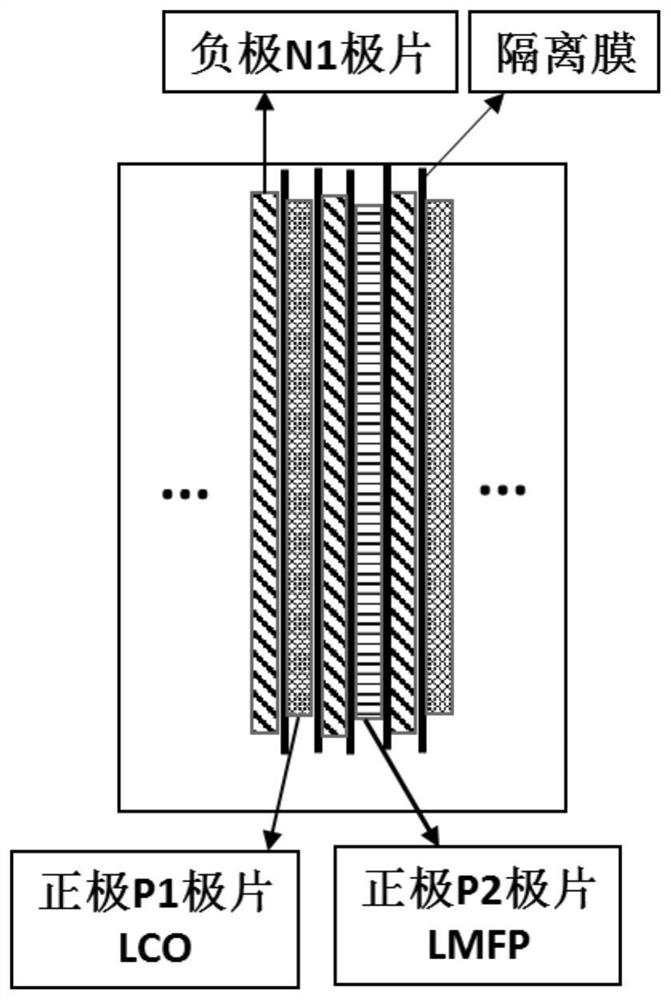

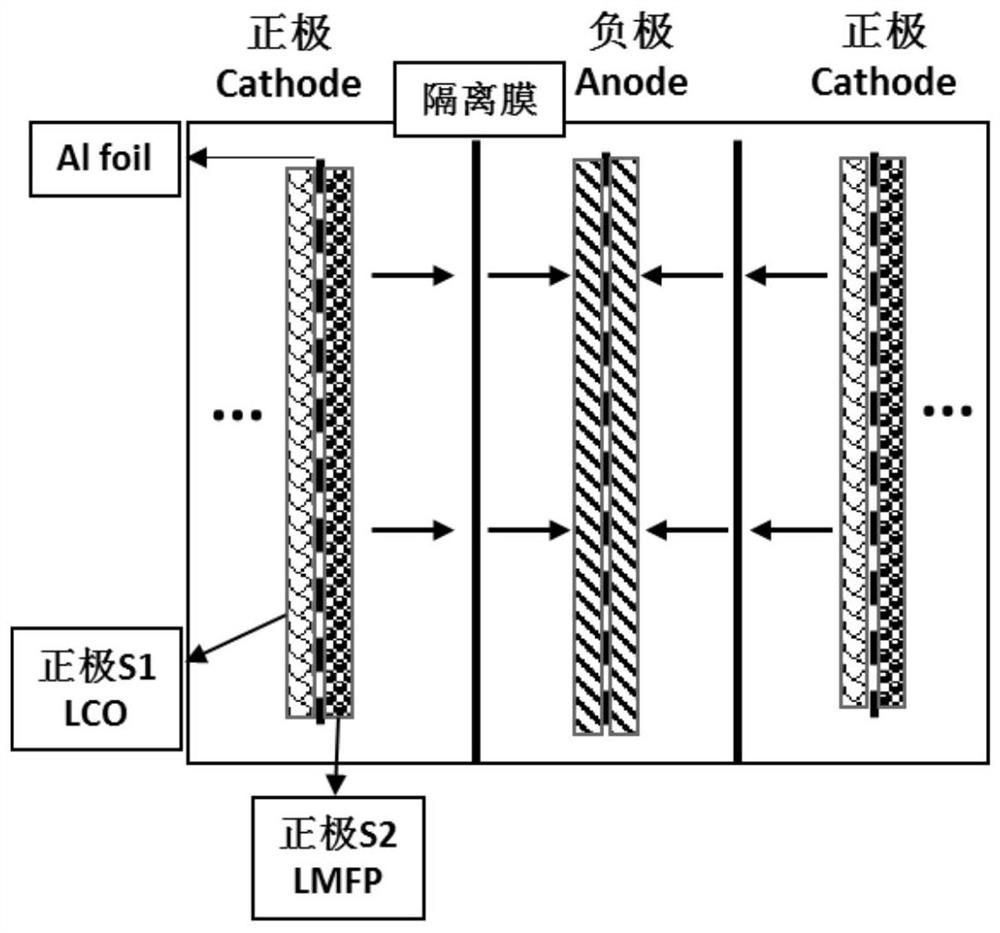

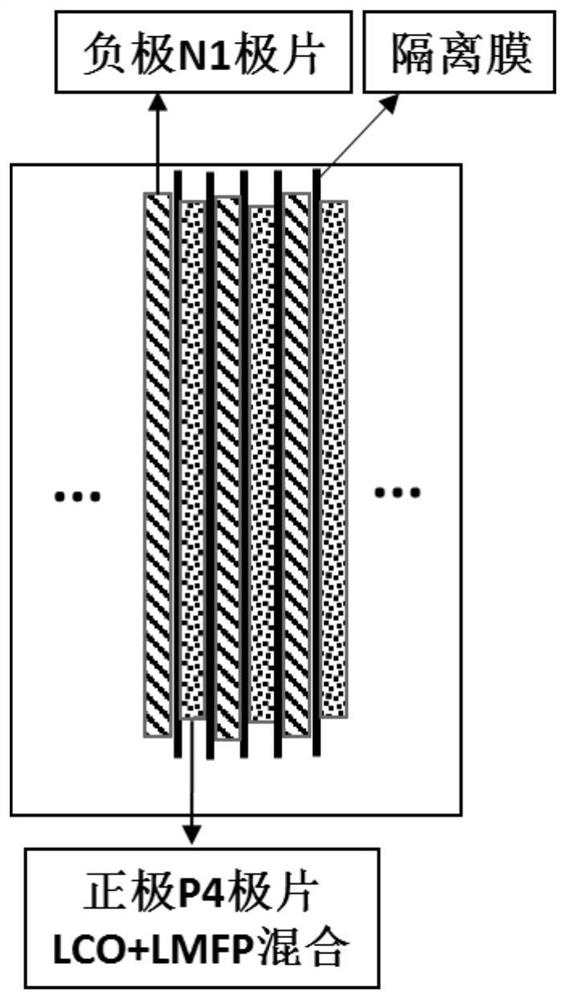

High-voltage positive pole piece and lithium ion secondary battery comprising same

InactiveCN112864360AImprove stabilityImprove securitySecondary cellsPositive electrodesPhysical chemistryManganese

The invention relates to a high-voltage positive pole piece and a lithium ion secondary battery comprising the same. A positive active material in the positive pole piece comprises lithium ferric manganese phosphate (LMFP) and lithium cobalt oxide (LCO), and the lithium ferric manganese phosphate accounts for more than 10 wt% and less than or equal to 65 wt% of the positive active material. The lithium cobalt oxide and the lithium iron manganese phosphate are mixed, so that the stability of the lithium cobalt oxide in a high-voltage system can be effectively improved, and the safety performance of a battery can be improved; although the lithium ferric manganese phosphate has relatively low compaction density and gram volume, the lithium ferric manganese phosphate is mixed with the high-voltage lithium cobalt oxide, and the energy density of the system is not lost; besides, lithium ferric manganese phosphate has excellent cycle performance and is slow in attenuation, so that the cycle performance of the lithium ferric manganese phosphate can be effectively improved by doping the lithium ferric manganese phosphate into a high-voltage system.

Owner:ZHUHAI COSMX BATTERY CO LTD

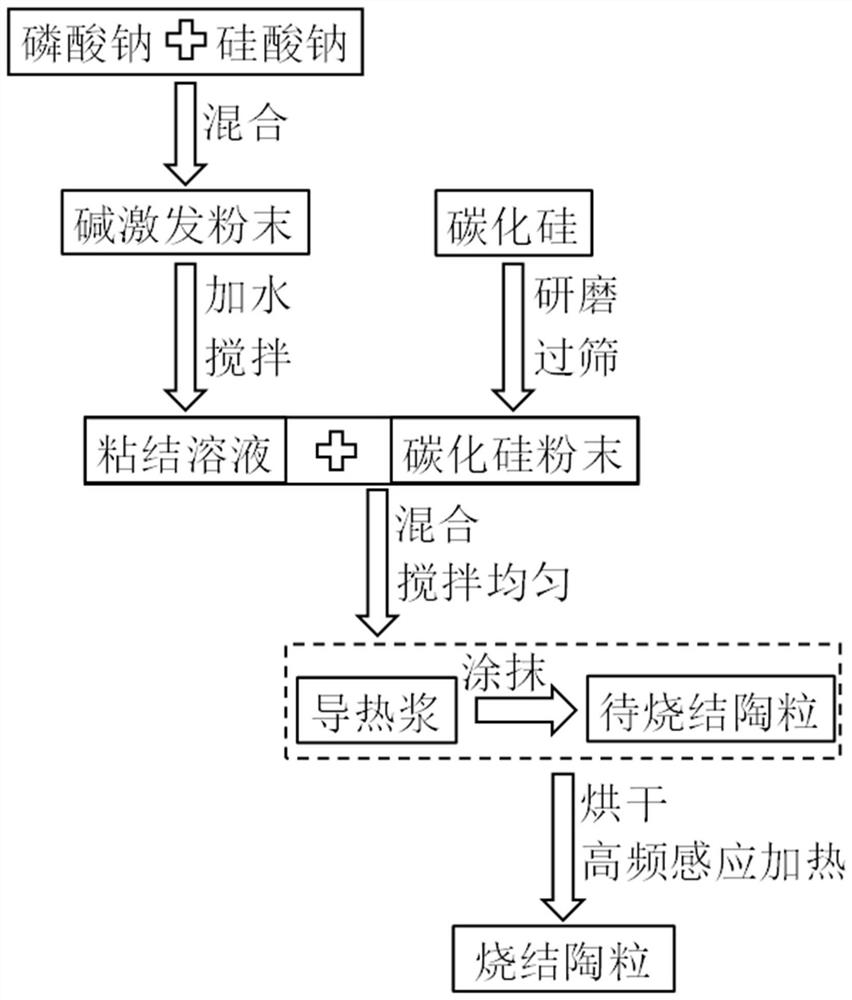

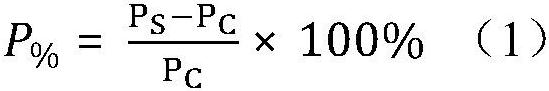

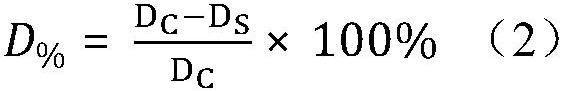

Method for quickly sintering ceramsite

ActiveCN111620719AAccess to a wide range ofReduce compacted densityCeramic materials productionClaywaresSodium phosphatesSlurry

The invention discloses a method for quickly sintering ceramsite, and the method comprises the following steps: mechanically grinding silicon carbide for 1-3 hours, and sieving with a 200-400-mesh sieve to obtain silicon carbide powder; weighing sodium phosphate and sodium silicate, and mixing to obtain alkali-activated powder; mixing water with the alkali-activated powder, and stirring until thesodium phosphate and the sodium silicate are completely dissolved to obtain a bonding solution; mixing the silicon carbide powder with the bonding solution, and uniformly stirring to obtain heat-conducting slurry; uniformly coating to-be-sintered ceramsite with the heat-conducting slurry, then drying, and finally performing high-frequency induction heating on the dried ceramsite for 2-8 minutes toobtain the sintered ceramsite. The method is simple in process, convenient to operate and wide in raw material obtaining way. Compared with a traditional ceramsite firing mode, the ceramsite firing method has the advantages that the consumed time is short, the ceramsite compaction density is reduced by 45.86% to the maximum extent, the fired ceramsite strength is improved by 56.97% to the maximumextent, and the ceramsite ignition loss is reduced by 35.92% to the maximum extent.

Owner:浙江慧科环保科技有限公司

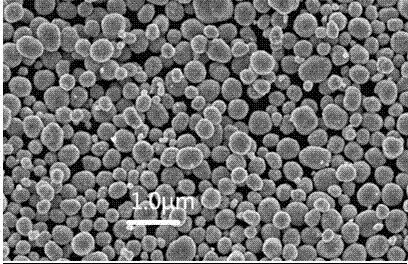

Low-temperature fast-charging artificial graphite negative electrode material, preparation method and low-temperature fast-charging battery

PendingCN113851614AHigh capacity densityIncrease compaction densityNegative electrodesSecondary cellsCarbon coatingHigh energy

The invention relates to a low-temperature fast-charging artificial graphite negative electrode material and a preparation method thereof, and a low-temperature fast-charging battery. The composite material comprises a graphite matrix, and carbon nanotubes and amorphous carbon coating the surface of the graphite matrix. The mass of the carbon nanotubes and the amorphous carbon is 0.5-5% of the mass of the graphite matrix; in the preparation process, petroleum coke, pitch coke or graphite electrode joint powder is adopted as a raw material, and after crushing, shaping and spheroidizing and high-temperature purification, CVD (Chemical Vapor Deposition) carbon coating is performed to obtain the low-temperature quick-charge artificial graphite negative electrode material. Compared with the prior art, the small-particle-size graphite single particles used in the invention have better low-temperature fast charging performance; a high-temperature purification mode is adopted, so that the graphite has higher purity and crystallinity; by adopting a two-step cooling mode, internal stress generated in the material preparation process can be eliminated; a battery prepared from the low-temperature fast-charging artificial graphite negative electrode material has relatively high energy density and good low-temperature fast-charging performance.

Owner:上海昱瓴新能源科技有限公司

Electrode plate and lithium ion battery comprising same

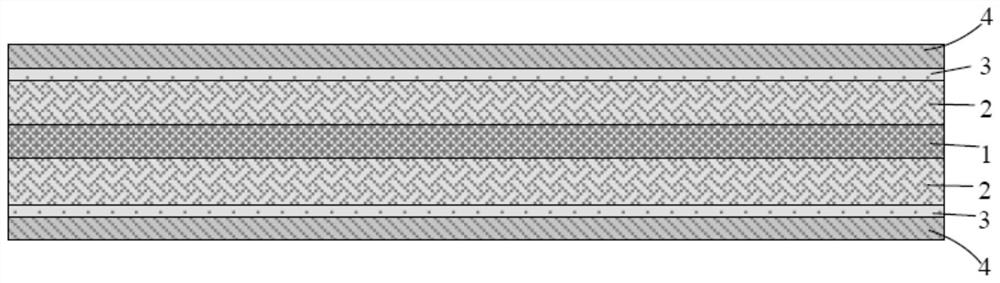

ActiveCN114039027AImprove needlestick safetyPlay a role in wrappingNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceElectrical performanceLithium-ion battery

The invention provides an electrode plate and a lithium ion battery comprising the same. The electrode plate of the present invention comprises: a current collector having two opposite surfaces; an active material layer coated on at least one surface of the current collector; a first coating layer coated on the active material layer; and a second coating layer coated on the first coating layer; wherein the first coating at least comprises a first polymer and a first conductive agent; and the second coating includes at least a second polymer. According to the invention, by constructing the double-layer coating, not only can the needling safety of the battery be improved, but also the electrical performance of the battery can be ensured not to be influenced to the greatest extent.

Owner:ZHUHAI COSMX BATTERY CO LTD

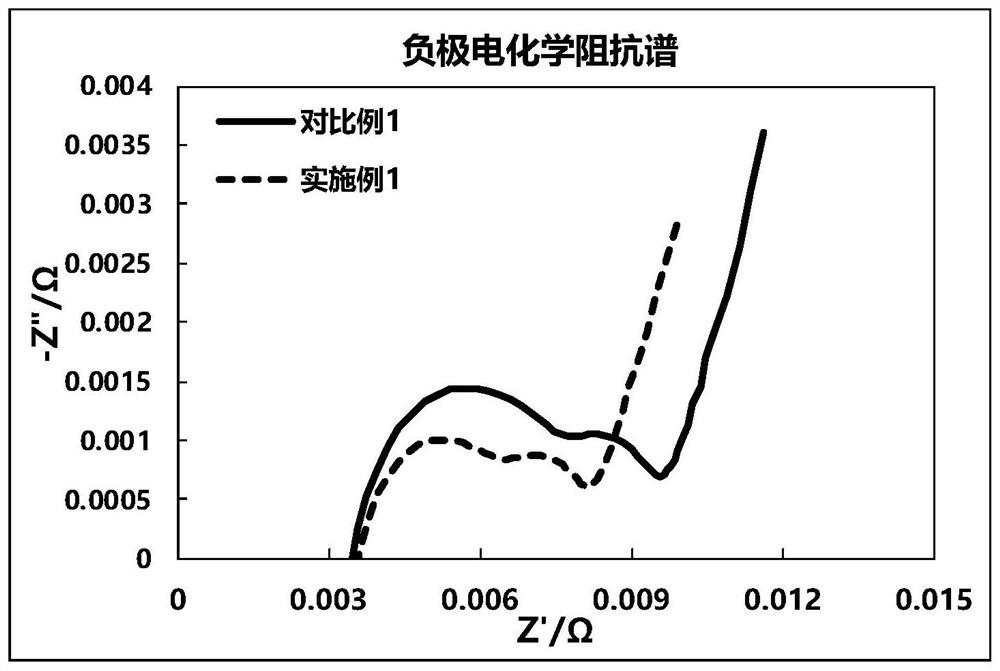

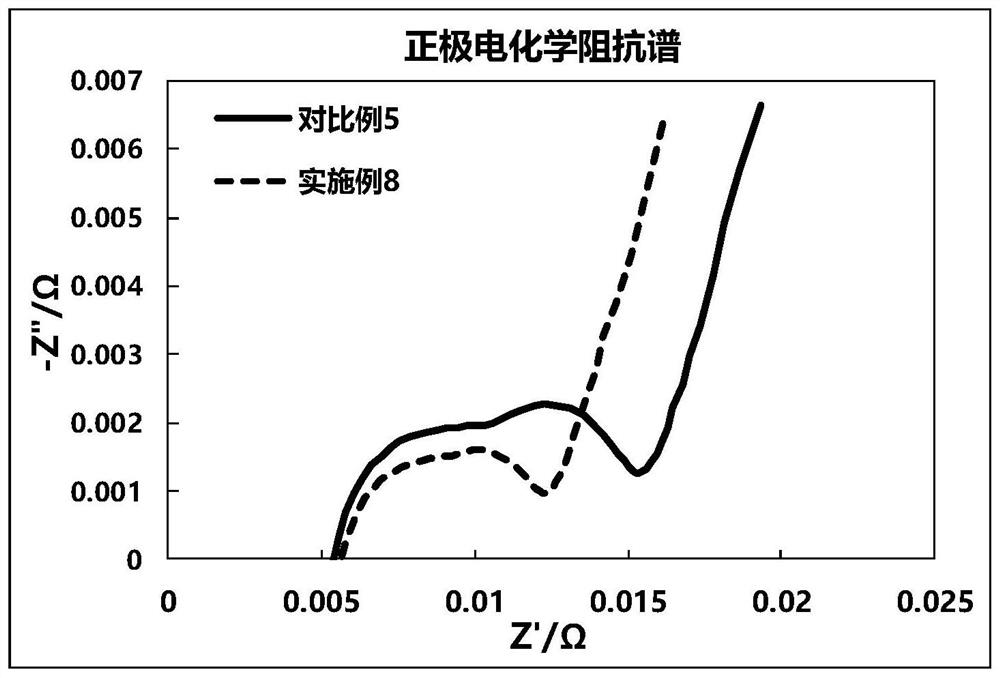

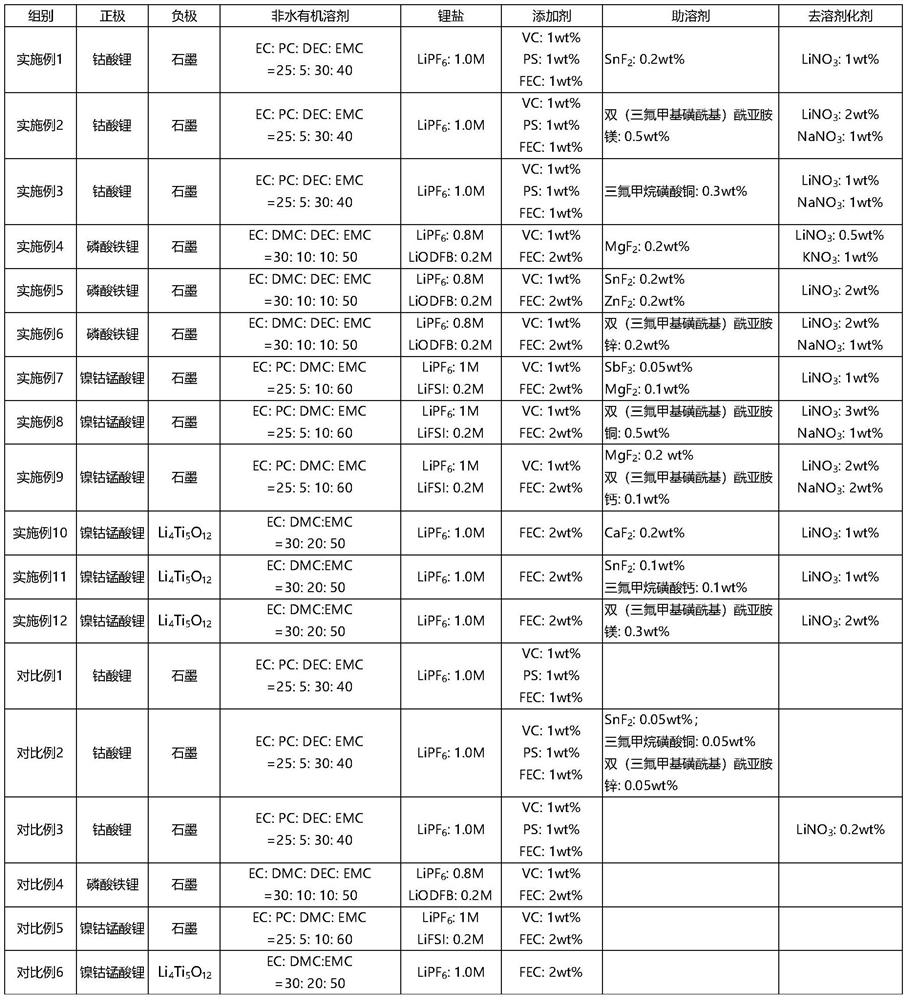

Lithium ion battery non-aqueous electrolyte and lithium ion battery using same

PendingCN114597491AReduce the amount of coatingIncreased desolvation rateSecondary cellsOrganic electrolytesElectrolytic agentMagnesium salt

The invention provides a lithium ion battery electrolyte, which is characterized in that the lithium ion battery electrolyte comprises a desolvation agent and a cosolvent, the desolvation agent is alkali metal nitrate, and the cosolvent is an organic solvent. The cosolvent is selected from one or more of tin salt, magnesium salt, zinc salt, calcium salt, antimony salt and copper salt of hydrofluoric acid, bis (trifluoromethylsulfonyl) imide and trifluoromethanesulfonic acid. The desolvation agent is added into the electrolyte without changing other elements of the lithium ion battery, so that the energy potential barrier of the desolvation step in the charge-discharge process of the lithium ion battery is reduced, the speed of removing the solvation sheath from the solvation Li < + > is increased, and the charge transfer impedance is reduced, thereby reducing the electrochemical polarization; and the rate capability and the low-temperature performance of the lithium ion battery are improved.

Owner:SINOCHEM INT CORP

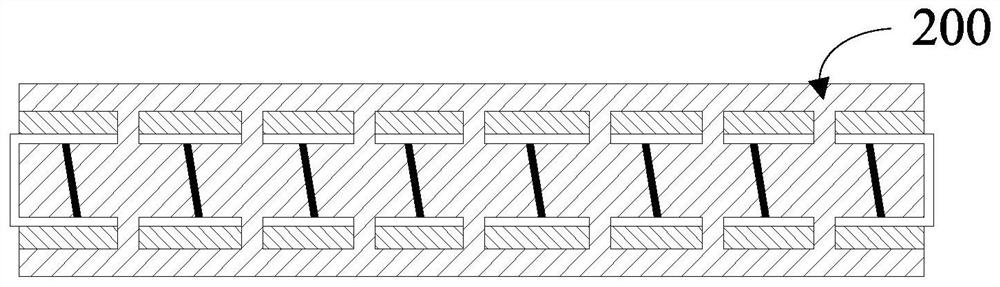

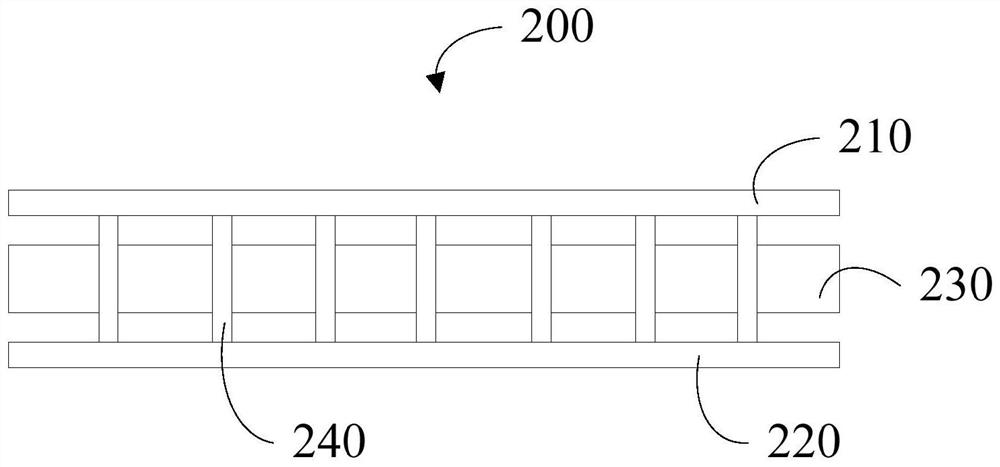

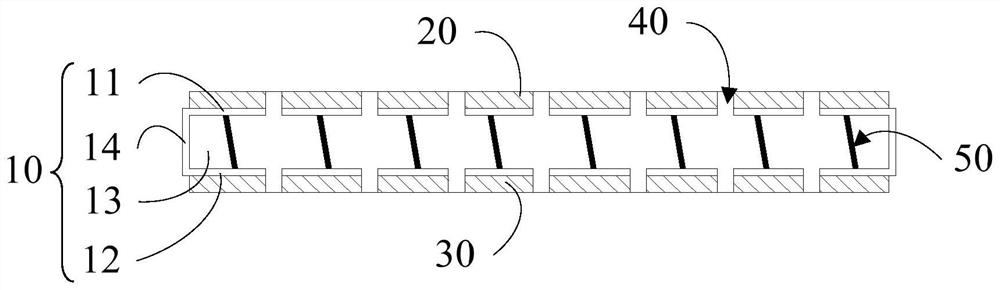

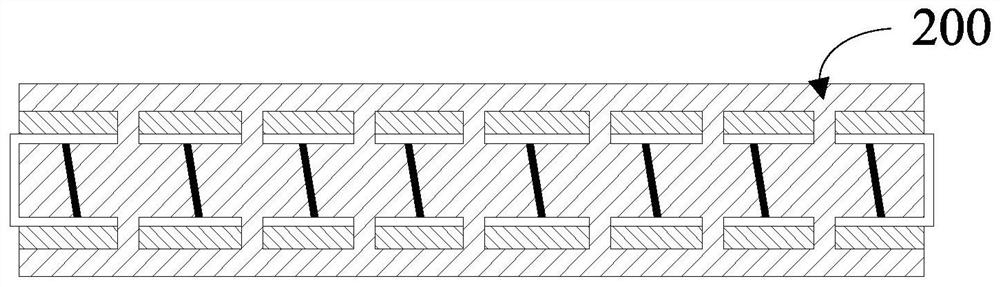

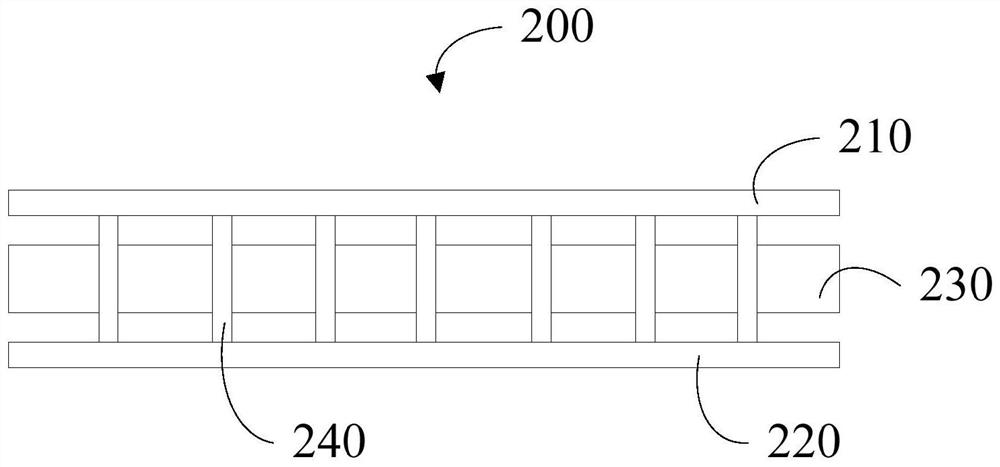

Current collector, battery pole piece and method for making current collector

ActiveCN113036150BReduce compacted densityIncrease the setting areaElectrode carriers/collectorsPositive electrodesEngineeringPole piece

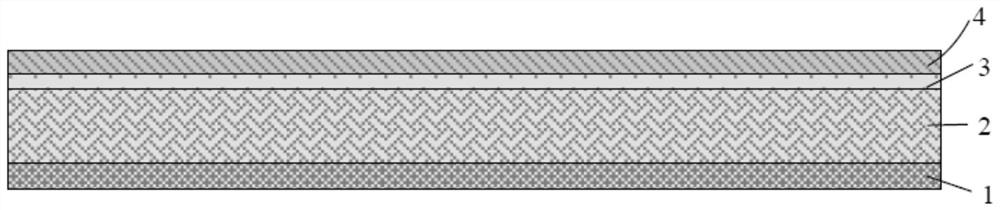

The application discloses a current collector, a battery pole piece and a method for making the current collector, which belong to the technical field of batteries. The current collector includes: a first current collector layer, a first coating layer, a second coating layer and a second current collector layer stacked in sequence, there is an inner cavity between the first coating layer and the second coating layer, and the The first coating layer and the second coating layer are supported and connected by supporting columns; wherein, the current collector further includes through holes, and the through holes sequentially penetrate through the first current collector layer, the first coating layer, and the second coating layer. The plating layer and the second current collector layer, and the through hole communicates with the inner cavity. In this way, the compaction density of the active material on the current collector can be reduced, the polarization of the battery can be reduced, and the purpose of improving the charging and discharging performance of the battery can be achieved.

Owner:ZHUHAI COSMX BATTERY CO LTD

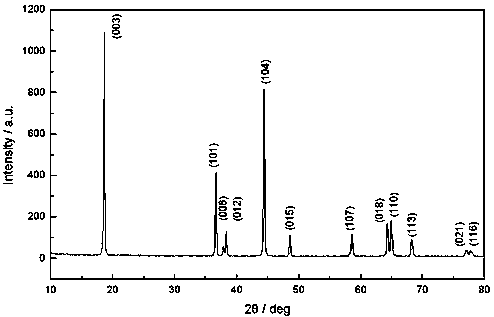

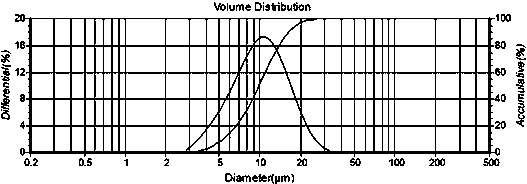

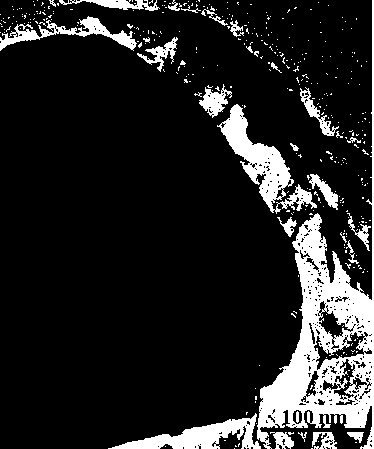

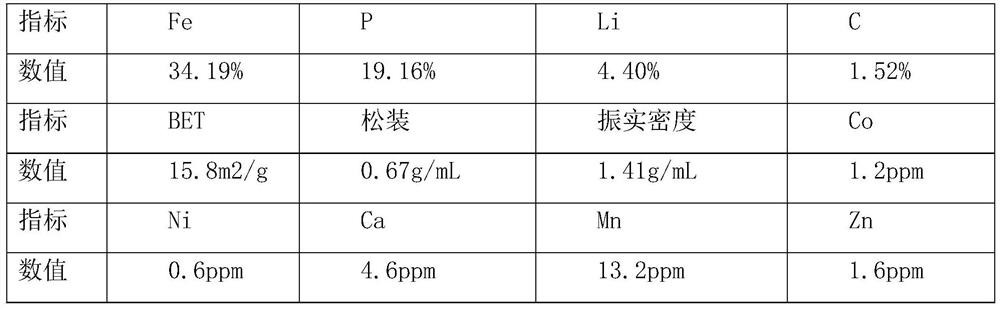

A kind of preparation method of high compaction high capacity lithium iron phosphate

ActiveCN109867268BEnable recyclingReduce energy consumptionCell electrodesSecondary cellsSucrosePolyethylene glycol

The invention discloses a preparation method of high-compression high-capacity lithium iron phosphate. Weigh iron phosphate, lithium carbonate, polyethylene glycol and sucrose, then mix them, add alcohol for wet grinding; spray dry the slurry, and crush the spray-dried materials to obtain crushed materials; put the crushed materials into the roller The sintering is carried out in the first furnace, and the sintering is divided into four stages, namely, the heating section, the heat preservation section, the decarburization section and the cooling section. After crushing, screening, and iron removal in the wet room, vacuum packaging is carried out to obtain high-compression and high-capacity lithium iron phosphate. The method of the invention is simple and low in cost, and at the same time, the lithium iron phosphate with high compacted density and good electrical performance can be obtained through gas treatment of carbon dioxide.

Owner:湖北云翔聚能新能源科技有限公司

Current collector, battery pole piece and current collector manufacturing method

ActiveCN113036150AReduce compacted densityIncrease the setting areaElectrode carriers/collectorsPositive electrodesMechanical engineeringBattery cell

The invention discloses a current collector, a battery pole piece and a current collector manufacturing method, and belongs to the technical field of batteries. The current collector comprises a first current collector layer, a first plating layer, a second plating layer and a second current collector layer which are sequentially stacked, wherein an inner cavity is formed between the first plating layer and the second plating layer, and the first plating layer and the second plating layer are supported and connected through a supporting column; and the current collector further comprises a through hole, the through hole sequentially penetrates through the first current collector layer, the first plating layer, the second plating layer and the second current collector layer, and the through hole is communicated with the inner cavity. Therefore, the compaction density of an active material on the current collector can be reduced, the polarization of the battery is reduced, and the purpose of improving the charge-discharge performance of the battery is achieved.

Owner:ZHUHAI COSMX BATTERY CO LTD

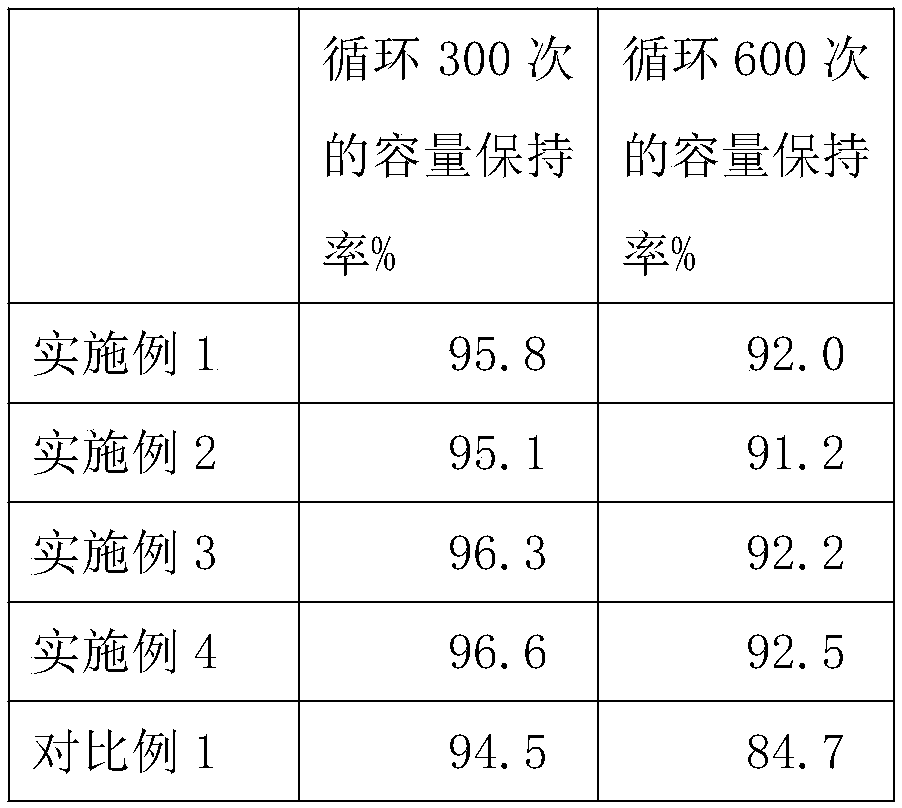

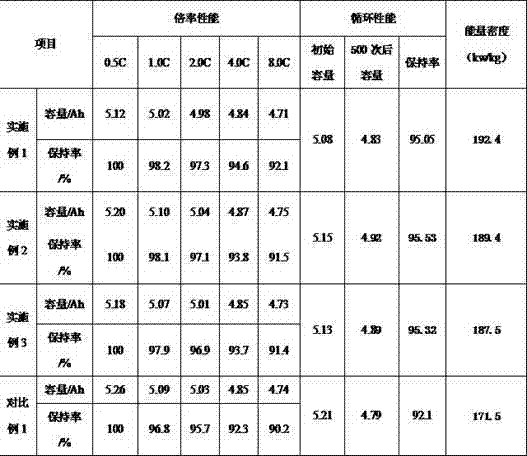

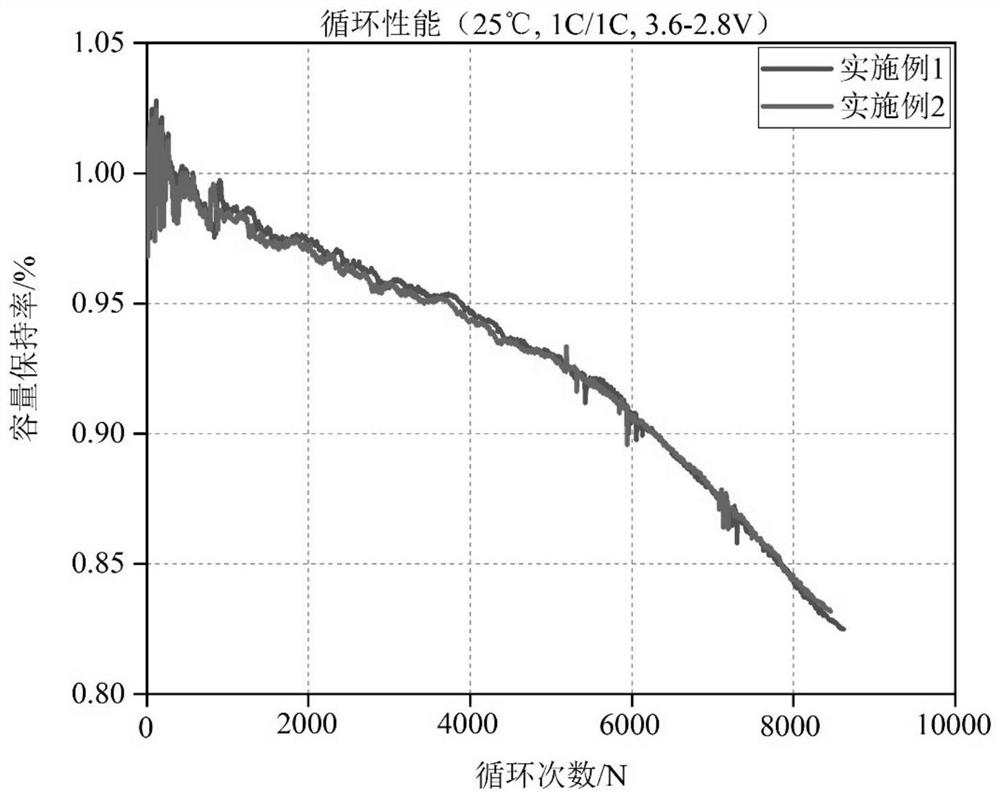

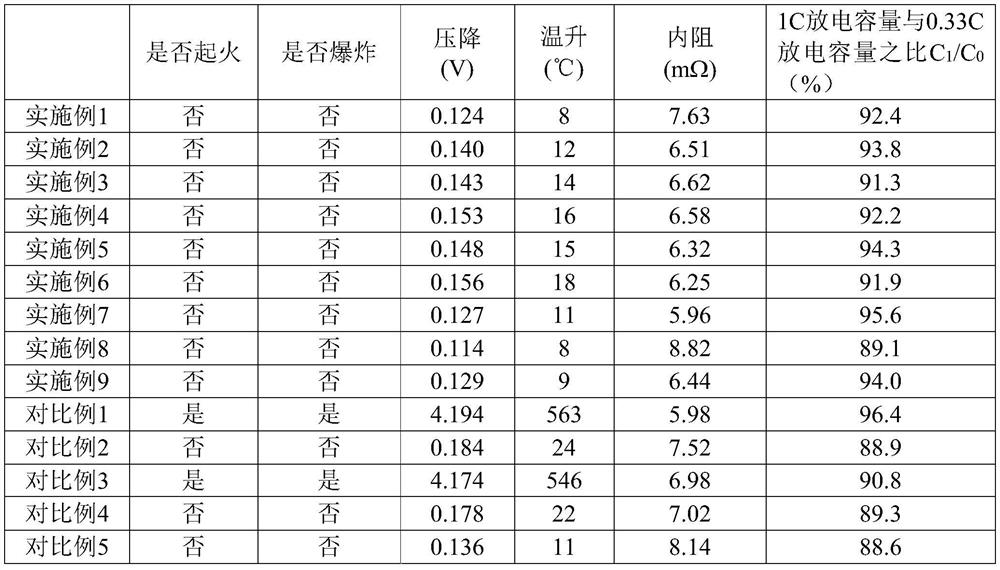

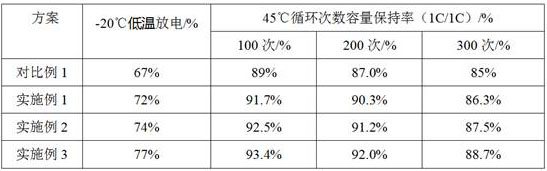

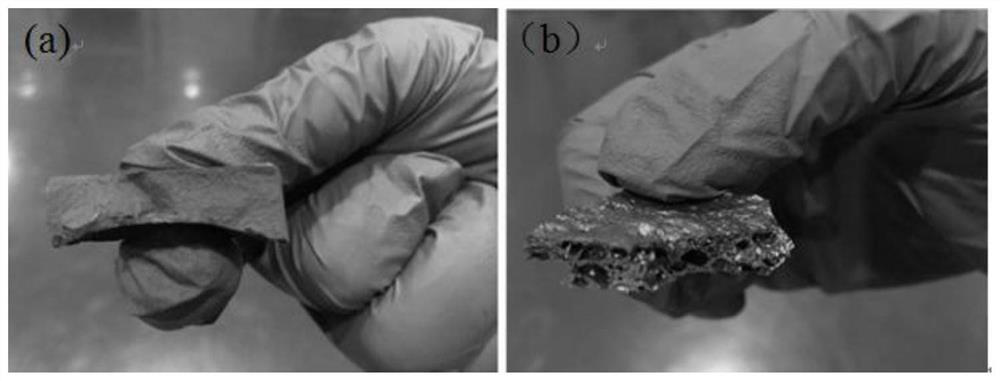

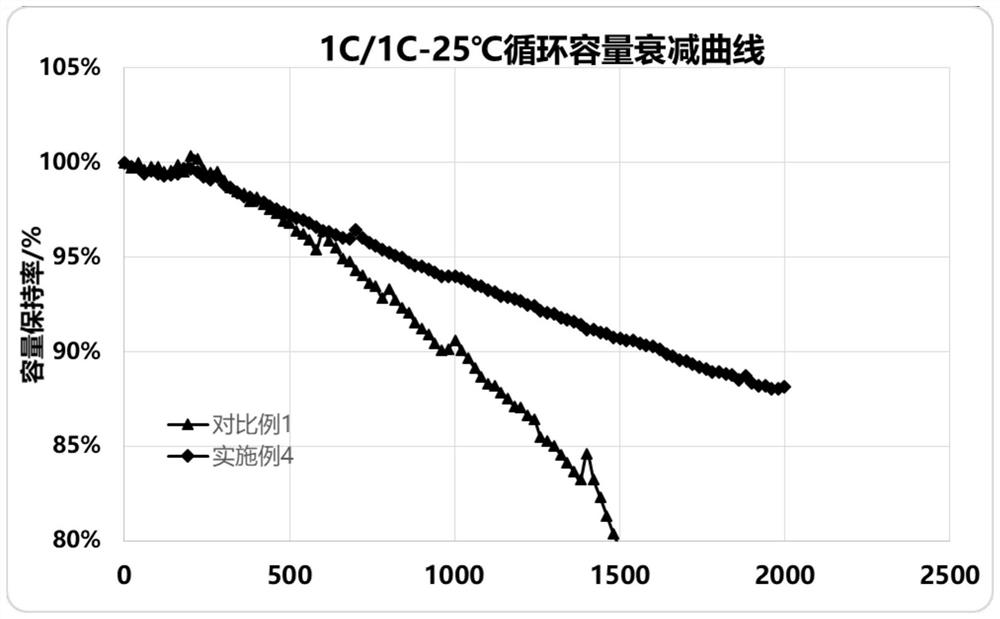

A preparation method of a lithium-ion battery with improved high-voltage low-temperature discharge and cycle performance

ActiveCN109888175BEvenly dispersedReduce compacted densityElectrode manufacturing processesSecondary cellsPhysical chemistryHigh voltage battery

Owner:ZHUHAI COSMX BATTERY CO LTD

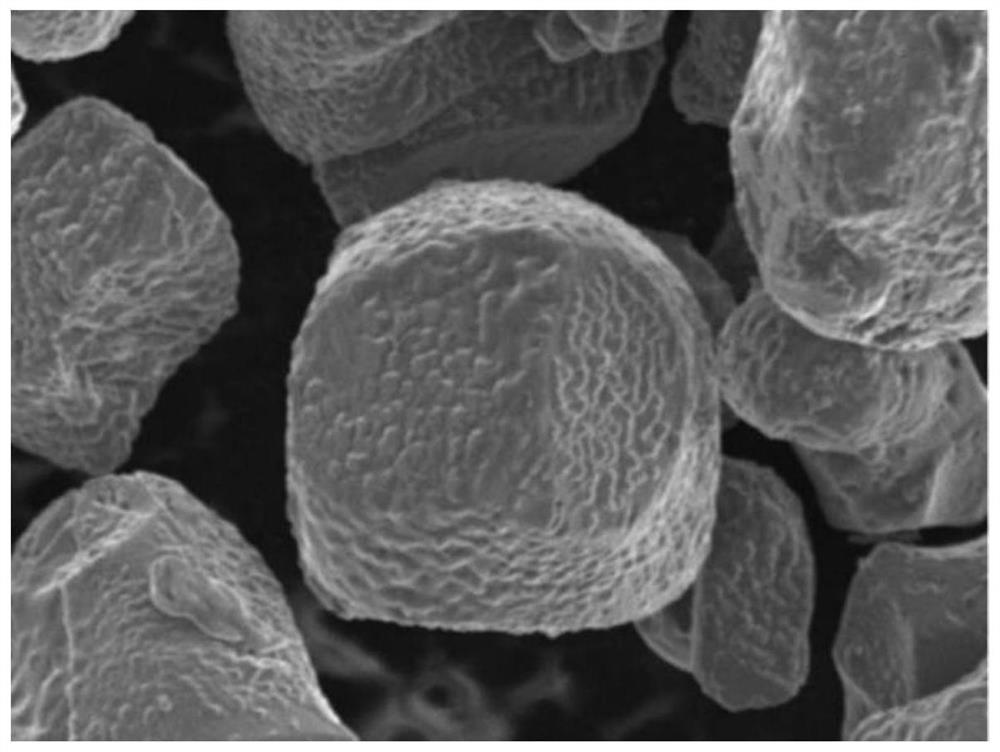

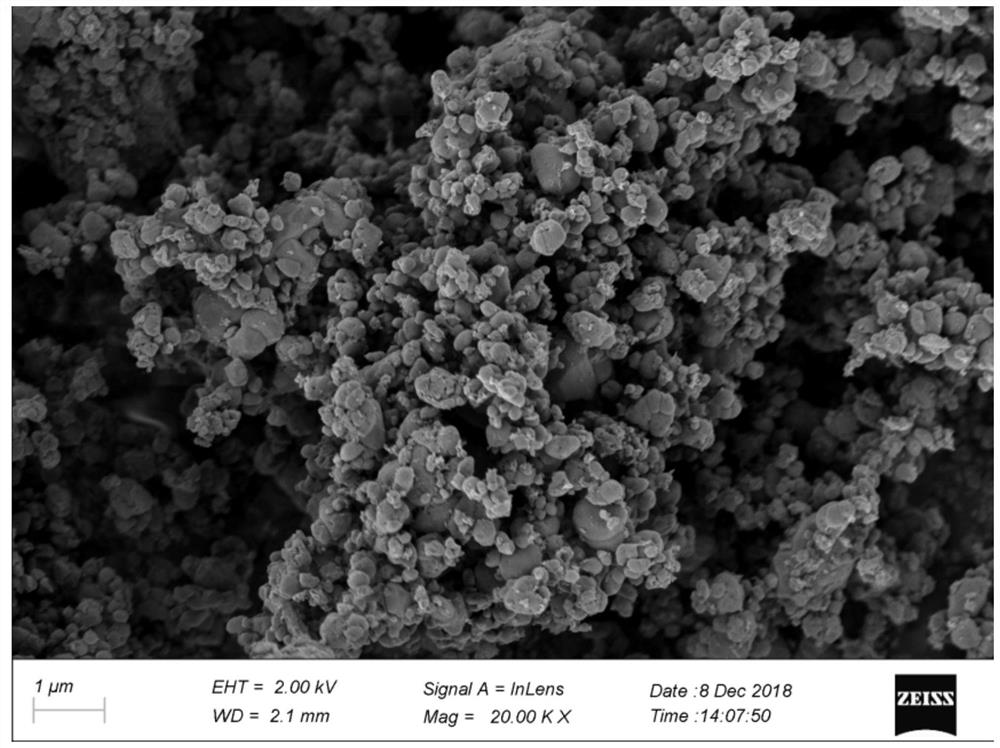

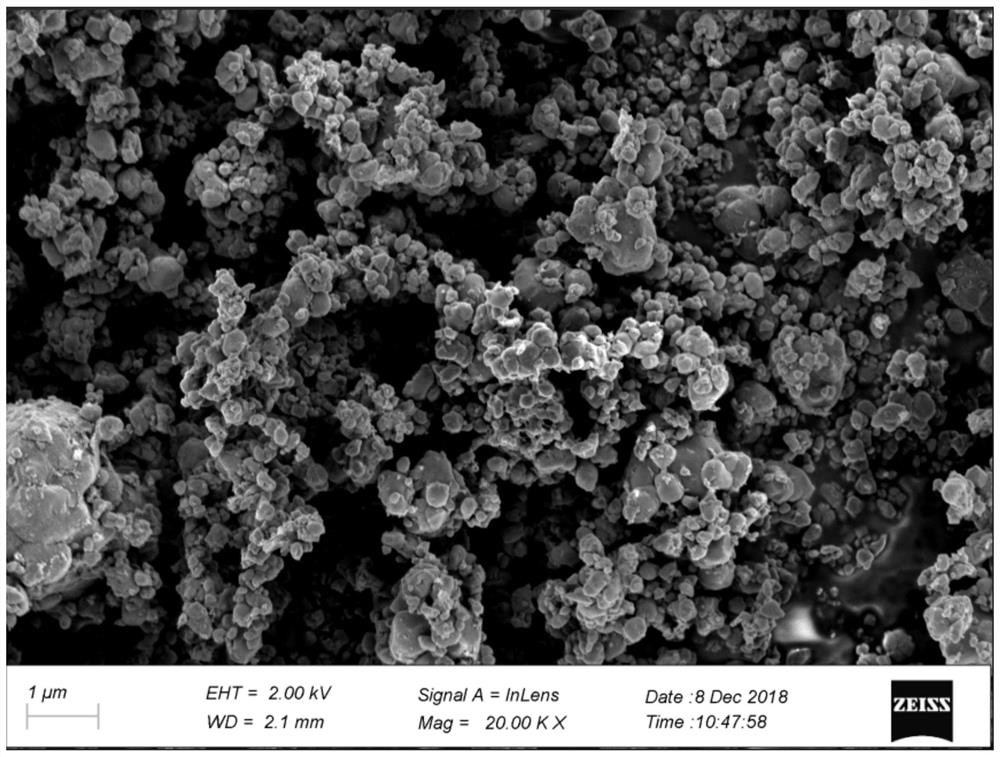

A kind of preparation method of silicon carbon negative electrode material and lithium ion battery

ActiveCN108963208BCoated evenlyReduce compacted densityCell electrodesSecondary cellsElectrical batteryLithium-ion battery

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

A kind of negative electrode and its preparation method and application

ActiveCN112952035BLow areal densityReduce compacted densityNegative electrodesSecondary cellsGraphene coatingElectrical battery

The invention provides a negative electrode and its preparation method and application. The negative electrode includes a current collector and a negative electrode active layer, and the negative electrode active layer includes a first negative electrode active material, a second negative electrode active material, a conductive agent and a binder; the first negative electrode active material includes graphite, and the first negative electrode active material The two negative electrode active materials include graphene-coated silicon-oxygen materials, and the chemical formula of the silicon-oxygen materials is SiO x , 0<x<2. In the present invention, by mixing the graphite-based negative electrode active material with the graphene-coated silicon-oxygen material, on the one hand, the coating of graphene can largely inhibit the pulverization of the silicon-oxygen material caused by the volume change during charging and discharging. The safety performance and cycle performance of the battery are improved. On the other hand, the blending of the two negative active materials can greatly improve the cycle performance of the battery and increase the cycle life of the battery on the basis of ensuring the energy density of the battery.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

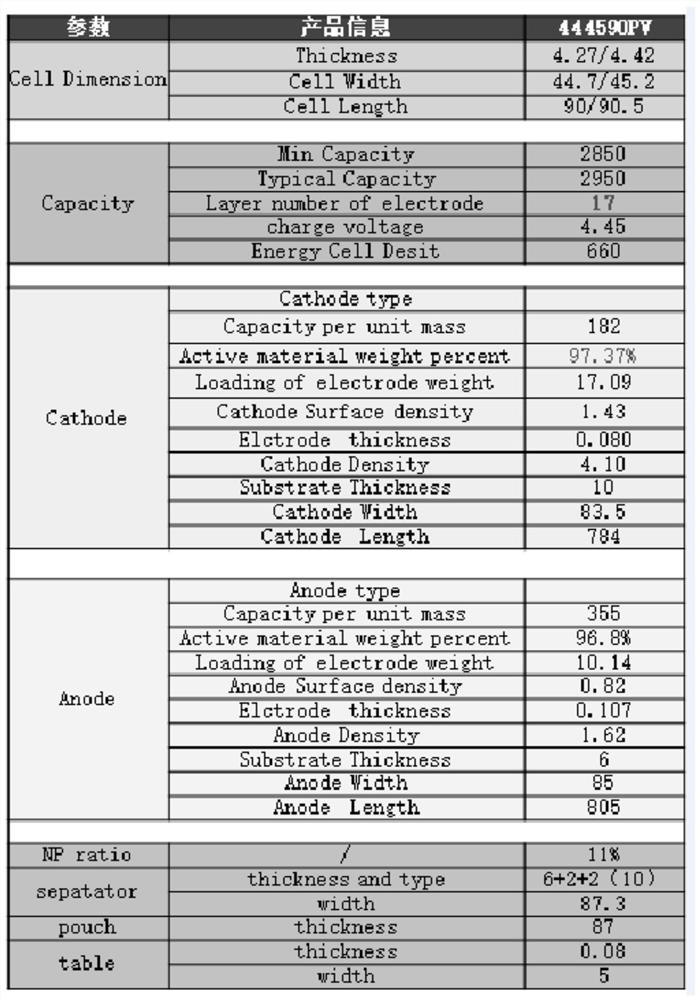

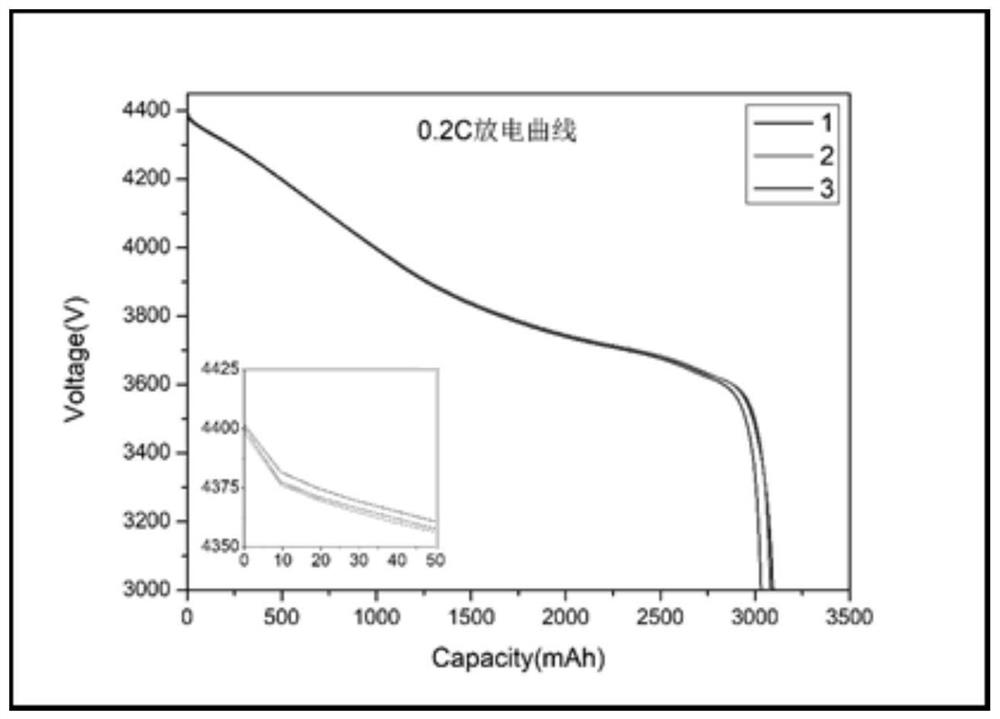

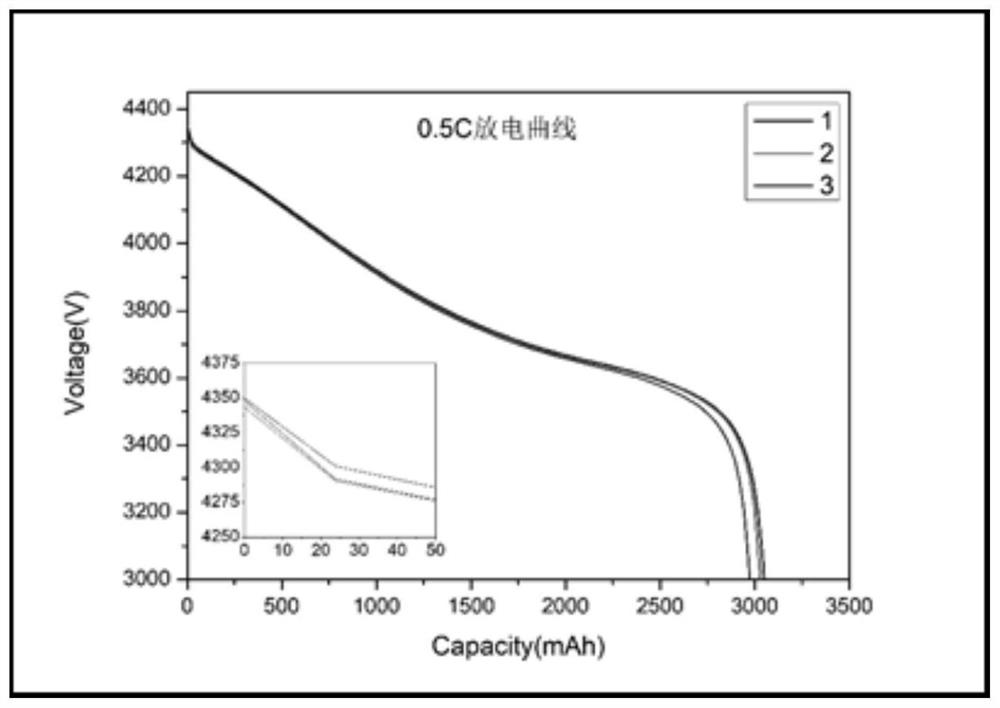

Battery formula for 3C multiplying power charging on 4.45 V voltage platform and preparation method of battery formula for 3C multiplying power charging on 4.45 V voltage platform

PendingCN114497488AIncrease energy densityHigh liquid retention coefficientCell electrodesSecondary cellsPyrrolidinonesButadiene-styrene rubber

The invention discloses a battery formula for 3C multiplying power charging on a 4.45 V voltage platform and a preparation method thereof, the battery formula comprises a positive electrode and a negative electrode, and is characterized in that the positive electrode comprises lithium cobalt oxide, CNT (carbon nano tube), LITX200 and polyvinylidene fluoride (adhesive), and the negative electrode comprises graphite, SP (carbon black conductive agent), CMC (sodium carboxymethyl cellulose), SBR (styrene butadiene rubber) and NMP (N-methyl pyrrolidone); the ratio of parts of lithium cobalt oxide to CNT (carbon nanotubes) to LITX200 to polyvinylidene fluoride (an adhesive) is 100: 12.5: 0.3: 1, and the ratio of parts of lithium cobalt oxide to CNT (carbon nanotubes) to LITX200 to polyvinylidene fluoride (the adhesive) is 100: 12.5: 0.3: 1; the ratio of the graphite to the SP (carbon black conductive agent) to the CMC (sodium carboxymethyl cellulose) to the SBR (styrene butadiene rubber) to the NMP (N-methyl pyrrolidone) is 100: 0.5: 1.3: 3.1: 1. The battery is thin in thickness, high in energy density, low in compaction density and high in liquid retention coefficient, the gram volume is designed according to 183, the positive electrode adopts a pure carbon black system, and the safety performance and the conductivity of the battery are effectively improved.

Owner:四川驰久新能源有限公司

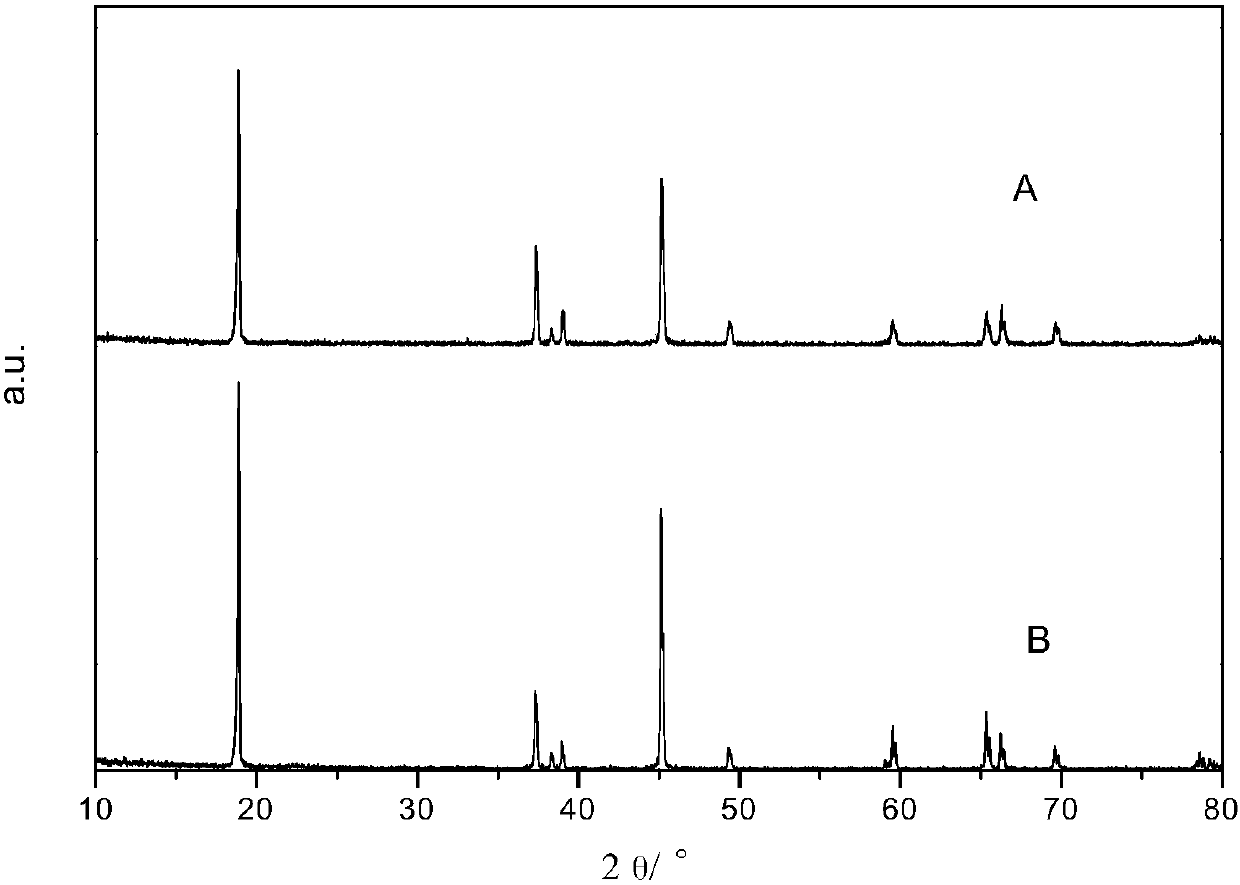

A kind of preparation method of graphene composite lithium ion battery ternary cathode material

ActiveCN104157854BSolving Dispersion ProblemsLower polarization internal resistanceCell electrodesSecondary cellsManganeseCobalt

The invention particularly relates to a preparation method for a ternary positive electrode material of a graphene composite lithium ion battery. The preparation method comprises the following steps of firstly preparing a ternary positive electrode material precursor by a crystallization control-coprecipitation method; performing multi-step sintering to prepare the ternary positive electrode material, wherein the mole ratio of nickel to manganese to cobalt (namely x to y to z) is equal to (0.30-0.90) to (0.50-0.80) to (0.05-0.50), and x+y+z=1; and finally preparing the ternary positive electrode material of the graphene composite lithium ion battery. According to the preparation method disclosed by the invention, the problem that graphene is difficult to disperse in the ternary positive electrode material is solved, the internal polarization resistance is greatly reduced, and high-current rate discharge is realized; furthermore, high discharge capacity and long cycle life are kept. The technology is simple, and the preparation method is low in energy consumption and favorable for large-scale production.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

A kind of preparation method of lithium iron phosphate

ActiveCN110627032BAchieving co-extractionReduce water dropletsCell electrodesPhosphorus compoundsLithium chlorideLithium iron phosphate

The invention discloses a preparation method of lithium iron phosphate. The method comprises the following steps: adding water into ferric chloride and lithium chloride in a molar ratio of 1: (1.03-1.05), and carrying out stirring and mixing to obtain a mixed solution; mixing tributyl phosphate and an N235 extracting agent according to a volume ratio of (6-10): 1, and carrying out uniform mixing under stirring to obtain an extracting agent; subjecting the mixed solution and the extracting agent to 6-8 stages of countercurrent extraction, and performing phase splitting to obtain an organic phase and a water phase; allowing the organic phase to enter a combustion furnace in a spray state, introducing air at the same time for combustion at a temperature of 300 DEG C to 450 DEG C, and performing dust collection to obtain a combustion material; and putting the obtained combustion material into a roller way furnace, performing calcining under the protection of an inert atmosphere, performingcooling to obtain a calcined material, carrying out jet milling on the calcined material, performing screening, and removing iron to obtain lithium iron phosphate. The method is simple in process andshort in process flow and can prepare the lithium iron phosphate material with high conductivity, low internal resistance, and excellent electrical properties.

Owner:HUBEI YUHAO HIGH-TECH NEW MATERIAL CO LTD

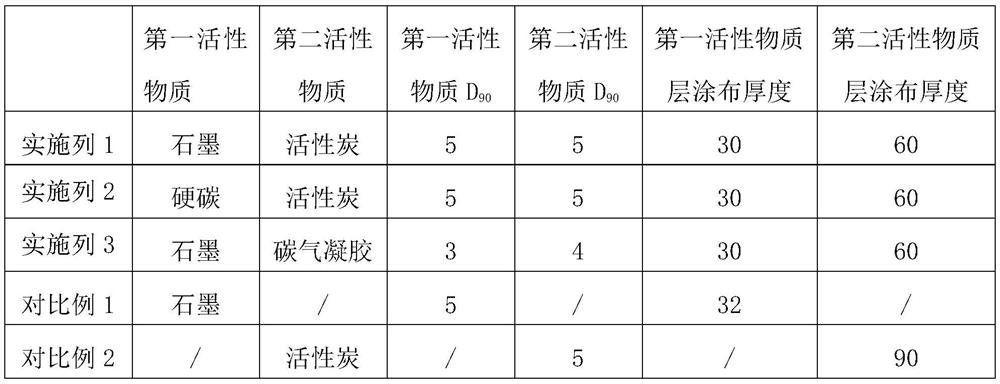

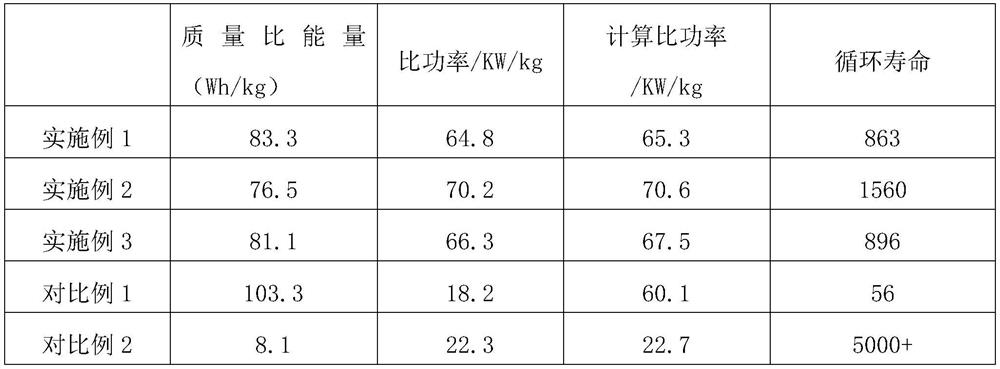

Negative pole piece, preparation method thereof and lithium ion capacitor based on negative pole piece

PendingCN114464463AHigh gram capacityGood capacitance characteristicsHybrid capacitor electrodesHybrid/EDL manufactureElectrolytic agentActivated carbon

The invention discloses a negative pole piece in the field of capacitors, the negative pole piece comprises a negative current collector, and a first active material layer and a second active material layer which sequentially coat the negative current collector, the first active material layer comprises a first active material, and the second active material layer comprises a second active material; the first active substance is at least one of soft carbon, hard carbon, graphite and a silicon carbon material; the second active substance is at least one of graphene, activated carbon, foamy carbon and carbon aerogel. According to the scheme, through the combination of the first active material layer and the second active material layer, the electrolyte transmission pressure under high power can be effectively relieved, the polarization internal resistance is reduced, and the circulation attenuation caused by insufficient electrolyte is reduced.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD +1

Preparation method of lithium iron phosphate

ActiveCN110627032AAchieving co-extractionReduce water dropletsCell electrodesPhosphorus compoundsLithium chlorideCombustion

The invention discloses a preparation method of lithium iron phosphate. The method comprises the following steps: adding water into ferric chloride and lithium chloride in a molar ratio of 1: (1.03-1.05), and carrying out stirring and mixing to obtain a mixed solution; mixing tributyl phosphate and an N235 extracting agent according to a volume ratio of (6-10): 1, and carrying out uniform mixing under stirring to obtain an extracting agent; subjecting the mixed solution and the extracting agent to 6-8 stages of countercurrent extraction, and performing phase splitting to obtain an organic phase and a water phase; allowing the organic phase to enter a combustion furnace in a spray state, introducing air at the same time for combustion at a temperature of 300 DEG C to 450 DEG C, and performing dust collection to obtain a combustion material; and putting the obtained combustion material into a roller way furnace, performing calcining under the protection of an inert atmosphere, performingcooling to obtain a calcined material, carrying out jet milling on the calcined material, performing screening, and removing iron to obtain lithium iron phosphate. The method is simple in process andshort in process flow and can prepare the lithium iron phosphate material with high conductivity, low internal resistance, and excellent electrical properties.

Owner:HUBEI YUHAO HIGH-TECH NEW MATERIAL CO LTD

A kind of preparation method of lithium-ion battery cathode with high rate performance

ActiveCN109119619BImprove conductivityImprove stabilityCell electrodesHigh rateLithium iron phosphate

Owner:JIANGXI DIBIKE

A kind of preparation method of lithium-ion battery hybrid positive electrode

ActiveCN108933242BExtend your lifeIncrease the output voltageElectrode carriers/collectorsSecondary cellsHigh rateHigh energy

Owner:JIANGXI DIBIKE

A Particle-Based Wax Perspiration Method

ActiveCN109810725BIncrease heat transfer areaIncreased flow poresPetroleum wax recoveryParaffin waxWarm water

A particle-based wax sweating method, comprising the following steps: 1) padding the bottom of a sweating device with water, 2) heating the raw wax to a liquid state, adding sweating particles, and then adding it to the sweating device; Cool down to 10-20°C below the melting point at a rate of h; 4) Drain the pad water, send the warm water pump to the sweating tank, heat at a rate of 0.5-2°C / h and collect sweating paraffins with different melting points; 5) Wait until the end of heating After waxing, the melted high melting point paraffin product flows into the intermediate tank; 6) use steam to purge the remaining sweat particles and the last fraction of the sweat tank, and then filter and separate the two to recover the sweat particles. The method of the invention reduces the compaction density of the perspiration raw material, is conducive to the outflow of oil and low-melting wax, improves the fluidity of the perspiration liquid, and doubles the separation effect; at the same time, the perspiration product has a relatively high yield and a melting range. Relatively narrow, the molecular weight of the wax product is concentrated, and the product enthalpy value is relatively high.

Owner:上海焦耳蜡业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com