Low-temperature fast-charging artificial graphite negative electrode material, preparation method and low-temperature fast-charging battery

An artificial graphite negative electrode, low temperature technology, applied in the direction of negative electrode, battery electrode, secondary battery, etc., can solve the problem of affecting the charging and discharging performance of the material, peeling off the surface coating, reducing the specific capacity of the material, etc., to achieve superior high current charging. Discharge performance, small diffusion resistance, effect of improving diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the low-temperature fast-charging artificial graphite negative electrode material of the present invention comprises the following steps:

[0039] 1. Crushing and spheroidizing:

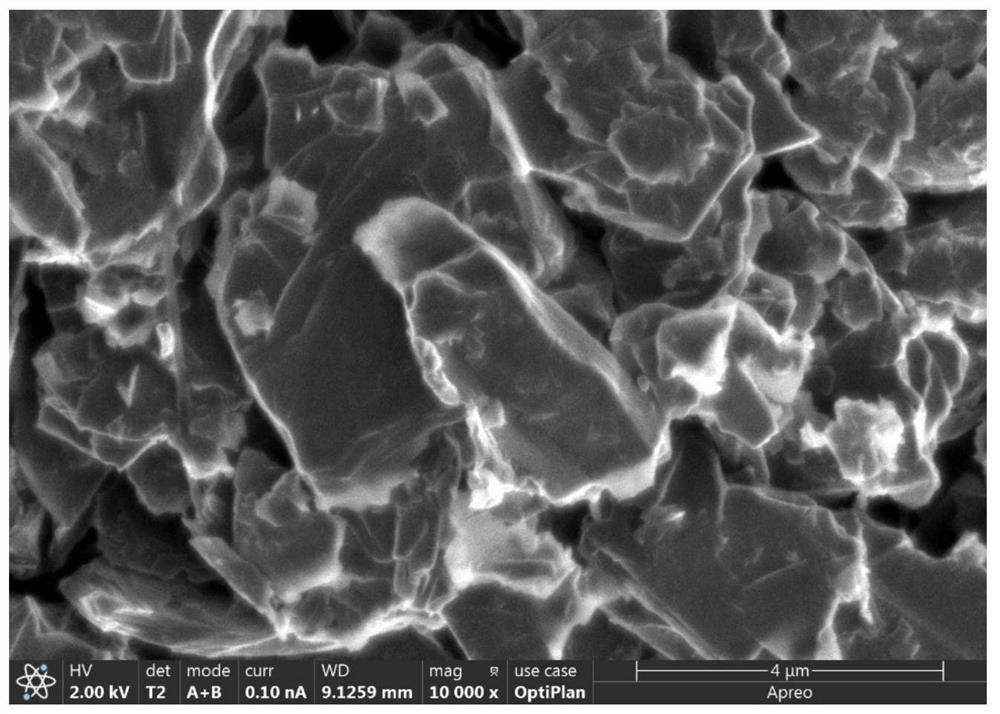

[0040] The raw materials are pulverized and spheroidized to obtain graphite precursor powder. The raw materials used are one or more of petroleum coke or pitch coke or graphite electrode joint powder with a particle size of less than 10mm. The particle size D50 of the graphite precursor powder is 2-7 microns.

[0041] 2. High temperature purification:

[0042] Put the graphite precursor powder into a high-temperature purification furnace, pass in an inert protective gas, and raise the temperature to 2600-3000°C at a heating rate of 1-20°C / min, and at the same time pass in the purification gas chlorine or Freon, and keep it warm for 1-96h , and then stop feeding the purified gas chlorine or freon, and cool with the furnace under the condition of inert protective gas...

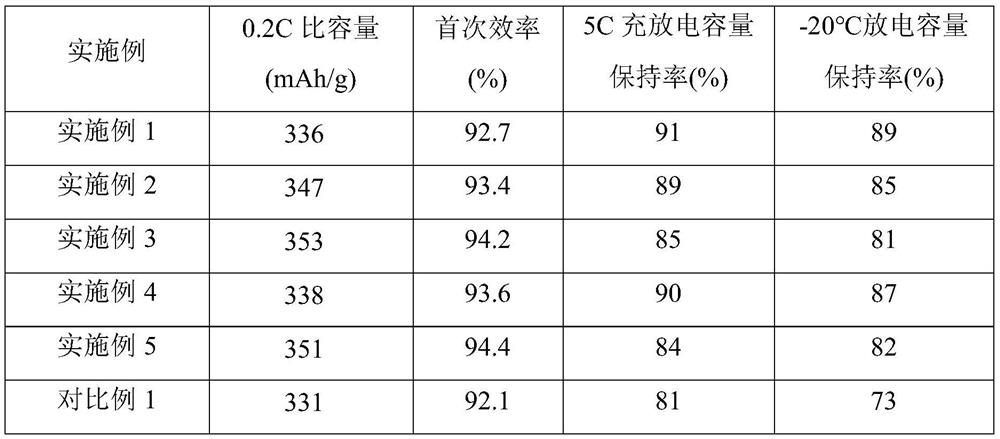

Embodiment 1

[0056] Petroleum coke with a particle size of less than 10 mm is pulverized by a mechanical mill and a shaper, and shaped into balls until the particle size D50 is 5 microns to obtain graphite precursor powder. Put the graphite precursor powder into a push boat type high-temperature graphite purification furnace, pass in an inert protective gas, raise the temperature to 2600°C at a heating rate of 10°C / min, pass in the purified gas chlorine, keep it for 96 hours, and then stop the flow Enter the purified gas chlorine, and cool with the furnace under the condition of inert protective gas to obtain the graphite matrix.

[0057] Put 10Kg of the obtained graphite matrix into the hearth of the rotary kiln; rotate the hearth at a speed of 10rpm, raise the temperature at a speed of 15°C / min, and at the same time feed inert protective gas nitrogen at a flow rate of 500L / h, when the temperature reaches 1100°C , adjust the flow rate of inert protection gas nitrogen to 2000L / h, feed cata...

Embodiment 2

[0061] Petroleum coke with a particle size of less than 10 mm is pulverized by a mechanical mill and a shaper, and shaped into balls until the particle size D50 is 2 microns to obtain graphite precursor powder. Put the graphite precursor powder into a push boat type high-temperature graphite purification furnace, pass in an inert protective gas, raise the temperature to 2800°C at a heating rate of 1°C / min, pass in the purified gas Freon, keep it warm for 48 hours, and then stop the flow Inject the purified gas Freon, cool with the furnace under the condition of inert protective gas, and obtain the graphite matrix.

[0062] Put 10Kg of the obtained graphite matrix into the hearth of the rotary kiln; rotate the hearth at a speed of 10rpm, raise the temperature at a speed of 3°C / min, and at the same time feed inert protective gas nitrogen at a flow rate of 250L / h, when the temperature reaches 1100°C , adjust the flow rate of the inert protection gas nitrogen to 1000L / h, and simul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com