Patents

Literature

45results about How to "Low degree of graphitization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of graphite cathode material

ActiveCN102030326ALess amount of intercalationIncrease spacingCell electrodesCarbon layerOrganic solvent

The invention provides a preparation method of a graphite cathode material. In the method provided by the invention, a twice cladding method is utilized to cover the bitumencarb with resin carbon and then cover graphite particles with the bitumencarb, thereby forming a gradient structure with different carbon layers. The resin carbon layers have large intervals, and good combination with electrolyte. The resin carbon layers form stable electrolytic films, the lithium ions can enter the bitumencarb layer through the electrolyte membrane and then enter the graphite layer, and organic solvent molecules are blocked by the bitumencarb layer without being inserted into graphite pieces. In addition, the resin carbon has good mechanical strength, and the cycle life of the cathode material can be enhanced. The carbon is covered on the surface of the graphite particles to form the insertable structure for the lithium ions, thereby enhancing the inserting speed. Furthermore, the gaps of the resin carbon can store the lithium ions, thereby enhancing the capacity of the cathode material. The graphite cathode material obtained by the invention has the advantages that the capacity is above 360 mAh / g, the first cycle columbic efficiency is more than 95% and the cycle charging-discharging can be performed more than 3000 times, and rapid charging and discharging can be realized.

Owner:湖北联投恒达石墨有限公司

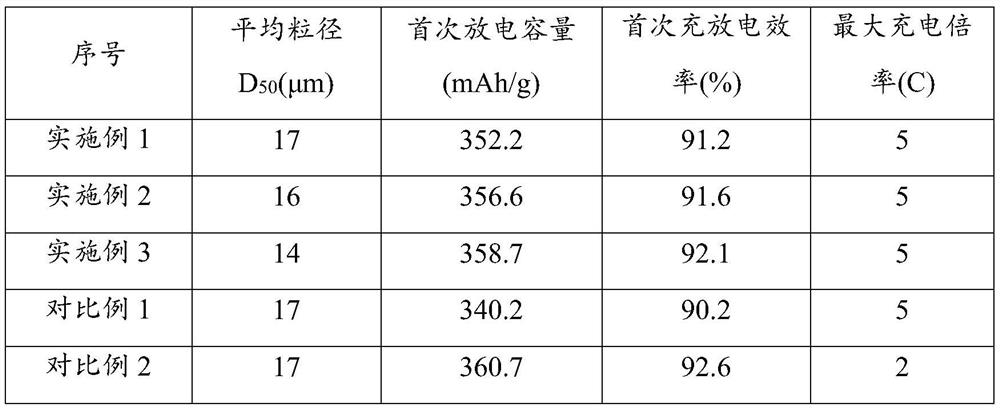

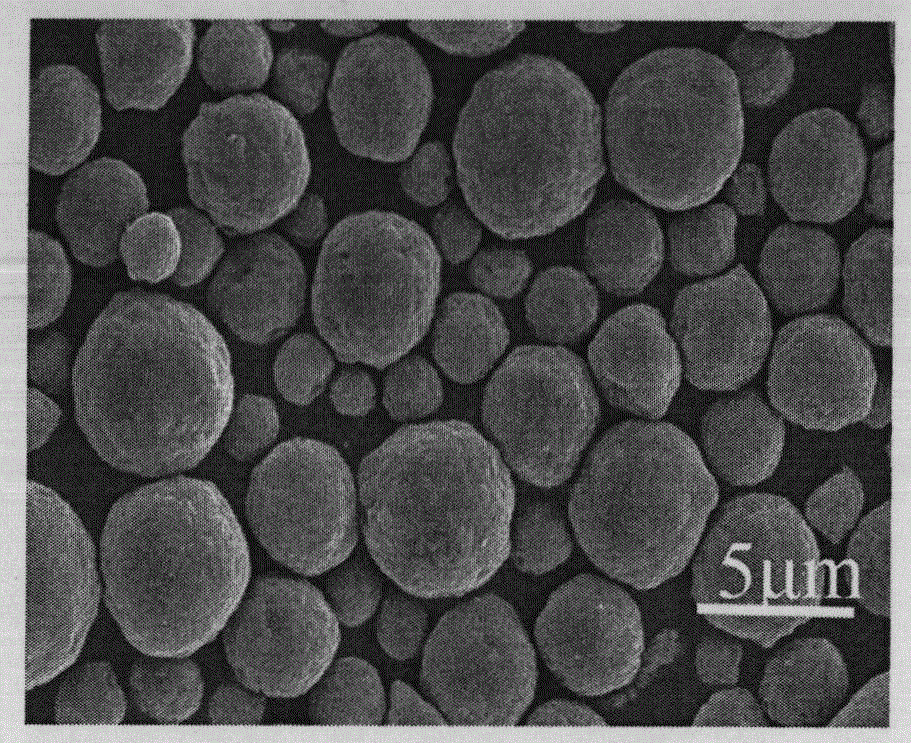

Composite graphite cathode material and preparation method thereof

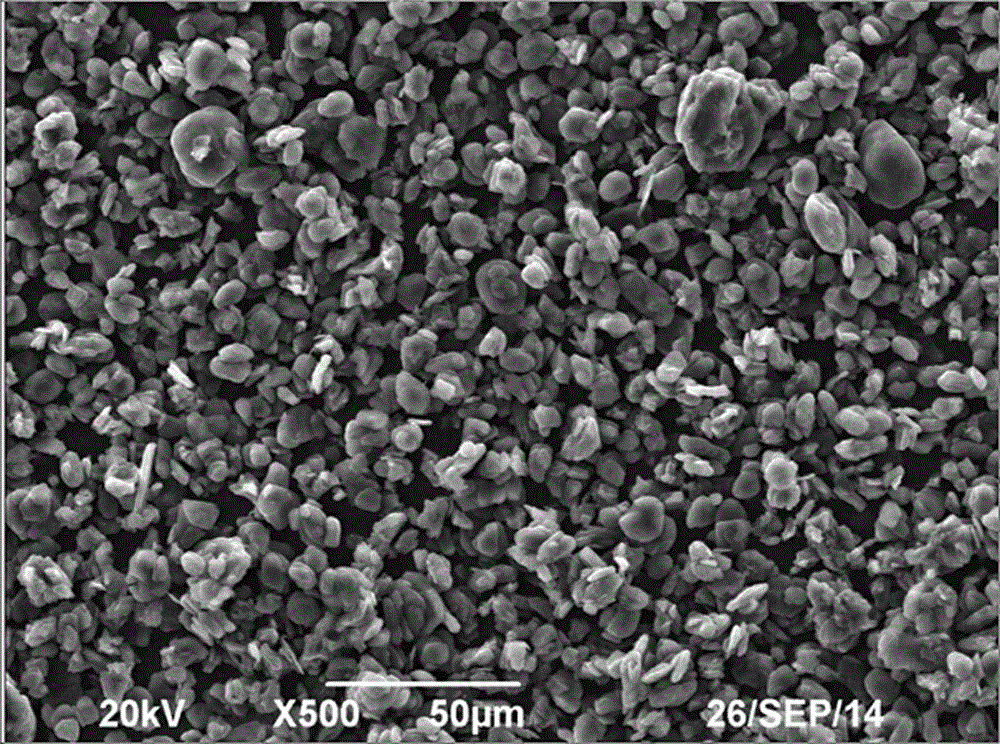

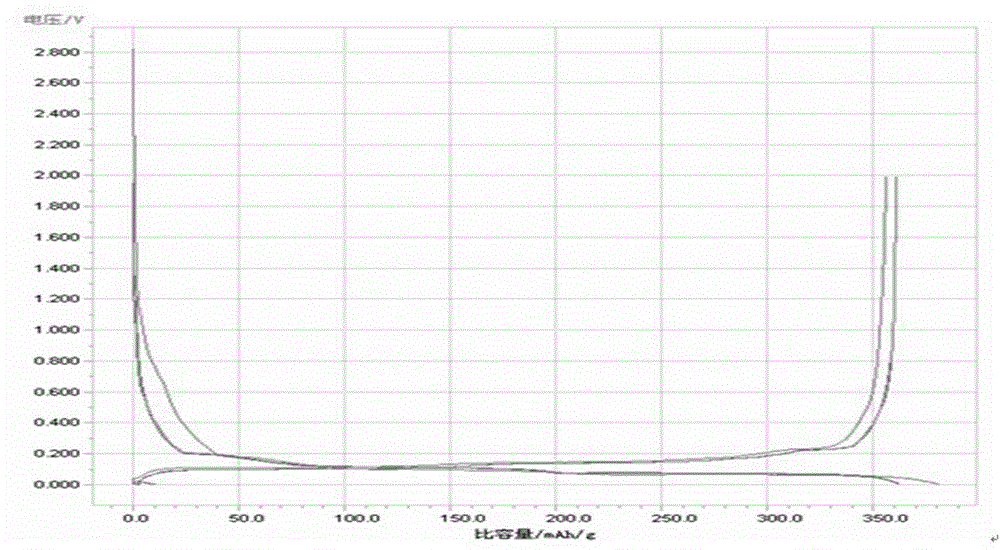

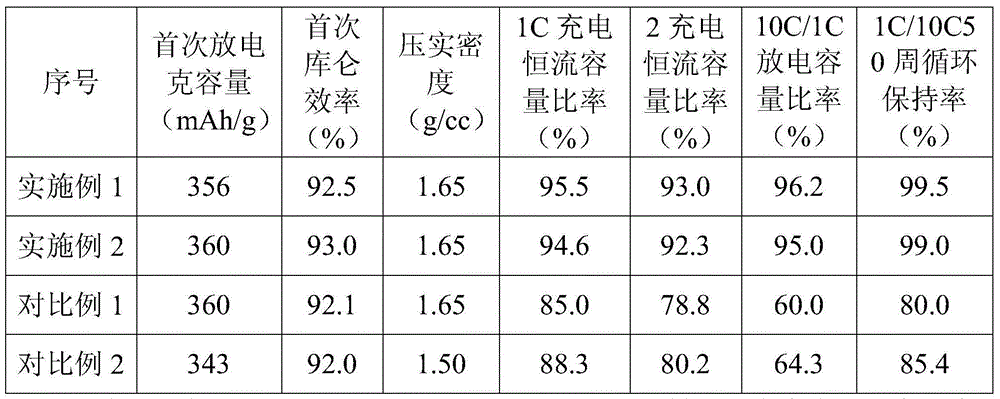

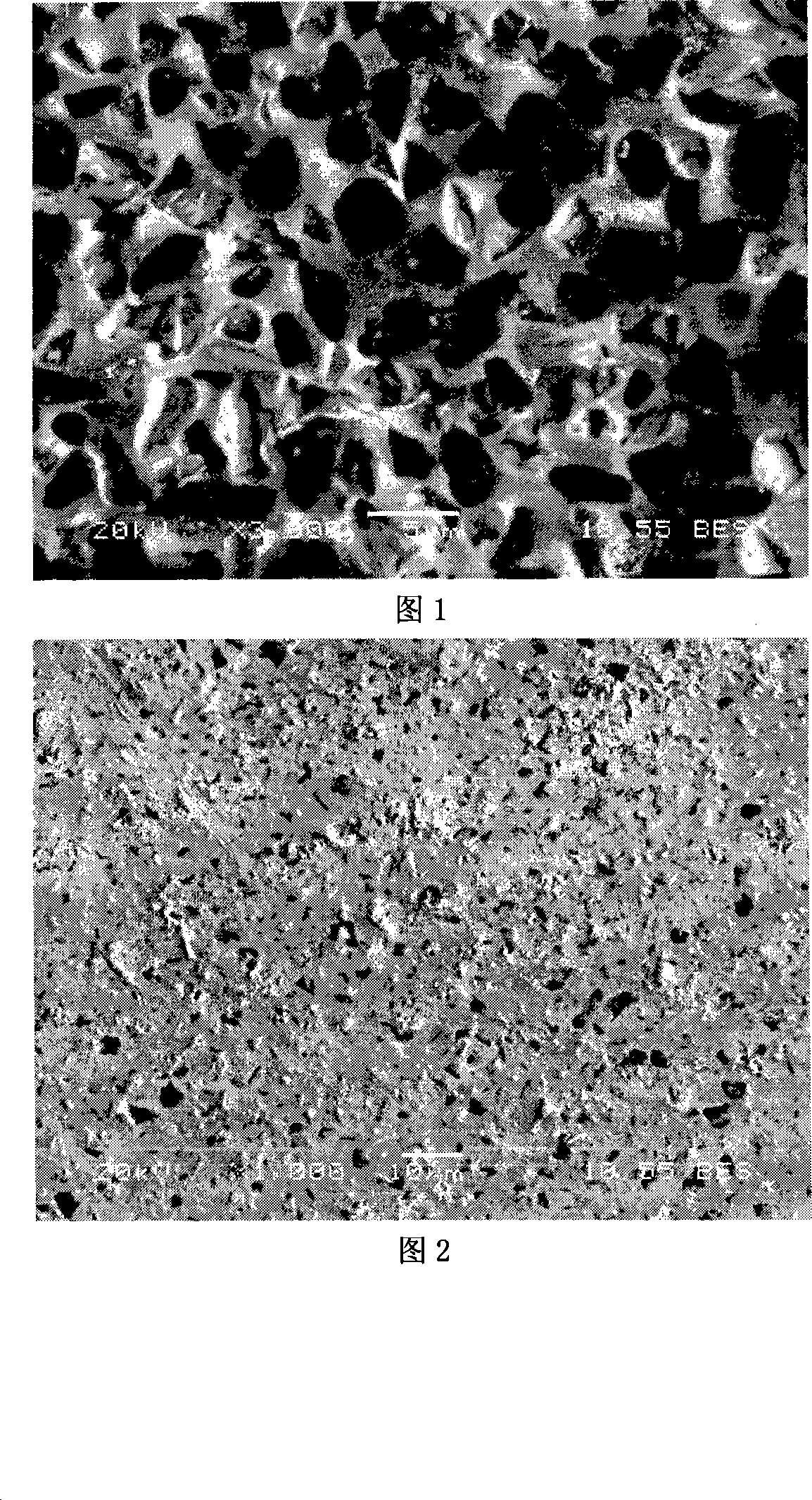

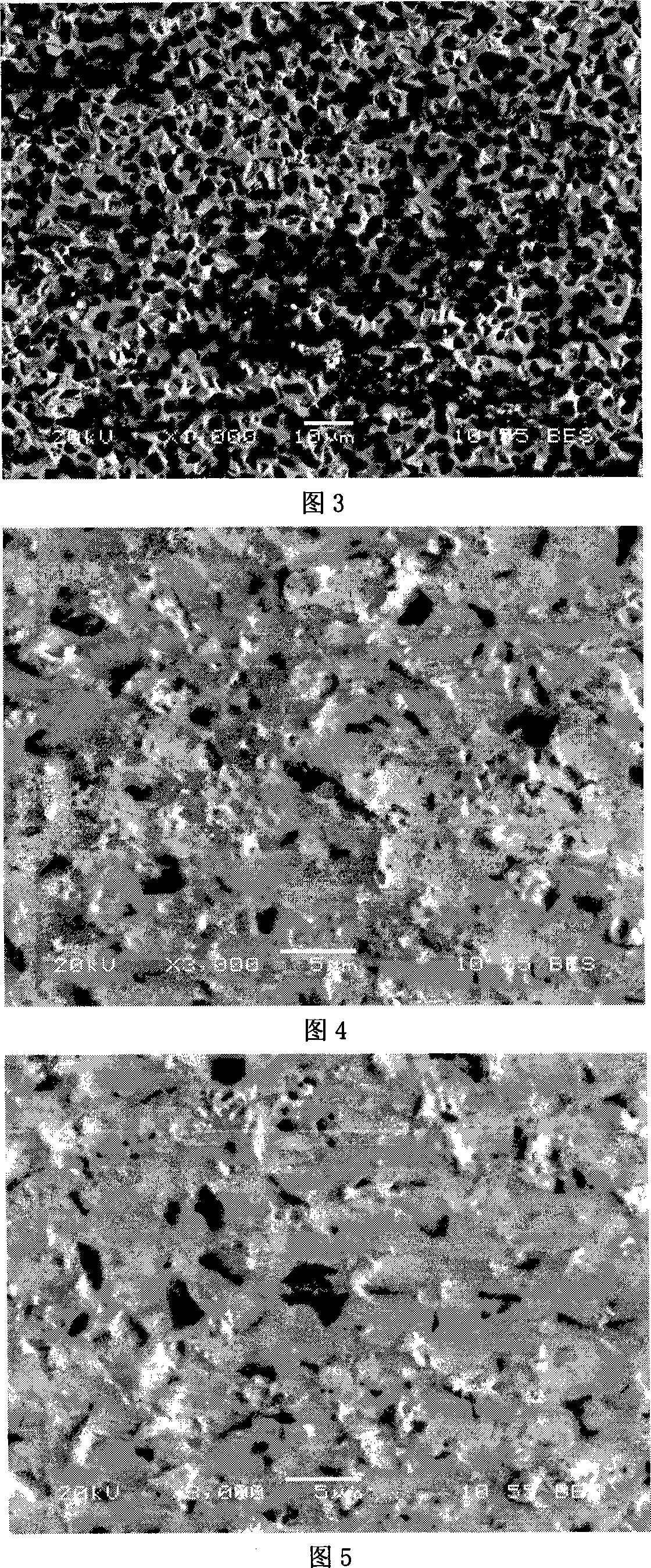

ActiveCN104609400AImprove cycle performanceGood high current charge and discharge performanceCell electrodesCarbonizationGraphite particle

The invention discloses a composite graphite cathode material and a preparation method thereof. The composite graphite cathode material comprises graphite particles a and b, wherein the graphite particles a are secondary artificial graphite particles formed by granulating, coating and bonding oil-based petroleum coke; the graphite particles b are secondary composite graphite particles, adopting core-shell structures, formed by removing impurities from small-particle diameter natural graphite balls, and spherodizing, coating and bonding the small-particle diameter natural graphite balls; the composite graphite material is prepared by mixing the graphite particles a and b, adding a binding agent, coating, bonding and performing high temperature carbonization. By compounding the two secondary graphite particles with different characteristics to prepare the composite graphite material, the capacity of graphite is improved and the problems that the graphite is poor in rate capability, poor in high-current charge and discharge performance, poor in compacting performance are solved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

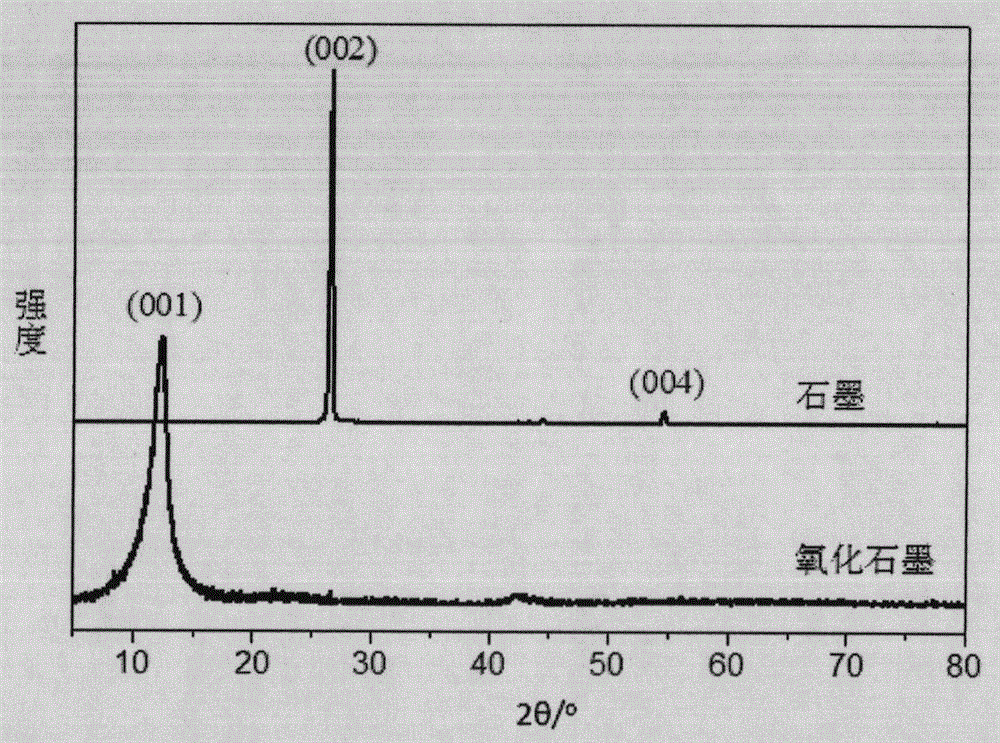

Lithium iron phosphate composite material coated with ternary carbon source and preparation method of material

ActiveCN103794760AImprove conductivitySolve the small diffusion coefficient of lithium ionsCell electrodesSecondary cellsReduction ActivityCarbonization

The invention provides a lithium iron phosphate composite material coated with a ternary carbon source and a preparation method of the material and belongs to the technical field of positive materials for lithium ion cells, aiming at the defects of poor conductivity and low tap density of lithium iron phosphate. The invention provides a modification method of the lithium iron phosphate composite material coated with the ternary carbon source according to the characteristics including pyrolysis characteristics, carbonization degrees, dispersion manners, residual carbon structures, reduction activity and the like of different carbon sources, based on a process and reaction process of preparing the lithium iron phosphate by using a carbon heat reduction method; micro-molecular water-soluble organic matters, high-molecular polymers, graphene compounds, iron source compounds, phosphorus source compounds and lithium source compounds are ball-grinded and homogenized and then are dried to prepare a composite precursor; then the composite precursor is sintered to obtain the lithium iron phosphate composite material. According to the lithium iron phosphate composite material coated with the ternary carbon source, the problems that the conductivity of the lithium iron phosphate composite material is low, the lithium ion diffusion coefficient is low, the tap density is low, and the like are solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Artificial graphite negative electrode material with gradient structure and preparation and application thereof

ActiveCN109585803AExcellent rate performanceImprove cycle performanceMaterial nanotechnologyCell electrodesPorosityHigh rate

The invention belongs to the technical field of a lithium ion battery negative electrode material, and particularly discloses an artificial graphite negative electrode material with a gradient structure. The artificial graphite negative electrode material is a carbon material with a core / shell structure, and the graphitization degree and the porosity of the carbon material are in gradient distribution in a radial direction; and from core to shell, the graphitization degree is gradually reduced, and the porosity is gradually reduced. The invention also provides the artificial graphite negativeelectrode material with the gradient structure. By pore-forming, catalyst carrying and two-segment electro-forging on anthracite, the negative electrode material with the graphitized and porosity dual-gradient structure can be prepared; and the material with the gradient structure is compatible with the advantages of high reversible capacity, high rate performance, long cycle lifetime and the like.

Owner:湖南宸宇富基新能源科技有限公司

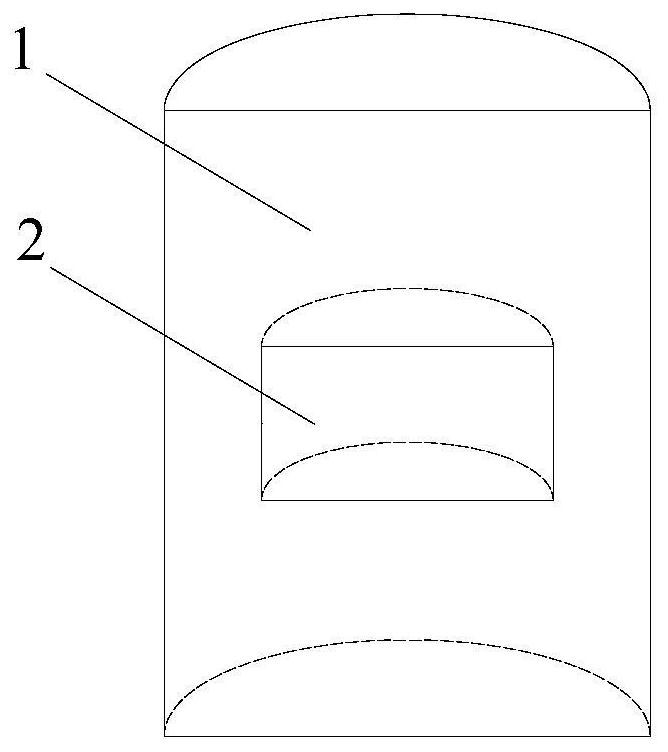

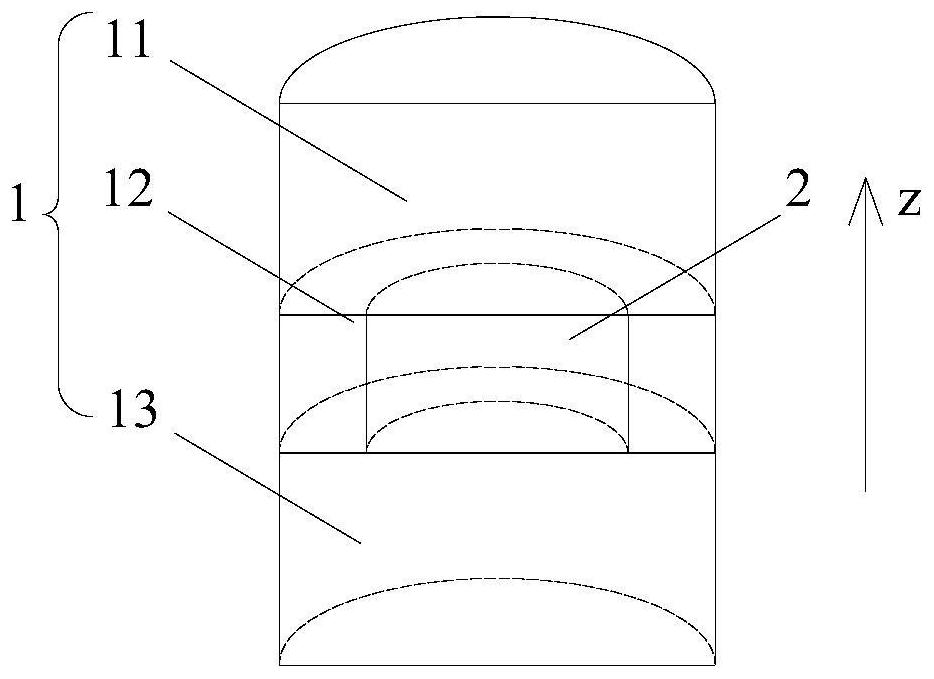

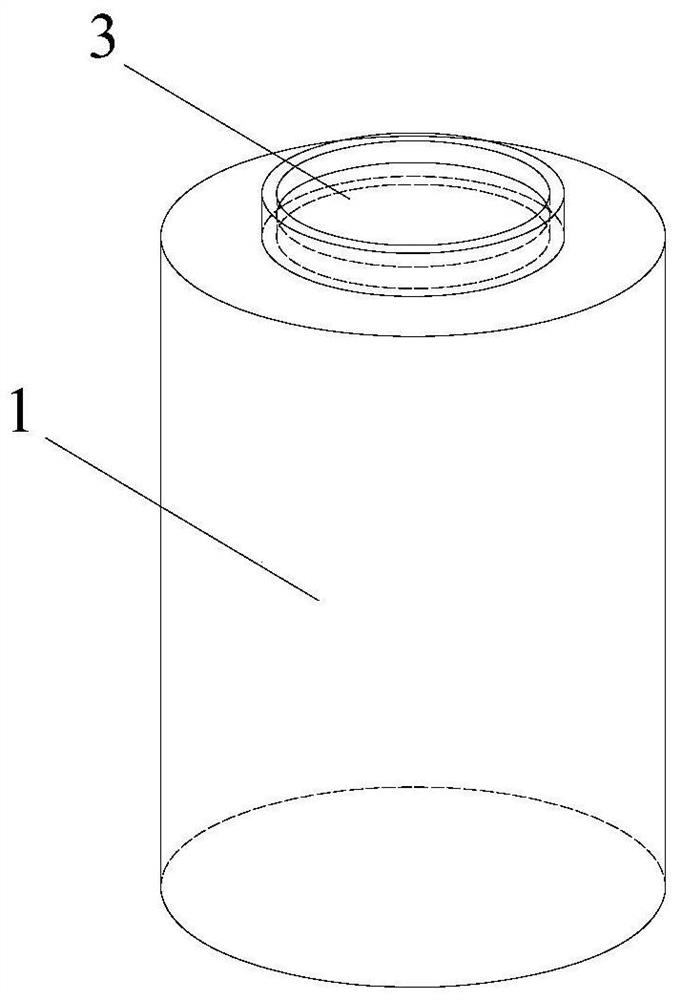

Method for preparing pantograph slide plate composite carbon core of electric locomotive (including high-speed train) by using cold isostatic pressing process

InactiveCN104494447AEffective combinationMeet the requirementsPower current collectorsAdditive ingredientSlide plate

The invention relates to a method for preparing a pantograph slide plate composite carbon core of an electric locomotive (including a high-speed train) by using a cold isostatic pressing process. The method uses various carbon materials for producing a pantograph slide plate carbon core material by a certain formula, or uses a carbon material and branch-shaped nickel powder or copper powder for burdening by a certain formula requirement to prepare the pantograph slide plate composite carbon core; the process comprises the following steps: the ingredients are treated by using a grinding process or a planetary mixing process; a mold sleeve is produced by requirements of a cold isostatic press; then, the materials are evenly added through a vibrator into the mold sleeve; the mold sleeve is put in the cold isostatic press; the compression molding is finished by the cold isostatic press to prepare a composite carbon core blank; and the blank is roasted and dipped to prepared a high-performance pantograph slide plate carbon core composite material of the electric locomotive. The carbon core has the advantages of good electric conductivity, heat resistance, electric arc resistance, high mechanical strength, good lubricating performance and wearing resistance, low production cost and easy realization of industrialization.

Owner:赵飞 +2

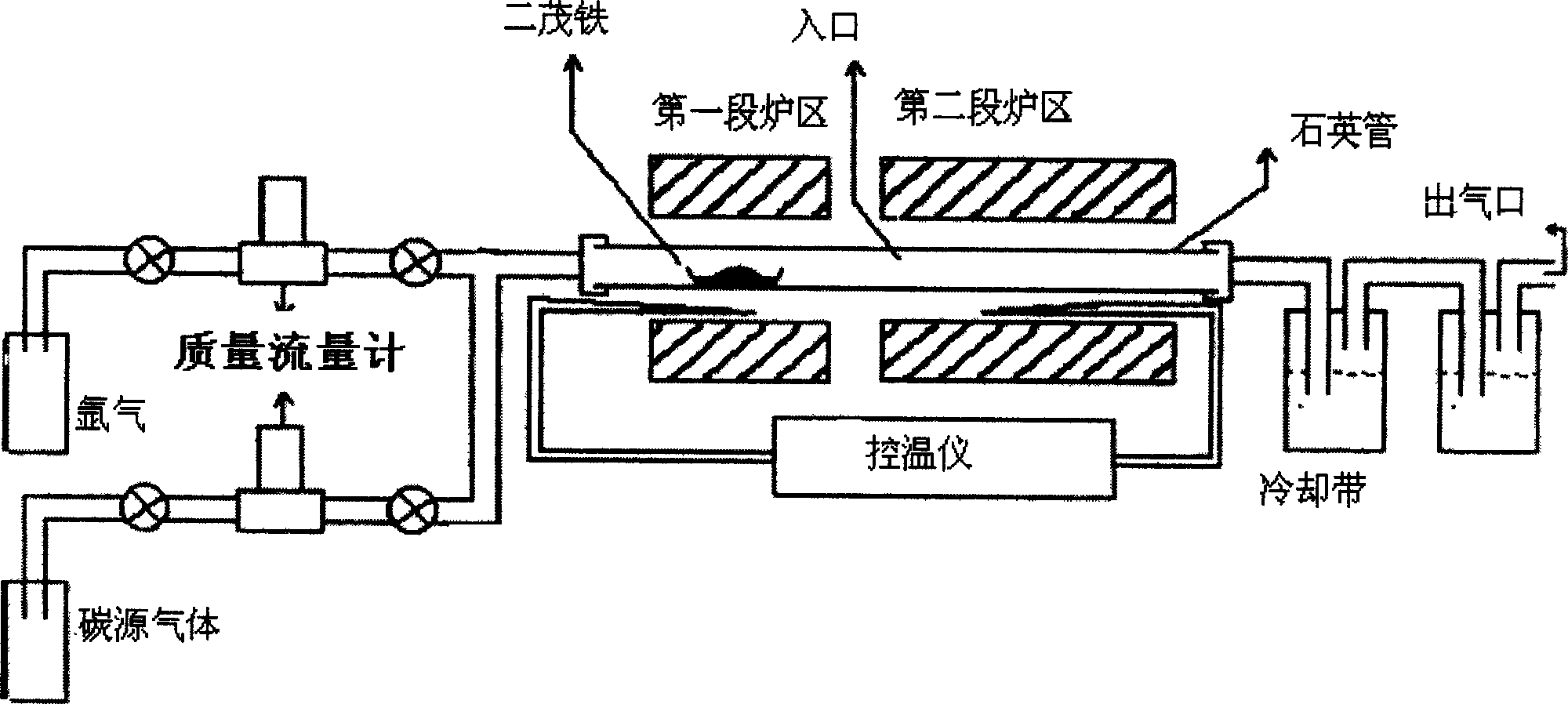

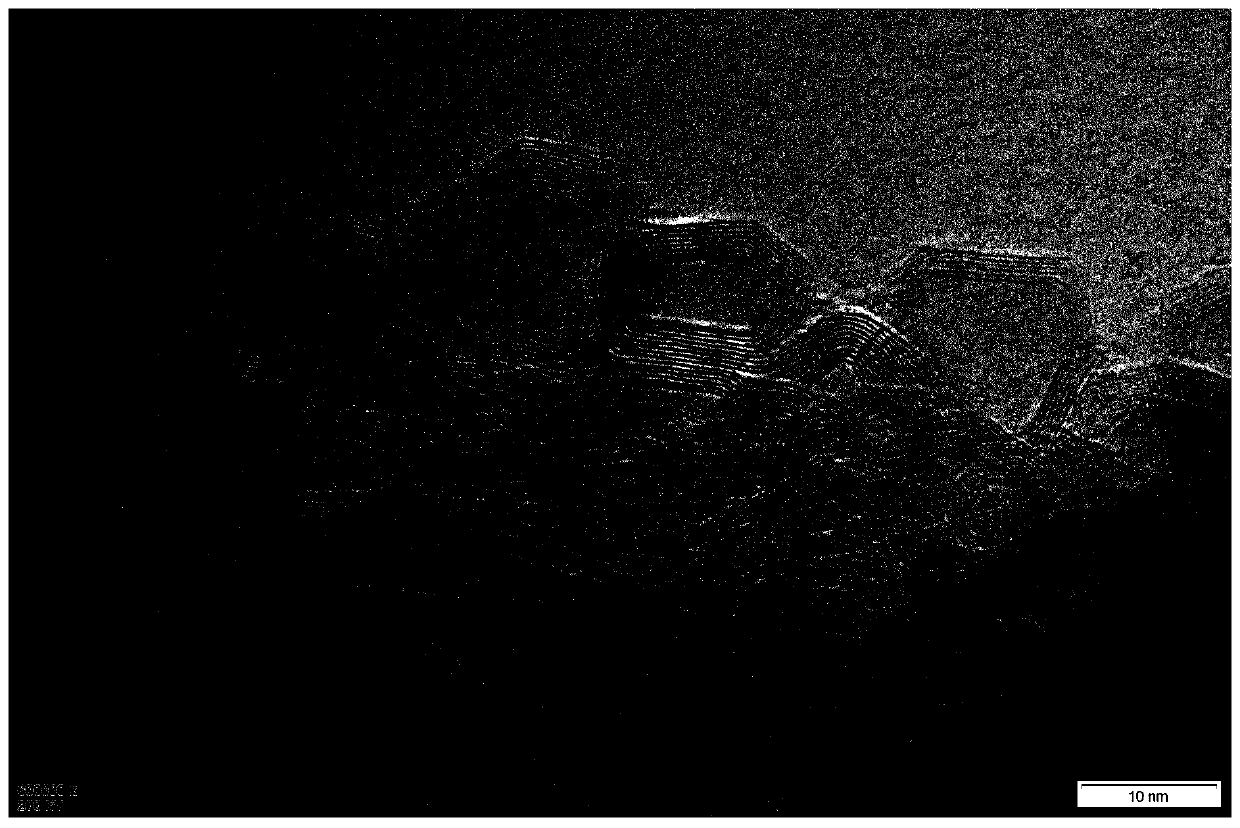

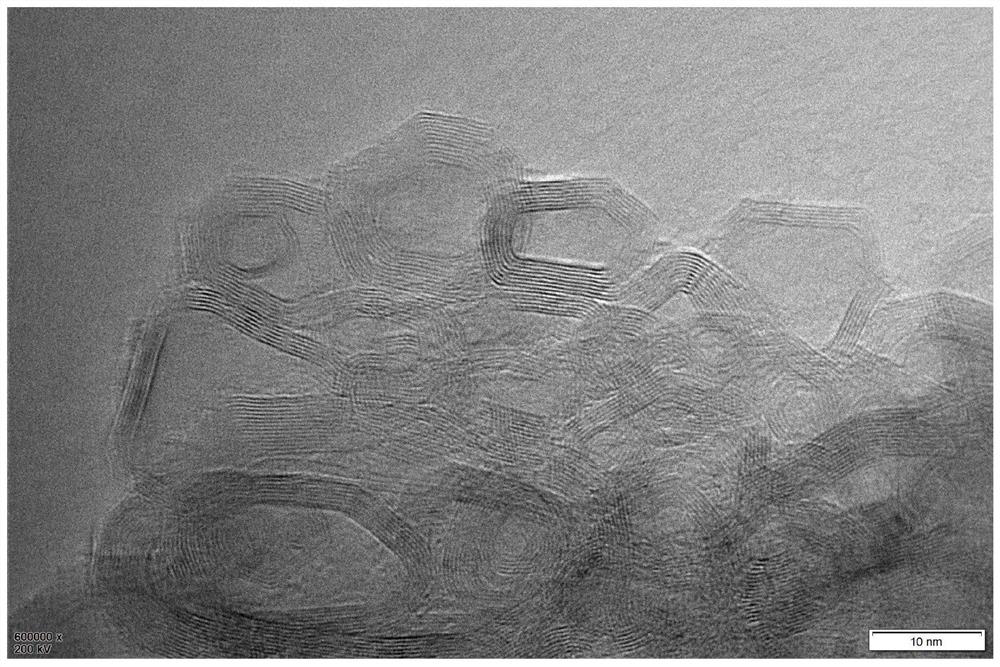

Method of in-situ filling symbiotic iron nanometer wire on thin wall nanometer pipe

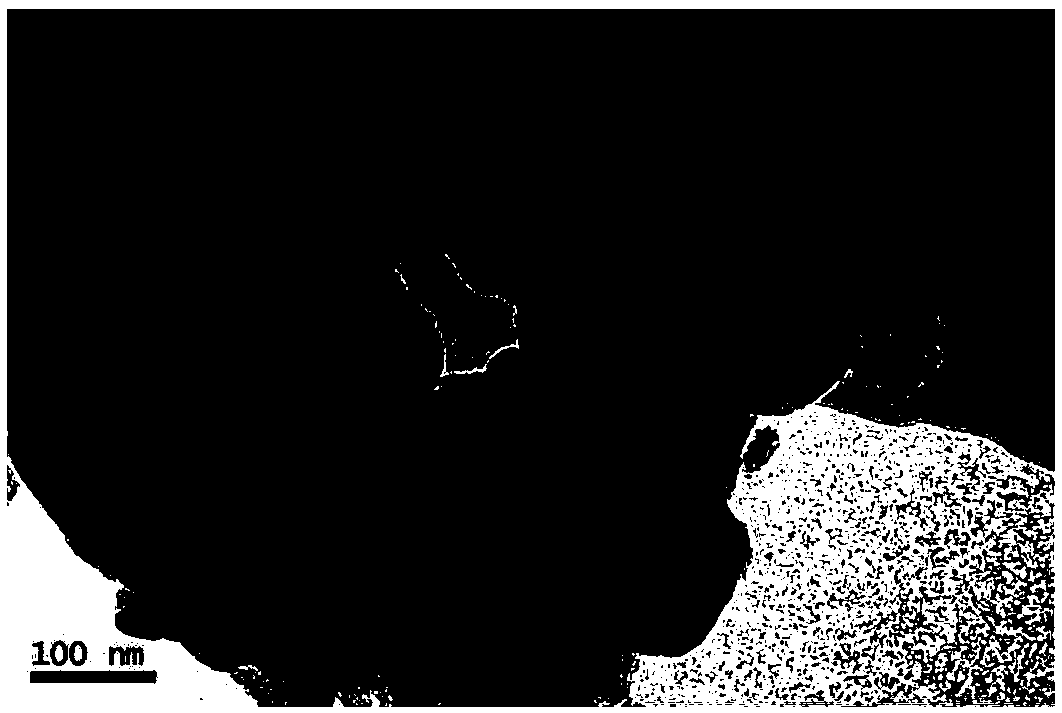

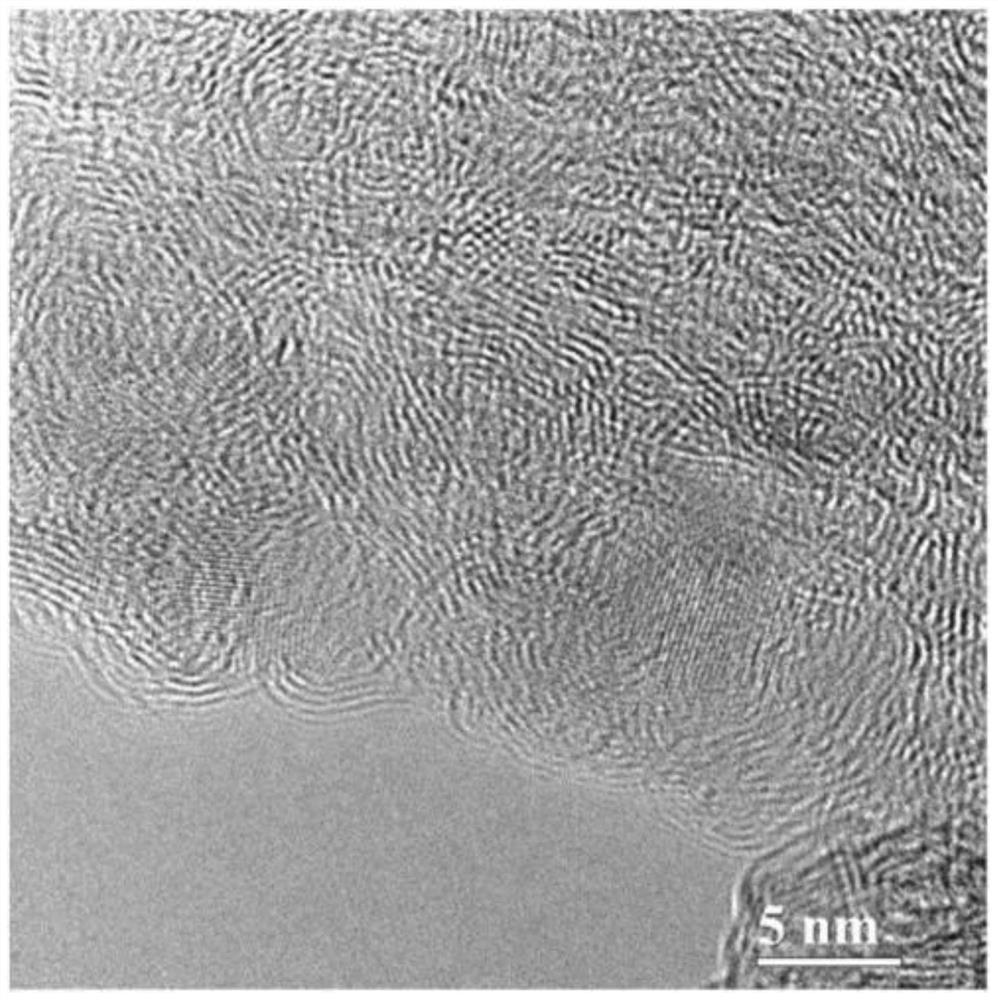

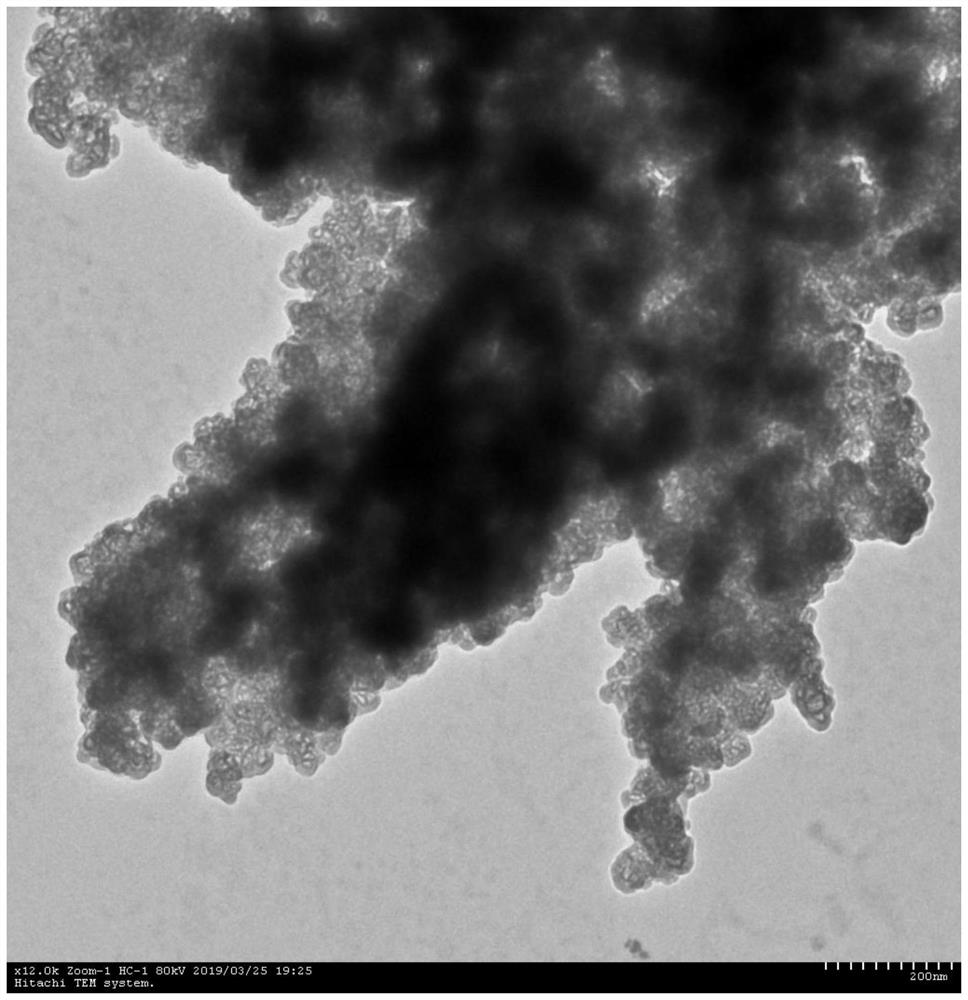

InactiveCN1868868AThe preparation process is simple and controllableLow degree of graphitizationNanostructure manufactureNanowireOrganic solvent

A process for preparing the in-situ symbiotic thin-wall carbon nano-tubes and iron nanowires filled in said nanotube includes such steps as dissolving ferrocene in Cl contained organic solvent, filling Ar gas in air-tight quartz tube, heating, controlling the temp at the end of capillary tube inserted in said quartz tube to be 250-300 deg.C, filling H2, pumping said solution in reactor, reaction, stopping to fill H2, and cooling.

Owner:TSINGHUA UNIV

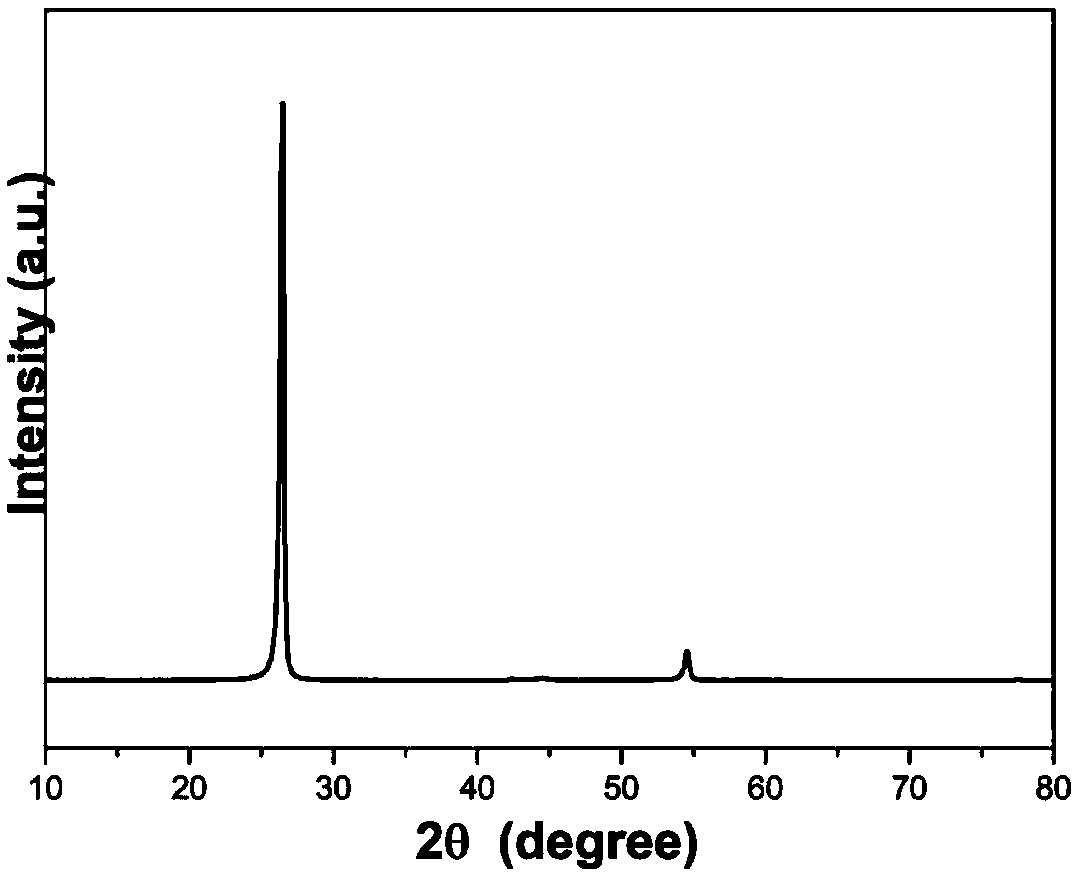

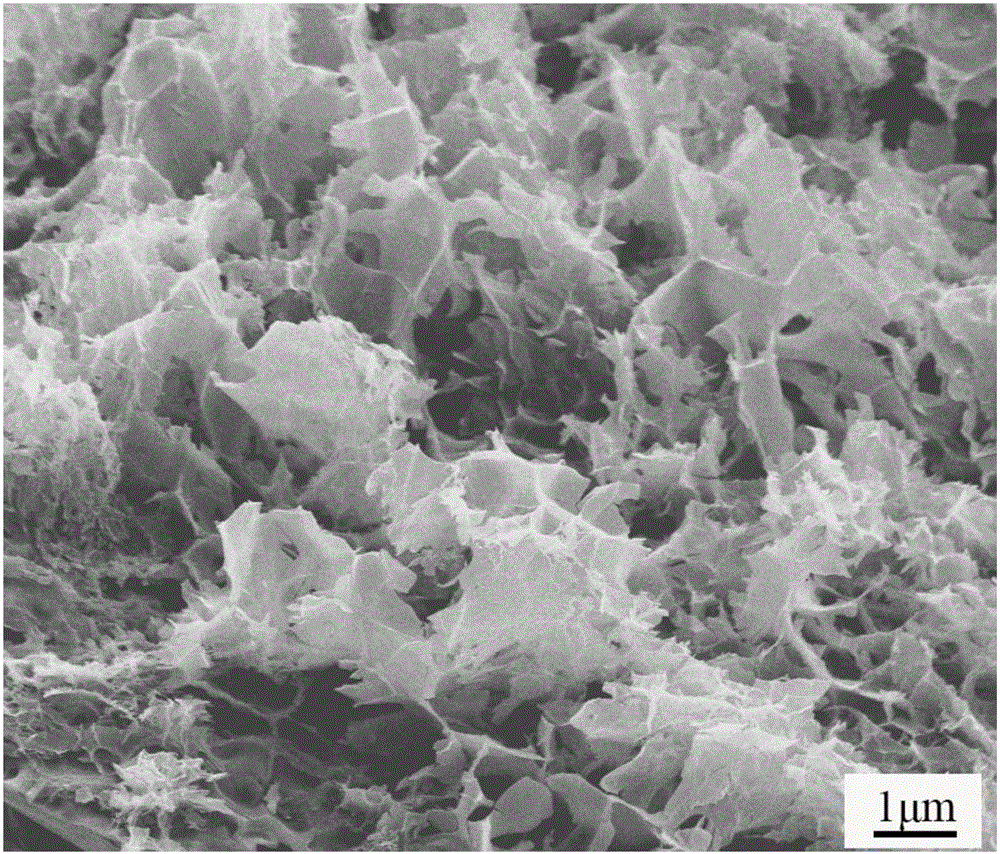

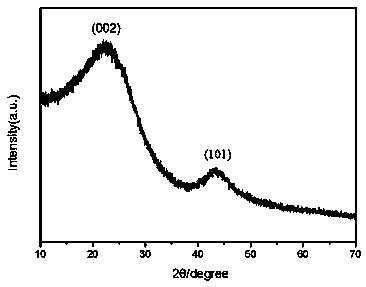

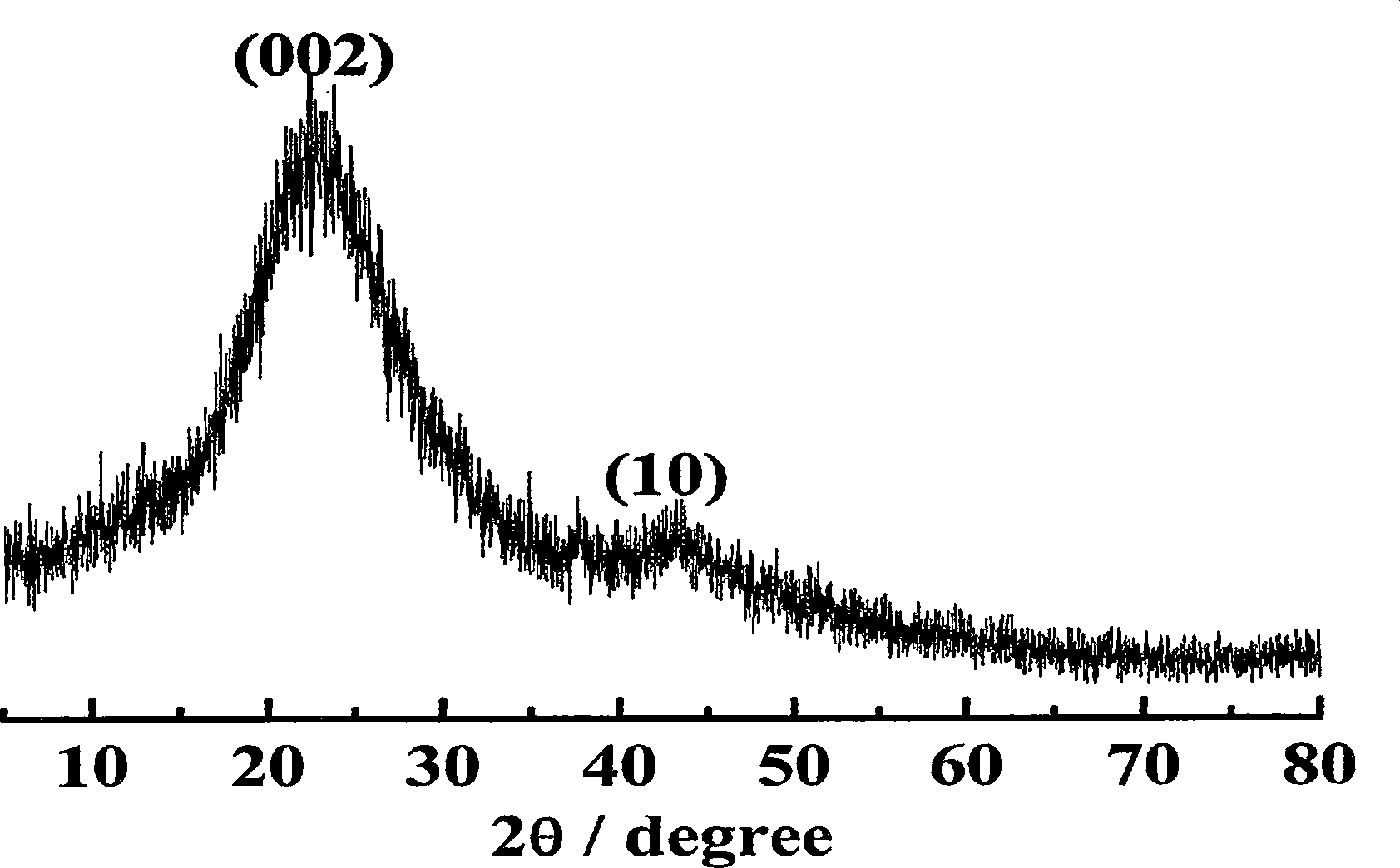

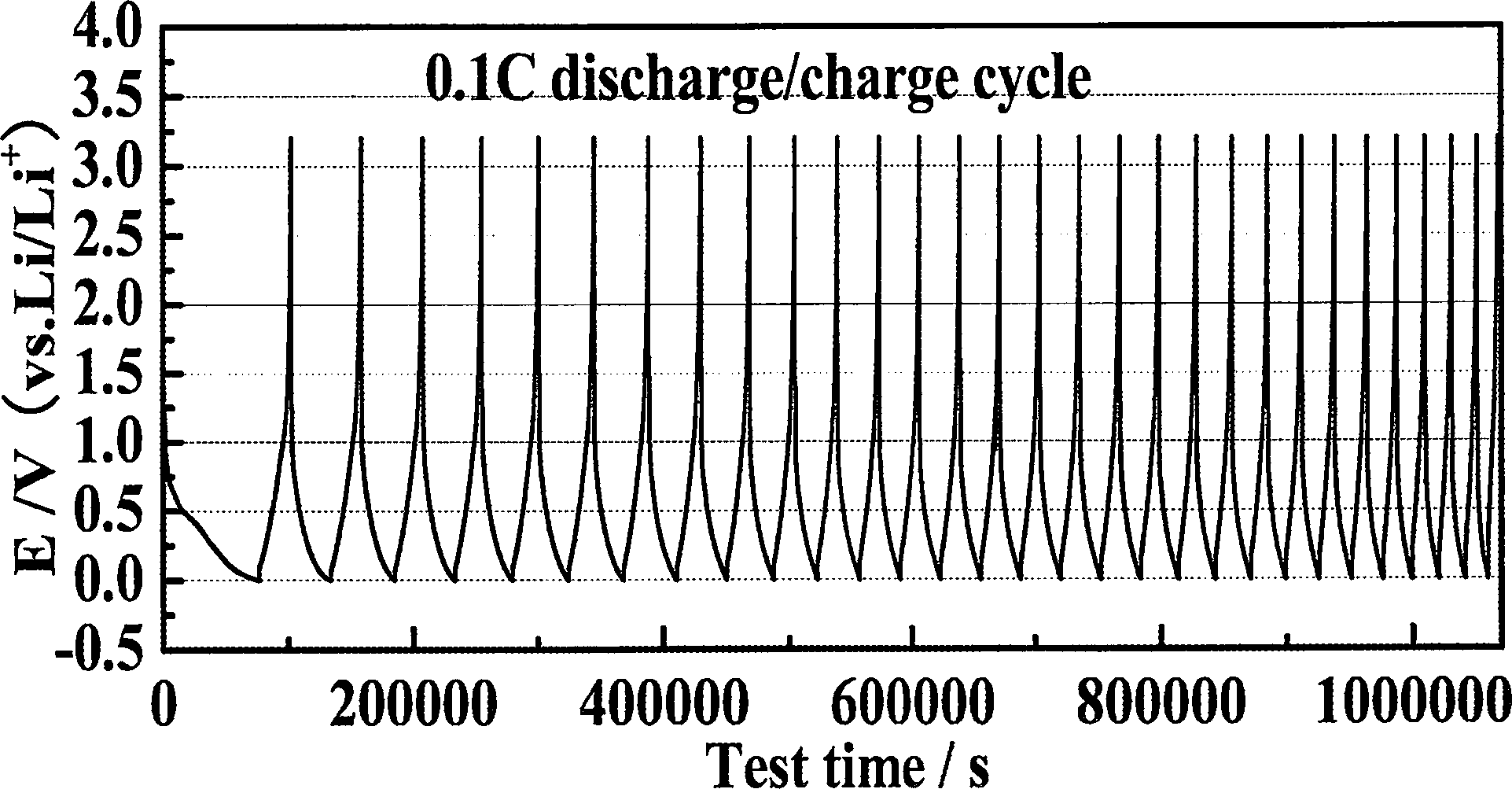

Preparation method for carbon nano-sheet matrix material and application of carbon nano-sheet matrix material in sodium-ion battery

ActiveCN106517179ARaw materials are cheap and easy to getSimple processMaterial nanotechnologyCarbon compoundsSodium-ion batteryMaterials science

The invention discloses a preparation method for a carbon nano-sheet matrix material and an application of the carbon nano-sheet matrix material in a sodium-ion battery. The method comprises the following steps: adopting lignin, resorcinol, formaldehyde and sodium carbonate for preparing a lignin gel according to a solution method; carbonizing the lignin gel at 400-1600 DEG C; activating with magnesium chloride at 600-1000 DEG C, thereby acquiring the carbon nano-sheet matrix material. The method has the advantages that the raw materials are easily acquired, the preparation process is simple and the repeatability is high. The prepared carbon nano-sheet matrix material has the advantages of low degree of graphitization, regular sheet structure, large specific area, abundant reaction active sites, moderate interlayer spacing, high electrical conductivity, and the like. When the carbon nano-sheet matrix material is applied to the sodium-ion battery, an excellent battery performance can be presented.

Owner:CENT SOUTH UNIV

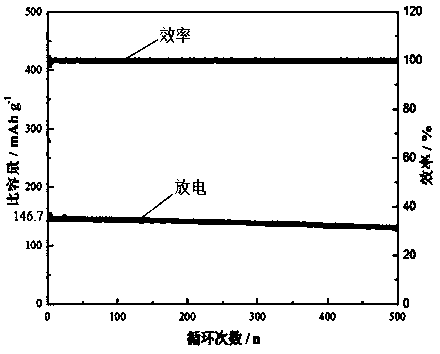

Preparation method for carbon negative electrode material of sodium ion battery

InactiveCN107634223AImprove electrochemical performanceFast transferCell electrodesSecondary cellsInorganic particleNew energy

The invention relates to a preparation method for a carbon negative electrode material of a sodium ion battery, and belongs to the technical field of synthesis of a new energy material. The preparation method comprises the steps of washing and drying acquired sakura petals, performing calcination in a protection atmosphere, taking out a product after reaction is completed, placing the product in an HC1 solution, immersing the product under a room temperature, and finally, fully washing the immersed product with deionized water and obtaining the carbon negative electrode material of the sodiumion battery after drying. According to the preparation method, the sakura petals are used as a raw material and are successfully converted to a carbon material by high-temperature calcination, the carbonized petals are immersed in an acid liquid to remove inorganic particles formed in a surface, and the sheet-shaped carbon negative electrode material with a corrugated surface of the sodium ion battery is obtained. The material is beneficial for rapid ion and electron transmission and is suitably used as a high-activity electrode material for the sodium ion battery.

Owner:KUNMING UNIV OF SCI & TECH

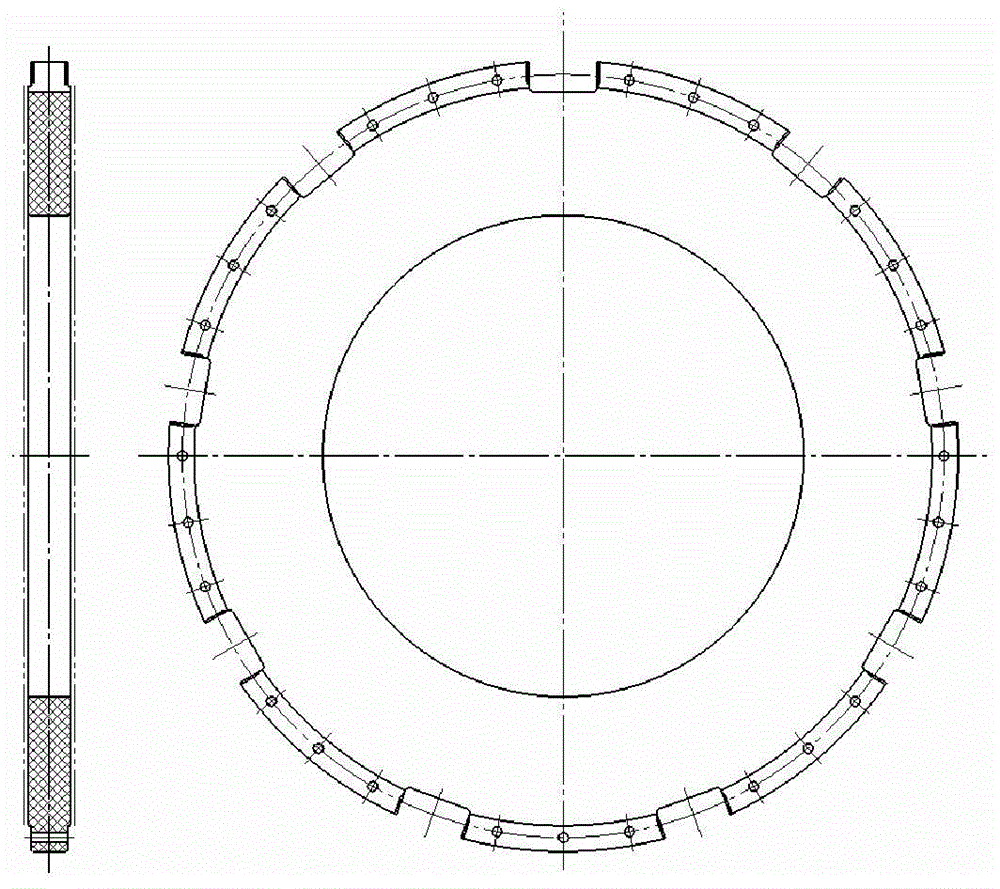

Manufacturing method of carbon/carbon composite material brake disk friction pair for planes

The invention discloses a manufacturing method of a carbon / carbon composite material brake disk friction pair for planes. The carbon / carbon composite material brake disk friction pair is made by means of deposition through different deposition gas sources, wherein a static disk is made by depositing mixed gas of propylene gas and nitrogen gas; a movable disk is made by depositing mixed gas of natural gas and dimethylmethane gas. The obtained static disk and movable disk are arranged in a brake device in sequence according to the assembly requirement of a plane wheel brake device, and each movable disk and each static disk form a friction pairs. The brake disk made by depositing a mixed gas source of propylene gas and nitrogen gas taken as a static disk, and a carbon disk made by depositing a mixed gas source of natural gas and dimethylmethane gas is taken as a movable disk to construct a friction pair, thereby improving brake pressure-torque gain and keeping the gain in a reasonable range. Moreover, a hard disk and a soft disk are arranged as a pair on the surface of the material, and a friction surface is worn uniformly and is smooth and flat in a braking process, thereby ensuring the output of a large torque, effectively lowering the brake vibration magnitude and improving the convergence of brake vibration.

Owner:XIAN AVIATION BRAKE TECH

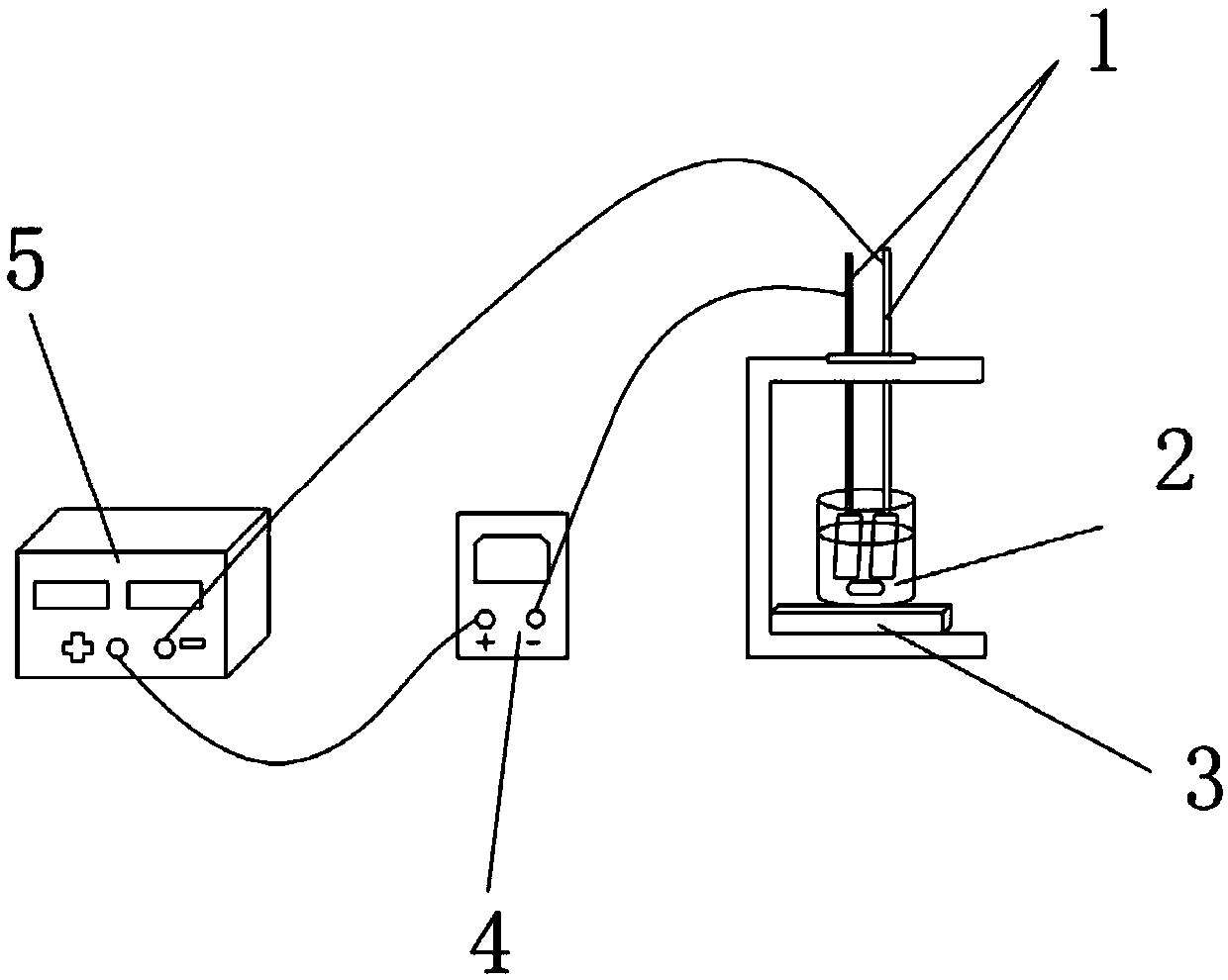

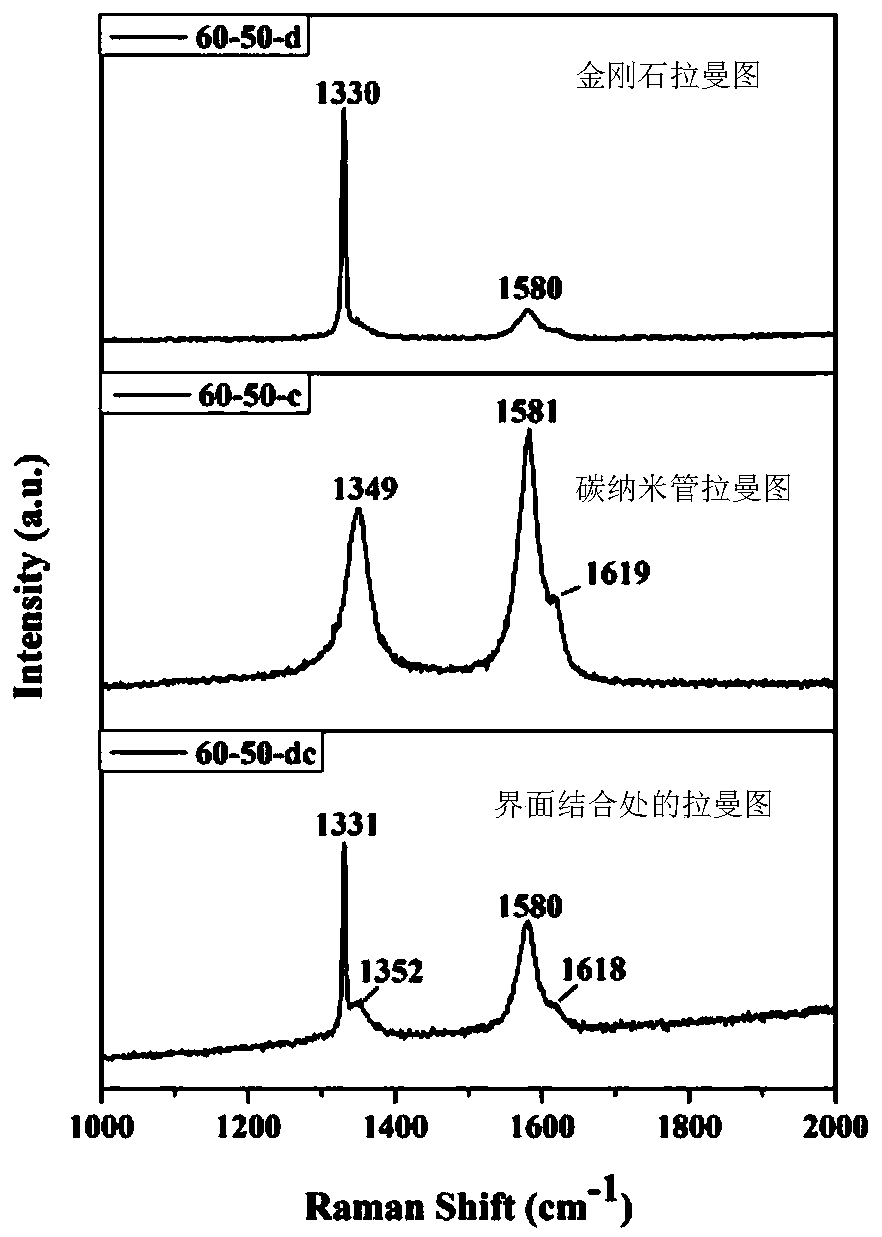

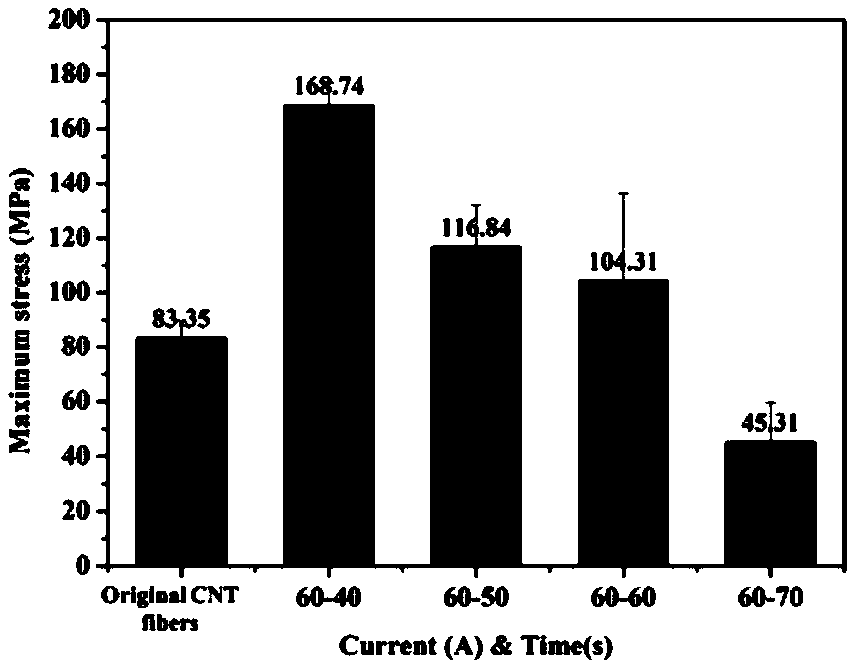

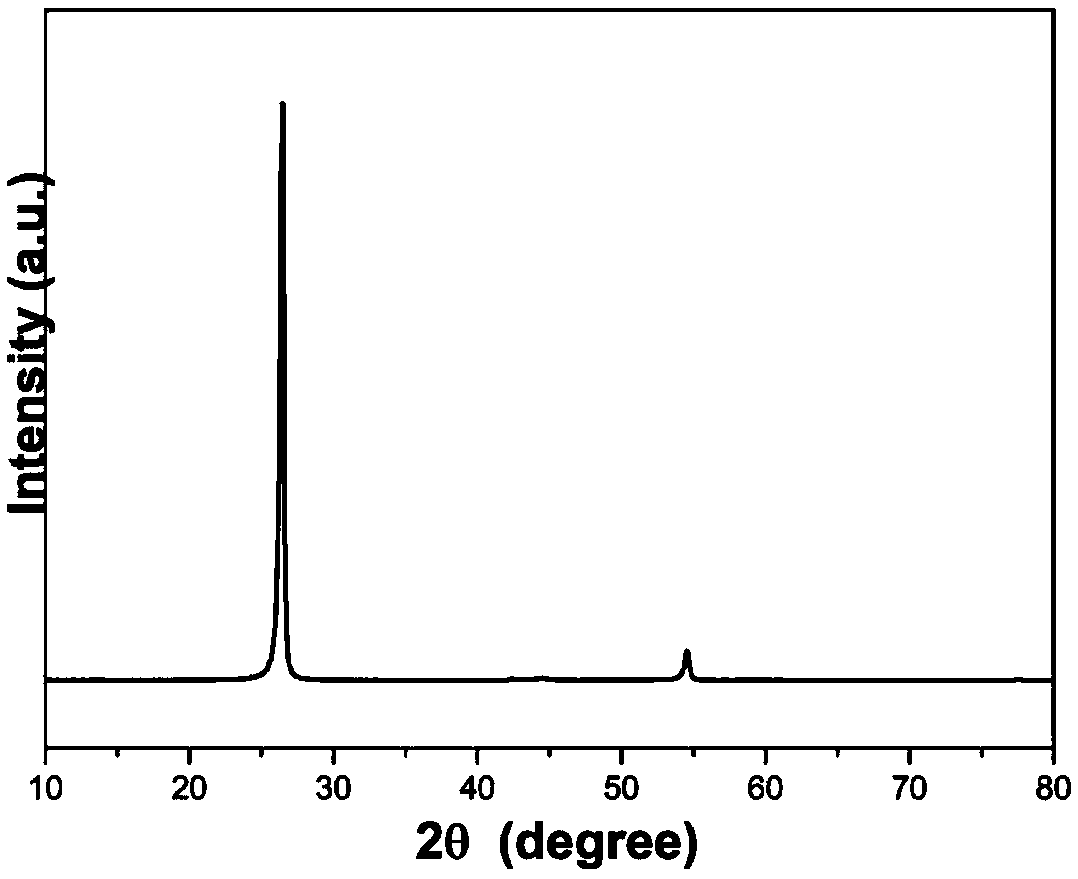

Preparation method of diamond and carbon nanotube fiber composite material

InactiveCN109518305AHigh hardnessHigh melting pointElectrophoretic coatingsFibre chemical featuresFiberCarbon nanotube

The invention provides a preparation method of a diamond and carbon nanotube fiber composite material. The preparation method comprises the following steps: (1) acquiring diamonds and a solvent of certain mass, and dispersing the diamonds uniformly by way of ultrasonic dispersion to form a diamond solution; (2) attaching the diamonds uniformly to the surfaces of carbon nanotube fibers by means ofelectrophoresis codeposition by taking the carbon nanotube fibers as an anode and a stainless steel plate as a cathode; and (3) putting the carbon nanotube fibers with uniformly attached diamond particles into a high frequency induction furnace, and making current to cure and sinter the diamonds and the carbon nanotube fibers to obtain the diamond and carbon nanotube fiber composite material. Thecomposite material obtained by the technical scheme not only has high hardness of the diamonds, but also has high strength and high toughness of the carbon nanotube fibers.

Owner:HUAQIAO UNIVERSITY

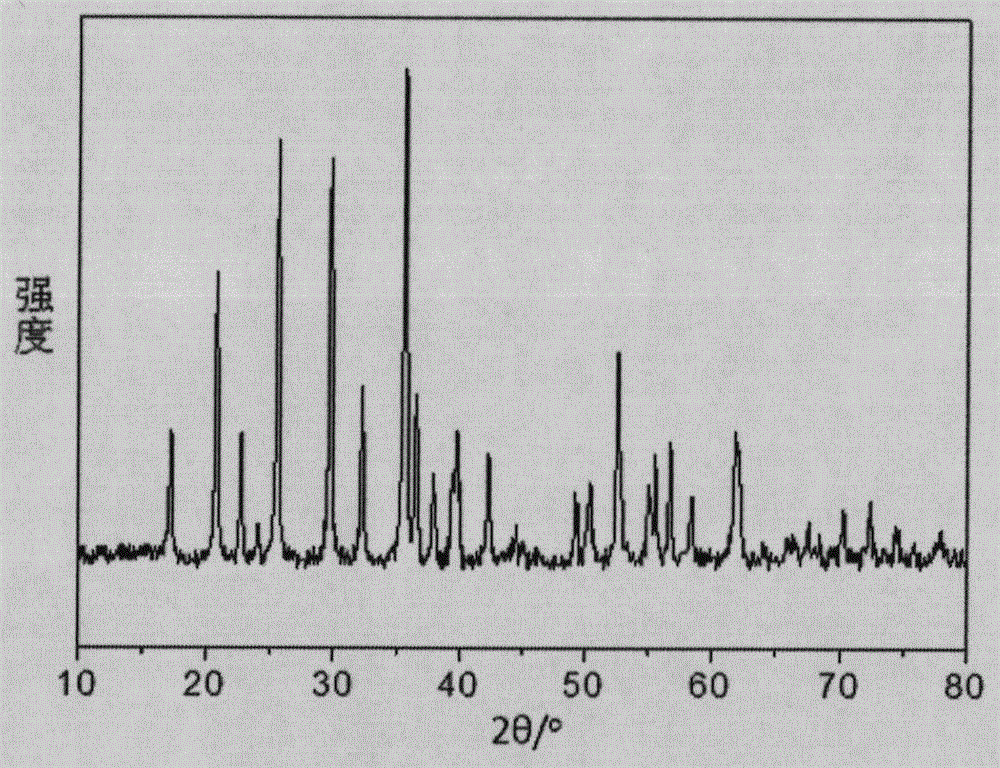

Graphite negative-electrode material with graphitization degree and hole diameter double-gradient structure, preparation method of material and application of material

ActiveCN109301225AExcellent rate performanceImprove cycle performanceCell electrodesSecondary cellsPorous carbonPore diameter

The invention belongs to the technical field of lithium ion battery negative-electrode materials, and particularly discloses a graphite negative-electrode material with a graphitization degree and hole diameter double-gradient structure. The graphite negative-electrode material is a carbon material with a core / shell structure, the graphitization degree and the hole diameter of the carbon materialare distributed in a radial gradient manner, the graphitization degree from a core to a shell is gradually reduced, and the hole diameter from the core to the shell is gradually reduced. The inventionfurther provides a preparation method of the graphite negative-electrode material with the double-gradient structure of the graphitization degree and the hole diameter. The graphite negative-electrode material serves as a catalyst in porous carbon pore gaps, and subsequent secondary electrical forging treatment is implemented to prepare the negative-electrode material with the double-gradient structure of the graphitization degree and the hole diameter. The material with the gradient structure has the advantages of high reversible capacity and rate performance, long cycle life and the like.

Owner:湖南宸宇富基新能源科技有限公司

Artificial graphite composite negative electrode material for lithium ion battery as well as preparation method and application of artificial graphite composite negative electrode material

PendingCN114597361AGood compatibilityGood magnification performanceGraphiteSecondary cellsCarbon coatingLithium electrode

The invention provides an artificial graphite composite negative electrode material and a preparation method and application thereof. The preparation method comprises the following steps: (1) calcining green coke at a high temperature of 800-1200 DEG C, and cooling to obtain shallow calcined coke; (2) crushing and shaping the shallow calcined coke obtained in the step (1) to obtain coke powder; (3) mixing the coke powder obtained in the step (2) with asphalt, and granulating to obtain secondary particles; (4) carrying out graphitization treatment on the secondary particles obtained in the step (3), and then scattering and screening to obtain screened materials; and (5) carrying out carbon coating treatment on the screened material obtained in the step (4) to obtain the artificial graphite composite negative electrode material. The graphite negative electrode material prepared by the method is used for the lithium ion battery, has high capacity and high magnification at the same time, and is simple in preparation process and relatively high in practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

Cathode material of carbon in lithium ion battery in high capacity, and method

This invention discloses a method for manufacturing the cathode material for lithium batteries from distiller's grains. The method comprises: (1) putting the distiller's grains into an oven, and carbonizing under inert gas protection; (2) activating the carbonization product with a strong base solution; (3) washing the activation product with water till neutral, filtering to obtain the solid, and drying to obtain the cathode material for lithium batteries.

Owner:LANZHOU UNIVERSITY

Diamond ultrathin saw bit with nickel aluminium alloy as base and manufacturing method thereof

The invention relates to a ni-al alloy-based diamond ultra-thin saw blade used for precise cutting in single (multi) crystal silicon, glass, ceramic, gem processing, etc. industries and the preparation method of the diamond ultra-thin saw blade. 50-70 units (volume percentage) of the nickel (5-20 micro meters) with the purity more than 99.9%, 10-30 units of aluminium powder (5-20 micro meters) and 20-30 units of titanium-plated artificial diamond grains (5-10 micro meters) are uniformly mixed in a three dimensional material mixer, then arranged into a die and cold pressed to a biscuit with the diameter dimension of Phi 25-200mm multiplied by 100-400 Mum on a four-column hydraulic press under a forming pressure of 100-500kgf / cm<2>; after that, a hot pressing and sintering is achieved by two sections; the heating of the mixture is firstly achieved in a vacuum hot pressing sintering furnace till the temperature is increased to 670-700 DEG C, and the temperature is kept for 5-60 minutes; after that, the temperature is increased to 750-800 DEG C and kept for 5-60 minutes with the hot pressure of 100-400kgf / cm<2>; the temperature is then gradually cooled to below 200 DEG C with the pressure in the furnace and the diamond saw blade can be gained after a discharge. The invention has the advantages of high strength, high rigidity, high ductility, high density, long service life, etc.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

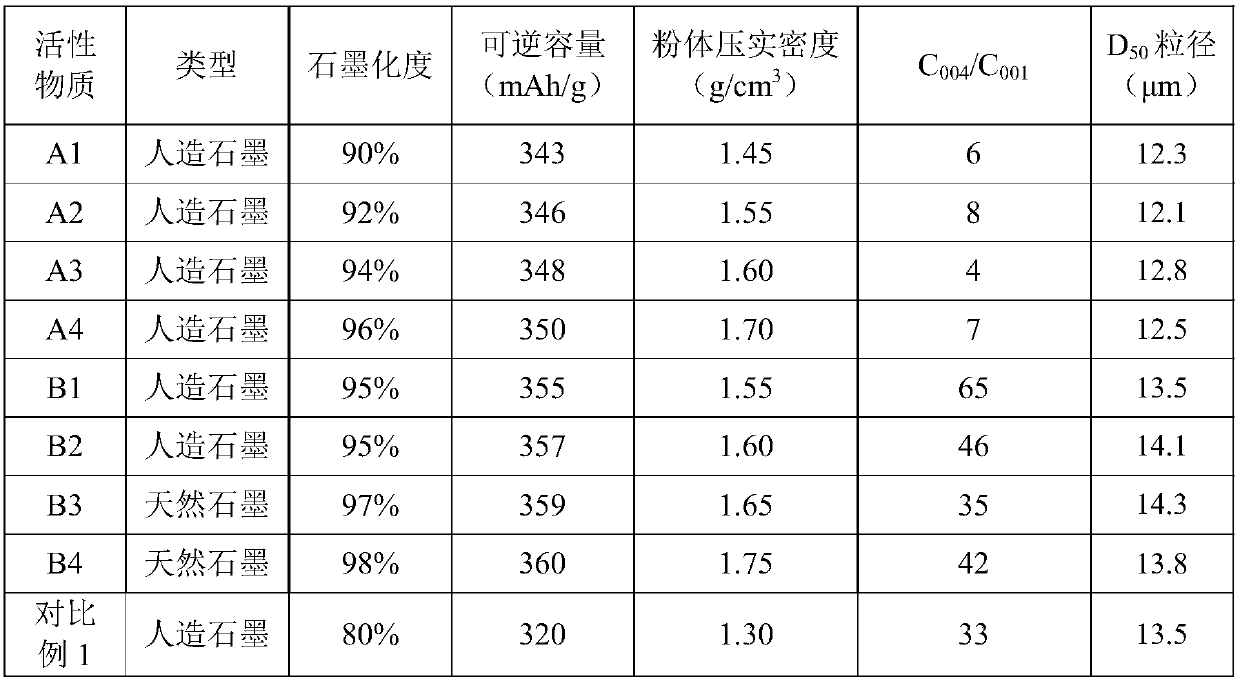

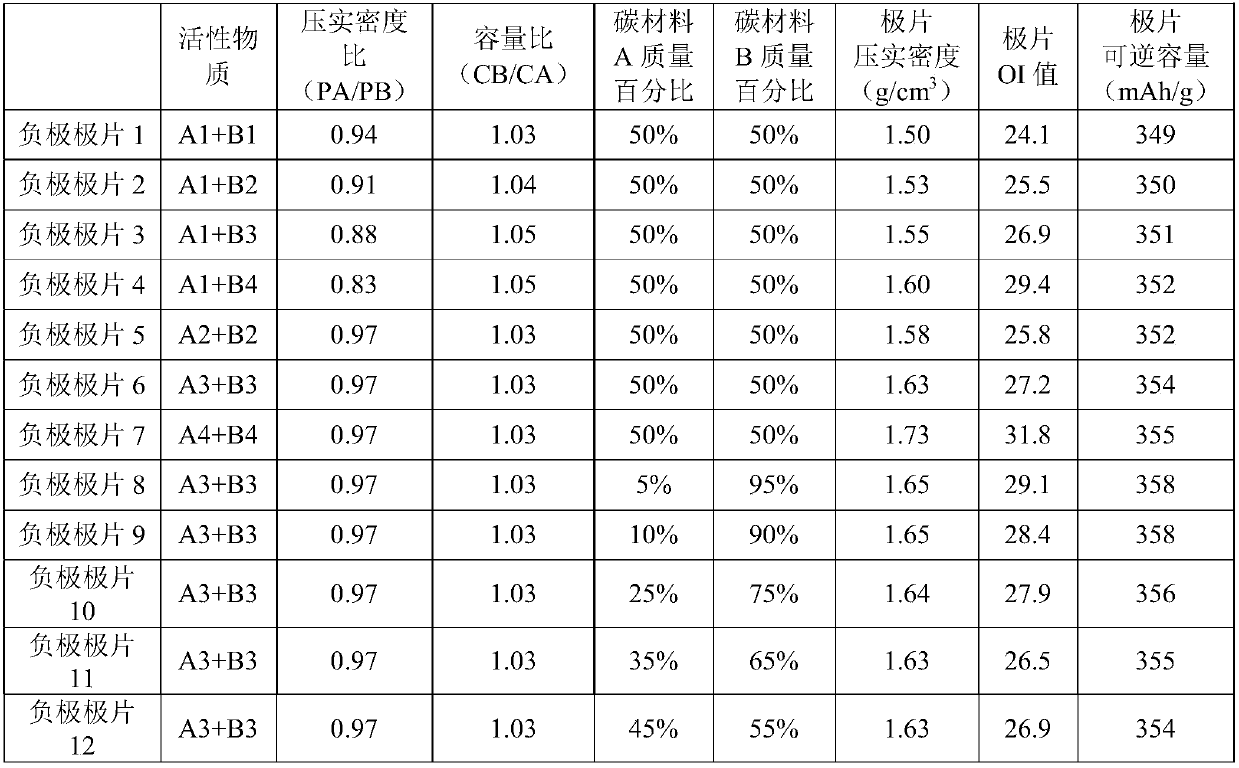

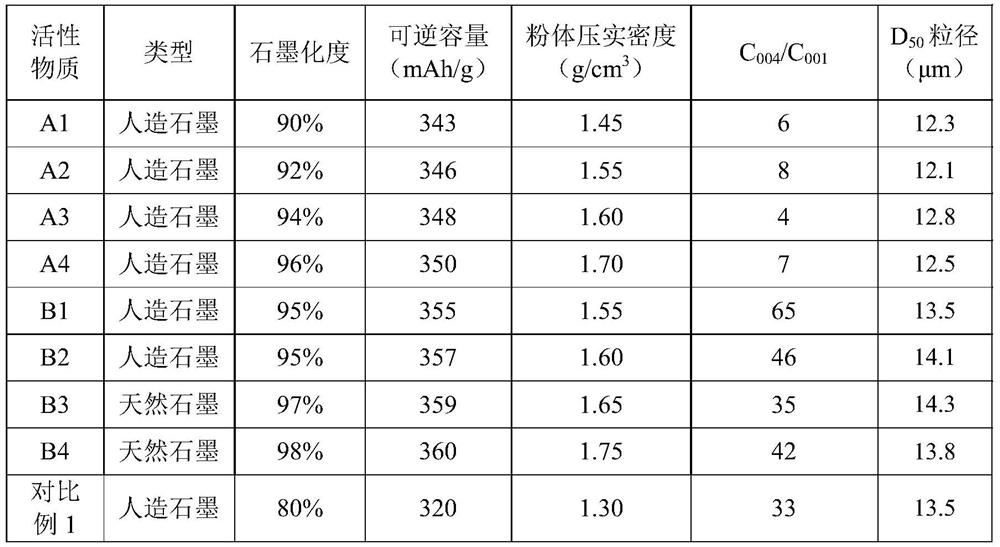

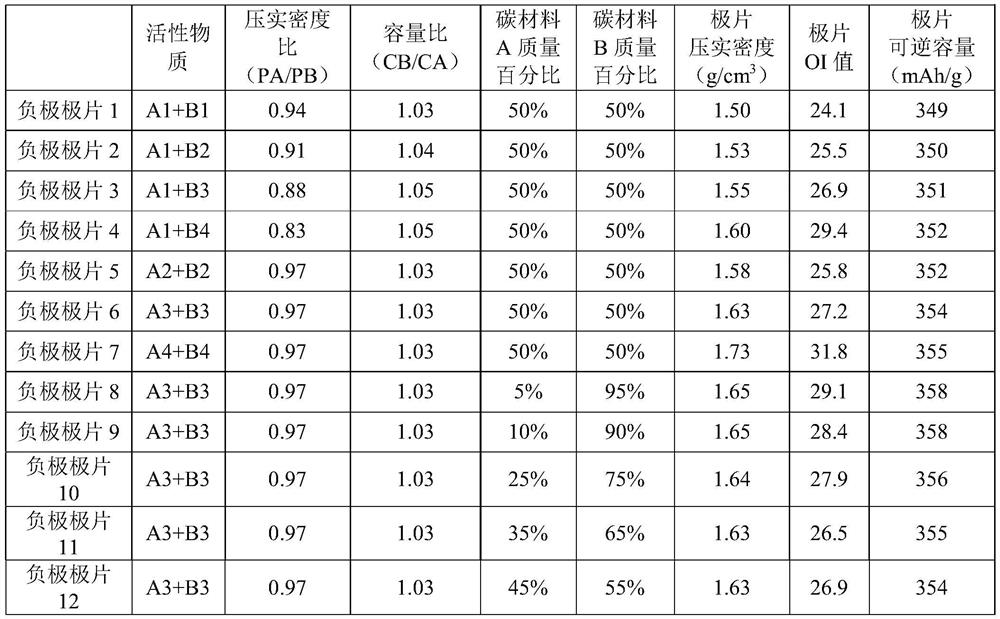

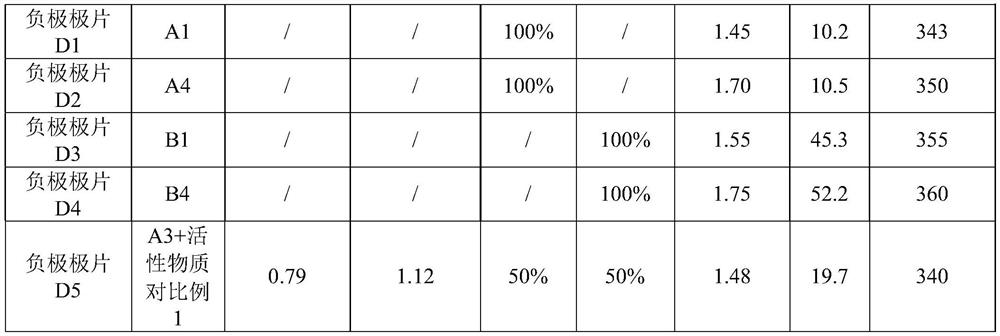

Secondary battery

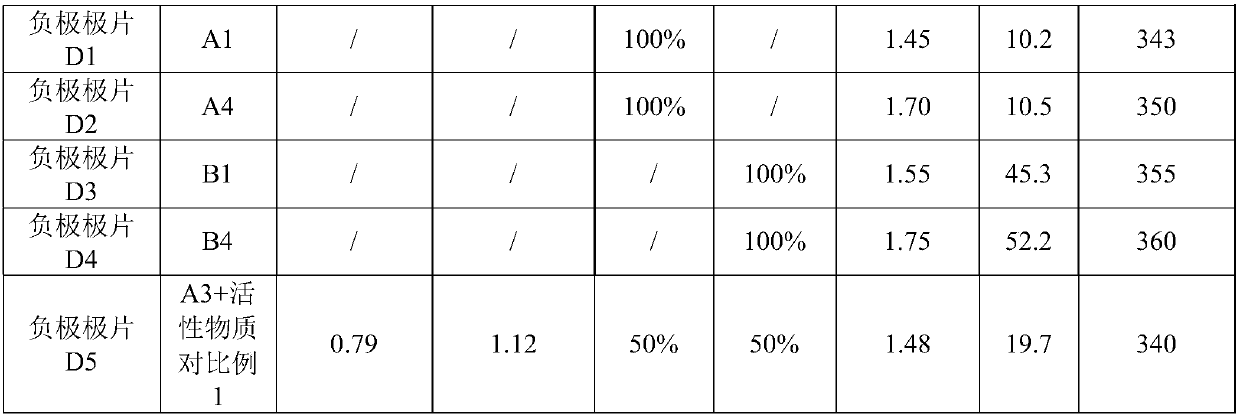

ActiveCN110148714AImprove structural stabilityImprove cycle lifeNegative electrodesSecondary cellsGramPole piece

The invention relates to a secondary battery including a positive electrode pole piece, a negative electrode pole piece, an isolating membrane and an electrolyte. The positive electrode pole piece includes a positive active material layer containing a ternary positive electrode material. The negative electrode pole piece includes a negative active material layer, and active materials contain a carbon material A and a carbon material B. The carbon material B has a high reversible capacity and cooperates with the ternary positive electrode material to achieve a high gram capacity of the battery.Compared with the carbon material B, the carbon material A has a low degree of graphitization, a relatively large interlayer spacing and higher mechanical strength. The combination of the two carbonmaterials ensures that the negative electrode pole piece has both high reversible capacity and good pressure resistance, and the cycle life of the battery is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

Method for preparing strontium-rich activated carbon by aid of hydrothermal processes

ActiveCN109665526ALittle change in structureLarge hole volumeCarbon compoundsWater/sewage treatment by substance additionActivated carbonHydrogen

The invention discloses a method for preparing strontium-rich activated carbon by the aid of hydrothermal processes. The method includes steps of a), pretreating activated carbon, to be more specific,placing the proportioned activated carbon in diluted edible hydrochloric acid solution, heating the proportioned activated carbon in the diluted edible hydrochloric acid solution, carrying out impurity removal cleaning, further carrying out suction filtration, repeatedly washing the activated carbon, washing off surface residual acid liquid, boiling the activated carbon by water, then repeatedlyrinsing the activated carbon until the pH (potential of hydrogen) value of the activated carbon is 6.5-8.5, placing the activated carbon in drying ovens and drying the activated carbon for standby application; b), impregnating and loading strontium salt, to be more specific, slowly adding the pretreated proportioned activated carbon into impregnation liquid with diffusing agents and coupling agents, impregnating and stirring the activated carbon for 10 min, then adding strontium salt solution into the impregnation liquid and uniformly mixing and stirring the strontium salt solution and the activated carbon with each other in the impregnation liquid; c), carrying out hydrothermal reaction procedures, to be more specific, placing impregnated activated carbon solution in hydrothermal reactionkettles, keeping the temperatures constant for 2-6 hours after the hydrothermal reaction temperatures are increased and reach 130-250 DEG C and the pressures of the reaction kettles reach approximately 1MPa, carrying out still standing and temperature reduction after reaction is completely carried out, carrying suction filtration and cleaning, washing off surface residual impregnation liquid, then placing reaction products in drying ovens, and drying the reaction products at the temperatures of 120-150 DEGC to obtain the impregnated-hydrothermal strontium-rich activated carbon.

Owner:XIAMEN QUANJIALE NEW MATERIAL TECH CO LTD

Lithium iron phosphate composite material coated with ternary carbon source and preparation method thereof

ActiveCN103794760BEvenly dispersedLow degree of graphitizationCell electrodesSecondary cellsReduction ActivityCarbonization

The invention provides a lithium iron phosphate composite material coated with a ternary carbon source and a preparation method of the material and belongs to the technical field of positive materials for lithium ion cells, aiming at the defects of poor conductivity and low tap density of lithium iron phosphate. The invention provides a modification method of the lithium iron phosphate composite material coated with the ternary carbon source according to the characteristics including pyrolysis characteristics, carbonization degrees, dispersion manners, residual carbon structures, reduction activity and the like of different carbon sources, based on a process and reaction process of preparing the lithium iron phosphate by using a carbon heat reduction method; micro-molecular water-soluble organic matters, high-molecular polymers, graphene compounds, iron source compounds, phosphorus source compounds and lithium source compounds are ball-grinded and homogenized and then are dried to prepare a composite precursor; then the composite precursor is sintered to obtain the lithium iron phosphate composite material. According to the lithium iron phosphate composite material coated with the ternary carbon source, the problems that the conductivity of the lithium iron phosphate composite material is low, the lithium ion diffusion coefficient is low, the tap density is low, and the like are solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

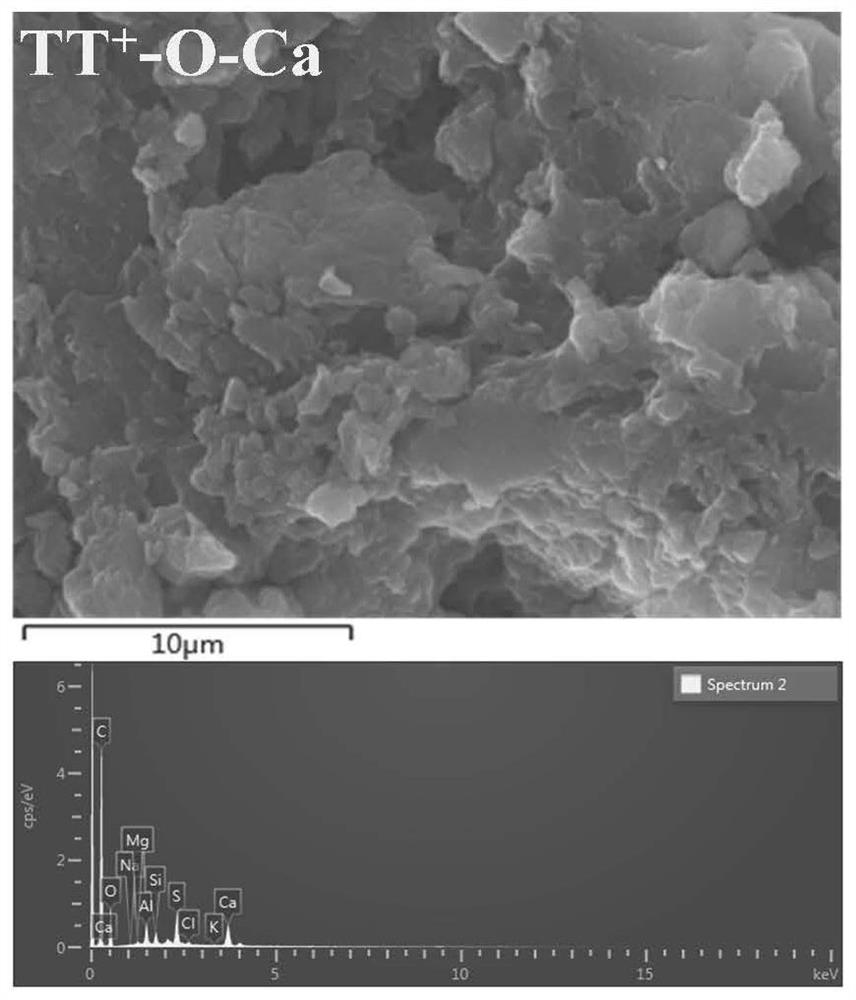

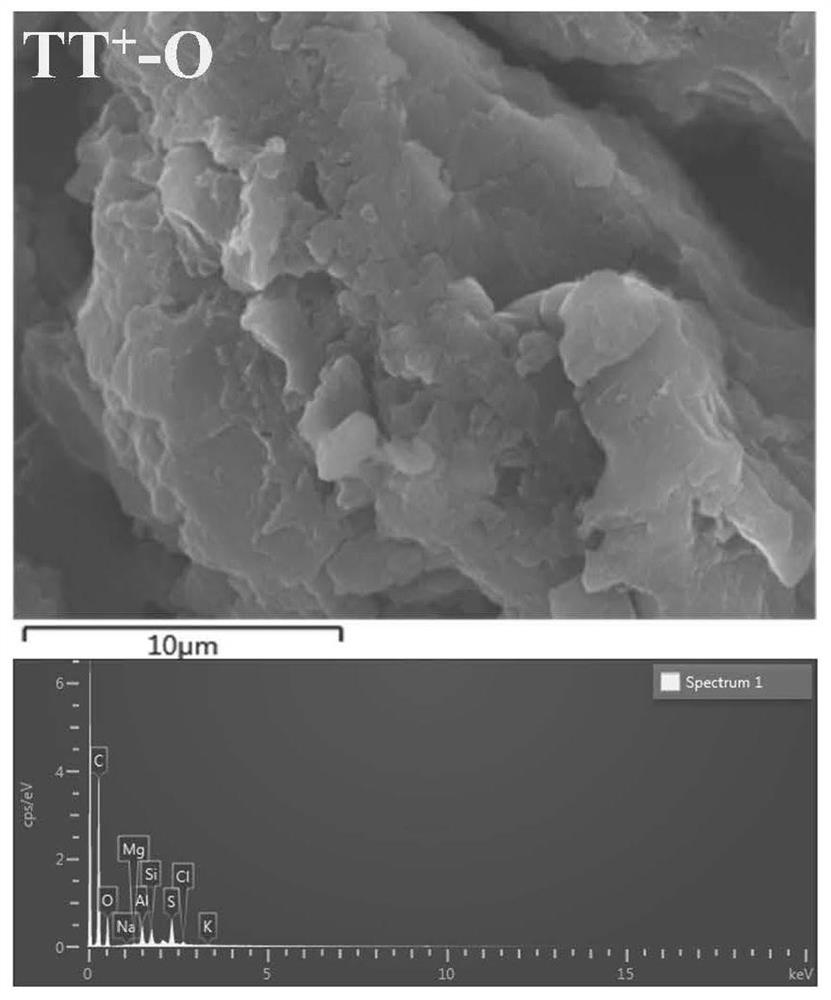

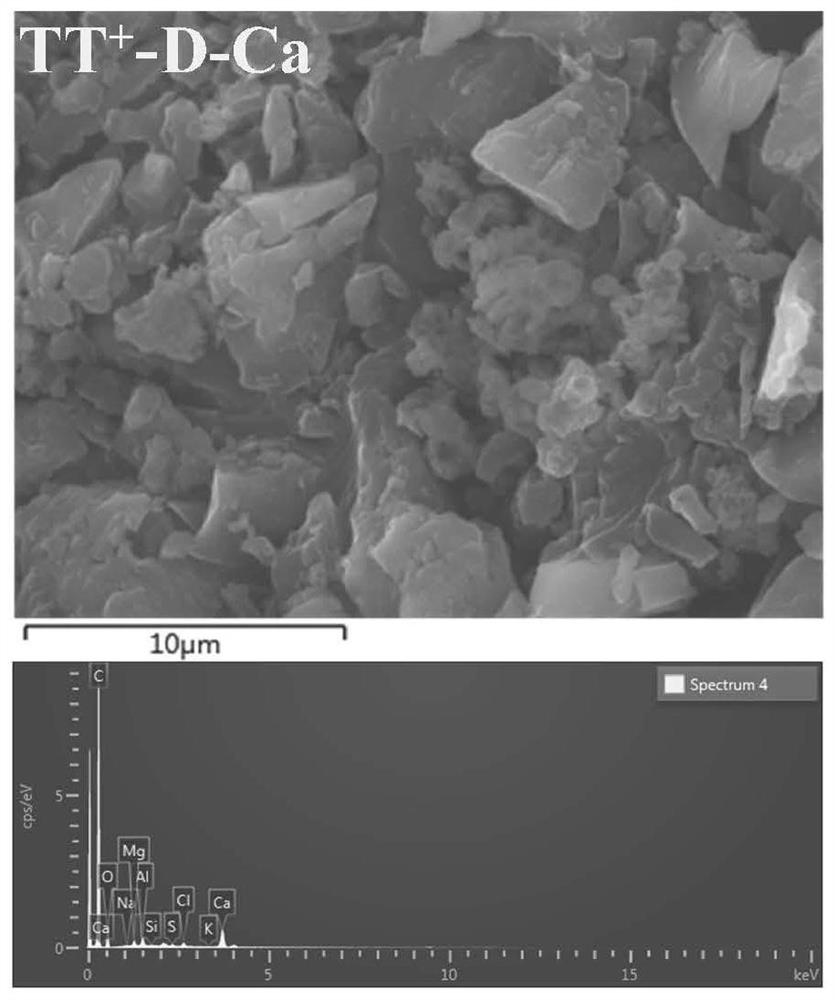

Steam gasification method for anthracite

InactiveCN111849557AImprove gasification effectLow degree of graphitizationGasification processes detailsCombustible gas productionSyngasCarboxylic group

The invention provides a steam gasification method for anthracite. The steam gasification method comprises the following steps: carrying out acid pickling demineralization and reoxidation treatment onanthracite, mixing the treated anthracite with a calcium source, and carrying out a gasification reaction on an obtained calcium-added coal sample and steam. According to the method, a large number of carboxyl functional groups are added into the demineralized anthracite through oxidation, and the graphitization degree of the anthracite is reduced ; and through combined use of Ca<2+> in the calcium source, gasification performance is improved and a reaction temperature zone is advanced. Results of embodiments show that according to the steam gasification method for anthracite provided by theinvention, the initial temperature of steam gasification is 560 DEG C, and the generation rate of synthesis gas reaches the maximum at 710 DEG C; the maximum generation rate of H2 is 1.480 mmol.min<-1>.G<-1>; the maximum generation rate of CO2 is 0.493 mmol.min<-1>.G<-1>; and a carbon conversion rate tends to be gentle at a temperature below 750 DEG C and reaches the highest at 850 DEG C.

Owner:INNER MONGOLIA UNIV OF TECH

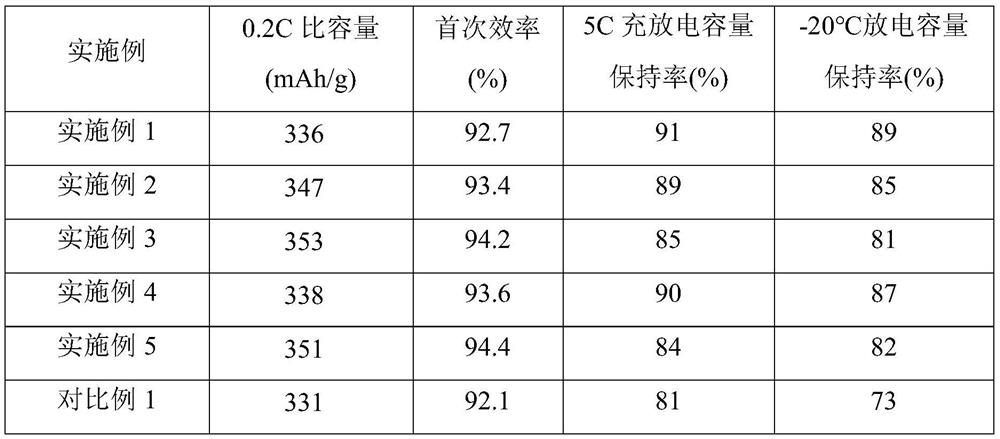

Low-temperature fast-charging artificial graphite negative electrode material, preparation method and low-temperature fast-charging battery

PendingCN113851614AHigh capacity densityIncrease compaction densityNegative electrodesSecondary cellsCarbon coatingHigh energy

The invention relates to a low-temperature fast-charging artificial graphite negative electrode material and a preparation method thereof, and a low-temperature fast-charging battery. The composite material comprises a graphite matrix, and carbon nanotubes and amorphous carbon coating the surface of the graphite matrix. The mass of the carbon nanotubes and the amorphous carbon is 0.5-5% of the mass of the graphite matrix; in the preparation process, petroleum coke, pitch coke or graphite electrode joint powder is adopted as a raw material, and after crushing, shaping and spheroidizing and high-temperature purification, CVD (Chemical Vapor Deposition) carbon coating is performed to obtain the low-temperature quick-charge artificial graphite negative electrode material. Compared with the prior art, the small-particle-size graphite single particles used in the invention have better low-temperature fast charging performance; a high-temperature purification mode is adopted, so that the graphite has higher purity and crystallinity; by adopting a two-step cooling mode, internal stress generated in the material preparation process can be eliminated; a battery prepared from the low-temperature fast-charging artificial graphite negative electrode material has relatively high energy density and good low-temperature fast-charging performance.

Owner:上海昱瓴新能源科技有限公司

Preparing method for collector shoe

The invention discloses a preparing method for a collector shoe. The method includes the following steps: a, selecting coke and asphalt as per the mass ratio of (3.6-5):1; b, placing the raw materials in a crusher for crushing, then placing the crushed raw materials in a ball mill for ball milling for 3-5 h; c, placing powder in a pressing machine, and pressing the powder into precast blocks, wherein the pressing temperature is 150-200 DEG C, the pressing pressure is 600 Mpa-750 Mpa; d, placing the precast blocks in a box-type atmosphere furnace and sintering the blocks under inert gas shielding, wherein the temperature inside the box-type atmosphere furnace is increased from the room temperature to 1200 DEG C to 1300 DEG C gradually, then performing heat preservation for 100-160 min, cooling to the room temperature after heat preservation, and finally obtaining a finished product of the collector shoe. The collector shoe prepared through adopting the method has a certain porosity, excellent mechanical strength and electrical conductivity, and facilitates improving the copper infiltration efficiency and quantity in a follow-up copper infiltration technology, the preparation technology is simple and efficient, and production popularization can be facilitated.

Owner:常州市赛尔交通器材有限公司

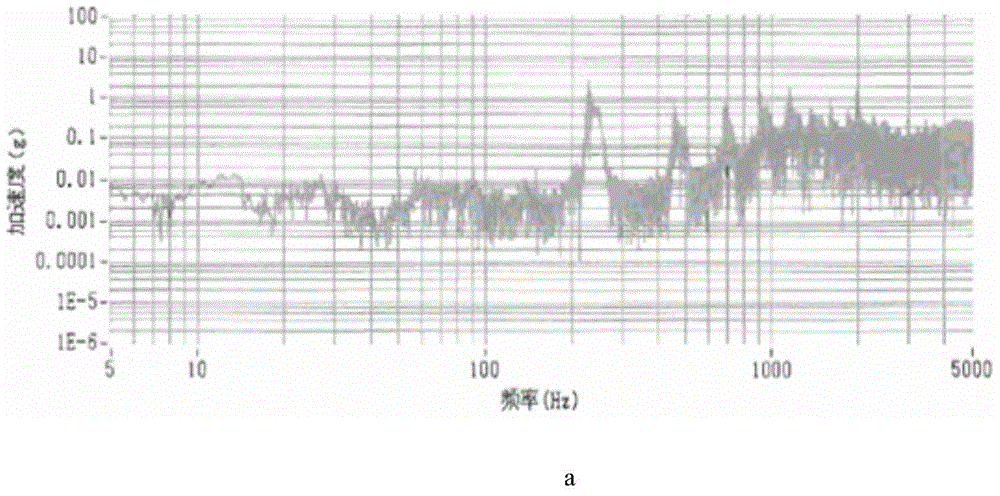

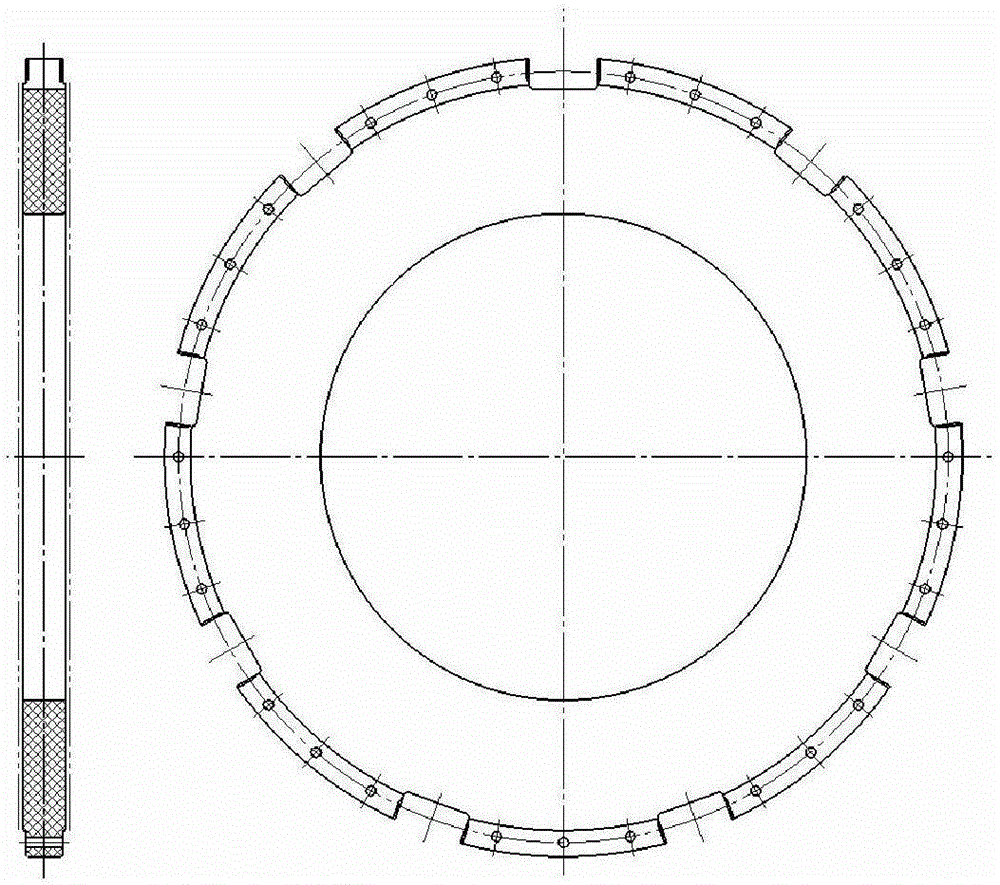

Preparation method of aircraft carbon/carbon composite brake disc friction couple

ActiveCN103982578BLow degree of graphitizationReduce wearBraking discsCarbon compositesProcess engineering

The invention discloses a manufacturing method of a carbon / carbon composite material brake disk friction pair for planes. The carbon / carbon composite material brake disk friction pair is made by means of deposition through different deposition gas sources, wherein a static disk is made by depositing mixed gas of propylene gas and nitrogen gas; a movable disk is made by depositing mixed gas of natural gas and dimethylmethane gas. The obtained static disk and movable disk are arranged in a brake device in sequence according to the assembly requirement of a plane wheel brake device, and each movable disk and each static disk form a friction pairs. The brake disk made by depositing a mixed gas source of propylene gas and nitrogen gas taken as a static disk, and a carbon disk made by depositing a mixed gas source of natural gas and dimethylmethane gas is taken as a movable disk to construct a friction pair, thereby improving brake pressure-torque gain and keeping the gain in a reasonable range. Moreover, a hard disk and a soft disk are arranged as a pair on the surface of the material, and a friction surface is worn uniformly and is smooth and flat in a braking process, thereby ensuring the output of a large torque, effectively lowering the brake vibration magnitude and improving the convergence of brake vibration.

Owner:XIAN AVIATION BRAKE TECH

Method for producing desulfurized denitrated carbon

PendingCN110606484AReduce energy consumptionEmission reductionGas treatmentOther chemical processesWear resistantCarbonization

The invention discloses a method for producing desulfurized denitrated carbon. An external heating type carbonization and activation integrated furnace is adopted; in a carbonization section, materials are gradually heated in a certain low-temperature range and under the condition of air isolation, the materials are slowly heated so that colloid in the materials is pyrolyzed in order, and effective pores of a desulfurization process are achieved to the maximum extent by controlling the pyrolysis speed and controlling the size of molecules overflowing during pyrolysis; in an activation section,the materials continue to be heated to 650 DEG C or above to start polycondensation, part of components of the materials start coking to form high-strength carbon, at the moment, the materials form developed pores along with a water gas reaction in an activating agent atmosphere, and the pore structure and the abrasion resistance of the active coke are kept or improved while the compressive strength and the ignition point are improved. The method has the advantages of low energy consumption, less emission, automatic production, low working intensity, high equipment safety and reliability, andlow maintenance cost and personnel cost; the raw material consumption is reduced by 20-40%, the wear-resistant and compression-resistant strength is high, and the regeneration cycle frequency is high.

Owner:淮北中清环保科技有限公司

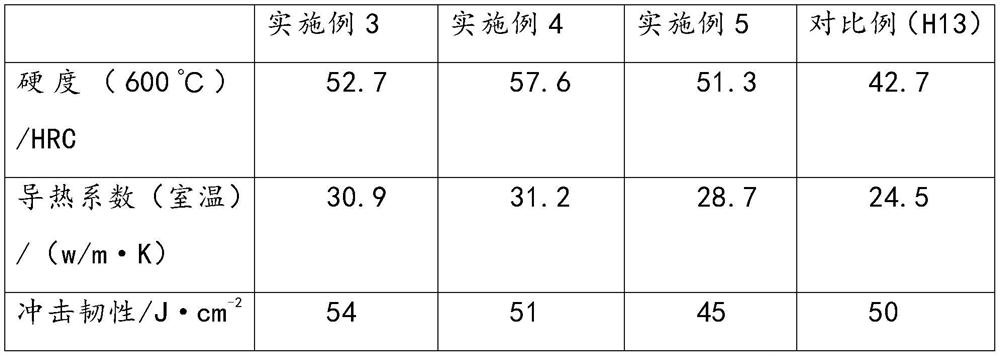

Production process of hot work die steel with high thermal conductivity and high heat strength

The invention relates to a production process of high-heat-conductivity and high-heat-strength hot work die steel, and belongs to the technical field of hot work die steel. A base body of the die steel comprises 0.32%-0.38% of C, 1.2%-1.6% of W, 3.6%-4.2% of Mo, 0.08%-1.4% of V, 0.06%-0.1% of Mn, 0.15%-0.18% of Cr, 0.02%-0.04% of S i and the balance Fe, a nucleating auxiliary is added into the base body, the nucleating auxiliary is prepared from nanoscale carbon powder, boron nitride and tantalum powder, more crystal nucleuses are provided for the base body, tantalum and carbon form tantalum carbide at the high temperature, the effects of refining grains and improving heat conductivity are achieved, and the heat conductivity of the die steel is improved. Meanwhile, a high-melting-point strengthening phase formed by tantalum carbide and boron nitride forms dispersion strengthening, so that the strength of the matrix is improved; through testing, the hardness of the hot work die steel reaches 51.3-57.6 HRC at the temperature of 600 DEG C, and the heat conductivity coefficient of the hot work die steel reaches 28.7-31.2 w / m.K at the room temperature.

Owner:冯希良

Preparation method of silicon carbide single crystal with reduced carbon wrapping

PendingCN114182348AReduce depositionLow degree of graphitizationPolycrystalline material growthFrom condensed vaporsCarbide siliconSingle crystal

The invention relates to the technical field of crystal preparation, and discloses a preparation method of a silicon carbide single crystal with reduced carbon wrapping, the method at least comprises the steps of charging and crystal growth, the charging step comprises: adding silicon carbide powder and an oxide into a crystal growth container, the oxide being silicon dioxide and / or cerium dioxide; wherein the silicon carbide powder and the oxide form a wrapped reaction structure, a laminated reaction structure or a composite reaction structure in the crystal growth container; the wrapping reaction structure comprises a silicon dioxide layer and a silicon carbide powder layer wrapping the silicon dioxide layer; the laminated reaction structure comprises a silicon carbide powder layer and a cerium dioxide layer, and an isolator is arranged between the cerium dioxide layer and the silicon carbide powder layer and is not in direct contact with the silicon carbide powder layer; the composite reaction structure comprises a silicon dioxide layer, a silicon carbide powder layer and a cerium dioxide layer, wherein the silicon dioxide layer is wrapped with the silicon carbide powder layer and the cerium dioxide layer, and an isolator is arranged between the cerium dioxide layer and the silicon carbide powder layer without direct contact. The method can effectively reduce the graphitization degree of the silicon carbide crystals.

Owner:江苏吉星新材料有限公司 +1

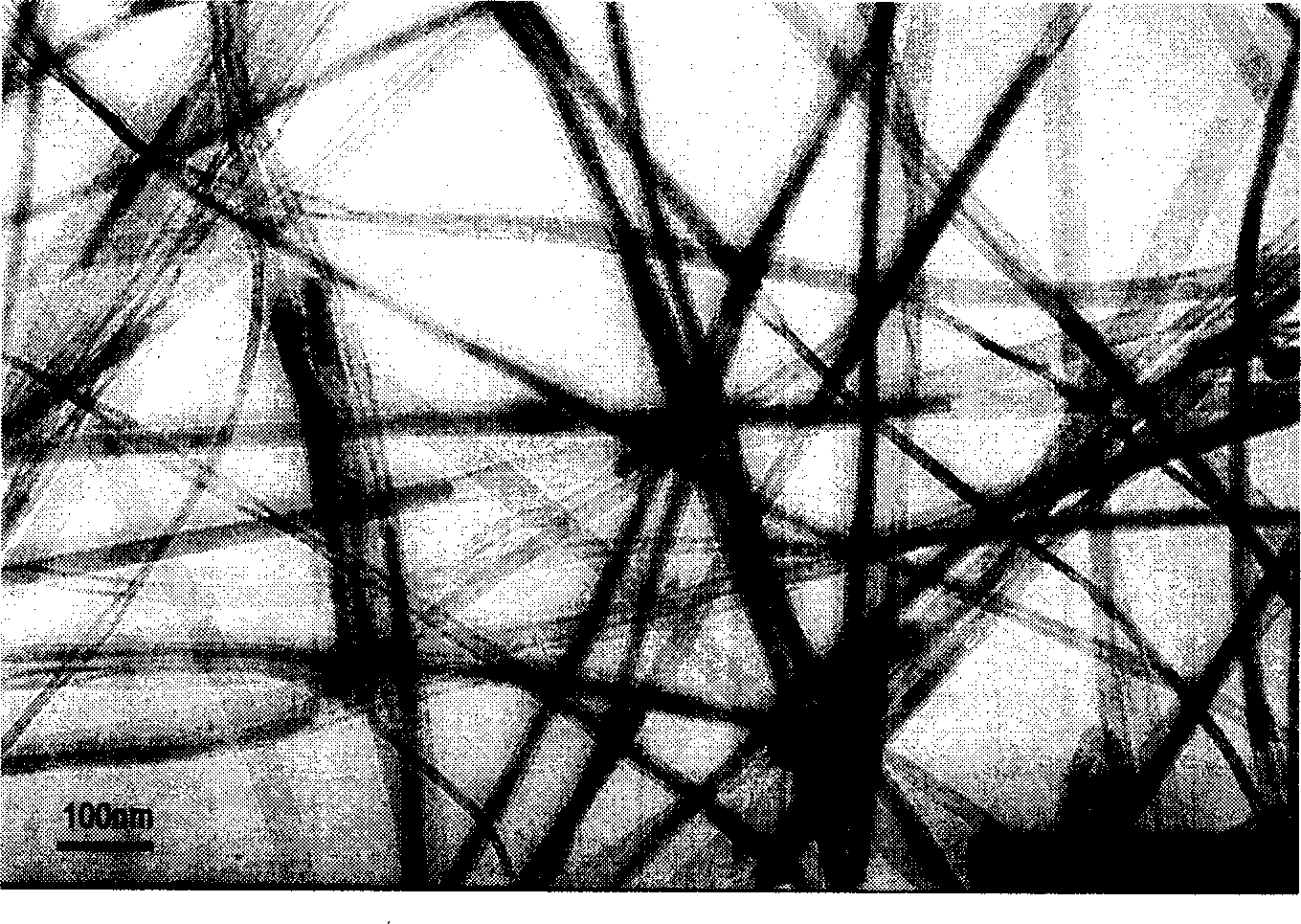

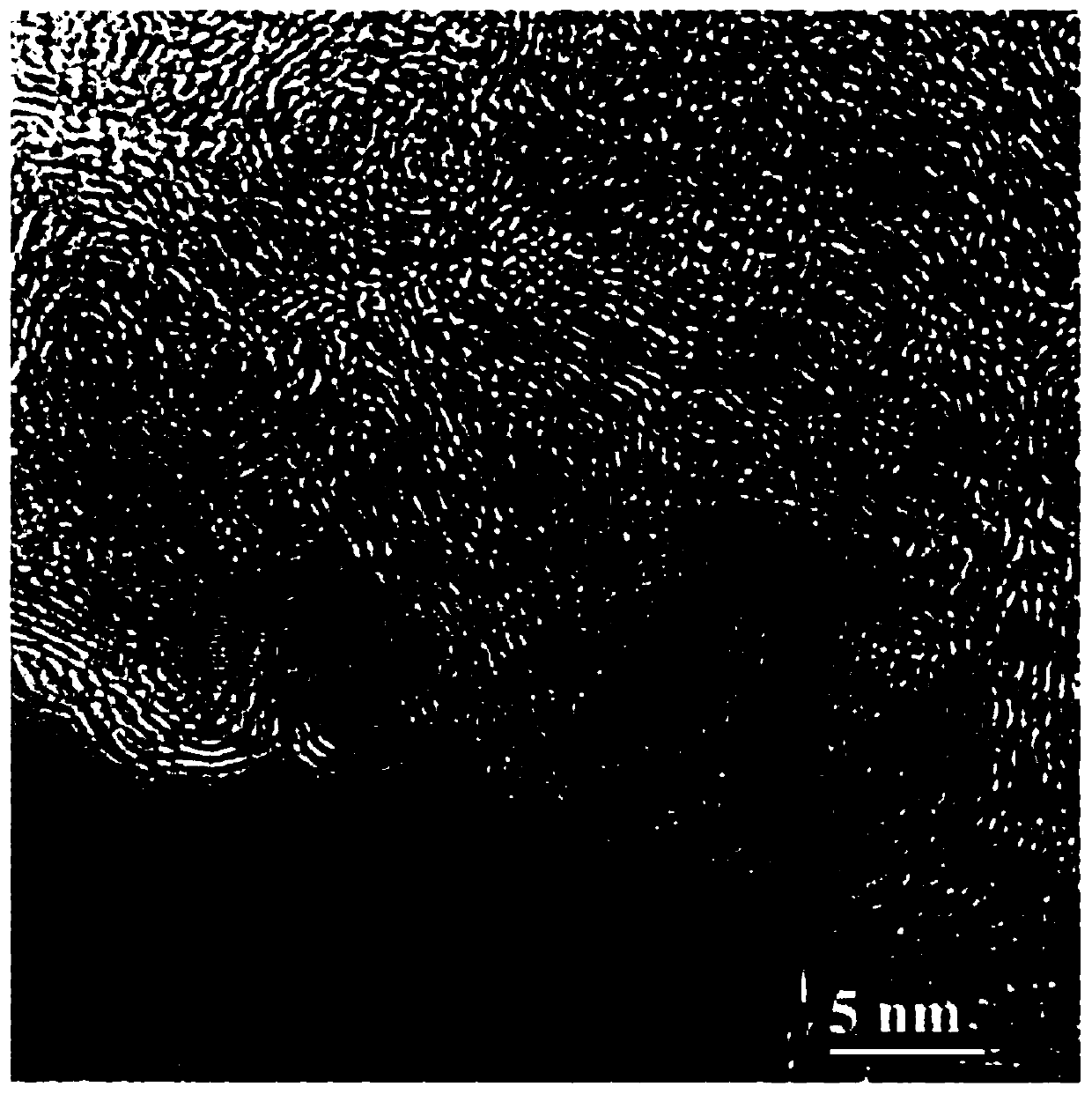

Method for nondestructive dispersion of double-walled carbon nanotube by combination of N, N-dimethylformamide and ethylene glycol

ActiveCN102442659BLow degree of graphitizationLower surface energyCarbon compoundsEnergy inputPhysical chemistryGlycol synthesis

Relating to the technical field of nano-materials, the invention provides a method for nondestructive dispersion of a double-walled carbon nanotube by combination of N, N-dimethylformamide and ethylene glycol. Before dispersion, the double-walled carbon nanotube has a diameter of 2-10nm and a tube bundle diameter of 50-200nm. And the Raman spectrum ratio between a complete peak and a defect peak of the double-walled carbon nanotube is 5-6.3. The method comprises the steps of: taking ethylene glycol as a dispersion matrix, adding a dispersion conditioning agent N, N-dimethylformamide (in a volume ratio of 1:99-10:90), subjecting the mixture to ultrasonic dispersion for 8-24h, thus obtaining a double-walled carbon nanotube solution with a concentration up to 1.0mg mL<-1>. In the solution, the double-walled carbon nanotube has a diameter of 2-10nm, a tube bundle diameter of 10-100nm, and a Raman spectrum ratio between its complete peak and defect peak is 4.8-6.1. The dispersed double-walled carbon nanotube does not suffer obvious destruction in terms of its graphitization degree, but its length is cut short and the tube bundle is opened, thus bringing convenience for its application in various fields.

Owner:北京旭江科技有限公司

A metal-based superhard composite material and its preparation method

ActiveCN105624505BImprove wettabilityImprove the interface binding forceSuperhard materialBoron nitride

The invention discloses a metal based superhard composite and belongs to the field of superhard composites. The metal based superhard composite is prepared from the following raw materials in percentage by weight: 20-68.8 percent of nano metal powder, 30-75 percent of coated diamond or / and coated cubic boron nitride powder and 0.2-5 percent of a wetting agent. The invention also discloses a preparation method of the metal based superhard composite. The preparation method comprises the following steps: mixing the nano metal powder, the superhard material powder and the wetting agent, and cold pressing to form a green body; and placing the green body in a vacuum or reducing atmosphere, and sintering, wherein the sintering temperature is higher than the melting point of the nano metal powder and lower than the inactive temperature of the superhard material. According to the metal based superhard composite prepared by the preparation method, the size proportion of the superhard material and metal can be accurately controlled, and thus thermophysical characteristic of the prepared metal based superhard composite can be accurately controlled, the production process is rapid, and equipment is simple; and meanwhile, the diamond or cBN breaking rate is lowered by adopting the coated superhard material.

Owner:FUNIK ULTRAHARD MATERIAL

Method for preparing carbon nano hollow polyhedron by using hydrothermal method

ActiveCN110963490AReduce energy consumptionInnovativeCarbon compoundsNanotechnologyChemical synthesisGraphite

The invention discloses a method for preparing a carbon nano hollow polyhedron by using a hydrothermal method and belongs to the field of nano graphite preparation. According to the method, a chemicalsynthesis method is utilized, pyrene with a benzene ring structure is taken as a raw material, a reaction is carried out under an alkaline condition and at a relatively low temperature, and a prepared reaction product is high in graphitization degree, the cavity volume is large, and the reaction product has potential characteristics of light weight and high strength. The method is low in energy consumption, short in consumed time and high in product quality, the adopted chemical synthesis method is completely different from the prior art, and innovation and novelty are achieved.

Owner:TSINGHUA UNIV

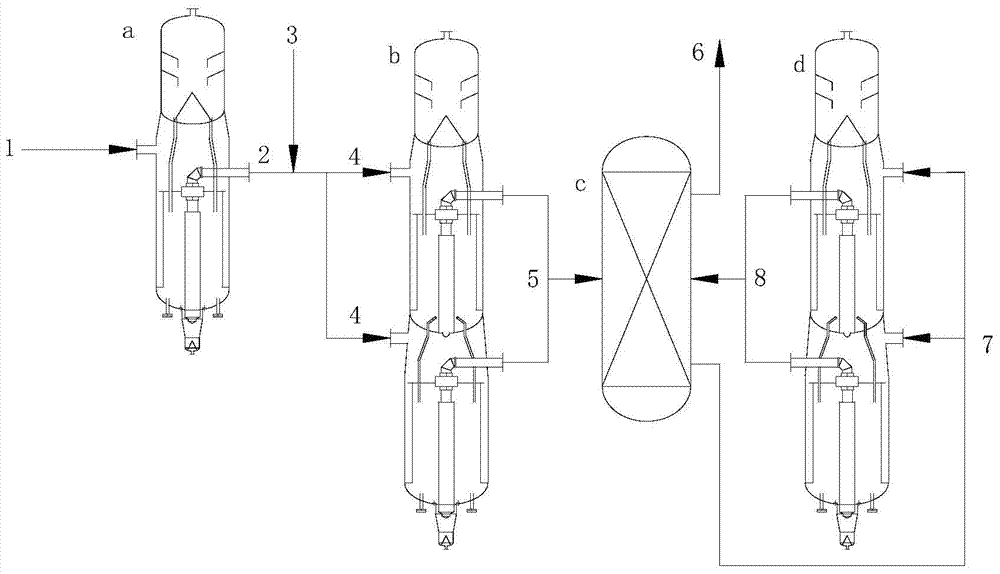

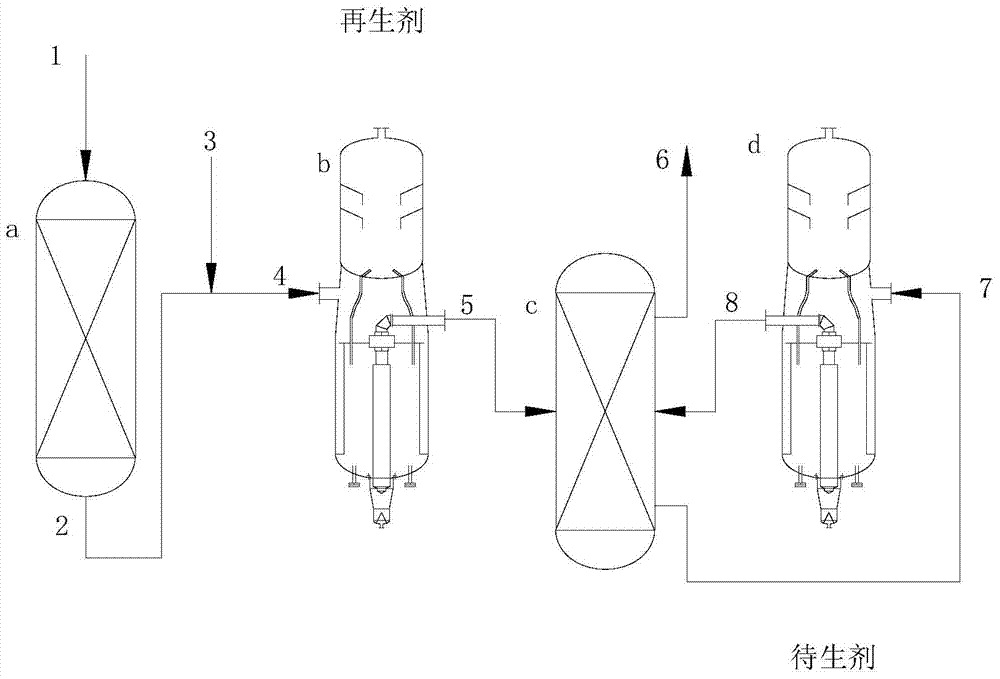

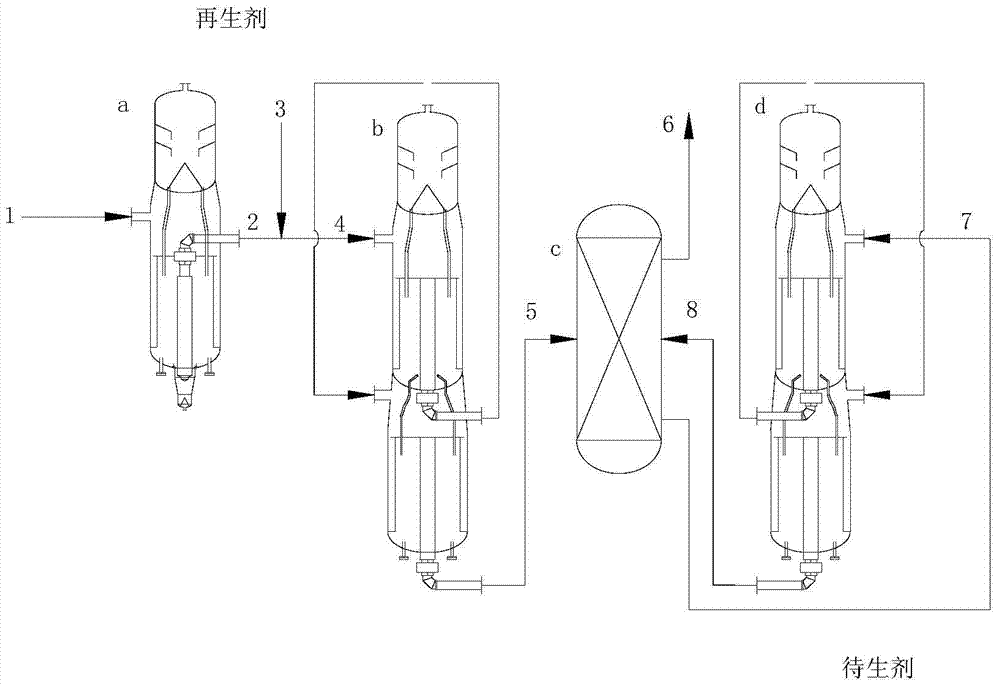

A process for producing propylene using oxygen-containing compounds as raw materials

ActiveCN104876784BSolve the contradiction of high yield but fast deactivationAtom utilization is highHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveEnergy consumption

The invention discloses a process for producing propylene by taking oxygenated compounds as raw materials. The process comprises the steps of converting methanol in the oxygenated compounds into dimethyl ether to the maximum extent, then, carrying out contact reaction on dimethyl ether and a molecular sieve based catalyst under a high-severity condition, and next, delivering the reaction product into a separation system; introducing residual components except for propylene to a hydrocarbon conversion reaction region to further generate propylene; and returning non-propylene parts as circular logistics to the hydrocarbon conversion reaction region to carry out circular reaction, wherein the catalyst used in the hydrocarbon conversion reaction region is from a carbon deposition agent obtained after catalyzing the oxygenated compounds to react under the high-severity condition. By using the process, the yield of propylene can be effectively increased, the flow of the circular logistics can be reduced, the energy consumption of the process can be reduced, and the total life of the catalyst can be favorably prolonged; and the process can be used in industrial production of propylene prepared from methanol.

Owner:ZHEJIANG UNIV

A method for preparing carbon nano-hollow polyhedron by hydrothermal method

ActiveCN110963490BReduce energy consumptionHigh degree of graphitizationCarbon compoundsNanotechnologyChemical synthesisGraphite

The invention discloses a method for preparing a carbon nano hollow polyhedron by using a hydrothermal method and belongs to the field of nano graphite preparation. According to the method, a chemicalsynthesis method is utilized, pyrene with a benzene ring structure is taken as a raw material, a reaction is carried out under an alkaline condition and at a relatively low temperature, and a prepared reaction product is high in graphitization degree, the cavity volume is large, and the reaction product has potential characteristics of light weight and high strength. The method is low in energy consumption, short in consumed time and high in product quality, the adopted chemical synthesis method is completely different from the prior art, and innovation and novelty are achieved.

Owner:TSINGHUA UNIV

a secondary battery

ActiveCN110148714BImprove structural stabilityImprove cycle lifeSecondary cellsNegative electrodesElectrolytic agentElectrical battery

The present application relates to a secondary battery, which includes a positive pole piece, a negative pole piece, a separator and an electrolyte, the positive pole piece includes a positive active material layer, and the positive active material layer contains a ternary positive material. The negative electrode sheet includes a negative electrode active material layer, where the active material includes carbon material A and carbon material B. The above-mentioned carbon material B has a relatively high reversible capacity, and cooperates with the ternary positive electrode material to achieve a high gram capacity of the battery. Compared with carbon material B, carbon material A has a lower degree of graphitization, relatively larger interlayer spacing, and higher mechanical strength. The mixed use of two carbon materials can ensure that the negative electrode sheet has both high reversible capacity and good pressure resistance, and improves the cycle life of the battery.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com