a secondary battery

A secondary battery and electrolyte technology, applied to secondary batteries, battery electrodes, circuits, etc., can solve problems such as diving, cycle attenuation, and negative electrode kinetics reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] When the secondary battery is a lithium-ion battery, a conventional lithium-ion battery preparation method can be used, which at least includes the following steps:

[0047] Step 1. Coating the positive electrode slurry including the positive electrode active material, conductive agent and binder on the surface of the positive electrode current collector, forming a positive electrode active material layer after drying, and obtaining the positive electrode sheet;

[0048] Step 2, coating the negative electrode slurry including the negative electrode active material and the binder on the surface of the negative electrode current collector, forming a negative electrode active material layer after drying, and obtaining the negative electrode sheet;

[0049] Step 3: Stack the positive pole piece, the separator and the negative pole piece sequentially, and then wind or press them to obtain a bare cell, then inject electrolyte, and package to obtain a secondary battery.

[005...

Embodiment

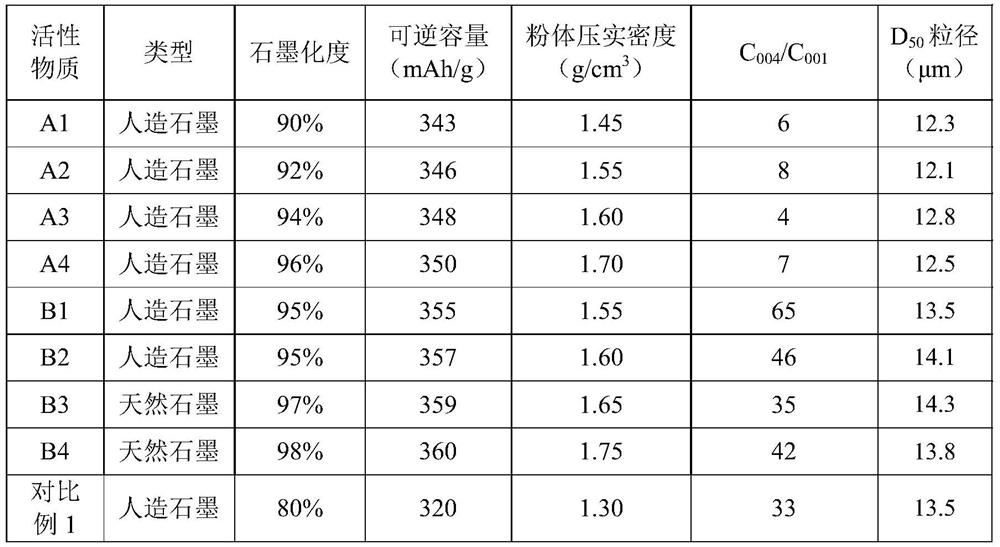

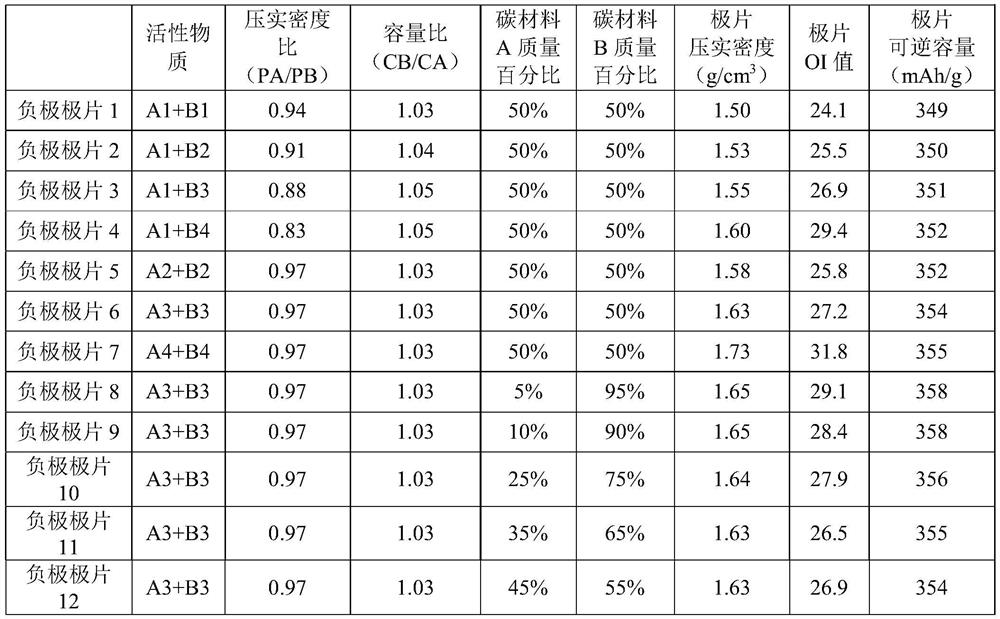

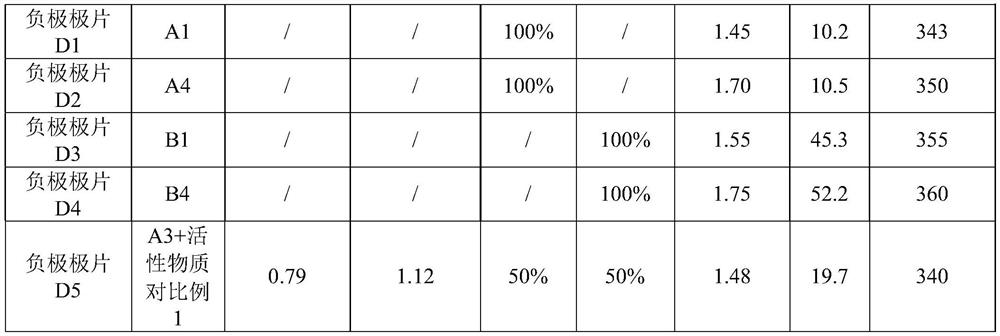

[0076] Preparation of negative electrode sheet

[0077] Mix carbon material A and carbon material B with conductive agent carbon black Super P and binder styrene-butadiene rubber (SBR) according to the weight ratio of 92:3:5 according to different proportions, add solvent N-methylpyrrolidone, stir and mix Negative electrode slurry is obtained after uniformity. Evenly coat the negative electrode slurry on the coating layer of the negative electrode current collector, dry it at 80-90°C after coating, perform cold pressing, slitting, and cutting into pieces, and then dry it under vacuum at 110°C for 4 hours. Negative electrode sheets 1 to 12 were obtained. The preparation method of the negative pole pieces D1-D5 is similar to that of the negative pole pieces 1-12, except that the carbon material has changed. Wherein, carbon material A includes carbon materials A1-A4, and carbon material B includes carbon materials B1-B4. The physical and chemical parameters of the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com