A method for preparing carbon nano-hollow polyhedron by hydrothermal method

A technology of carbon nanometer and polyhedron, which is applied in the direction of nanotechnology, chemical instruments and methods, carbon compounds, etc., can solve the problems of high energy consumption and low degree of graphitization of products, and achieve low energy consumption, high degree of graphitization, cavity bulky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

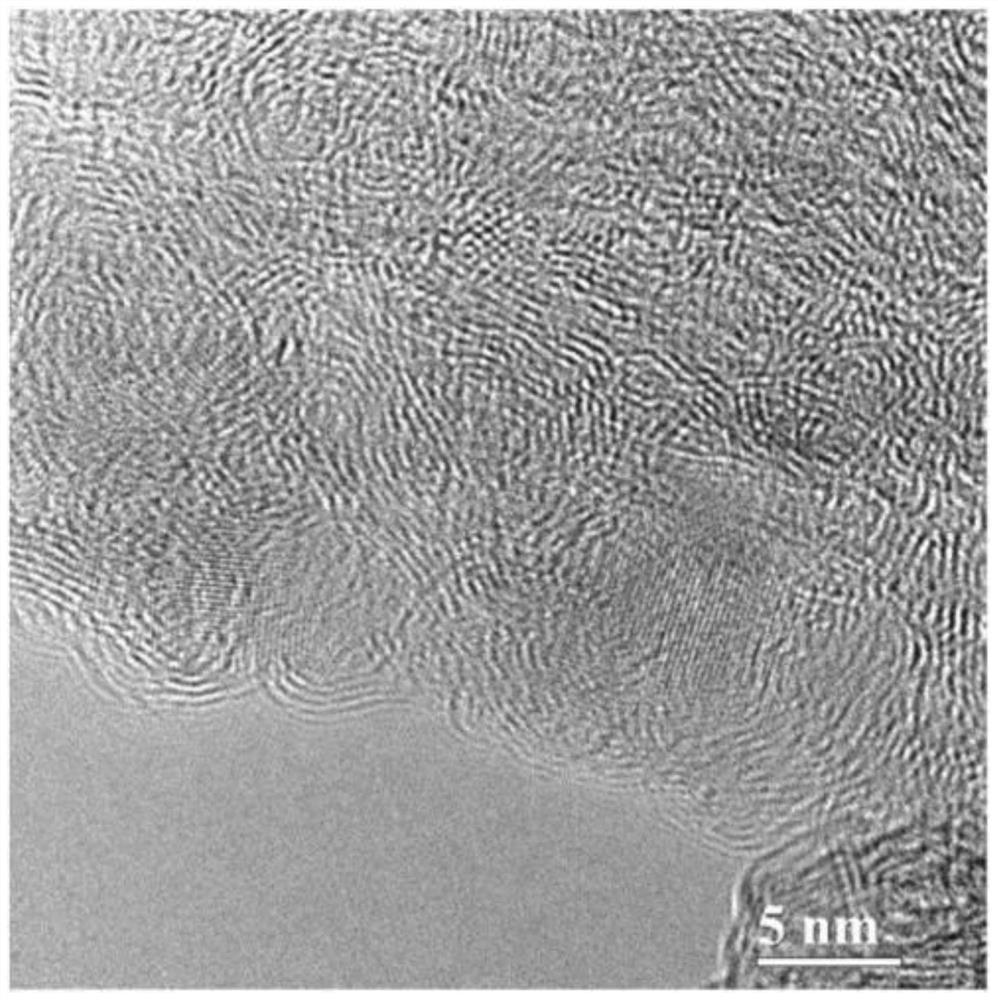

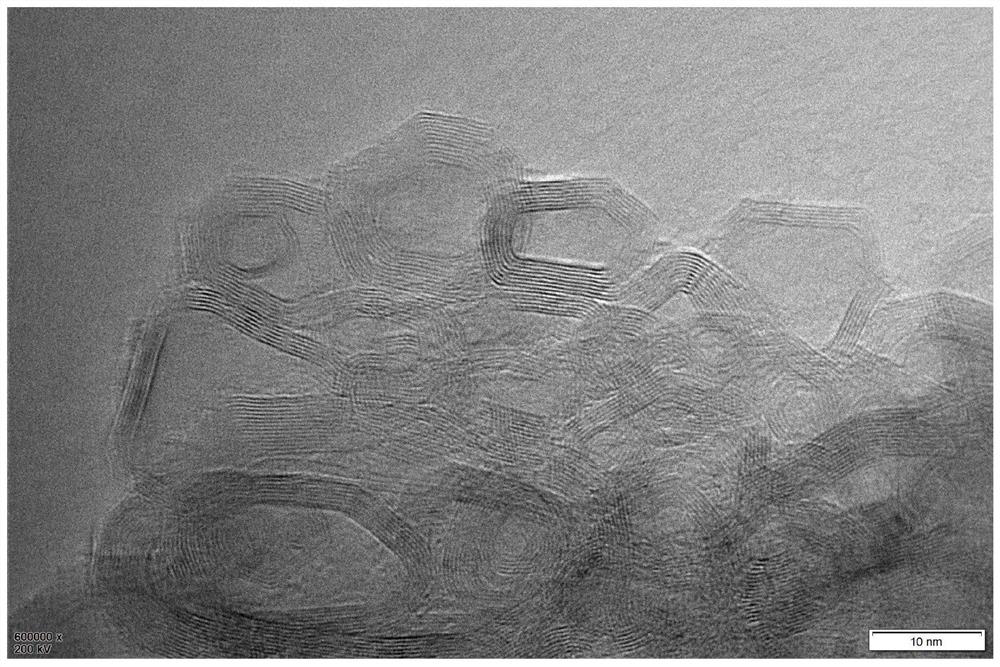

[0035] In this embodiment, mesoporous carbon CMK-3 is used as a template and a hydrothermal method is used to synthesize hollow nano-polyhedron graphite spheres. The method comprises the following steps:

[0036] (1) Use 2M sulfuric acid solution to prepare ammonium persulfate solution, the final concentration of ammonium persulfate is 1M, add 0.5g of mesoporous carbon CMK-3 to 30mL of the above solution, stir and reflux at 60°C for 12h, and then use deionized Wash the mesoporous carbon CMK-3 several times with water and ethanol, filter it, and dry it at 60°C for more than 6 hours for later use;

[0037] (2) Grind 0.5g of pyrene into 40mL of concentrated nitric acid, stir and reflux at 80°C for 10h, wash with deionized water and ethanol, filter and dry at 60°C for more than 6h to obtain 1,3,6-trinitropyrene ;

[0038] (3) Add 0.05g of oxidized CMK-3 prepared in step (1) and 0.1g of 1,3,6-trinitropyrene prepared in step (2) into 50ml of 0.2M NaOH solution, and After ultrasoni...

Embodiment 2

[0043] In this embodiment, mesoporous carbon CMK-3 is used as a template and a hydrothermal method is used to synthesize hollow nano-polyhedron graphite spheres. The method comprises the following steps:

[0044] (1) Same as step (1) in Example 1;

[0045] (2) Same as step (2) in Example 1;

[0046] (3) Add 0.05g of oxidized CMK-3 prepared in step (1) and 0.1g of 1,3,6-trinitropyrene prepared in step (2) into 50ml of 1.2M ammonia solution, and After ultrasonic crushing, heat to 200°C in a polytetrafluoroethylene reactor and react for 10 hours;

[0047] (4) Same as step (4) in Example 1.

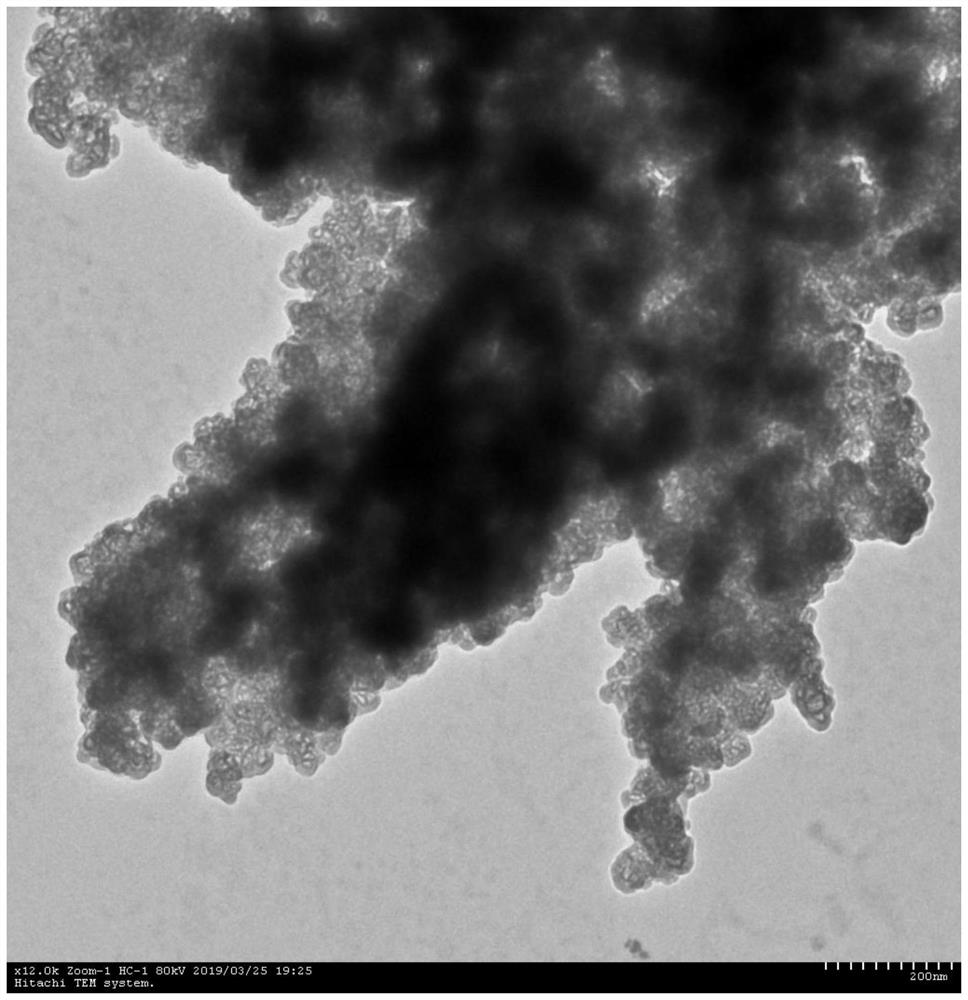

[0048] The hollow nano-polyhedron graphite sphere prepared in this embodiment is tested, and its common TEM picture is as follows Figure 5 shown.

Embodiment 3

[0050] In this embodiment, mesoporous carbon CMK-3 is used as a template and a hydrothermal method is used to synthesize hollow nano-polyhedron graphite spheres. The method comprises the following steps:

[0051](1) Use deionized water to prepare 1M ammonium persulfate solution, add 0.5g of mesoporous carbon CMK-3 to 30mL of the above solution, stir and reflux at 60°C for 12h, then wash, filter and dry for later use;

[0052] (2) Same as step (2) in Example 1;

[0053] (3) Same as step (3) in Example 1;

[0054] (4) Same as step (4) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com