Diamond ultrathin saw bit with nickel aluminium alloy as base and manufacturing method thereof

A technology of nickel-aluminum alloy and artificial diamond, which is applied in the field of nickel-aluminum-aluminum-based diamond ultra-thin saw blades, can solve the problems that the manufacturing technology of nickel-aluminum-aluminum-based diamond ultra-thin saw blades has not been reported, and achieve long life and high rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mixing

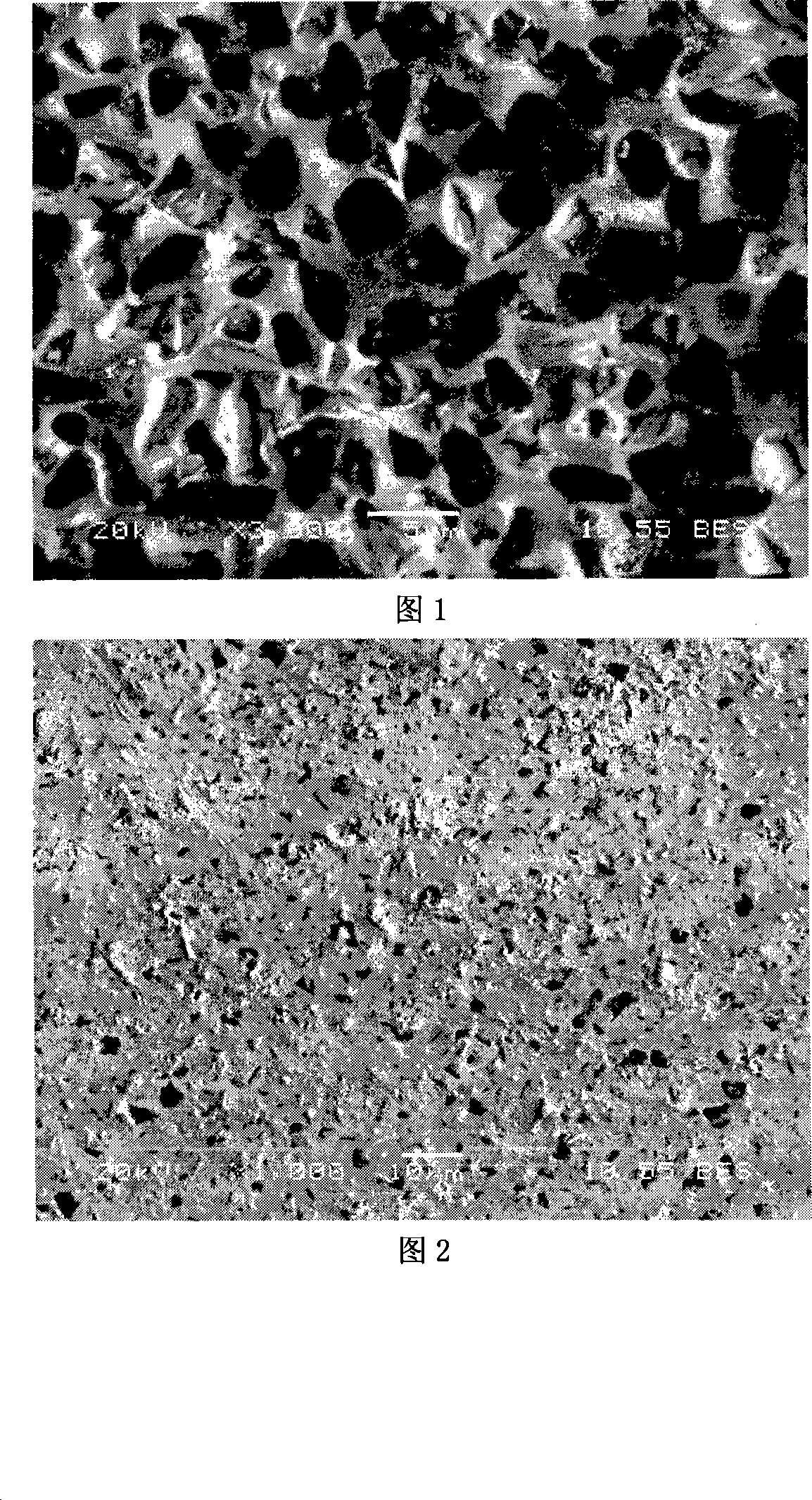

[0028] Select 70 parts of nickel powder with a purity of more than 99.9%, 10 parts of aluminum powder with a purity of more than 99.8% and 20 parts of titanium-coated artificial diamond particles (particle size is 5 microns to 10 microns) and fully mix them in a three-dimensional mixer.

[0029] (2) cold press forming

[0030] Put the mixed powder (1) into the mold and cold press it on a four-column hydraulic press with a pressure of 300kgf / cm 2 , hold the pressure for 10 minutes, and press it into a φ100mm×400μm disc.

[0031] (3) Put the saw blade blank (2) into the hot-press sintering furnace, first heat it to 670°C, keep it warm for 30 minutes, then continue to heat it to 800°C and keep it warm for 20 minutes, and the hot-pressing pressure is 300kgf / cm 2 .

[0032] (4) Slowly cool down to below 200°C with the furnace under pressure, and get out of the furnace to obtain a nickel-aluminum alloy diamond ultra-thin saw blade containing 70 parts of nickel...

Embodiment 2

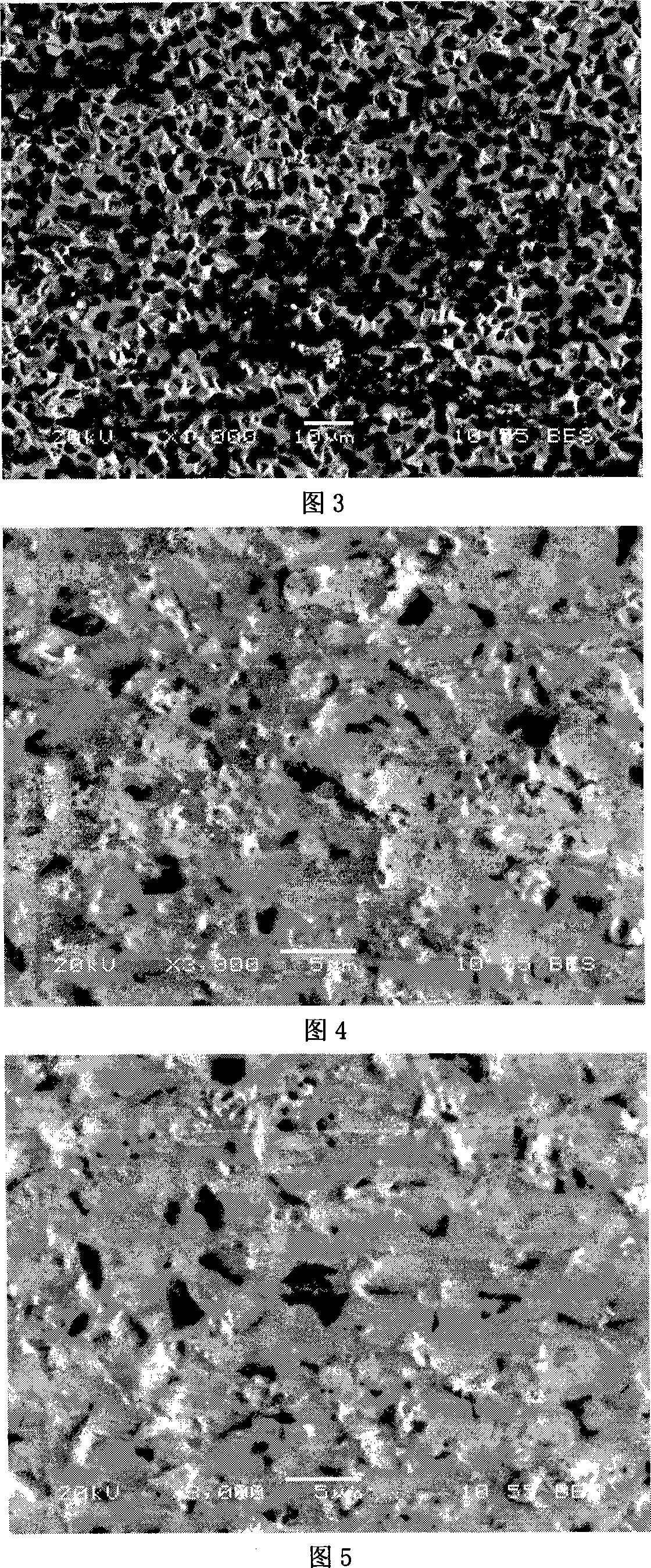

[0035] Select 70 parts of nickel powder with a purity of more than 99.9%, 10 parts of aluminum powder with a purity of more than 99.8% and 20 parts of titanium-coated artificial diamond particles (particle size is 5 microns to 10 microns) and fully mix them in a three-dimensional mixer.

[0036] (2) cold press forming

[0037] Put the mixed powder (1) into the mold, and cold press it on a four-column hydraulic press with a pressure of 400kgf / cm 2 , hold the pressure for 10 minutes, and press it into a φ100mm×400μm disc.

[0038] (3) Put the saw blade blank (2) into the hot-press sintering furnace, heat it to 690°C, keep it warm for 30 minutes, then continue to heat it to 760°C and keep it warm for 20 minutes, and the hot-pressing pressure is 200kgf / cm 2 .

[0039] (4) Slowly cool down to below 200°C with the furnace under pressure, and get out of the furnace to obtain a nickel-aluminum alloy diamond ultra-thin saw blade containing 70 parts of nickel, 10 parts of aluminum and...

Embodiment 3

[0042] Select 50 parts of nickel powder with a purity of more than 99.9%, 20 parts of aluminum powder with a purity of more than 99.8%, and 30 parts of titanium-plated artificial diamond particles (with a particle size of 5 microns to 10 microns) and fully mix them in a three-dimensional mixer.

[0043] (2) cold press forming

[0044] Put the mixed powder (1) into the mold and cold press it on a four-column hydraulic press with a pressure of 300kgf / cm 2 , hold the pressure for 10 minutes, and press it into a φ100mm×400μm disc.

[0045] (3) Put the saw blade blank (2) into the hot-press sintering furnace, first heat it to 700°C, keep it warm for 10 minutes, then continue to heat it to 750°C and keep it warm for 60 minutes, and the hot-pressing pressure is 100kgf / cm 2 .

[0046] (4) Slowly cool under pressure with the furnace to below 200°C, and then get out of the furnace to obtain a nickel-aluminum alloy-based diamond ultra-thin saw blade containing 50 parts of nickel, 20 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com