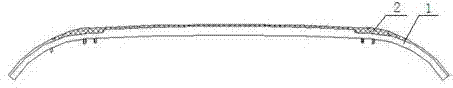

Method for preparing pantograph slide plate composite carbon core of electric locomotive (including high-speed train) by using cold isostatic pressing process

A technology of pantograph slide plate and cold isostatic press, which is applied to electric vehicles, current collectors, vehicle parts, etc., and can solve problems such as low service life, micro cracks, and slide plate breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] step one

[0074] Select formula 1 according to the electrical conductivity, mechanical strength and self-lubricating characteristics of the carbon core material of the skateboard:

[0075] Flake graphite 15%; acicular graphite 15%; carbon fiber 0.5%; carbon powder 69.5%; the particle size of flake graphite, acicular graphite and carbon powder is 180---300 mesh.

[0076] step two

[0077] The high-efficiency mechanical alloy grinding process is used to process formula 1. Various carbon materials in formula 1 have different characteristics. This process effectively combines carbon materials with different characteristics to form a variety of complementary advantages. The comprehensive requirements for the carbon core material of the electric locomotive pantograph slide plate have a particle size of 180-300 mesh.

[0078] step three

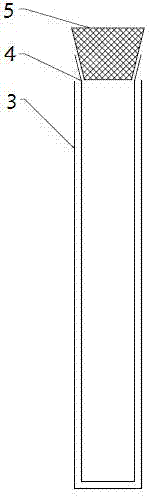

[0079] Using the cold isostatic pressing molding process to prepare carbon core blanks:

[0080] After the powder treatment is complete...

Embodiment 2

[0085] step one

[0086] Select formula 2 according to the electrical conductivity, mechanical strength and self-lubricating characteristics of the carbon core material of the skateboard:

[0087] Flake graphite 30%; high-purity graphite 25%; carbon fiber 2.0%; carbon powder 43%;

[0088] The particle size of flake graphite, high-purity graphite and carbon powder is 180---250 mesh.

[0089] step two

[0090] The high-efficiency mechanical alloy grinding process is used to process formula 2. Various carbon materials in formula 2 have different characteristics. This process effectively combines carbon materials with different characteristics to form a variety of complementary advantages. The comprehensive requirements for the carbon core material of the electric locomotive pantograph slide plate, the particle size is 180-220 mesh.

[0091] step three

[0092] Using the cold isostatic pressing molding process to prepare carbon core blanks:

[0093] After the powder treatment...

Embodiment 3

[0098] step one

[0099] Select formula three according to the electrical conductivity, mechanical strength and self-lubricating characteristics of the carbon core material of the skateboard:

[0100] Flake graphite 20%; needle graphite 20%; carbon fiber 1%; carbon powder 59%;

[0101] The particle size of flake graphite, needle graphite and carbon powder is 180---230 mesh.

[0102] step two

[0103] The high-efficiency mechanical alloy grinding process is used to process formula 3. Various carbon materials in formula 3 have different characteristics. This process effectively combines carbon materials with different characteristics to form a variety of complementary advantages. The comprehensive requirements for the carbon core material of the electric locomotive pantograph slide plate have a particle size of 180-240 mesh.

[0104] step three

[0105] Using the cold isostatic pressing molding process to prepare carbon core blanks:

[0106] After the powder treatment is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com