Preparing method for collector shoe

A current collector and slider technology, which is used in the field of preparing current collector sliders, achieves good mechanical strength and electrical conductivity, reduces the temperature difference in the furnace, and improves the copper infiltration efficiency and copper infiltration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

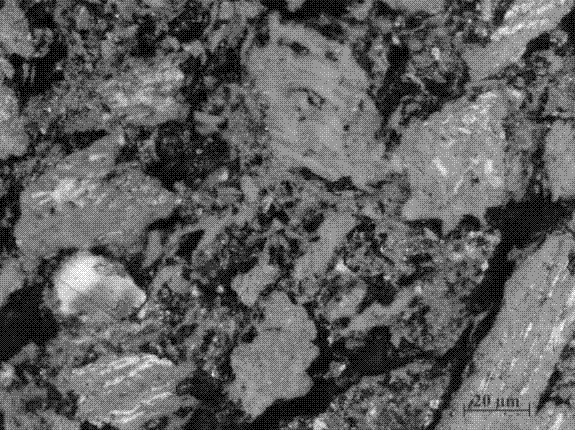

Image

Examples

Embodiment 1

[0026] A preparation method of a current collector slider, the preparation method comprising the following steps:

[0027] (a) Select raw materials: select coke and pitch according to the mass ratio of 3.6:1;

[0028] (b) Crushing and milling: Put the above raw materials into the crusher for 3 minutes and then put them into the ball mill for 3 hours. The ball milling medium can be stainless steel balls with a diameter of 8-15mm. The ball mill speed is 500rpm, and the ball-to-material ratio is 10:1;

[0029] (c) Compression: Preheat the ball-milled powder to 150°C, then put the preheated powder into a mold with a temperature of 150°C, and press the powder into a prefabricated block with a pressure of 650Mpa;

[0030] (d) Sintering: Put the pressed prefabricated block into a box-type atmosphere furnace for sintering. The sintering atmosphere is hydrogen-argon mixed gas. The molar ratio of hydrogen and argon in the hydrogen-argon mixed gas is 0.8:1 and hydrogen-argon is mixed T...

Embodiment 2

[0032] A preparation method of a current collector slider, the preparation method comprising the following steps:

[0033] (a) Select raw materials: select coke and pitch according to the mass ratio of 3.8:1;

[0034] (b) Crushing and milling: put the above raw materials into the crusher for 5 minutes, and then put them into the ball mill for 3 hours. The ball milling medium can be stainless steel balls with a diameter of 8-15mm. The speed of the ball mill is 520rpm, and the ball-to-material ratio is 10 :1;

[0035] (c) Compression: Preheat the ball-milled powder to 160°C, then put the preheated powder into a mold with a temperature of 160°C, and press the powder into a prefabricated block with a pressure of 600Mpa;

[0036] (d) Sintering: Put the pressed prefabricated block into a box-type atmosphere furnace for sintering. The sintering atmosphere is hydrogen-argon mixed gas. The molar ratio of hydrogen and argon in the hydrogen-argon mixed gas is 1:1 and hydrogen-argon is m...

Embodiment 3

[0038] A preparation method of a current collector slider, the preparation method comprising the following steps:

[0039] (a) Select raw materials: select coke and pitch according to the mass ratio of 4:1;

[0040] (b) Crushing and milling: put the above raw materials into the crusher for 6 minutes, and then put them into the ball mill for 3.5 hours. The ball milling medium can be stainless steel balls with a diameter of 8-15mm. The ball mill speed is 520rpm, and the ball-to-material ratio is 12:1;

[0041] (c) Compression: Preheat the ball-milled powder to 180°C, then put the preheated powder into a mold with a temperature of 180°C, and press the powder into a prefabricated block with a pressure of 650Mpa;

[0042](d) Sintering: Put the pressed prefabricated block into a box-type atmosphere furnace for sintering. The sintering atmosphere is hydrogen-argon mixed gas. The molar ratio of hydrogen and argon in the hydrogen-argon mixed gas is 1.2:1 and hydrogen-argon is mixed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average resistivity | aaaaa | aaaaa |

| Average compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com