A process for producing propylene using oxygen-containing compounds as raw materials

A compound and propylene technology, applied in the field of propylene production, can solve the problem of high yield of by-products such as aromatic hydrocarbons and alkanes, and achieve the effects of high propylene selectivity, improved atom utilization, and inhibition of hydrogen transfer reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

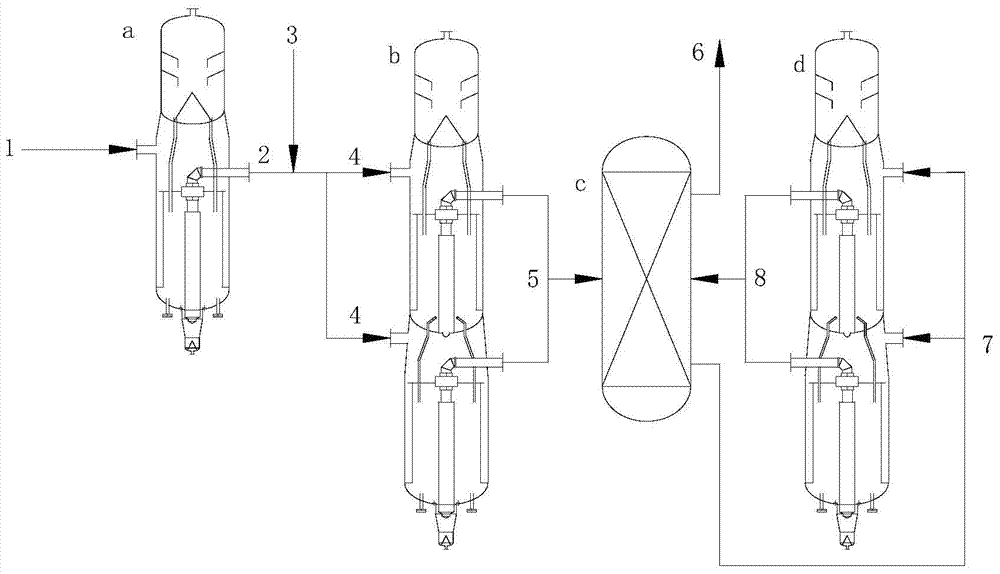

[0041] The process for producing propylene from oxygenates includes the following steps:

[0042] 1) The oxygenate stream 1 containing methanol is continuously fed into the first reaction zone a at 400 °C, 1 MPaG, and the mass space velocity of methanol is 1 h -1 The etherification reaction occurs in contact with the catalyst under certain conditions, and the reaction generates an oxygen-containing compound stream 2, and the first reaction zone a includes a fixed-bed reactor filled with an alumina catalyst;

[0043] 2) The oxygenate stream 2 at the outlet of the first reaction zone a is mixed with the diluent 3 and the stream 4 is passed into the second reaction zone b at 450 °C, 0.1 MPaG, oxygenate partial pressure 5 kPa, mass space velocity 0.5 h -1 Under certain conditions, it contacts with the molecular sieve catalyst to produce olefins, and generates a mixed hydrocarbon stream 5 including the target product propylene. The second reaction zone b comprises a moving bed rea...

Embodiment 2

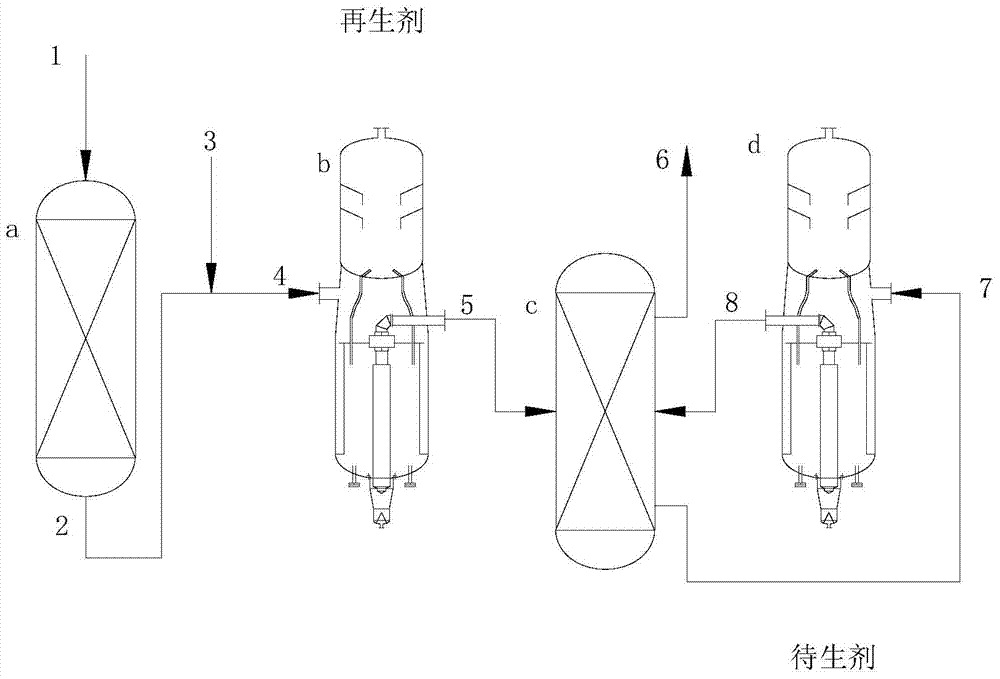

[0050] The process for producing propylene from oxygenates includes the following steps:

[0051] 1) The oxygenate stream 1 containing dimethyl ether is continuously fed into the first reaction zone a at 200 ℃, 0.1MPaG, and the oxygenate mass space velocity is 20 h -1 The etherification reaction occurs in contact with the catalyst under certain conditions, and the reaction generates an oxygen-containing compound stream 2, and the first reaction zone a includes a moving bed reactor filled with a molecular sieve catalyst;

[0052] 2) Mix the oxygenate stream 2 from the outlet of the first reaction zone a and the stream 4 of the diluent 3 into the second reaction zone b at 550 °C, 1 MPaG, oxygenate partial pressure 50 kPa, mass space velocity 10.0 h -1 Under certain conditions, it contacts with the molecular sieve catalyst to produce olefins, and generates a mixed hydrocarbon stream 5 including the target product propylene. The second reaction zone b comprises two moving bed react...

Embodiment 3

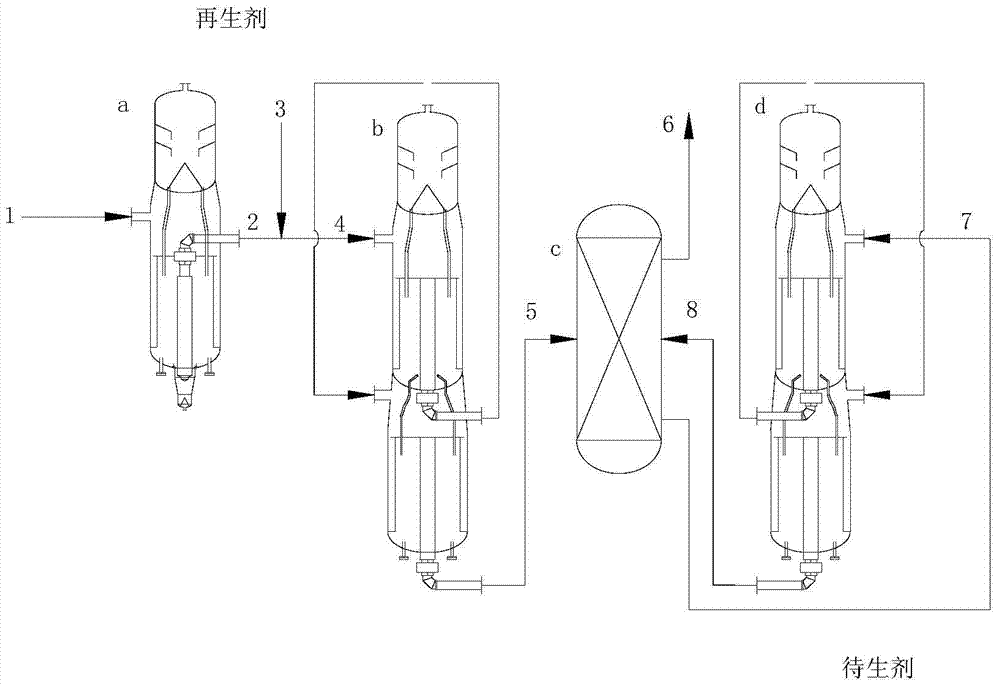

[0059] The process for producing propylene from oxygenates includes the following steps:

[0060] 1) The oxygenate stream 1 containing methanol and dimethyl ether is continuously fed into the first reaction zone a at 250 °C, 0.5 MPaG, and the oxygenate mass space velocity is 10 h -1 The etherification reaction occurs in contact with the catalyst under certain conditions, and the reaction generates an oxygen-containing compound stream 2. The first reaction zone a includes two moving bed reactors arranged in series and filled with molecular sieve catalysts;

[0061] 2) The oxygenate stream 2 at the outlet of the first reaction zone a is mixed with the diluent 3 and the stream 4 is passed into the second reaction zone b at 500 °C, 0.3 MPaG, oxygenate partial pressure 15 kPa, mass space velocity 5.0 h -1 Under certain conditions, it contacts with the molecular sieve catalyst to produce olefins, and generates a mixed hydrocarbon stream 5 including the target product propylene. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com