Preparation method for carbon nano-sheet matrix material and application of carbon nano-sheet matrix material in sodium-ion battery

A technology of carbon nanosheets and matrix materials is applied in the field of sodium ion batteries to achieve the effects of shortening transmission distance, cheap and readily available raw materials, and improving sodium storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

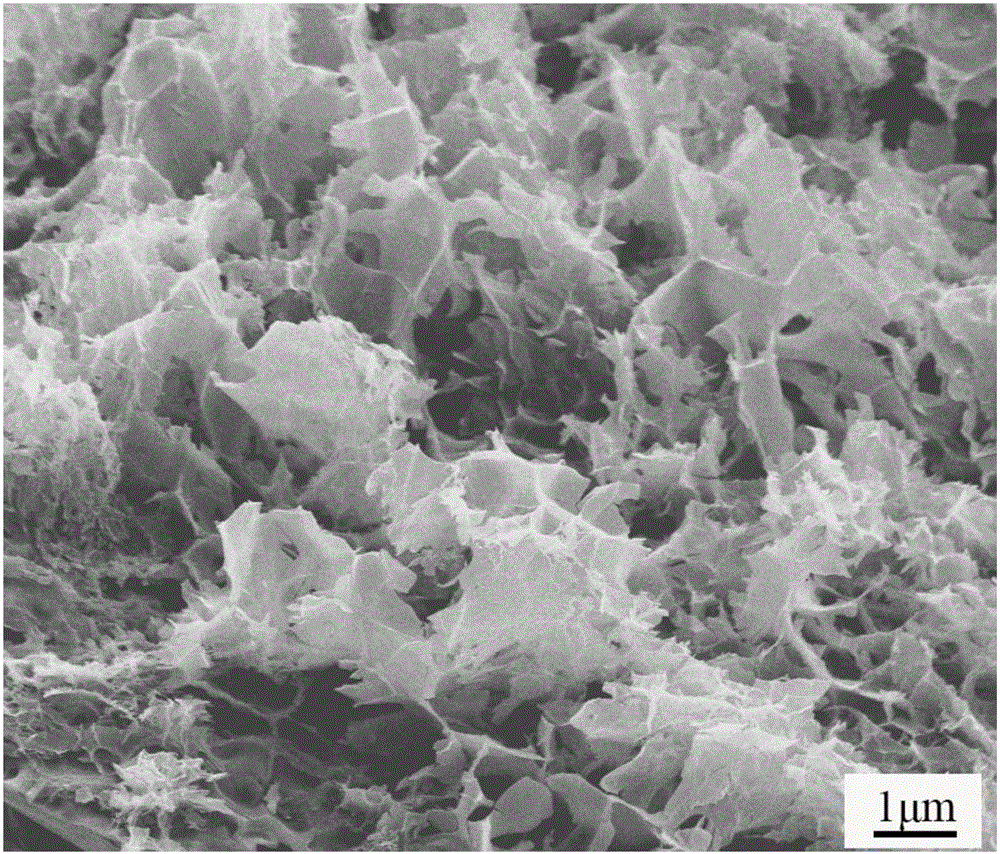

Embodiment 1

[0033] Add lignin, resorcinol, formaldehyde and sodium carbonate to deionized water in turn, the concentration of sodium carbonate in the solution is 0.1mol / L; the concentration of lignin is 1g / L; the concentration of resorcinol is 1g / L, and the concentration of formaldehyde 2g / L, stir evenly, the temperature of the mixed solution is 50°C, and the holding time is 10h to obtain lignin gel. Put 2g of lignin gel in a quartz tube furnace, protected by inert gas, and the heating rate is 5°C / min. Heat at 600°C for 1 hour to obtain gel carbide; mix 0.5g of gel carbonized product with 2g of magnesium chloride evenly, place in a quartz tube furnace, protect with inert gas, heat up at a rate of 5°C / min to 700°C, and hold for 1 hour , the obtained material is washed and dried to obtain a low graphitized carbon nanosheet matrix material, the thickness of the carbon nanosheet is concentrated at 50nm, and the specific surface area of the obtained carbon nanosheet matrix material is 2000m ...

Embodiment 2

[0036] Add lignin, resorcinol, formaldehyde and sodium carbonate to deionized water in sequence, the concentration of sodium carbonate in the solution is 0.15mol / L; the concentration of lignin is 2g / L; the concentration of resorcinol is 2g / L, and the concentration of formaldehyde 5g / L, stir evenly, the temperature of the mixed solution is 60°C, and the holding time is 20h to obtain lignin gel. Put 2g of lignin gel in a quartz tube furnace, protected by inert gas, and the heating rate is 3°C / min. Heat at 1000°C for 1 hour to obtain gel carbide; mix 0.5g of gel carbonized product with 2g of magnesium chloride evenly, place in a quartz tube furnace, protect with inert gas, heat up at a rate of 5°C / min to 900°C, and hold for 1 hour , the obtained material is washed and dried to obtain a low graphitization carbon nanosheet matrix material, the thickness of the carbon nanosheet is concentrated at 30nm, and the specific surface area of the obtained carbon nanosheet matrix material i...

Embodiment 3

[0039] Add lignin, resorcinol, formaldehyde and sodium carbonate to deionized water in turn, the concentration of sodium carbonate in the solution is 0.2mol / L; the concentration of lignin is 5g / L; the concentration of resorcinol is 1g / L, and the concentration of formaldehyde 4g / L, stir evenly, the temperature of the mixed solution is 90°C, and the holding time is 40h to obtain lignin gel. Put 2g of lignin gel in a quartz tube furnace, protected by inert gas, and the heating rate is 2°C / min To 800°C, keep warm for 2 hours to obtain gel carbide; mix 0.5g gel carbonized product with 1.5g magnesium chloride evenly, place in a quartz tube furnace, protect with inert gas, heat up at a rate of 5°C / min to 800°C, keep warm 1h, the obtained material is washed and dried to obtain a low graphitization carbon nanosheet matrix material, the thickness of the carbon nanosheet is concentrated at 75nm, and the specific surface area of the obtained carbon nanosheet matrix material is 1700m 2 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com