Preparation method of diamond and carbon nanotube fiber composite material

A carbon nanotube fiber and composite material technology, which is applied in the chemical characteristics of fibers, electrolytic coatings, textiles and papermaking, etc., can solve the problems of poor diamond dispersion, poor toughness of ordinary fibers, and short service life, and achieve an orderly degree. Elevated, low graphitization, enhanced tensile strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of diamond and carbon nanotube fiber composite material, comprising the following steps:

[0023] (1) Take a certain amount of diamond and a certain amount of solvent, and make the diamond evenly disperse to form a diamond solution 2 by means of ultrasonic dispersion; specifically, the particle size of the diamond is between 0.5 μm and 10 μm, and the carbon nanotube fiber The diameter is between 100 μm and 200 μm, and the length of the carbon nanotube fibers is between 0.5 cm and 10 cm. The solvent includes water and alcohol. The concentration of the prepared diamond solution 2 is between 0.0005wt.% and 0.01wt.%.

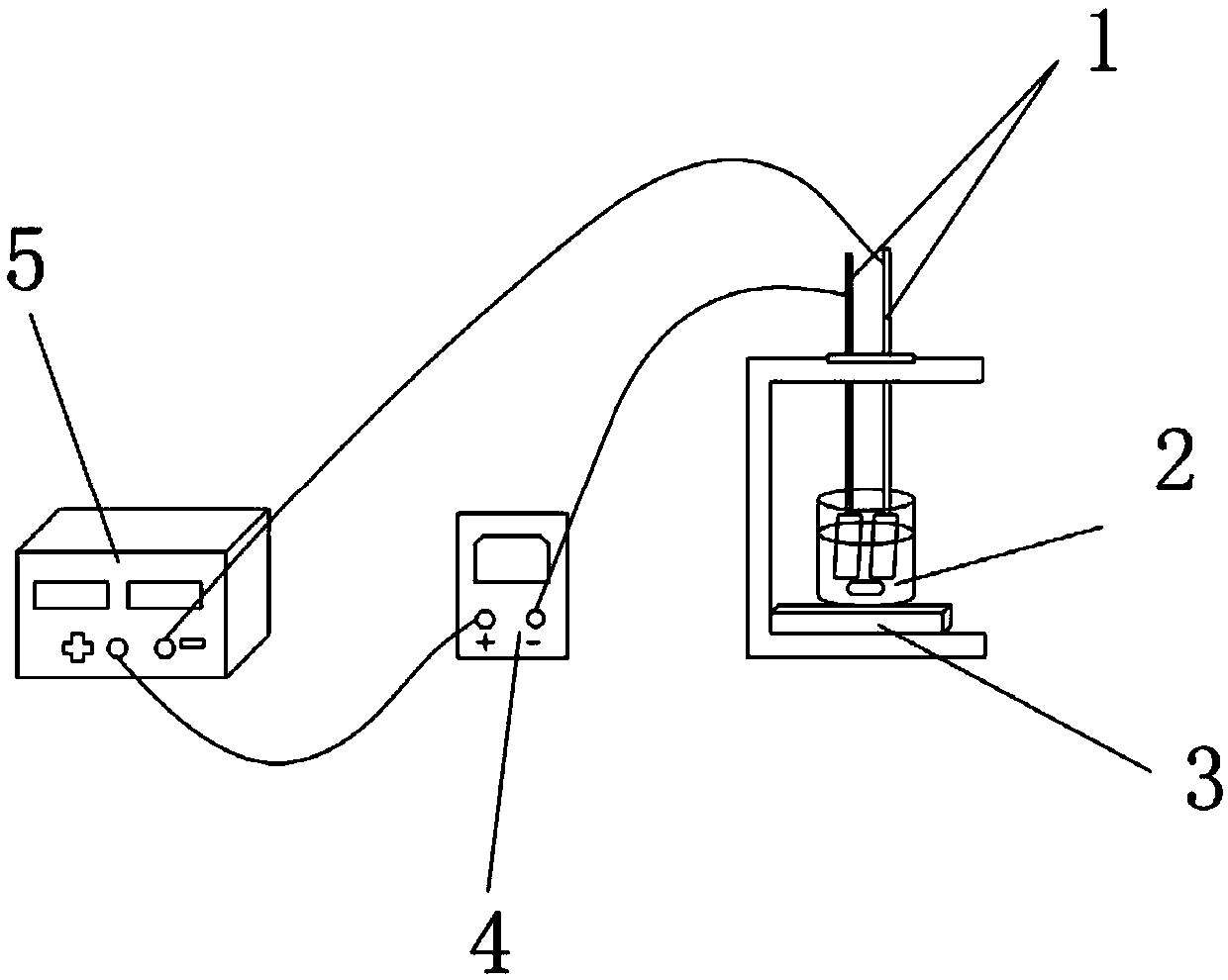

[0024] (2) With the carbon nanotube fiber as the positive pole and the stainless steel plate as the negative pole, the diamond is evenly adhered to the surface of the carbon nanotube fiber by the electrophoretic co-deposition method; specifically, the voltage used by the electrophoretic co-deposition method is 2V To 30V, the deposition ...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is that each parameter is different, specifically as follows:

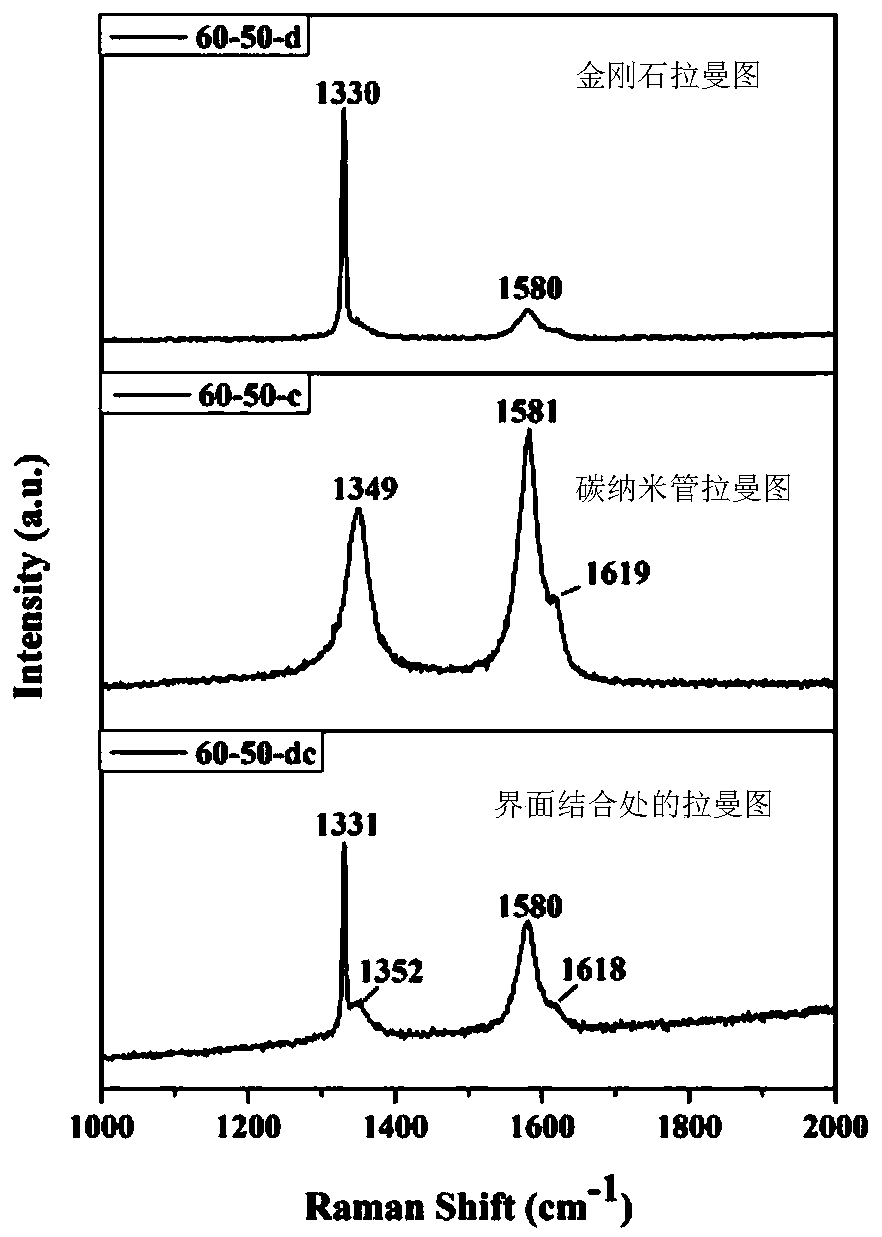

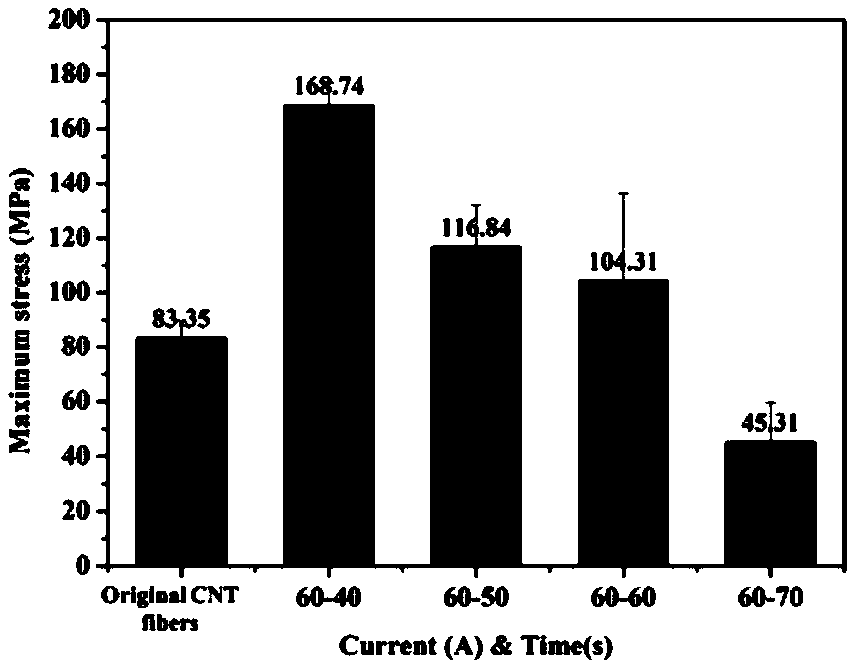

[0031] Take 4 cm of diamond powder with a particle size of 3 μm and carbon nanotube fibers with a diameter of 100 μm. Diamond powder was weighed by an electronic balance, and added to 100 ml of alcohol solution to prepare a diamond solution 2 with a concentration of 0.001 wt.%, and ultrasonically dispersed in the diamond solution 2 for 10 minutes. The carbon nanotube fiber is used as the positive electrode, the 304 stainless steel is used as the negative electrode, the DC voltage is 10V, and the time is 20s. Through the electrophoretic co-deposition method, the diamond is uniformly adhered to the surface of the carbon nanotube fiber. Take out the carbon nanotube fiber stuck with diamond, put it into a high-frequency induction sintering furnace after drying, and turn on a current of 60A for 50s under argon protective gas to obtain a diamond carbon nanot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com