Artificial graphite negative electrode material with gradient structure and preparation and application thereof

A technology of artificial graphite negative electrode and gradient structure, which is applied in nanotechnology, structural parts, battery electrodes and other directions for materials and surface science, can solve the problems of long process flow, regulation of structure and lack of effective regulation of graphitization degree, etc. To achieve the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

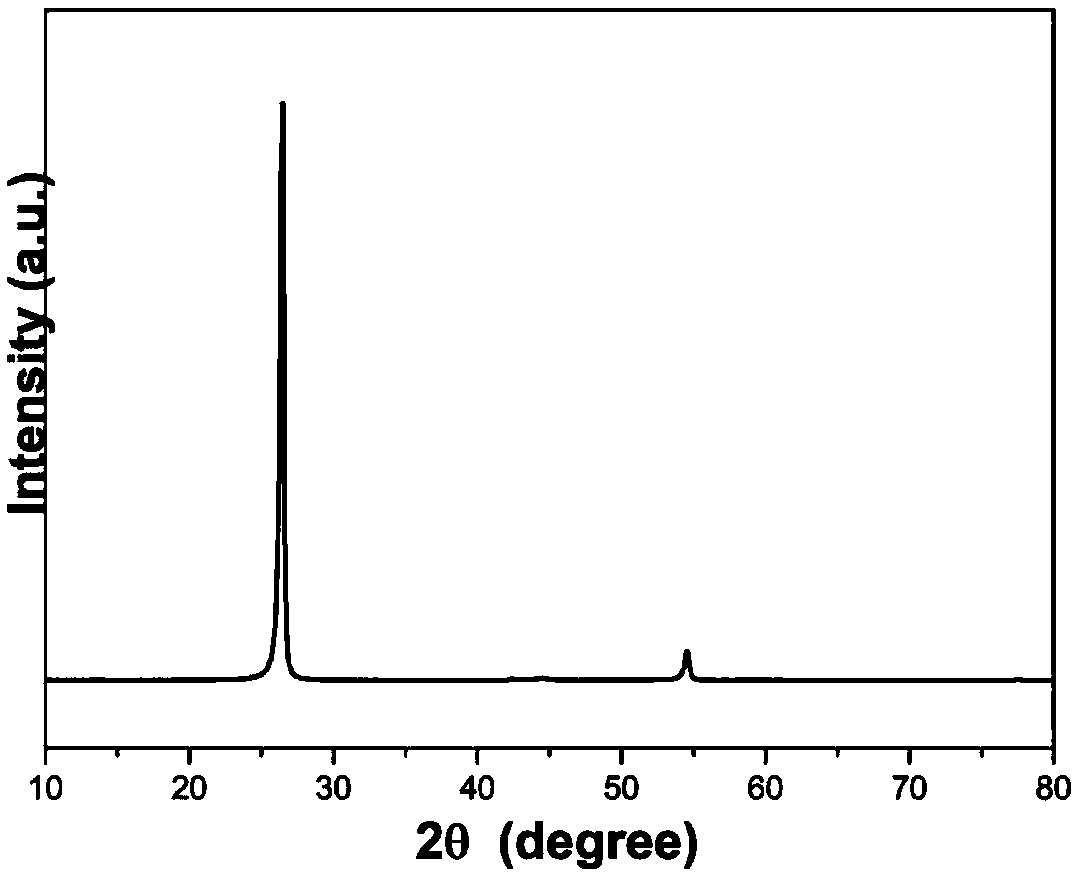

Image

Examples

Embodiment 1

[0078] (1) crushing, grading, and shaping the anthracite raw coal to obtain anthracite powder with a particle size range of 5-100 microns and an average particle size of 30 microns;

[0079] (2) Pretreating the anthracite powder treated in the first step. First, mix anthracite powder and potassium hydroxide as an activator in an aqueous solution at a mass ratio of 1:3, and after standing for 12 hours, continue stirring at 80° C. until the water evaporates to dryness to obtain a uniform mixture of anthracite and potassium hydroxide; The homogeneous mixture was placed in an argon atmosphere muffle furnace, and reacted at 800°C for 2 hours; after the reaction, the mixture was acid-washed and washed with water until neutral to remove excess potassium hydroxide, and activated after drying at 105°C for 24 hours After anthracite, the specific surface area is 1200m 2 / g, the average pore diameter is 5 nanometers, and the pore diameter range is 1-1000nm;

[0080] (3) After activation...

Embodiment 2

[0084] (1) crushing, grading, and shaping the anthracite raw coal to obtain anthracite powder with a particle size range of 5-100 microns and an average particle size of 30 microns;

[0085] (2) Pretreating the anthracite powder treated in the first step. First, mix anthracite powder and potassium hydroxide as an activator in an aqueous solution at a mass ratio of 1:4, and after standing for 12 hours, continue stirring at 80° C. until the water evaporates to dryness to obtain a uniform mixture of anthracite and potassium hydroxide; Put the homogeneous mixture into an argon atmosphere muffle furnace, and react at 850°C for 2 hours; after the reaction, the mixture is washed with acid and water until neutral to remove excess potassium hydroxide, and dried at 105°C for 24 hours to be activated After anthracite, the specific surface area is 1500m 2 / g, the average pore diameter is 8 nanometers, and the pore diameter range is 1-1000nm;

[0086] (3) After activation, the anthracite...

Embodiment 3

[0090] (1) crushing, grading, and shaping the anthracite raw coal to obtain anthracite powder with a particle size range of 5-100 microns and an average particle size of 30 microns;

[0091] (2) Pretreating the anthracite powder treated in the first step. First, mix anthracite powder and potassium hydroxide as an activator uniformly in an aqueous solution at a mass ratio of 1:5, and after standing for 12 hours, continue stirring at 80° C. until the water evaporates to dryness to obtain a uniform mixture of anthracite and potassium hydroxide; Put the homogeneous mixture into an argon atmosphere muffle furnace, and react at 850°C for 2 hours; after the reaction, the mixture is washed with acid and water until neutral to remove excess potassium hydroxide, and dried at 105°C for 24 hours to be activated After anthracite, the specific surface area is 1800m 2 / g, the average pore diameter is 10 nanometers, and the pore diameter range is 1-1000nm;

[0092] (3) Immerse the anthracit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com