High-performance water system zinc ion battery anode material, manufacturing method and application thereof

A zinc-ion battery and cathode material technology, applied in battery electrodes, active material electrodes, positive electrodes, etc., to achieve the effect of simple preparation process, low equipment requirements, and inhibition of dendrite growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

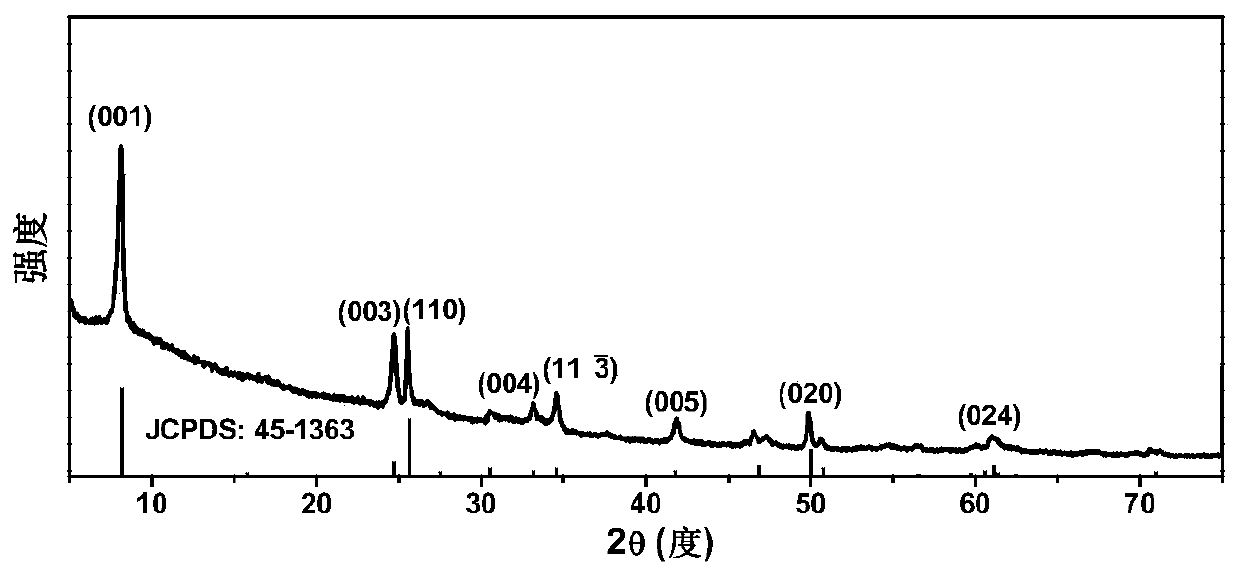

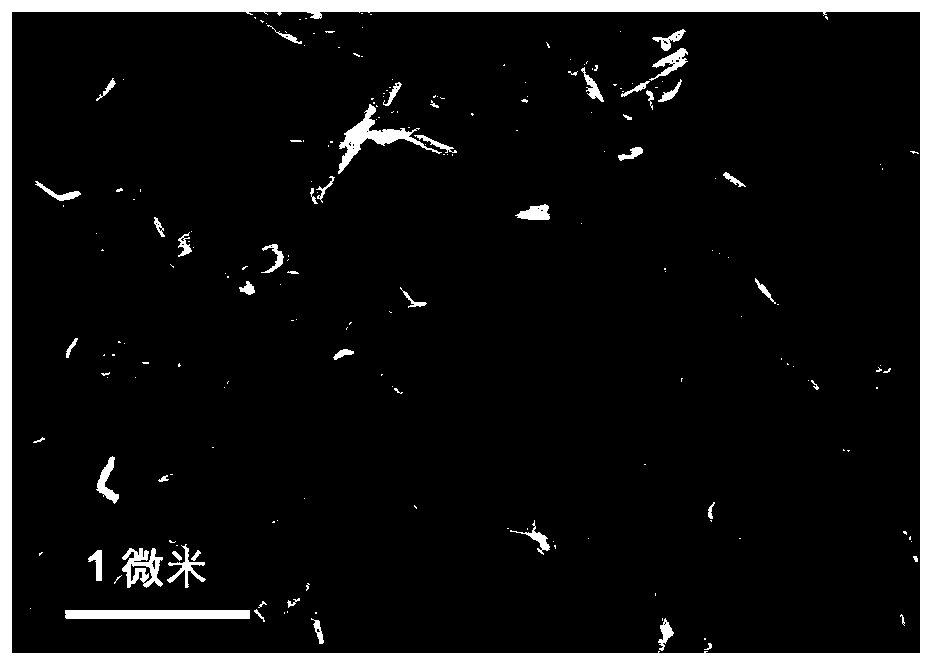

[0046] A high-performance aqueous zinc-ion battery cathode material (Na, Mn) ∑=1 V 8 o 20 0.04H 2 The preparation method of O comprises steps:

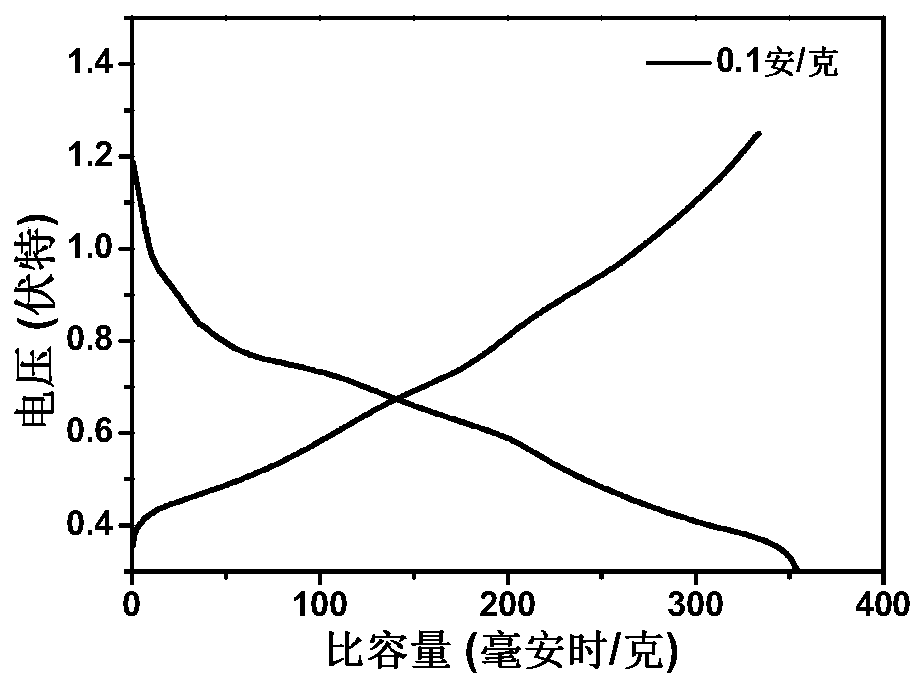

[0047] Weigh manganese sulfate, vanadium pentoxide and sodium sulfate according to the molar ratio of manganese element: vanadium element: sodium element is 1:13:7, fully disperse the weighed raw materials in 50mL water and stir for 30min to obtain a mixed solution; The mass concentration of vanadium pentoxide in the liquid is 0.55mol / L. The pH was adjusted to 2.5 with 37% aqueous acetic acid solution. Transfer the solution to a reaction kettle lined with polytetrafluoroethylene, place the reaction kettle in an oven, and conduct a hydrothermal reaction at 180°C for 72 hours. The precipitate after the hydrothermal reaction is separated by centrifugation, washed with absolute ethanol, and kept at temperature It is a positive electrode material for a zinc ion battery obtained after vacuum drying at 60° C. for 12 hours.

[0048] App...

Embodiment 2

[0063] A high-performance aqueous zinc-ion battery cathode material (Na, Mn) ∑=1 V 8 o 20 ·nH 2 The preparation method of O (n is 0.01-4), comprises steps:

[0064] Weigh manganese sulfate, vanadium pentoxide and sodium sulfate according to the molar ratio of manganese element: vanadium element: sodium element is 1:1:7, fully disperse the weighed raw materials in 50mL water and stir for 30min to obtain a mixed solution; The mass concentration of vanadium pentoxide in the liquid is 0.55mol / L. Adjust the pH to 2.5 with 36% acetic acid aqueous solution. Transfer the solution to a reaction kettle lined with polytetrafluoroethylene, place the reaction kettle in an oven, and conduct a hydrothermal reaction at 180°C for 72 hours. The precipitate after the hydrothermal reaction is separated by centrifugation, washed with absolute ethanol, and kept at temperature It is a positive electrode material for a zinc ion battery obtained after vacuum drying at 60° C. for 12 hours.

[006...

Embodiment 3

[0069] A high-performance aqueous zinc-ion battery cathode material (Na, Mn) ∑=1 V 8 o 20 ·nH 2 The preparation method of O (n is 0.01-4), comprises steps:

[0070] Take manganese sulfate, vanadium pentoxide and sodium sulfate according to the molar ratio of manganese element: vanadium element: sodium element is 20:13:7, fully disperse the weighed raw materials in 50mL water and stir for 30min to obtain a mixed solution; The mass concentration of vanadium pentoxide in the liquid is 0.55mol / L. Adjust the pH to 2.5 with 38% aqueous acetic acid solution. Transfer the solution to a reaction kettle lined with polytetrafluoroethylene, place the reaction kettle in an oven, and conduct a hydrothermal reaction at 180°C for 72 hours. The precipitate after the hydrothermal reaction is separated by centrifugation, washed with absolute ethanol, and kept at temperature It is a positive electrode material for a zinc ion battery obtained after vacuum drying at 60° C. for 12 hours.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com