Composite solid-state electrolyte, solid-state battery and preparation method of solid-state battery

A solid-state electrolyte and solid-state battery technology, which is applied in composite electrolytes, secondary batteries, circuits, etc., can solve the problems of poor electrolyte flexibility and mechanical properties, poor stability and compatibility, and limited scope of application, and achieve good combination stability , good self-supporting flexibility, optimized contact interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] An embodiment of the present invention provides a method for preparing a solid-state battery, comprising the following steps:

[0045] S10. Dissolving the polymer, lithium salt, ionic liquid, and inorganic solid electrolyte material in an organic solvent and then mixing them to obtain an electrolyte slurry; wherein, the polymer, the lithium salt, the ionic liquid, and the inorganic The mass ratio of the solid electrolyte material is 1: (0.1-0.6): (0.1-1): (0.05-0.2);

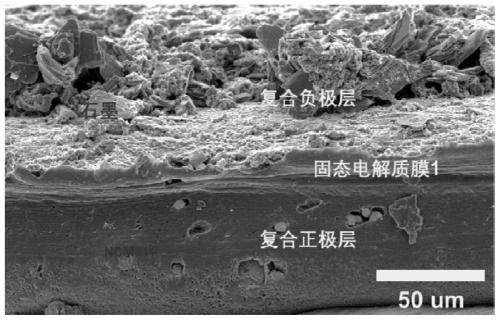

[0046] S20. Obtain the first pole piece, deposit the electrolyte slurry on the surface of the first pole piece away from the current collector, and form a composite solid electrolyte layer on the surface of the first pole piece;

[0047] S30. Deposit electrode slurry on the surface of the composite solid electrolyte layer away from the first pole piece to form a second pole piece to obtain a solid-state battery; wherein, the first pole piece and the second pole piece The sheets are independently selected...

Embodiment 1

[0075] A solid battery comprising the steps of:

[0076] ①Preparation of solid electrolyte membrane: PVDF, LiTFSI, ionic liquid (1-butyl-1-methylpyrrolidine bis(trifluoromethanesulfonyl)imide), LLZTO powder in mass ratio 100:50:30:10 , dissolved / dispersed in the solvent DMF and fully stirred for 8 hours to obtain a solid electrolyte slurry; pour the slurry into a polytetrafluoroethylene circular mold, heat and dry it under vacuum at 100°C overnight, and obtain a composite solid electrolyte membrane with a thickness of about 150 microns;

[0077] ② Preparation of positive electrode sheet: Dissolve / disperse positive electrode material NCM811, conductive agent sp, binder PVDF, and plasticizer succinonitrile in the solvent NMP in a ratio of 70:10:10:10, stir for 8 hours, and smear , 100 degrees vacuum heating and drying overnight to obtain the positive electrode sheet;

[0078] ③Preparation of solid-state battery: On the positive electrode sheet in step ②, control the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com