Steam gasification method for anthracite

A technology of anthracite and water vapor, applied in the field of coal gasification, can solve the problems of restricting the application of anthracite, high ignition point, and low volatile matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

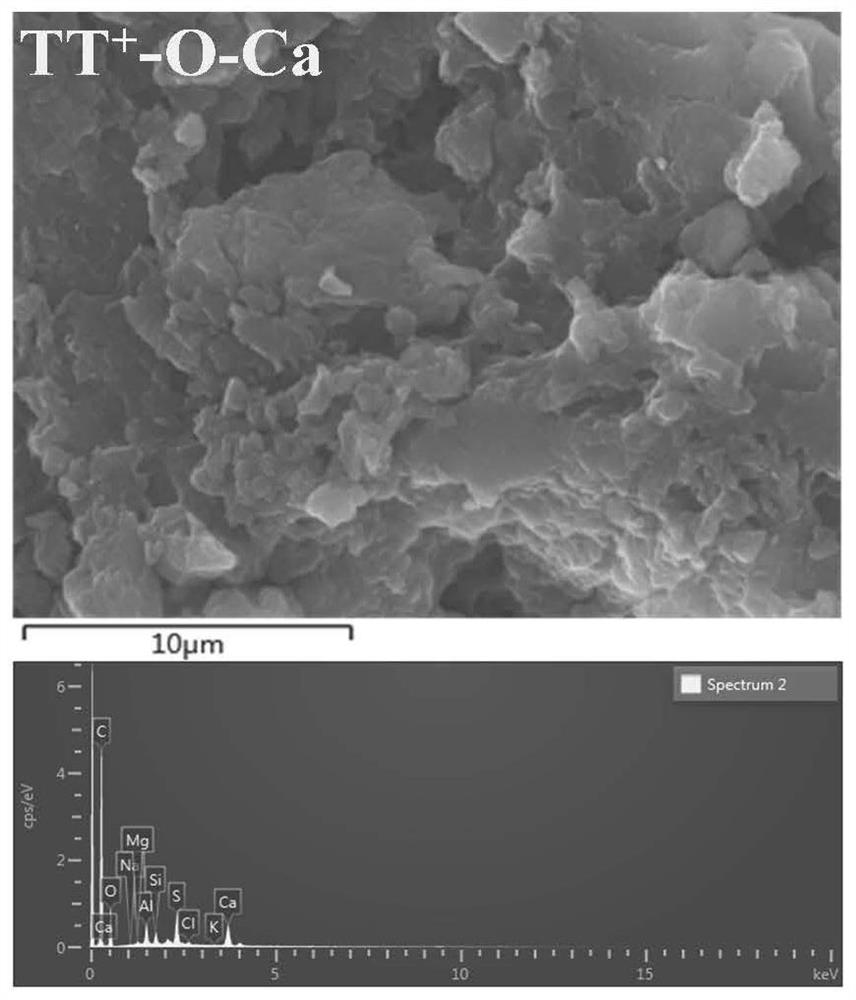

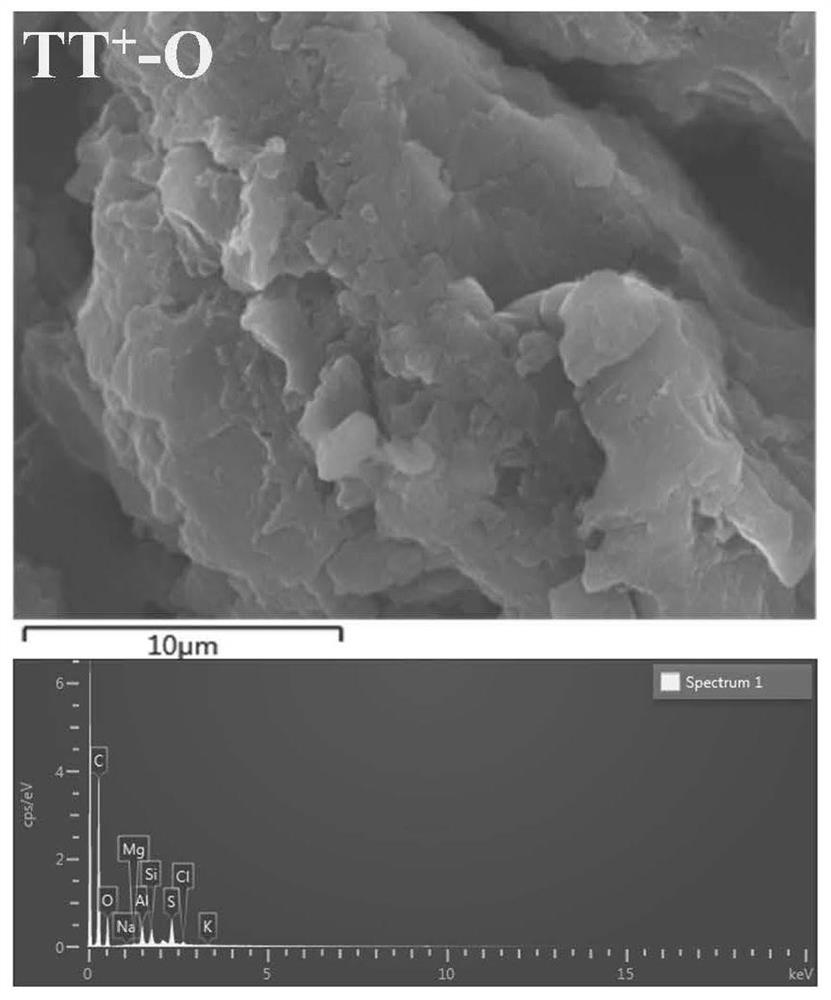

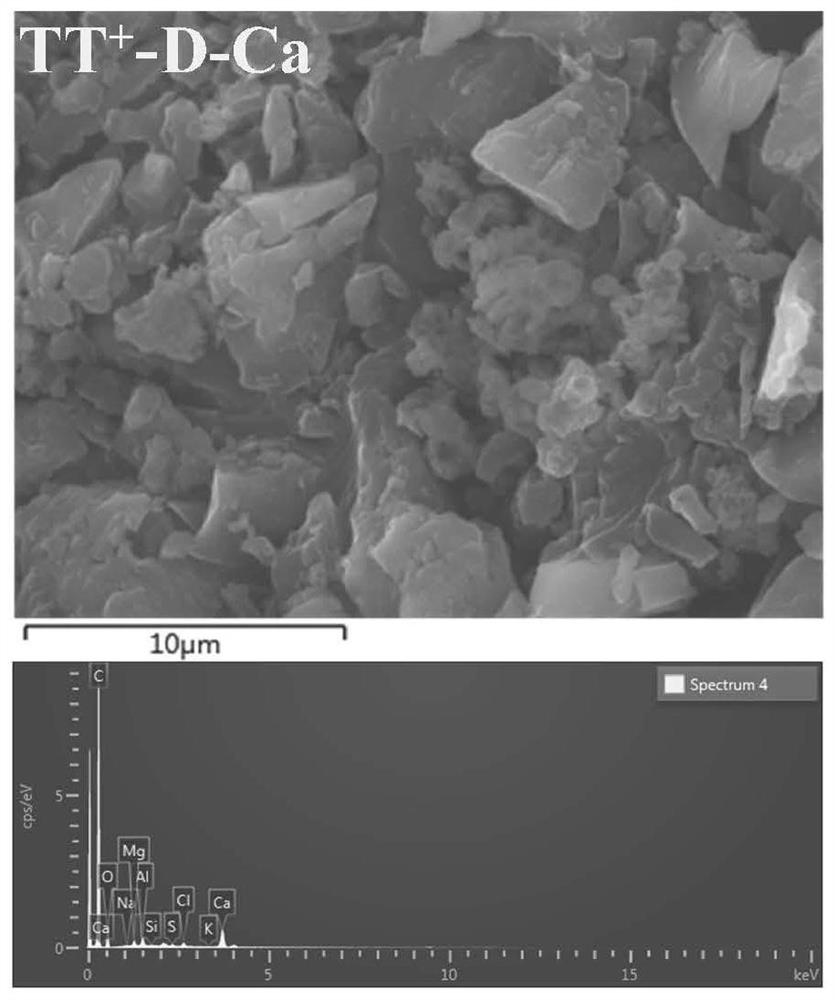

[0085] According to the ratio of 1g:10mL, the anthracite is placed in a hydrochloric acid solution with a mass concentration of 17% for pickling, at 200r·min -1 Pickling under the rotating speed of 12h, according to the ratio of 1g:10mL again, the anthracite after the hydrochloric acid solution pickling is placed in the hydrofluoric acid solution that mass concentration is 40%, at 200r·min -1 Pickling at a speed of 12 hours, then put the anthracite pickled with hydrofluoric acid solution in a Buchner funnel for suction filtration until the pH of the filtrate is neutral, and finally put the filter cake under a nitrogen atmosphere at 105°C Dry for 12 hours to obtain demineralized anthracite;

[0086] Crush the demineralized anthracite to a particle size of 200 mesh, weigh 10 g and place it in a beaker, add 180 mL of concentrated sulfuric acid with a mass concentration of 98%, and -1 Stir for 3 hours under the speed of rotation to obtain a black turbid liquid; at -4°C, slowly ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com