Cryogenic liquid gasification cold energy recycling device

A cryogenic liquid and cold energy recovery technology, applied in the field of heat exchange, can solve the problems of low recycling of high-quality cold energy, utilization rate not higher than 30%, and high cost of liquid refrigerant, so as to avoid waste, ensure safe production, The effect of saving cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

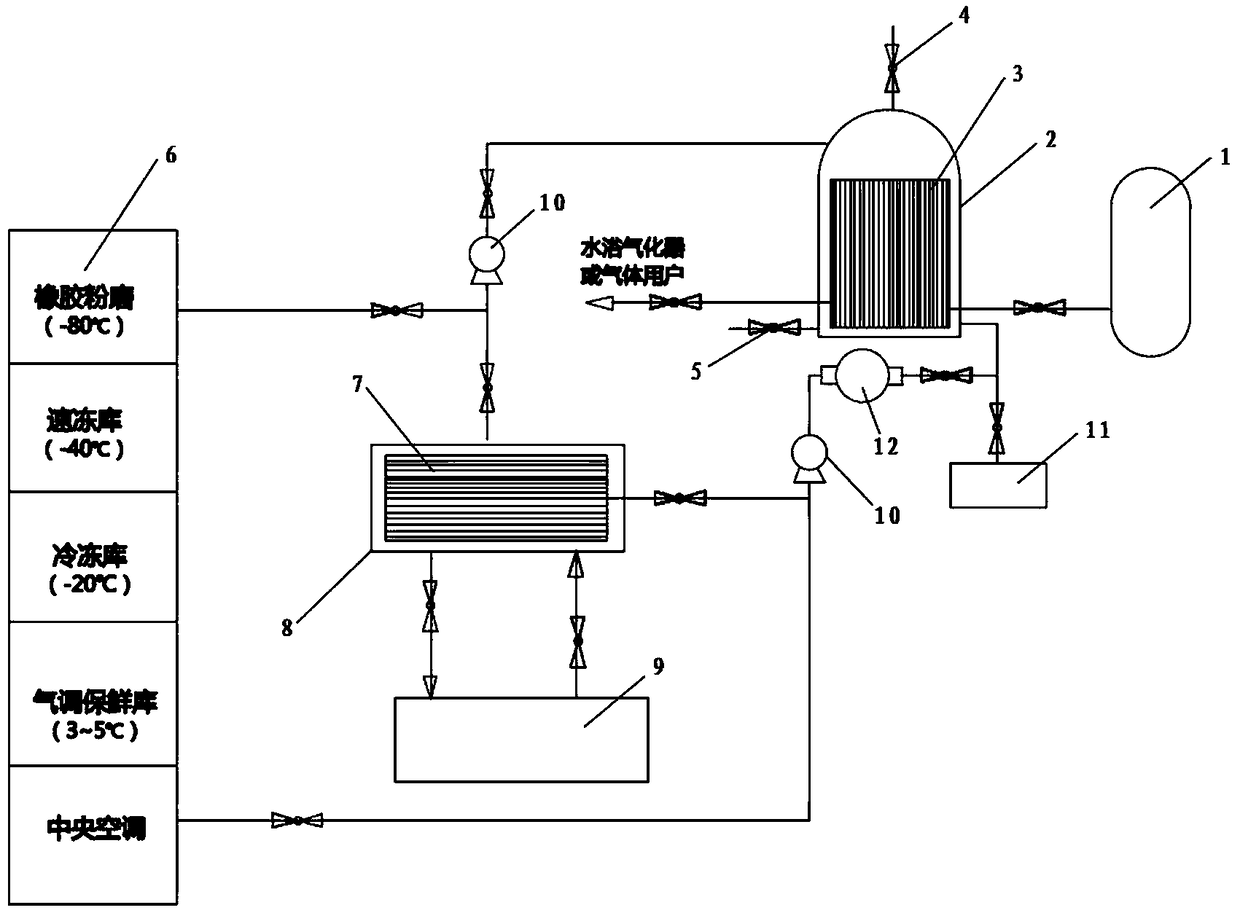

[0026] see figure 1 , figure 1 It is a cryogenic liquid gasification cold energy recovery and utilization device according to Embodiment 1 of the present invention. The device consists of a cryogenic liquid gasification system, a nitrogen circulation system and an end user to form a circulation loop. see figure 1 , the device specifically includes a cryogenic liquid storage tank 1, a nitrogen generator or a nitrogen storage container 11 and a closed nitrogen refrigerant vaporizer, the closed nitrogen refrigerant vaporizer includes a thermal insulation shell 2 and is arranged inside the thermal insulation shell 2 The heat exchanger 3 (specifically, it can be a heat exchange tube bundle group), the thermal insulation shell 2 is connected to the nitrogen generator or the nitrogen storage container 11 (specifically, it can be a nitrogen cylinder group), and the nitrogen generator or the nitrogen storage container 11 Provide circulating nitrogen gas into the heat preservation she...

Embodiment 2

[0038] According to an object of the present invention, the device should be able to adapt to small and medium-sized gasification devices as much as possible, and should also be able to adapt to multi-functional needs as much as possible. For this reason, different from the closed nitrogen refrigerant gasifier in Embodiment 1, the closed The nitrogen refrigerant vaporizer is a combination of multiple sets (not shown), which can be combined in series or in parallel. In this way, it can be flexibly designed according to the amount of gasification, which is more conducive to the cascade utilization of cold energy , the gasification effect is also better, and, under the premise of ensuring the cold energy recovery effect, the insulation shell 2 and the heat exchange tube bundle heat exchanger 3 of each set of the closed nitrogen refrigerant vaporizer can be designed to be better than The existing small size makes the overall structure of the device more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com