A method for detecting residual energy of a battery module

A battery module and detection method technology, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve the problems of high demand for testing instruments and high time and cost of residual energy detection, and achieve long-term solutions. Effect of discharge rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

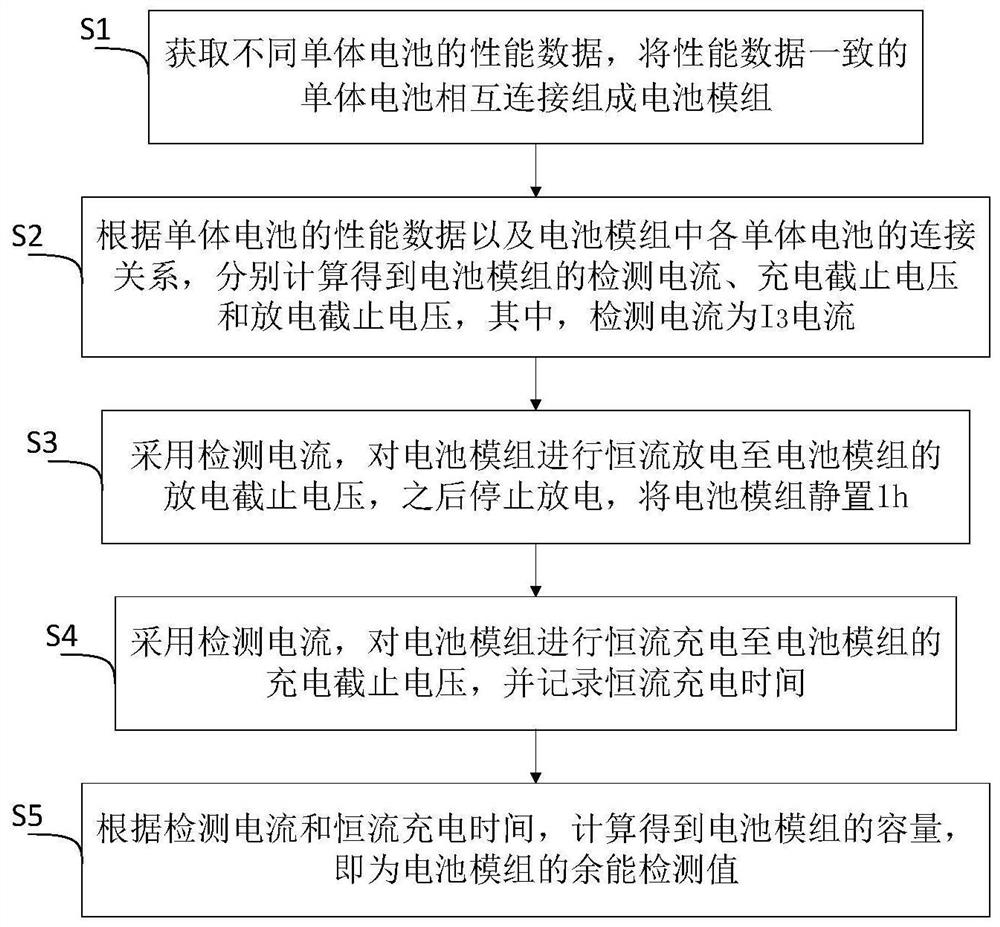

[0044] like figure 1 As shown, a method for detecting residual energy of a battery module includes the following steps:

[0045] S1. Obtain performance data of different single cells, and connect cells with consistent performance data to form a battery module;

[0046] S2, according to the performance data of the single cell and the connection relationship of each single cell in the battery module, calculate the detection current, charge cut-off voltage and discharge cut-off voltage of the battery module respectively, wherein the detection current is I 3 current;

[0047] S3. Use the detection current to discharge the battery module with constant current to the discharge cut-off voltage of the battery module, then stop the discharge, and let the battery module stand for 1h;

[0048] S4. Use the detection current to charge the battery module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com