Double-coal lock coal crushing, pressurizing and dry ash discharging gasification furnace

A technology of crushed coal pressurization and double coal locking, which is applied in fixed bed gasification, gasification device feeding tools, and the manufacture of combustible gas, etc. The effect of reducing the amount of dust and tar gas, improving gasification capacity, and reducing dust problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Low-rank coal with a water content of 35% is gasified, the gasification pressure is 4.0MPa, and the gasification temperature is 1050°C. The coal sample is crushed and screened to obtain a coal sample with a particle size of 5-50mm, which is loaded into the coal bunker for gasification. The raw material is then gasified through the following steps:

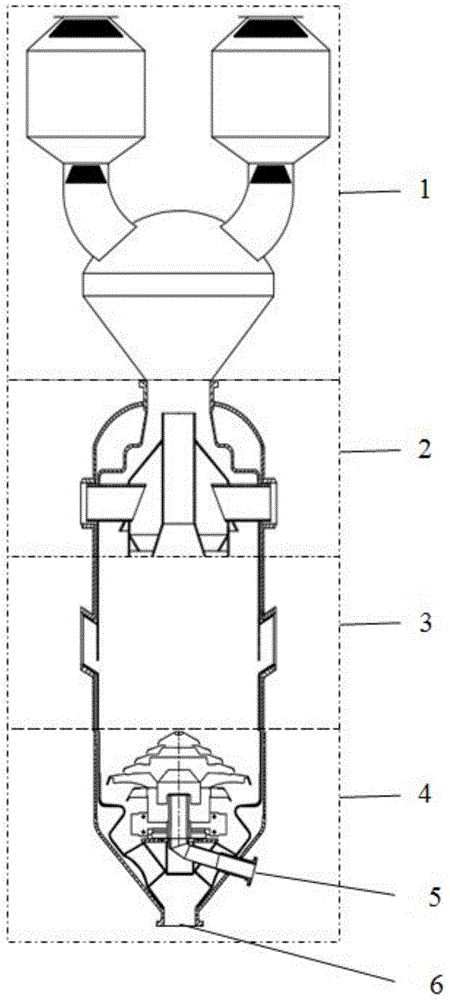

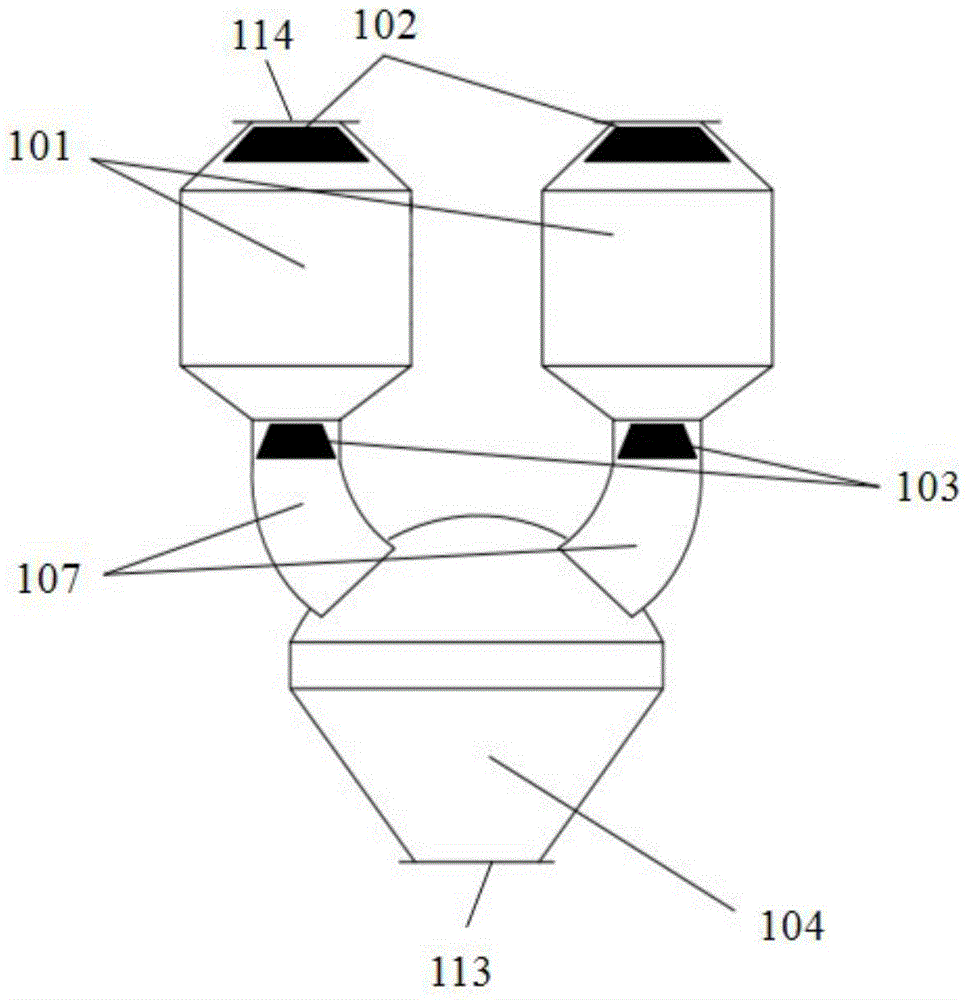

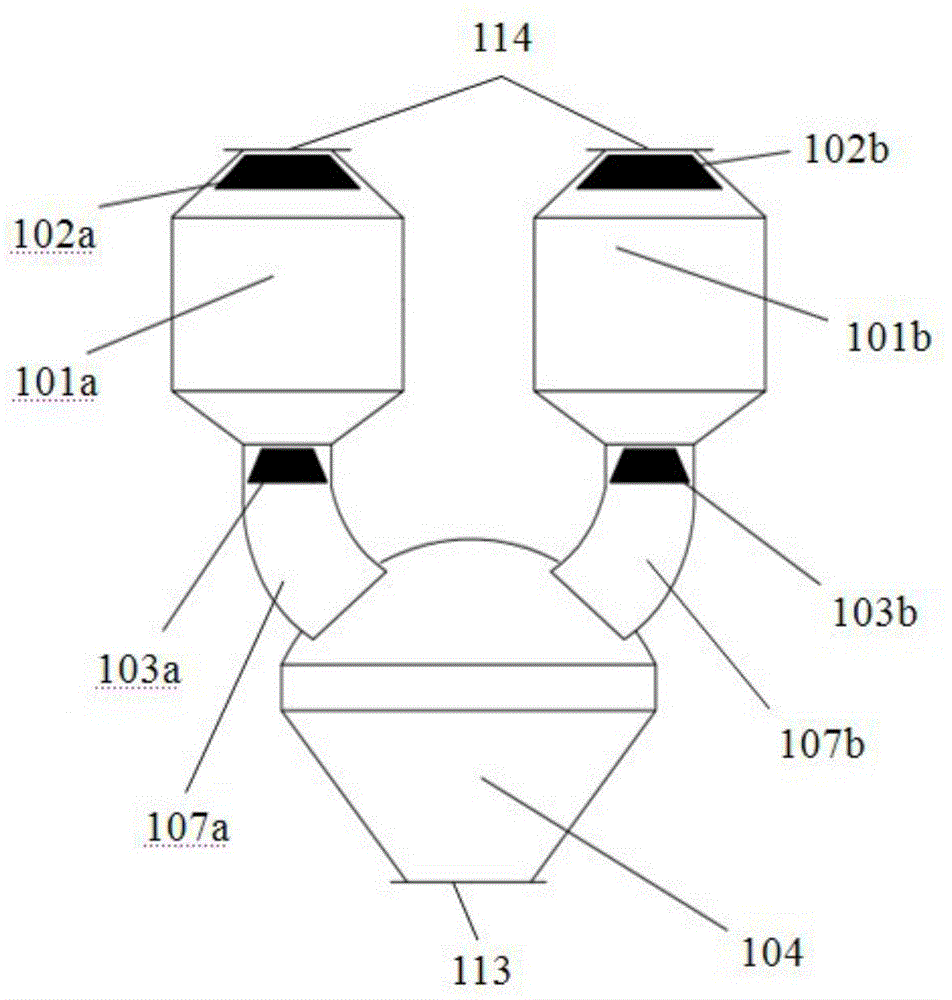

[0045] A new crushed coal pressurized dry ash gasification furnace, which includes a connected double coal lock feeding device 1 and a furnace body. There is a connected double coal lock feeding device 1 on the furnace body. Coal distributor 2, crude gas device 3 in the middle of the gasification chamber in the middle of the furnace body, rotary furnace grate 4 in the lower part of the furnace body, gasification agent inlet 5 and ash discharge port 6 at the bottom of the furnace body, gasification agent inlet 5 is located between the rotary grate 4 and the ash discharge port 6, and the gasification agent inlet 5 is connected...

Embodiment 2

[0054] Anthracite coal with a water content of 6% is used for gasification, the gasification pressure is 5.0MPa, and the gasification temperature is 1250°C. The coal sample is crushed and sieved to obtain a coal sample with a particle size of 5-50mm, which is loaded into the coal bunker to prepare raw materials for gasification. , and then gasify by the following steps:

[0055] Three gas passages 301 are provided in the middle of the gasification furnace to extract 36% of the crude gas. The position of the gas passages 301 on the inner wall 306 of the gasification furnace is measured from the bottom of the gasification chamber, which is 0.41 times the height of the gasification chamber. The included angle β307 is 35 degrees, the opening ratio of the baffle is 34%, the aperture of the small hole 303 is 6.4 mm, the baffle 302 is 1 / 6 circle, and the remaining 64% of the crude gas passes through the dry distillation and drying layer and then passes through the upper part of the ga...

Embodiment 3

[0057] Low-order bituminous coal with 20% water content is used for gasification, the gasification pressure is 5.4MPa, and the gasification temperature is 1150°C. The coal sample is crushed and sieved to obtain a coal sample with a particle size of 5-50mm, which is loaded into the coal bunker for gasification preparation. Good raw material, then gasification by the following steps:

[0058] There are four gas passages 301 in the middle of the gasification chamber to extract 5% of the crude gas. The gas passages 301 in the middle of the gasification chamber are measured from the bottom of the gasification chamber on the inner wall 306 of the gasification chamber. The height of the gasification chamber is 0.45 times. The included angle β307 is 32 degrees, the opening ratio of the baffle is 32%, the aperture of the small hole 303 is 4.4mm, the baffle 302 is 1 / 9 circle, and the remaining 95% of the crude gas passes through the dry distillation and drying layer and then passes thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com