LNG vaporizer with fuel heating function and heating control method thereof

A gas heating and heating control technology, applied in heat storage heaters, fluid heaters, container discharge methods, etc., can solve problems such as high operating costs, inability to meet gasification power, and inability to meet general pipeline gas transmission requirements, etc. Achieving good gasification effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

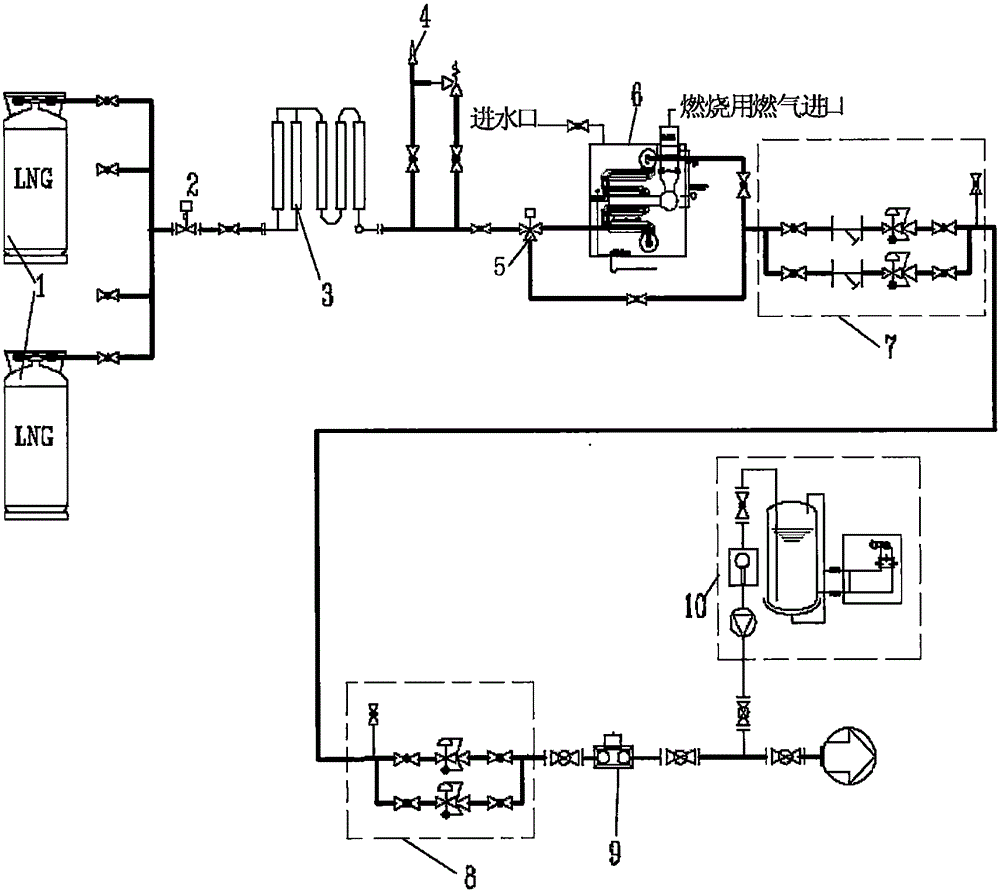

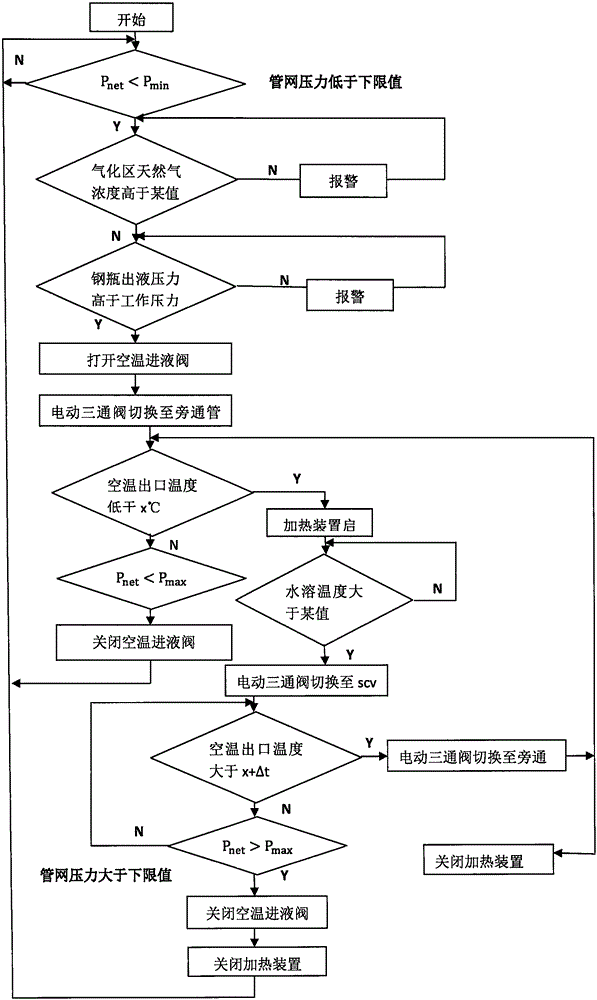

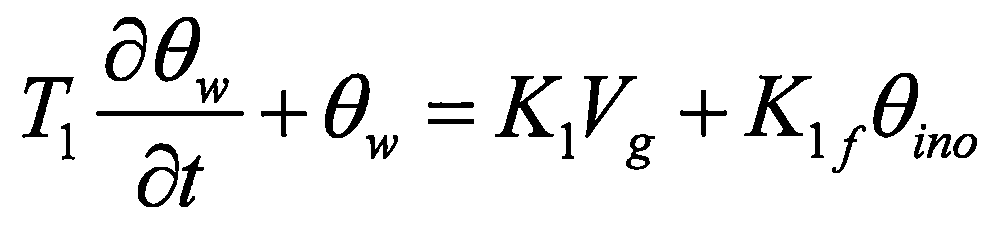

[0028] The principles and features of the present invention will be described below with reference to the accompanying drawings. The invention utilizes air heat source and gas combustion heat source to gasify LNG together. The LNG of the air-heated vaporizer realizes the gasification process by absorbing the heat of the external atmosphere, and the energy consumption is very low. In order to improve the heat exchange efficiency between LNG and the environment, the main part of the gasifier generally adopts low-temperature resistant aluminum alloy longitudinal finned tubes. It has a simple structure, small volume, light weight, easy manufacture and use, and large heat exchange area. Widely used in a low-temperature system. The main factors that affect the operation of the gasifier are flow rate, working cycle, working pressure, atmospheric temperature, relative atmospheric humidity, wind, sunshine and other conditions. The vaporizer should meet the following conditions:

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com