Method of in-situ filling symbiotic iron nanometer wire on thin wall nanometer pipe

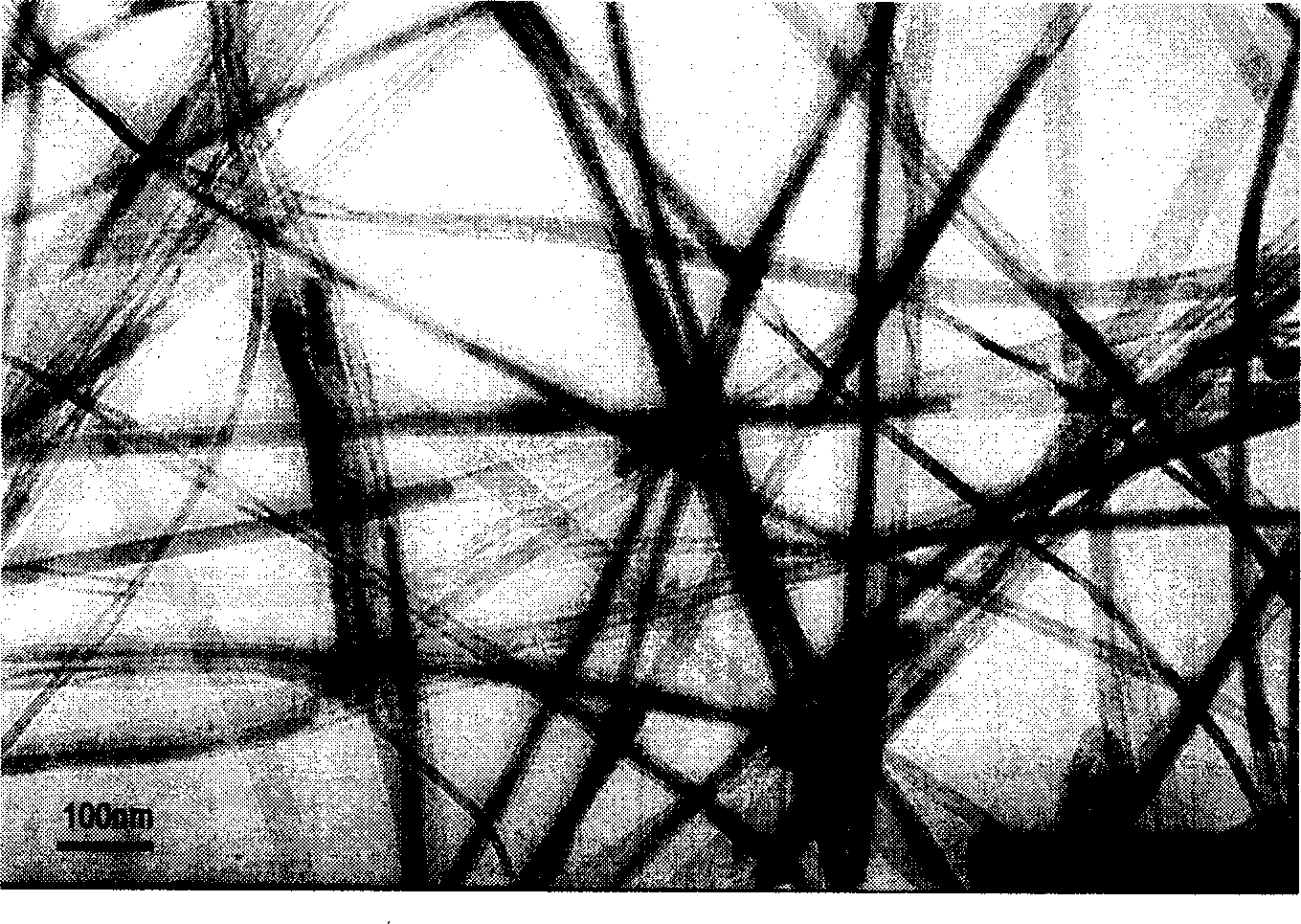

A technology of iron nanowires and carbon nanotubes, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of rough tube walls, low filling rate, and tube wall thickness, and achieve simple and controllable preparation processes. Strong controllability, simple process and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

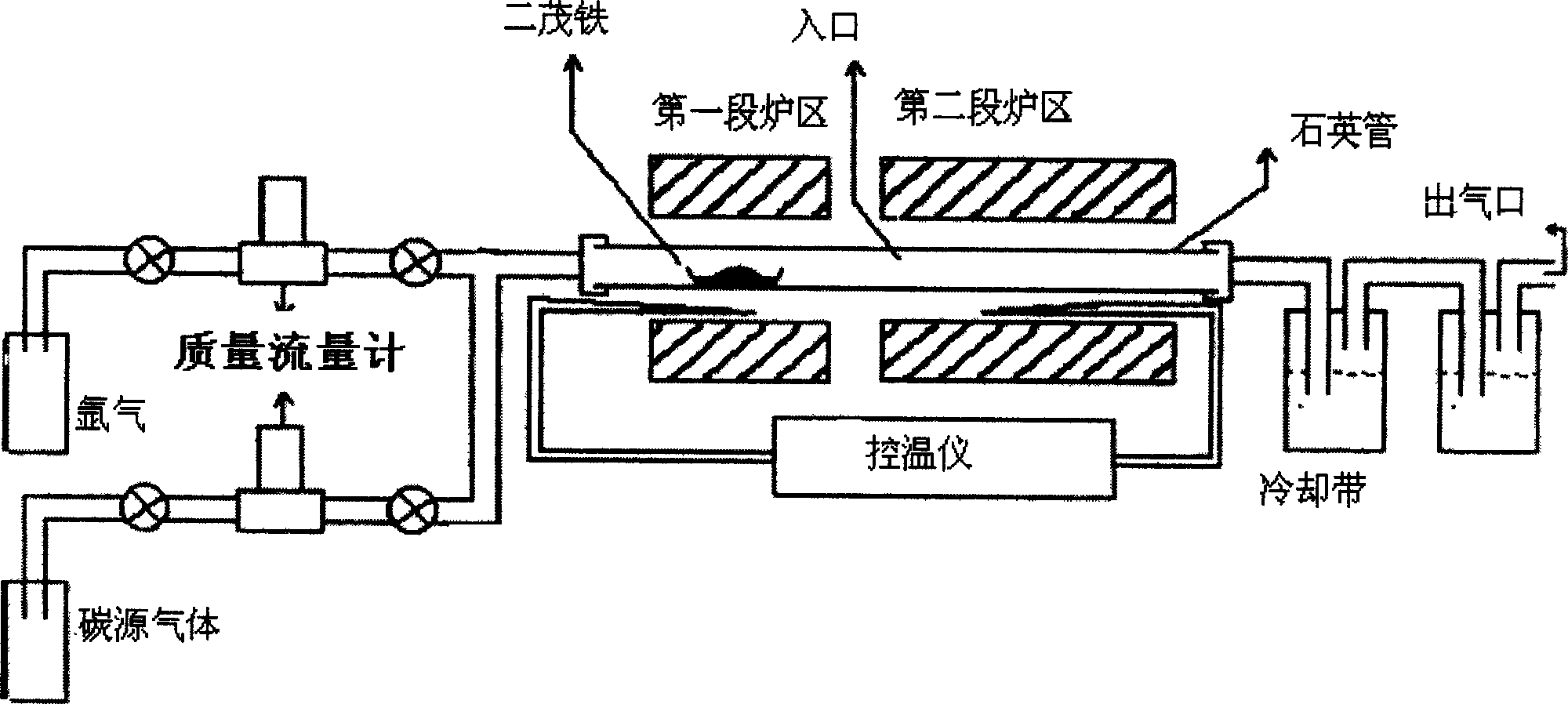

Method used

Image

Examples

Embodiment 1

[0039] 1) Weigh 1.0 g of ferrocene powder, dissolve it in 20 mL of dichlorobenzene solution, and mix evenly to form a brown-yellow transparent solution;

[0040] 2) Mount the quartz substrate on the quartz boat, then slowly push the quartz boat into the middle of the quartz tube, seal the two ends of the quartz tube with sealant, and use the heating gas expansion method to ensure the airtightness of the quartz tube.

[0041] 3) Pour argon gas into the quartz tube with a flow rate of 200mL / min, and heat it to the temperature required for the test at 750°C;

[0042] 4) Use a temperature controller to keep the temperature of the capillary port inserted into the quartz tube at 250°C;

[0043] 5) Adjust argon to 3000mL / min, and pass in 200mL / min of hydrogen;

[0044] 6) Turn on the precision flow pump and suck the reaction solution into the quartz tube at a feed rate of 0.4 mL / min;

[0045] 7) After 30 minutes, stop the hydrogen flow, reduce the argon flow rate to 200 mL / min, until the...

Embodiment 2

[0047] 1) Weigh 1.2 g of ferrocene powder and dissolve in 20 mL of dichlorobenzene solution and mix it evenly to form a brown-yellow transparent solution.

[0048] 2) Mount the quartz substrate on the quartz boat, then slowly push the quartz boat into the middle of the quartz tube, seal the two ends of the quartz tube with sealant, and use the heating gas expansion method to ensure the airtightness of the quartz tube.

[0049] 3) Pour argon gas into the quartz tube at a flow rate of 300 mL / min, and heat it to the temperature required for the test at 900°C.

[0050] 4) Use a temperature controller to keep the temperature of the capillary port inserted into the quartz tube at 300°C.

[0051] 5) Adjust the argon gas to 3000 mL / min, and pass in 200 mL / min hydrogen gas.

[0052] 6) Turn on the precision flow pump, and suck the reaction solution into the quartz tube at a feed rate of 0.6 mL / min.

[0053] 7) After 30 minutes, stop the hydrogen flow, reduce the argon flow rate to 200 mL / m...

Embodiment 3

[0055] 1) Weigh 1.8 g of ferrocene powder and dissolve in 20 mL of dichlorobenzene solution, mix it evenly to form a brown-yellow transparent solution.

[0056] 2) Mount the quartz substrate on the quartz boat, then slowly push the quartz boat into the middle of the quartz tube, seal the two ends of the quartz tube with sealant, and use the heating gas expansion method to ensure the airtightness of the quartz tube.

[0057] 3) Pour argon gas into the quartz tube at a flow rate of 300 mL / min, and heat it to the temperature required for the test at 820°C.

[0058] 4) Use a temperature controller to keep the temperature of the capillary port inserted into the quartz tube at 300°C.

[0059] 5) Adjust the argon gas to 3000 mL / min, and pass in 200 mL / min hydrogen gas.

[0060] 6) Turn on the precision flow pump, and suck the reaction solution into the quartz tube at a feed rate of 0.8 mL / min.

[0061] 7) After 30 minutes, stop the hydrogen flow, reduce the argon flow rate to 200 mL / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com