Nitrogen-doped porous carbon nanosheet-supported non-noble metal catalyst and preparation method thereof

A nitrogen-doped porous carbon, non-precious metal technology, used in chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc. Synthetic, good for repetition and environmental protection, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

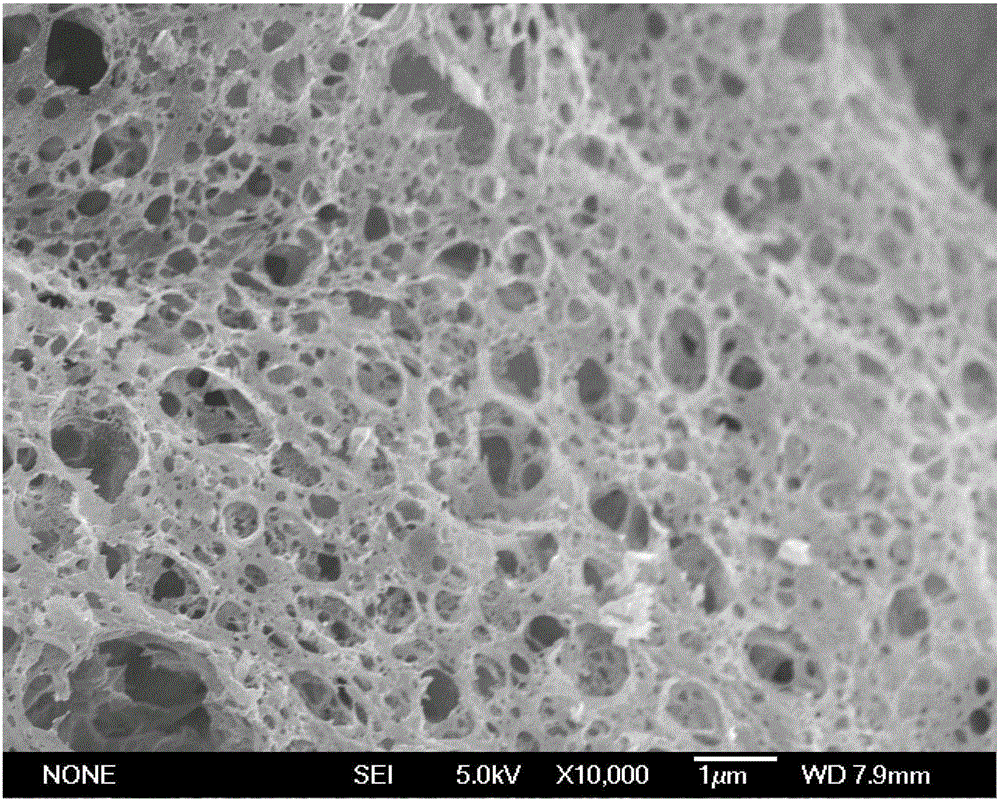

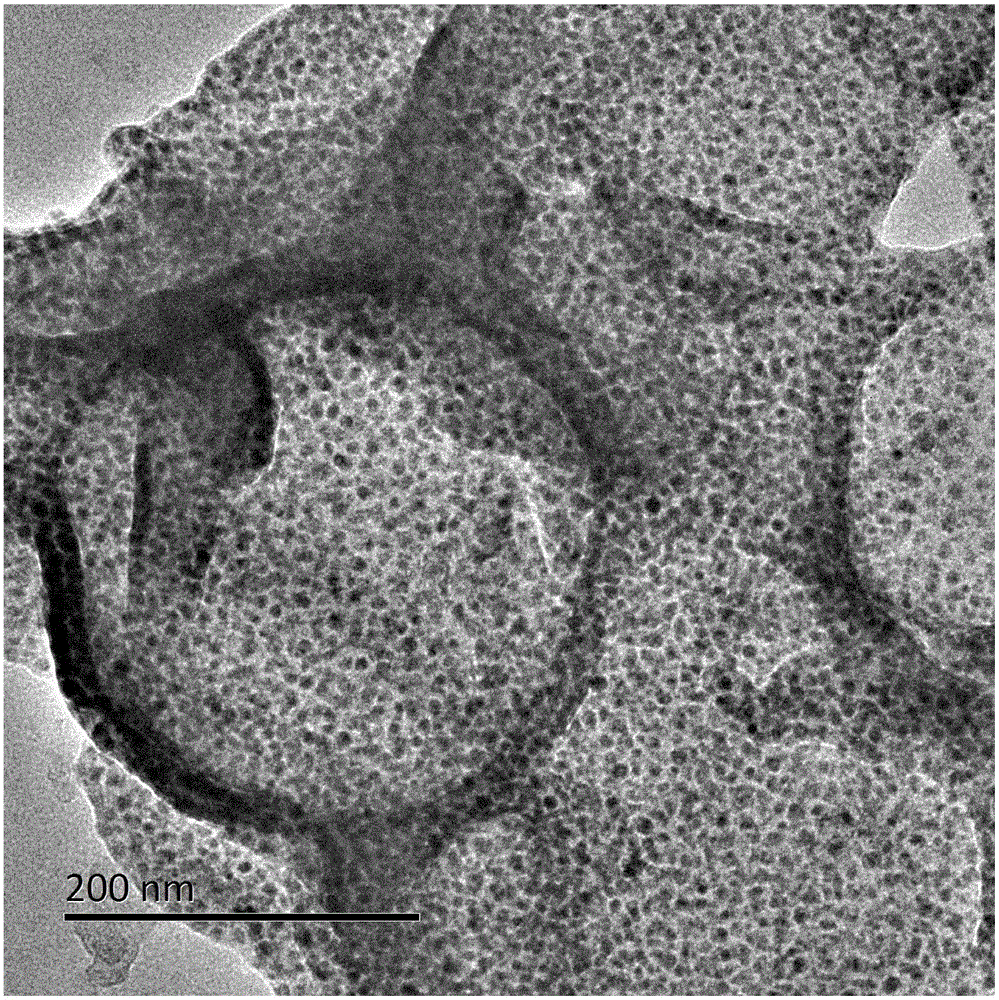

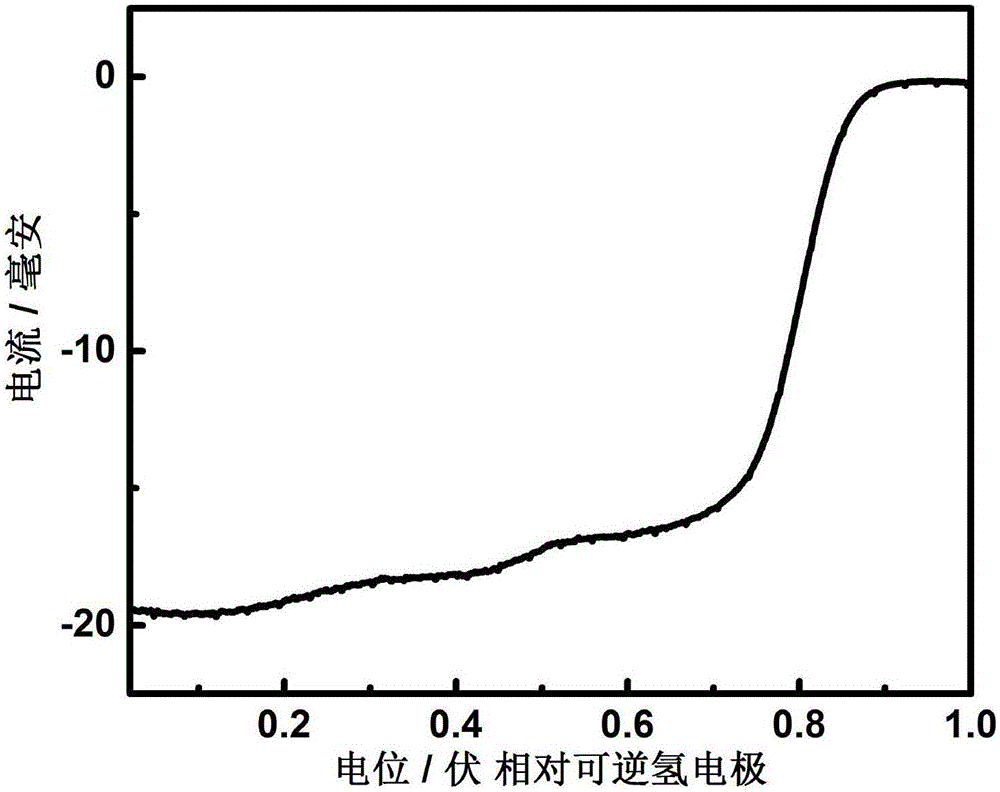

[0037] (1) Add 0.25 mol of vinylimidazole to a single-necked flask, then add 0.25 mol of nitric acid (concentration: 1 mol / L), stir at room temperature for 2 hours, then raise the temperature to 50°C, and stir for 12 hours to obtain a viscous liquid.

[0038] (2) Add 2.5 mol of cobalt nitrate to the ethanol solution of the viscous liquid above, stir at 70°C, react for 2 hours, and dry at 50°C to obtain a purple solid powder.

[0039] (3) Put the above solid powder into a porcelain boat, calcinate in a tube furnace, use N2 as protective gas, flow rate is 10mL / min, heat up to 100°C at a rate of 5°C / min, keep warm for 1 hour, and then The temperature was raised to 650°C at a rate of ℃ / min for calcination for 2 hours, and the product was naturally cooled to room temperature to obtain a black fluffy solid product, and the nitrogen-doped carbon nanosheet-supported Co catalyst was obtained after the product was ground.

Embodiment 2

[0041] (1) Add 0.1 mol of propenylimidazole to a one-necked flask, then add 1 mol of nitric acid, stir at room temperature for 2 hours, then raise the temperature to 60°C, stir for 15 hours, and obtain a viscous liquid.

[0042] (2) Add 0.05 mol of cobalt nitrate to the above viscous liquid, stir at 70° C., and react for 1 hour to obtain a purple solid powder.

[0043] (3) Put the above-mentioned solid powder into a porcelain boat, calcinate in a tube furnace, use N2 as protective gas, flow rate is 25mL / min, heat up to 100°C at a rate of 5°C / min, keep warm for 1 hour, and then The temperature was raised to 800°C at a rate of °C / min, kept at a temperature of 2 hours, and naturally cooled to room temperature to obtain a black fluffy solid, which was ground to obtain a catalyst powder.

Embodiment 3

[0045] (1) Add 1mol 1-butenylimidazole to a single-necked flask, then add 0.5mol nitric acid (concentration: 0.5mol / L), stir at room temperature for 2 hours, then heat up to 50°C and stir for 12 hours to obtain a viscous liquid .

[0046] (2) Add 0.05 mol of ferric nitrate to the above viscous liquid, stir at 70° C., and react for 2 hours to obtain solid powder.

[0047] (3) Put the above solid powder into a porcelain boat, calcinate in a tube furnace, use N2 as a protective gas, raise the temperature to 100 degrees at 5°C / min, keep it warm for 1 hour, then raise the temperature to 900°C at 5°C / min, and keep it warm After two hours, the temperature was naturally lowered to obtain a black fluffy solid, which was ground to obtain a catalyst powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com