Preparation method of silicon carbide single crystal with reduced carbon wrapping

A silicon carbide single crystal and carbon wrapping technology, which is applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problem that the silicon carbide crystal growth conditions are not easy to control, reduce the degree of graphitization of silicon carbide crystals, and have less difficulty in operation. and other problems, to achieve the effect of reducing structural defects, reducing the degree of graphitization, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

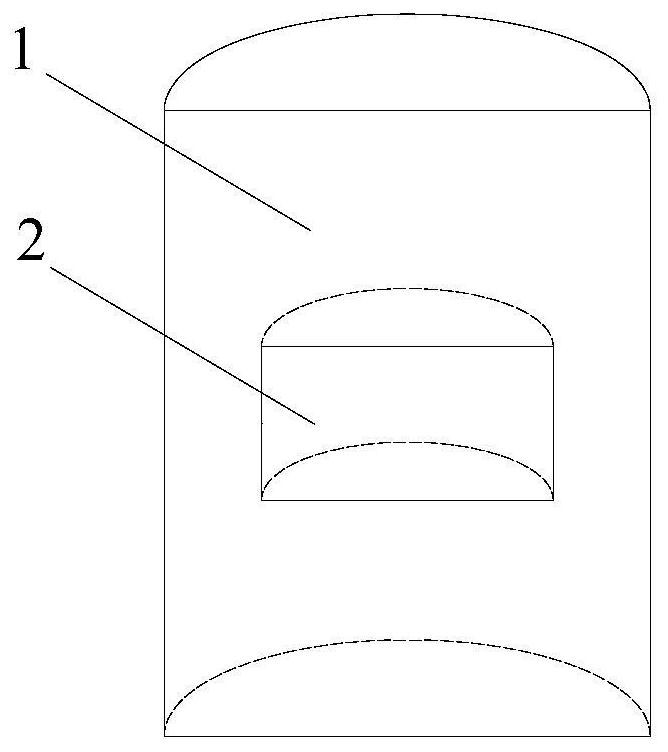

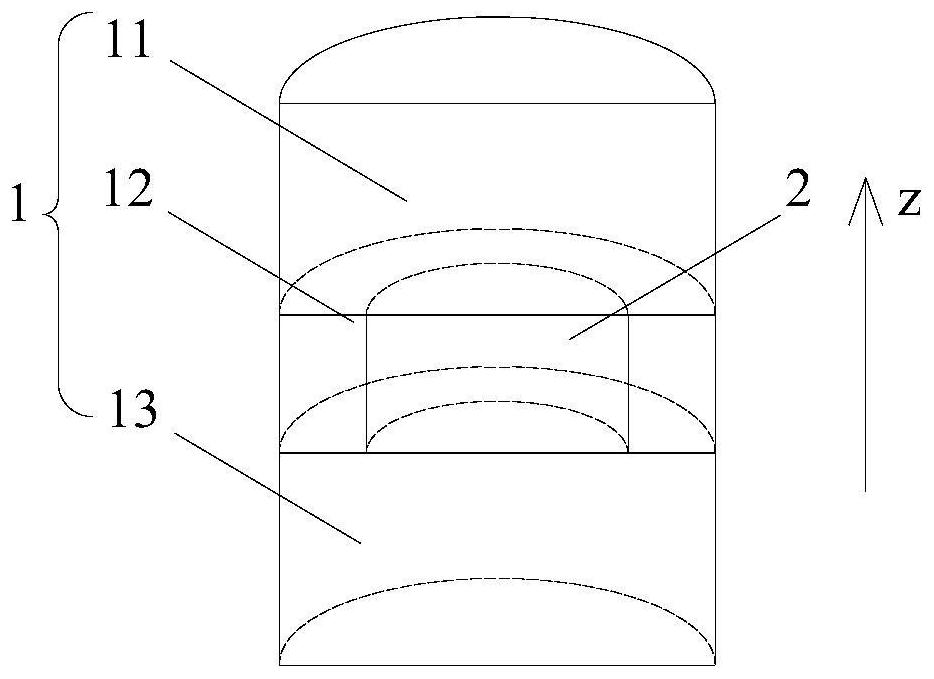

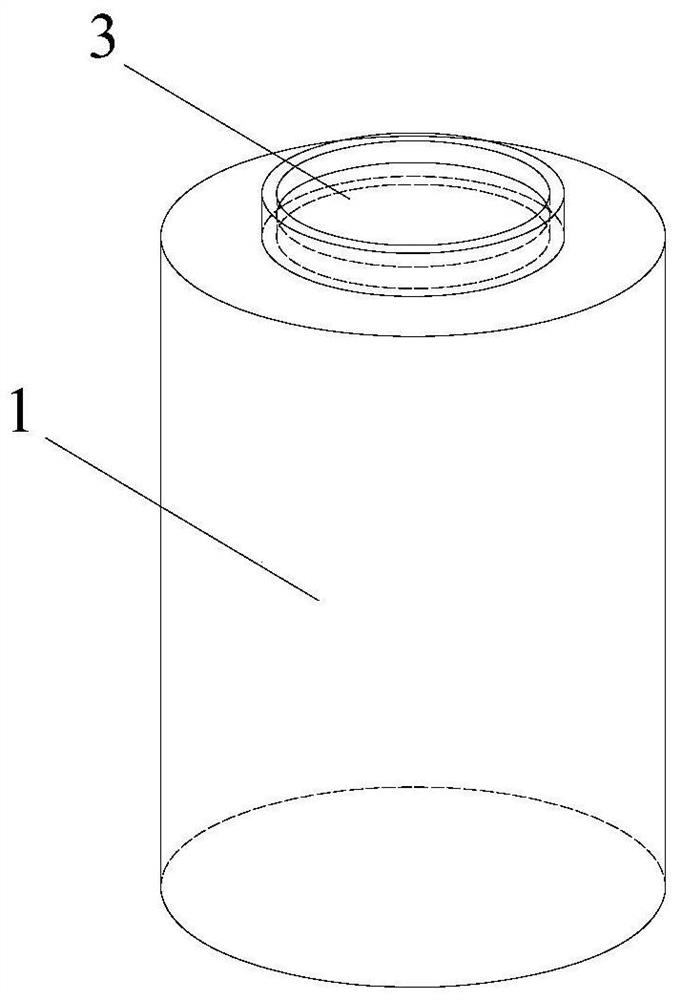

[0028] As previously mentioned, the present invention provides a method for reducing a silicon carbide single crystal of carbon wrapping, the method comprising the step of charge and long crystal, and the step of loading comprises: adding silicon carbide powder to a long crystal container. And oxides, oxides are silica and / or cerium oxide; wherein the silicon carbide powder and oxide form an encapsulated reaction structure, a laminated reaction structure, or a composite reaction structure; the wrapped reaction structure includes silica The layer 2 and the silicon carbide powder layer 1 wrapped outside the silica layer 2; the laminated reaction structure includes a silicon carbide powder layer 1 and a cerium oxide layer 3 disposed on the silicon carbide powder layer 1, a cerium oxide layer 3 and The silicon carbide powder layer 1 has a spacer without direct contact; the composite reaction structure includes a silicon dioxide layer 2, a silicon carbide powder layer 1 wrapped outsi...

Embodiment 1

[0049] (1) The silicon carbide powder is preheated at 300 ° C for 0.75 h.

[0050] (2) To the graphite crucible, the silicon carbide powder, silica, and cerium oxide, silicon carbide powder, silica powder, silica powder, silica powder, silica powder, silica powder 3kg of silicon carbide powder are added to the graphite crucible. ), The distance from the top of the silicon carbide powder is 20 mm from the top of the graphite crucible; wherein the silicon carbide powder, silica and cerium oxide form a composite reaction structure in the graphite crucible, see Figure 4The composite reaction structure includes a silicon dioxide layer 2, a silicon carbide powder layer 1 wrapped outside the silica layer 2 and a cerium oxide layer 3 disposed on the silicon carbide powder layer 1, and the cerium oxide layer 3 is placed as a The ratio of the barrier is placed and placed in the center position of the silicon carbide powder 11, the ratio of the tantalum crucible and the graphite crucible is ...

Embodiment 2

[0053] (1) The silicon carbide powder is preheated at 200 ° C for 1 h.

[0054] (2) To the graphite crucible, the silicon carbide powder, silica and cerium oxide, silicon carbide powder, silica powder, silicon dioxide powder, silica powder, silica powder, silicon carbide powder 3kg are 3100: 30: 1 ), The distance from the top of the silicon carbide powder is 20 mm from the top of the graphite crucible; wherein the silicon carbide powder, silica and cerium oxide form a composite reaction structure in the graphite crucible, see Figure 4 The composite reaction structure includes a silicon dioxide layer 2, a silicon carbide powder layer 1 wrapped outside the silica layer 2 and a cerium oxide layer 3 disposed on the silicon carbide powder layer 1, and the cerium oxide layer 3 is placed as a The ratio of the splitter is placed in the center position of the silicon carbide powder layer 11, the ratio of the tantalum crucible and the graphite crucible is 1: 100, and the silicon carbide pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com