Manufacturing method of carbon/carbon composite material brake disk friction pair for planes

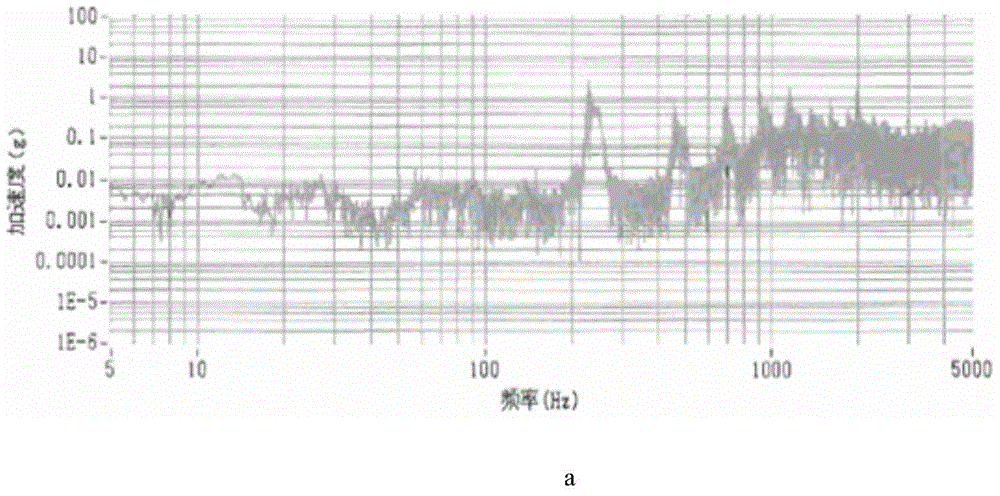

A technology of carbon composite materials and frictional duality, which is applied in the direction of brake discs, etc., can solve problems such as brake vibration and howling sound, large fluctuations in braking torque, and inconspicuous shock absorption effects, etc., to achieve reduced brake vibration and smooth braking Reliable, easy-to-implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

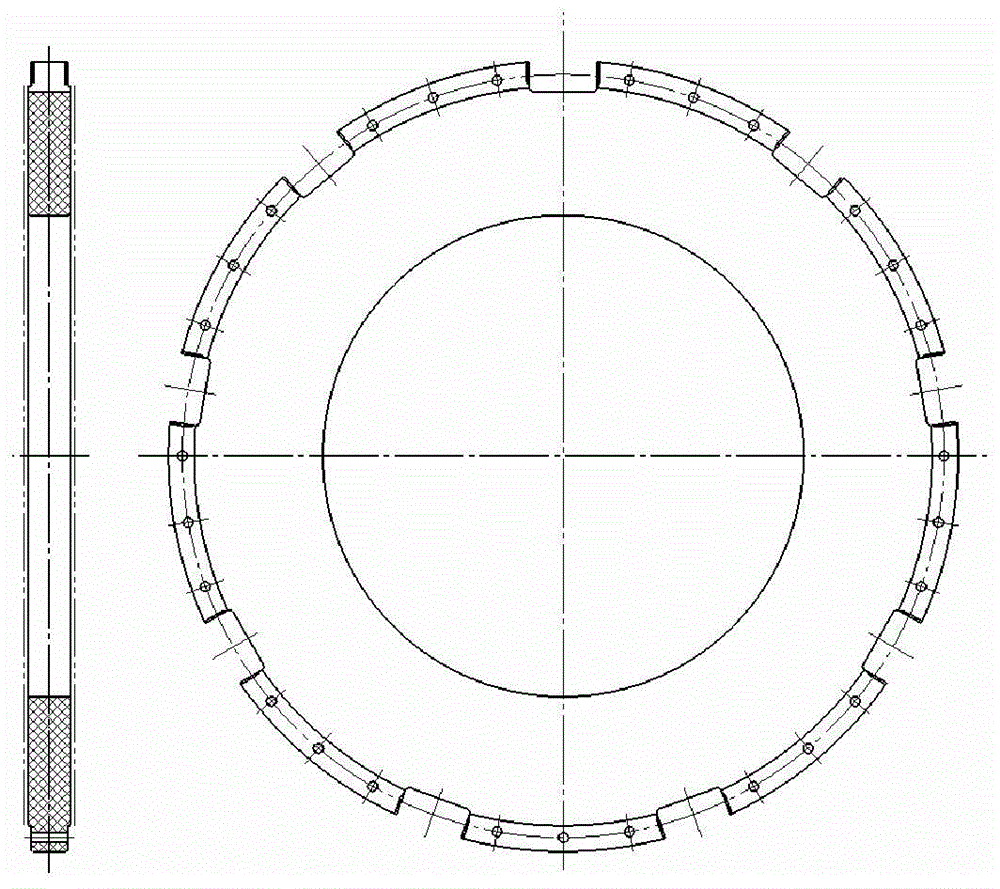

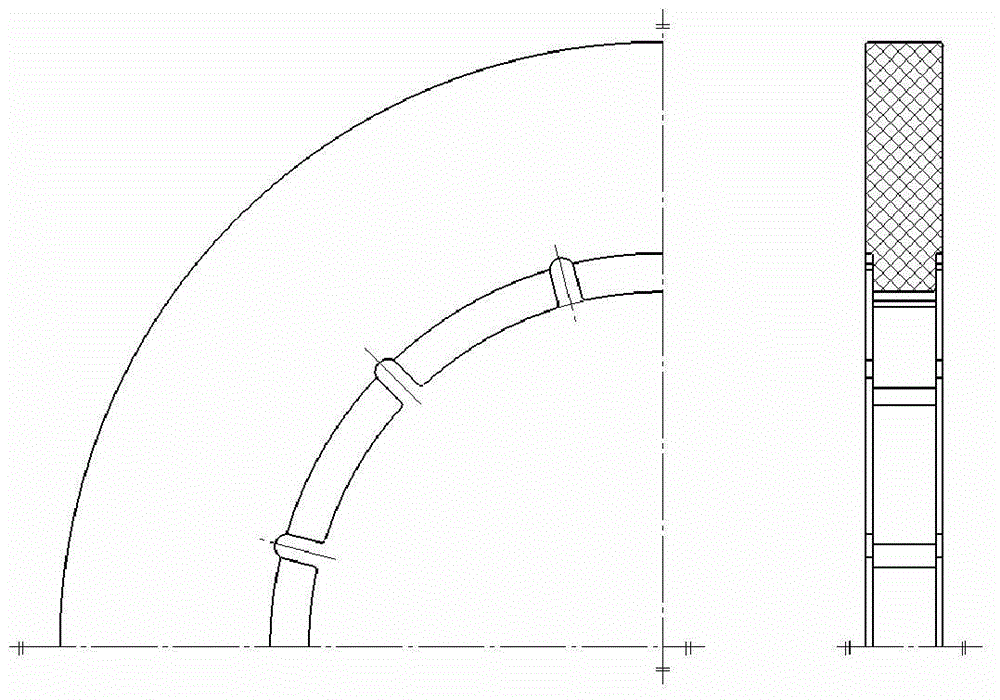

[0029] This embodiment is a method for preparing a friction couple of a carbon / carbon composite brake disc of an aircraft. The friction couple of the brake disc includes a moving disc and a static disc. The specific preparation process is:

[0030] Step 1. Prepare the moving disc.

[0031] The process of preparing the movable disk is to sequentially perform the first heat treatment, the first CVD deposition, rough machining, intermediate heat treatment, the second CVD deposition, the final heat treatment, and the finishing processing on the needle punched carbon felt of the movable disk as a whole, specifically:

[0032] Place the integral needle-punched carbon felt of the moving disc in a high-temperature furnace for the first heat treatment. The high-temperature furnace is evacuated until the furnace pressure is ≤500Pa, and the pressure is maintained for 10h. When the furnace pressure is ≤1.5KPa, the power is turned on, and the high-temperature heat treatment furnace is evacuated ...

Embodiment 2

[0050] This embodiment is a method for preparing a friction couple of a carbon / carbon composite brake disc of an aircraft. The friction couple of the brake disc includes a moving disc and a static disc. The specific preparation process is:

[0051] Step 1. Prepare the moving disc.

[0052] The process of preparing the movable disk is to sequentially perform the first heat treatment, the first CVD deposition, rough machining, intermediate heat treatment, the second CVD deposition, the final heat treatment, and the finishing processing on the needle punched carbon felt of the movable disk as a whole, specifically:

[0053] Place the integral needle-punched carbon felt of the moving plate in a high-temperature furnace for the first heat treatment. The high-temperature furnace is evacuated until the furnace pressure is ≤500Pa, and the pressure is maintained for 10.5h. When the furnace pressure is ≤1.5KPa, the power is turned on, and the high-temperature heat treatment furnace is evacuat...

Embodiment 3

[0071] This embodiment is a method for preparing a friction couple of a carbon / carbon composite brake disc of an aircraft. The friction couple of the brake disc includes a moving disc and a static disc. The specific preparation process is:

[0072] Step 1. Prepare the moving disc.

[0073] The process of preparing the movable disk is to sequentially perform the first heat treatment, the first CVD deposition, rough machining, intermediate heat treatment, the second CVD deposition, the final heat treatment, and the finishing processing on the needle punched carbon felt of the movable disk as a whole, specifically:

[0074] Place the integral needle-punched carbon felt of the moving plate in a high-temperature furnace for the first heat treatment. The high-temperature furnace is evacuated until the furnace pressure is ≤500Pa, and the pressure is maintained for 10.5h. When the furnace pressure is ≤1.5KPa, the power is turned on, and the high-temperature heat treatment furnace is evacuat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com