A kind of negative electrode and its preparation method and application

A technology of negative electrode and negative electrode slurry, which is applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of high expansion rate of silicon-carbon multi-component composite negative electrode material, poor doping uniformity, poor cycle performance, etc. Simple method, improved cycle life, and the effect of inhibiting pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

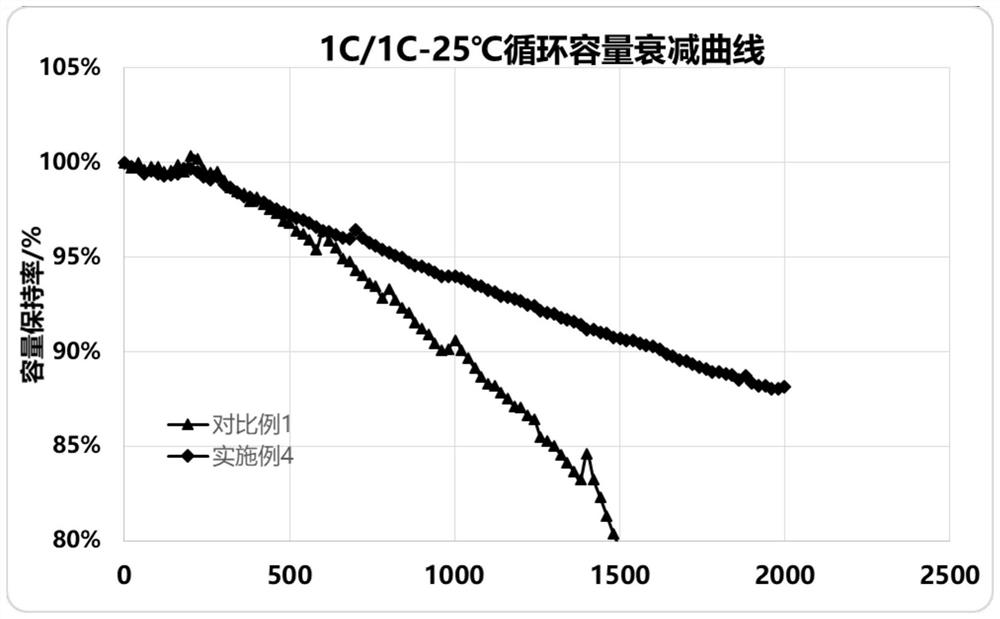

Examples

Embodiment 1

[0040] This embodiment provides a kind of negative pole, and described negative pole comprises copper foil and negative electrode active layer, and the silicon-oxygen material SiO that comprises natural graphite, graphene coating in described negative pole active layer 1.5 , Ketjen black and polyacrylic acid;

[0041] Among them, in the graphene-coated silicon-oxygen material, the mass proportion of graphene is 1.5%, and the graphene-coated silicon-oxygen material SiO 1.5 The mass proportion in all negative electrode active materials is 2%.

[0042] The preparation method of described negative electrode comprises:

[0043] (1) SiO material SiO 1.5 Stir with deionized water at a mass ratio of 1:13, sonicate, then add graphene slurry with a solid content of 4.5%, continue to stir, and then spray dry to obtain graphene-coated silicon-oxygen material SiO 1.5 ;

[0044] (2) Silicon-oxygen material SiO coated with natural graphite and graphene 1.5 , Ketjen Black, and polyacrylic ...

Embodiment 2

[0046] This embodiment provides a negative electrode, the negative electrode includes copper foil and a negative electrode active layer, the negative electrode active layer includes artificial graphite, graphene-coated silicon oxide material SiO, conductive carbon black, polyacrylic acid;

[0047] Wherein, in the graphene-coated silicon-oxygen material, the mass proportion of graphene is 2%, and the mass proportion of the graphene-coated silicon-oxygen material SiO in all negative electrode active materials is 2%.

[0048] The preparation method of described negative electrode comprises:

[0049] (1) Stir and ultrasonicate the silicon-oxygen material SiO and deionized water at a mass ratio of 1:15, then add graphene slurry with a solid content of 4.5%, continue stirring, and then spray dry to obtain graphene-coated Coated silicon-oxygen material SiO;

[0050] (2) Mix artificial graphite, graphene-coated silicon-oxygen material SiO, conductive carbon black, and polyacrylic aci...

Embodiment 3

[0052] This embodiment provides a kind of negative pole, and described negative pole comprises copper foil and negative pole active layer, and described negative pole active layer comprises artificial graphite, graphene-coated silicon-oxygen material SiO 0.5 , acetylene black, sodium carboxymethylcellulose, polyacrylonitrile and styrene-butadiene rubber;

[0053] Among them, in the graphene-coated silicon-oxygen material, the mass proportion of graphene is 2%, and the graphene-coated silicon-oxygen material SiO 0.5 The mass proportion in all negative electrode active materials is 1.5%.

[0054] The preparation method of described negative electrode comprises:

[0055] (1) SiO material SiO 0.5 Stir with deionized water at a mass ratio of 1:15, sonicate, then add graphene slurry with a solid content of 4.5%, continue to stir, and then spray dry to obtain graphene-coated silicon-oxygen material SiO 0.5 ;

[0056] (2) Silicon-oxygen material SiO coated with artificial graphite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com