Lithium ion battery and preparation method thereof

A lithium-ion battery and conductive agent technology, applied in the lithium-ion field, can solve problems such as insufficient electrolyte and short cycle life of lithium iron phosphate batteries, and achieve the effect of optimizing battery cell design and prolonging cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

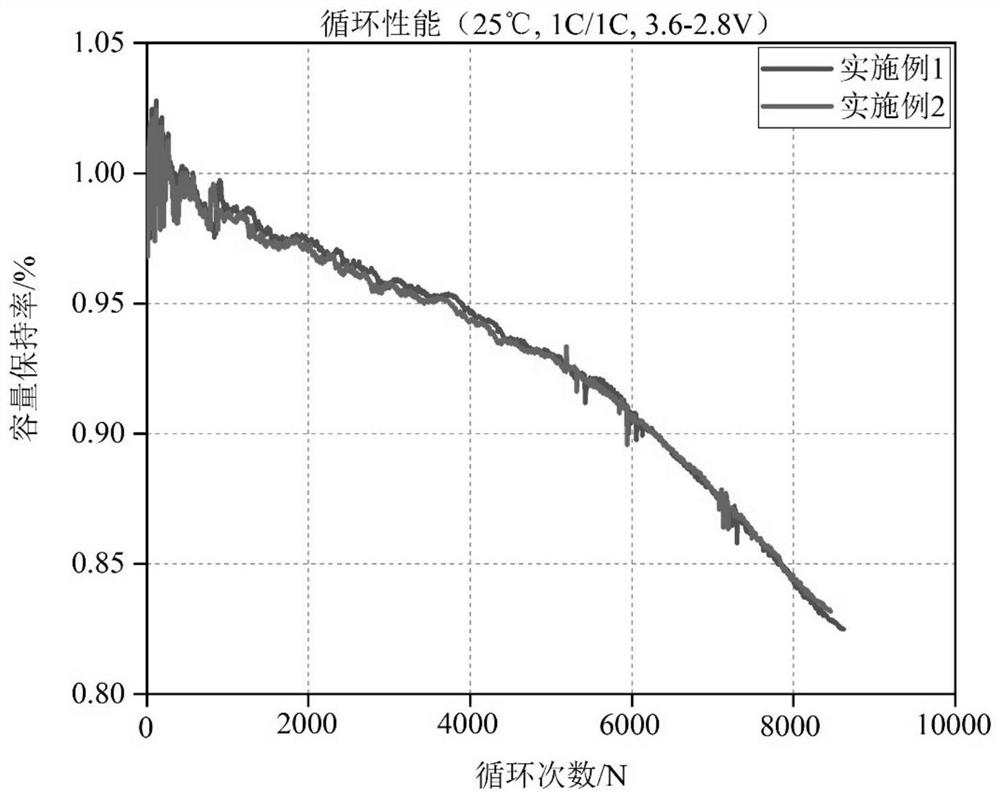

Examples

Embodiment 1

[0025] The positive electrode active material lithium iron phosphate (D 50 =0.55um), conductive agent SP, conductive agent CNT and positive electrode binder PVDF are weighed according to the weight ratio of 95:1:1:3, homogenized and coated on 12um aluminum foil, double-sided coated surface density 300g / m 2 , compacted density 2.25g / cm 3 , slitting, die-cutting, and making the positive electrode sheet;

[0026] Weigh the negative electrode active material graphite, conductive agent SP, negative electrode binder CMC and negative electrode binder SBR according to the weight ratio of 95.5:1:1.5:2, homogenize and coat on 4.5um copper foil, double-sided coating Area density 150g / m 2 , compacted density 1.50g / cm 3 , slitting, die-cutting, and making the negative electrode sheet;

[0027] The obtained positive electrode sheet and negative electrode sheet are laminated in a zigzag shape with a base film thickness of 12um and a double-sided adhesive layer thickness of 2um, with 29 l...

Embodiment 2

[0030] The positive electrode active material lithium iron phosphate (D 50 =1um), conductive agent SP, conductive agent CNT and positive electrode binder PVDF weighed according to the weight ratio of 94.5:1:1.5:3, homogenized and coated on 12um aluminum foil, double-sided coating surface density 280g / m 2 , compacted density 2.25g / cm 3 , slitting, die-cutting, and making the positive electrode sheet;

[0031] Weigh the negative electrode active material graphite, conductive agent SP, negative electrode binder CMC, and negative electrode binder SBR according to the weight ratio of 95:1.5:1.5:2, and coat it on 4.5um copper foil after homogenizing, double-sided coating Area density 140g / m 2 , compacted density 1.50g / cm 3 , slitting, die-cutting, and making the negative electrode sheet;

[0032] Laminate the obtained positive electrode sheet and negative electrode sheet in a zigzag shape with a base film thickness of 12um and double-sided adhesive layer thickness of 2um, with 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com