Lithium ion battery non-aqueous electrolyte and lithium ion battery using same

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion battery non-aqueous electrolyte, can solve the problems of battery production cost and use cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

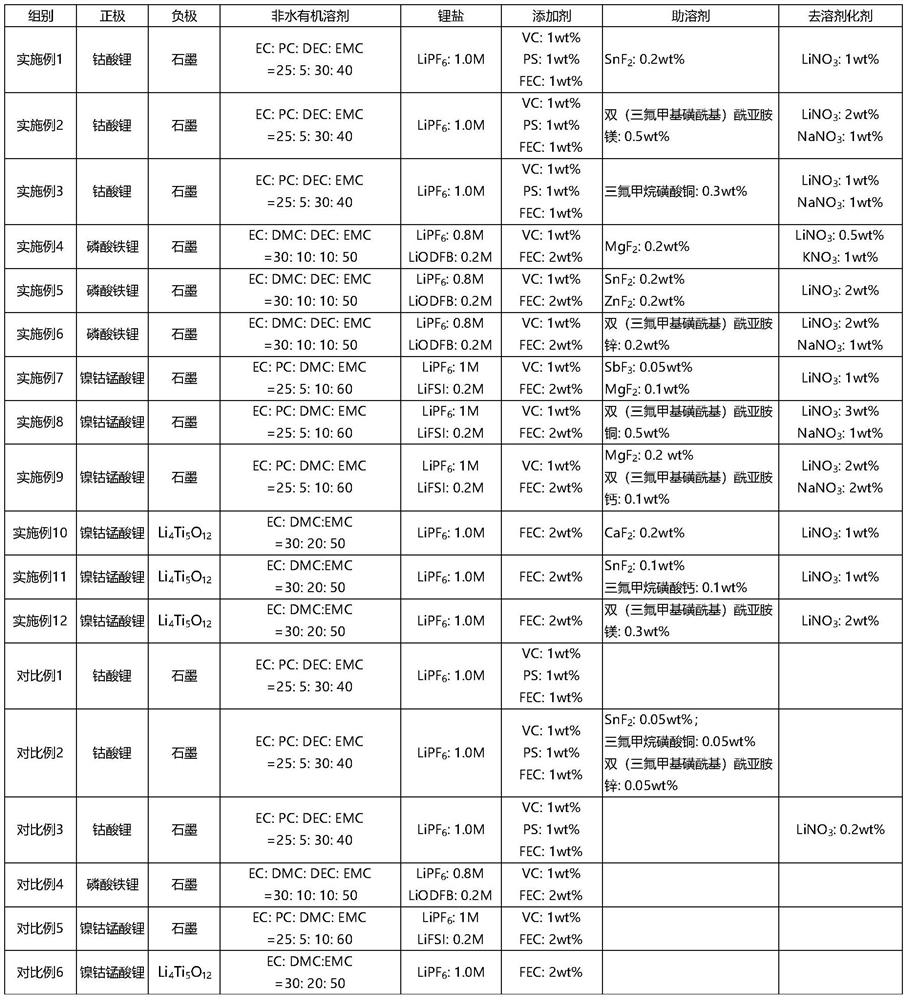

Embodiment 1

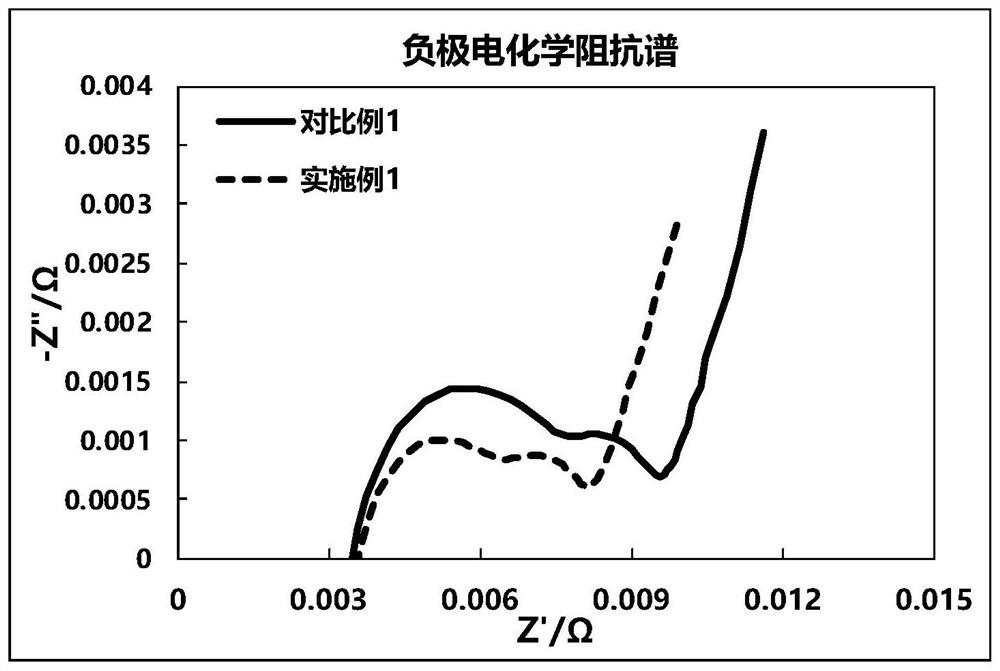

[0055] Example 1 Electrolyte was prepared by the following method: Ethylene carbonate (EC), propylene carbonate (PC), diethyl carbonate (DEC) and ethyl methyl carbonate were mixed in a glove box with water content 6 Dissolve to prepare an electrolyte with a lithium salt concentration of 1 mol / L; then, add an additive vinylene carbonate (VC) that accounts for 1% of the total electrolyte mass, and an additive 1 that accounts for 1% of the total electrolyte mass to the electrolyte, 3 propane sultone (PS) and additive fluorinated ethylene carbonate (FEC) accounting for 1% of the total mass of the electrolyte; after that, add 0.2% of the total electrolyte mass of the cosolvent SnF to the electrolyte 2 ; Finally, add the desolvation agent LiNO, which accounts for 1% of the total mass of the electrolyte. 3 , and fully stirred to obtain a non-aqueous electrolyte for lithium ion batteries.

[0056] The configured lithium-ion battery non-aqueous electrolyte is injected into the lithium ...

Embodiment 2

[0058] The composition of organic solvent, lithium salt and additive in the non-aqueous electrolyte of embodiment 2 is with embodiment 1; Difference is, in embodiment 2, in electrolyte, add the cosolvent two ( Trifluoromethylsulfonyl)imide magnesium; finally, add the desolvation agent LiNO accounting for 2% of the total mass of the electrolyte 3 and the desolvation agent NaNO, accounting for 1% of the total electrolyte mass 3 , and fully stirred to obtain a non-aqueous electrolyte for lithium ion batteries.

[0059] The configured lithium-ion battery non-aqueous electrolyte is injected into the lithium cobalt oxide / graphite soft pack battery, and the battery performance test is carried out through the processes of infiltration, formation, degassing, aging and capacity separation.

Embodiment 3

[0061] The composition of organic solvent, lithium salt and additive in the non-aqueous electrolyte of Example 3 is the same as that of Example 1; the difference is that in Example 3, the cosolvent trifluorocarbon that accounts for 0.3% of the total mass of the electrolyte is added in the electrolyte Copper methane sulfonate; finally, adding 1% of the total electrolyte mass, the desolvating agent LiNO 3 and the desolvation agent NaNO, accounting for 1% of the total electrolyte mass 3 , and fully stirred to obtain a non-aqueous electrolyte for lithium ion batteries.

[0062] The configured lithium-ion battery non-aqueous electrolyte is injected into the lithium cobalt oxide / graphite soft pack battery, and the battery performance test is carried out through the processes of infiltration, formation, degassing, aging and capacity separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com