High-voltage positive pole piece and lithium ion secondary battery comprising same

A technology of positive electrode and positive current collector, which is applied in the field of high-voltage positive electrode and lithium ion secondary battery containing the positive electrode, can solve the problems of battery fire, combustion, battery thermal runaway, etc., and improve the stability of performance. , improve safety performance, improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] As previously mentioned, the present invention also provides a method for preparing the above-mentioned positive electrode sheet for lithium-ion secondary batteries, comprising the following steps:

[0057] (1) Prepare the following mixed slurry:

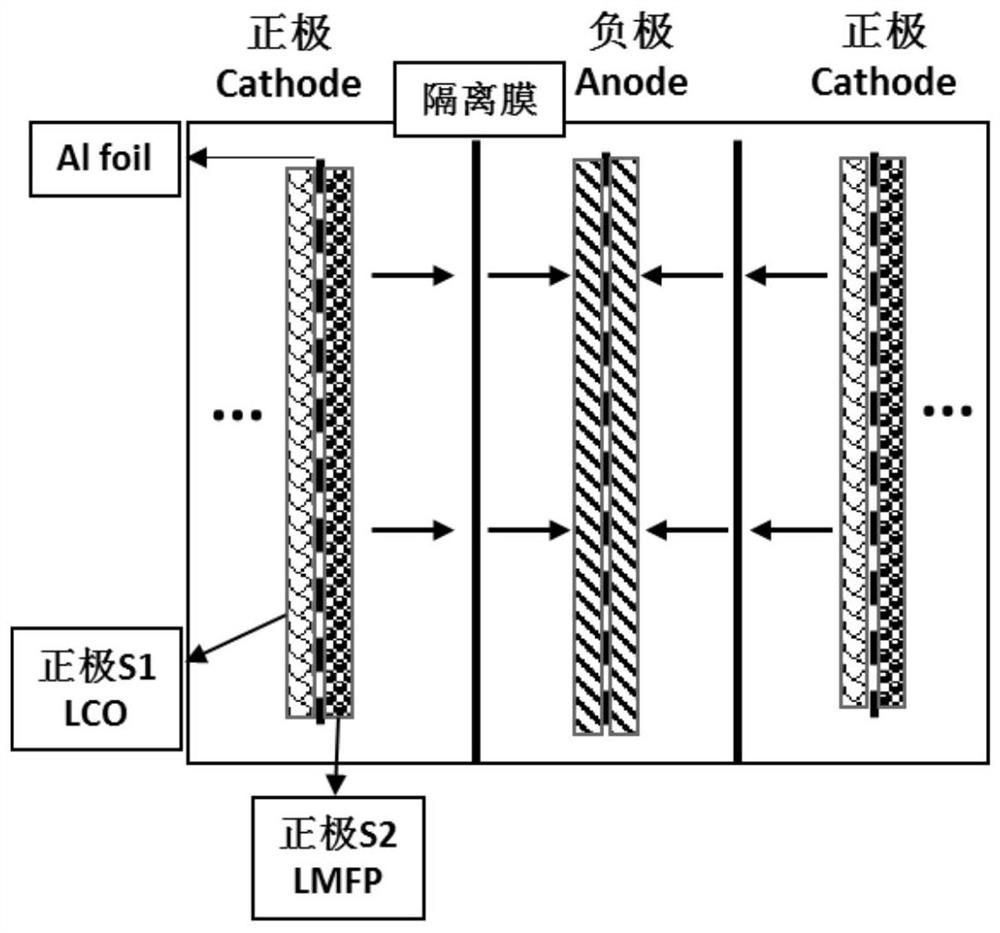

[0058] Mix and disperse lithium cobaltate, conductive agent and binder in an organic solvent uniformly to obtain mixed slurry S1; or,

[0059] Mix and disperse uniformly lithium iron manganese phosphate, a conductive agent and a binder in an organic solvent to obtain a mixed slurry S2; or,

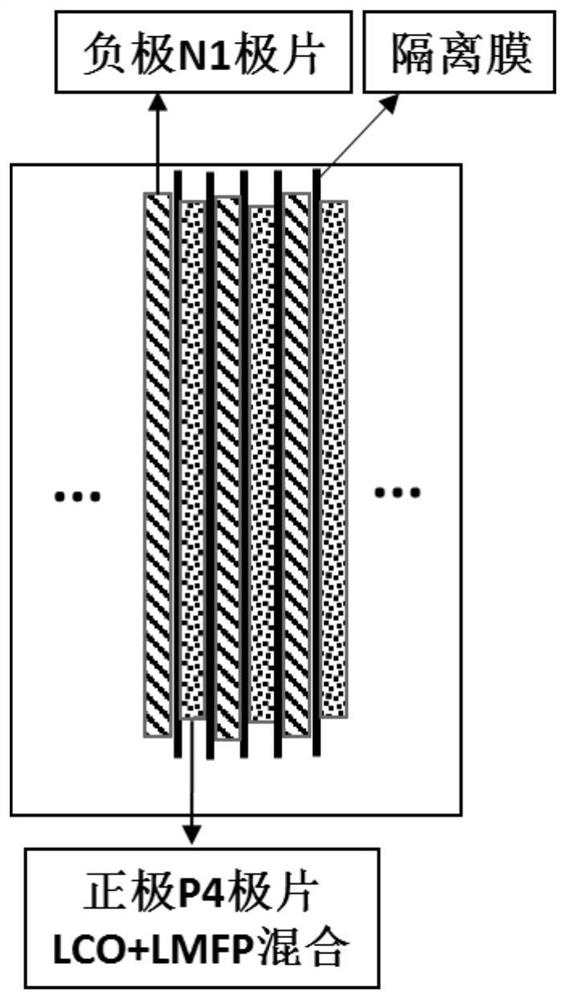

[0060] Mix lithium iron manganese phosphate, lithium cobaltate, conductive agent and binder in an organic solvent and disperse uniformly to obtain mixed slurry S3;

[0061] (2) Prepare the following positive pole pieces:

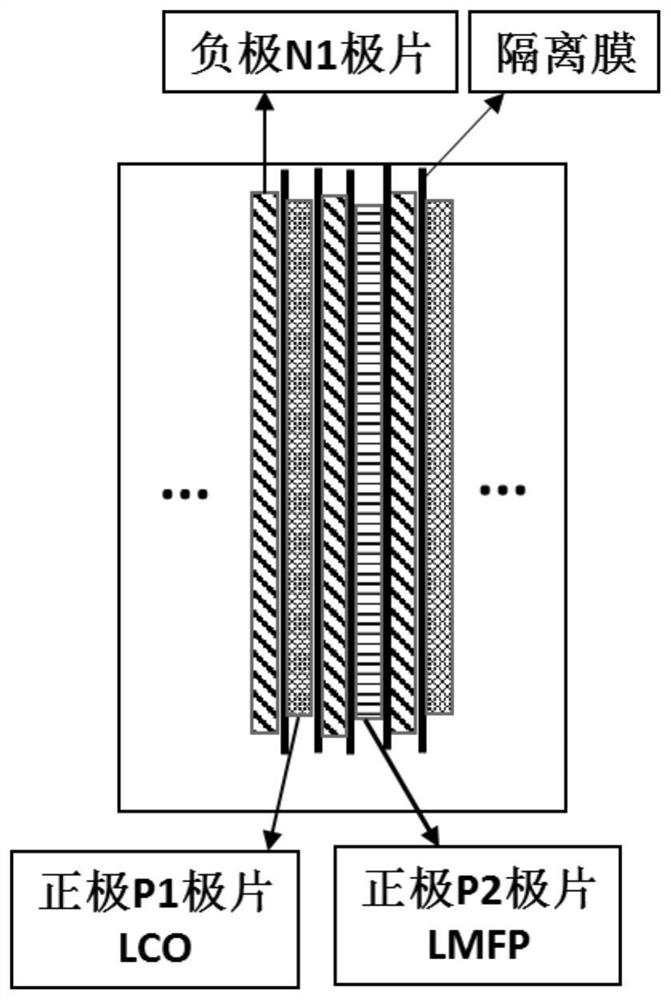

[0062] Coating the mixed slurry S1 on both sides of the positive electrode current collector to make the positive electrode sheet P1; or,

[0063] Coating the mixed slurry S2 on both sides of the positive electrode c...

preparation example 1

[0093] Mix the positive electrode active material LCO, the binder PVDF, and the conductive agent according to the mass ratio of 97wt%: 1.5wt%: 1.5wt%, and disperse them in N-methylpyrrolidone to make the positive electrode active material slurry S1, the slurry The solid content in is 70wt%. Apply the slurry S1 evenly on both sides of the aluminum foil, dry it under high temperature and vacuum at 100-120°C for 14 hours, and compact it with a roller press to 4.05g / cm 3 , the obtained positive pole piece is denoted as P1, and the thickness of the positive pole piece is 0.100mm.

preparation example 2

[0095] Mix the positive electrode active material LMFP, the binder PVDF, and conductive carbon black according to the mass ratio of 93.5wt%: 3.5wt%: 3.0wt%, and disperse them in N-methylpyrrolidone to make the positive electrode active material slurry S2 , the solid content in the slurry was 48wt%. Apply the slurry S2 evenly on both sides of the aluminum foil, dry it in vacuum at a high temperature of 100-120°C for 14 hours, and compact it with a roller press to 3.2g / cm 3 , the obtained positive pole piece is denoted as P2, and the thickness of the positive pole piece is 0.124 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com