A kind of preparation method of graphene composite lithium ion battery ternary cathode material

A lithium-ion battery and graphene composite technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of reducing the volumetric energy density of lithium-ion batteries, large amount of composite graphene, and poor batch stability. Realize the effects of high current rate discharge, high energy density and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

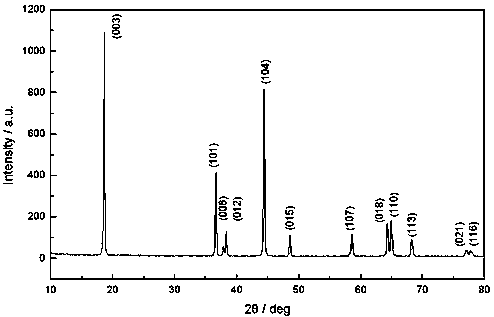

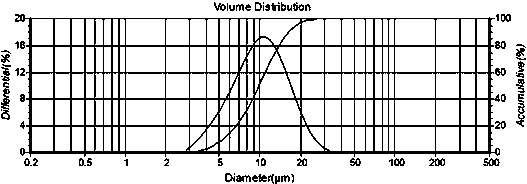

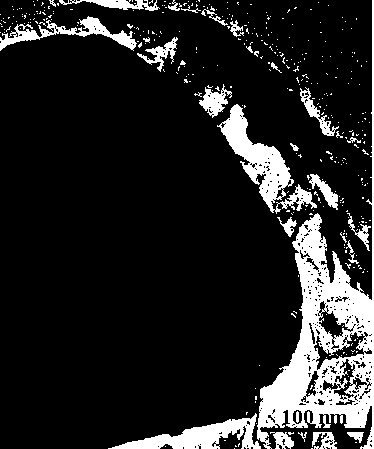

Image

Examples

Embodiment 1

[0032] Preparation process of graphene composite lithium-ion battery ternary cathode material:

[0033] (1) Preparation of ternary cathode material precursor by controlled crystallization-co-precipitation method

[0034] Prepare a mixed aqueous solution of nickel sulfate, manganese sulfate and cobalt sulfate. The total concentration of nickel, manganese and cobalt ions is 2.5mol / L, and the molar ratio of nickel, manganese and cobalt is 0.50:0.30:0.20, and an aqueous solution of sodium hydroxide is prepared. The concentration is 8.0mol / L L, the concentration of the configured ammonia water is 4.0mol / L, the above-mentioned nickel-manganese-cobalt mixed brine solution, sodium hydroxide, and ammonia water are respectively added to the reactor with 10L of primer in parallel flow with 3 metering pumps, and the volume of the reactor is The base liquid is 20L, the base liquid is deionized water, adjust the flow rate of the mixed salt solution, sodium hydroxide and ammonia water, contr...

Embodiment 2

[0047] Preparation process of graphene composite lithium-ion battery ternary cathode material:

[0048] (1) Preparation of ternary cathode material precursor by controlled crystallization-co-precipitation method

[0049] Prepare a mixed aqueous solution of nickel nitrate, manganese nitrate and cobalt nitrate. The total concentration of nickel, manganese and cobalt ions is 3.0mol / L, wherein the molar ratio of nickel, manganese and cobalt is 0.40:0.40:0.20, and an aqueous solution of sodium bicarbonate is prepared with a concentration of 1.5mol / L L, configure the mixed aqueous solution of ammonia water and disodium edetate, wherein the concentration of ammonia water is 1.8mol / L, the concentration of disodium edetate is 0.2mol / L, the above-mentioned nickel-manganese-cobalt mixed solution, bicarbonate Sodium, ammonia water and edetate disodium mixed solution are respectively fed into the reaction kettle with 10L of primer solution in parallel by 3 metering pumps, the volume of the...

Embodiment 3

[0055] Preparation process of graphene composite lithium-ion battery ternary cathode material:

[0056] (1) Preparation of ternary cathode material precursor by controlled crystallization-co-precipitation method

[0057] Prepare a mixed aqueous solution of nickel acetate, manganese acetate and cobalt acetate. The total concentration of nickel, manganese and cobalt ions is 1.5 mol / L, and the molar ratio of nickel, manganese and cobalt is 0.80:0.10:0.10. Lithium hydroxide aqueous solution is prepared with a concentration of 4.0 mol / L L, configure the mixed aqueous solution of ammonia water and citric acid, wherein the concentration of ammonia water is 2.5mol / L, and the concentration of citric acid is 0.3mol / L. 3 metering pumps are added in parallel to the reactor with 10L primer solution, the volume of the reactor is 20L, the primer solution is deionized water, and the flow rate of the mixed salt solution, lithium hydroxide, ammonia water and citric acid mixture is adjusted. Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com