Electrode plate and lithium ion battery comprising same

An electrode sheet and negative electrode technology, applied in battery electrodes, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problems of not requiring extensibility, deterioration of electrical properties, etc., to avoid short circuits and improve acupuncture safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

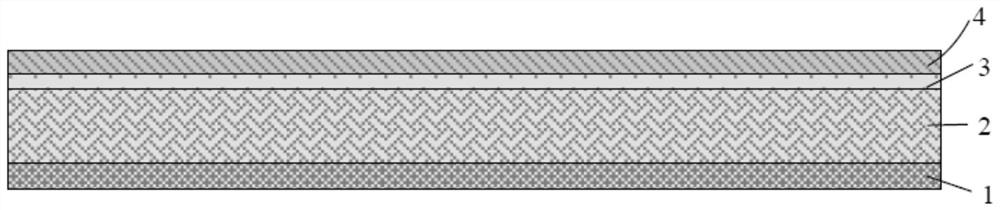

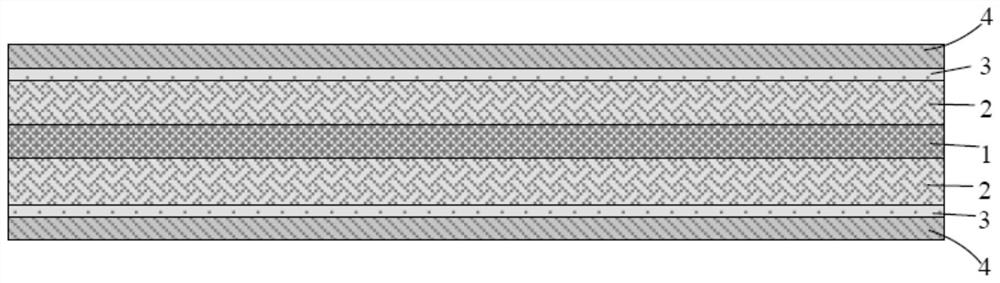

Image

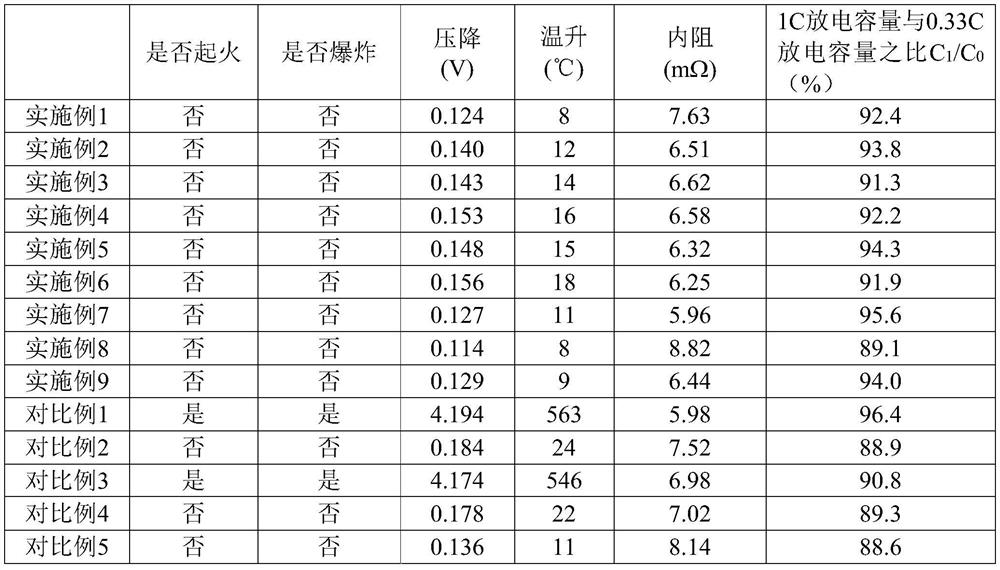

Examples

Embodiment 1

[0057] 1. Preparation of positive electrode sheet containing double-layer coating:

[0058] 1) Mix NCM high-nickel 8-series positive electrode (positive electrode active material), conductive agent superconducting carbon (Super-P), and binder polyvinylidene fluoride (PVDF) at a mass ratio of 97:1.5:1.5 to make positive electrode slurry Material, the positive electrode slurry is coated on both surfaces of the current collector aluminum foil, dried at 100°C to form a positive electrode active material layer, and then cold pressed to obtain a positive electrode sheet containing an active material layer;

[0059] 2) Dissolving the first polymer polyacrylonitrile, the first plasticizer polyvinyl carbonate, and the conductive agent acetylene black in the organic solvent N,N-dimethylacetamide (DMAC) at a mass ratio of 50:10:40 , mix uniformly to make the first coating slurry, apply the first coating slurry on the surface of the positive electrode active material layer in step 1), and...

Embodiment 2

[0069] 1. Preparation of positive electrode sheet containing double-layer coating:

[0070] 1) Mix NCM high-nickel 8-series positive electrode (positive electrode active material), conductive agent superconducting carbon (Super-P), and binder polyvinylidene fluoride (PVDF) at a mass ratio of 97:1.5:1.5 to make positive electrode slurry Material, the positive electrode slurry is coated on both surfaces of the current collector aluminum foil, dried at 100°C to form a positive electrode active material layer, and then cold pressed to obtain a positive electrode sheet containing an active material layer;

[0071] 2) Dissolve the first polymer polyvinyl alcohol, the first plasticizer polyethylene glycol methyl ether methacrylate, and acetylene black in the organic solvent DMAC at a mass ratio of 40:10:50, and mix them uniformly to form the first A coating slurry, coating the first coating slurry on the surface of the positive electrode active material layer in step 1), and drying w...

Embodiment 3

[0077] 1. Preparation of positive electrode sheet containing double-layer coating:

[0078] 1) Mix NCM high-nickel 8-series positive electrode (positive electrode active material), conductive agent superconducting carbon (Super-P), and binder polyvinylidene fluoride (PVDF) at a mass ratio of 97:1.5:1.5 to make positive electrode slurry Material, the positive electrode slurry is coated on both surfaces of the current collector aluminum foil, dried at 100°C to form a positive electrode active material layer, and then cold pressed to obtain a positive electrode sheet containing an active material layer;

[0079] 2) the first polymer polyvinyl alcohol and acetylene black are dissolved in the organic solvent N with a mass ratio of 50:50, in N-dimethylformamide (DMF), mix uniformly to make the first coating slurry, and The first coating slurry is coated on the surface of the positive electrode active material layer in step 1), and air-dried at 60° C. to obtain a positive electrode s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com