High-safety cylindrical lithium ion battery

A lithium-ion battery and lithium-ion technology, applied in the field of lithium-ion batteries, can solve the problems of limited function of high-energy density lithium-ion batteries, and achieve the effects of unaffected electrical properties, preventing thermal runaway, and high acupuncture safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

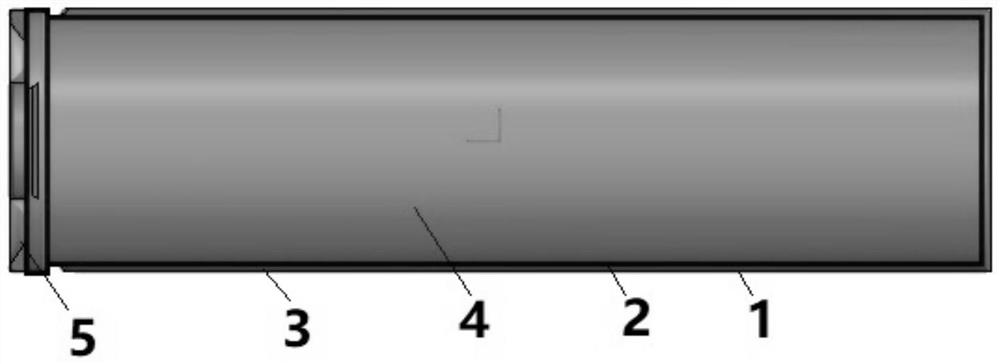

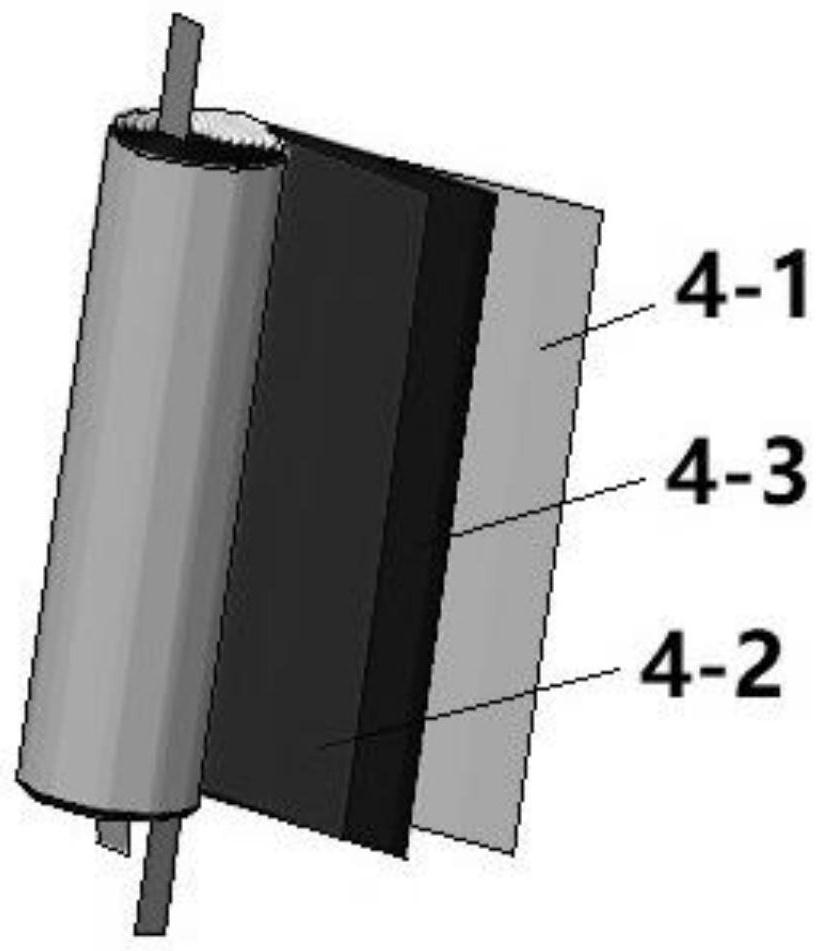

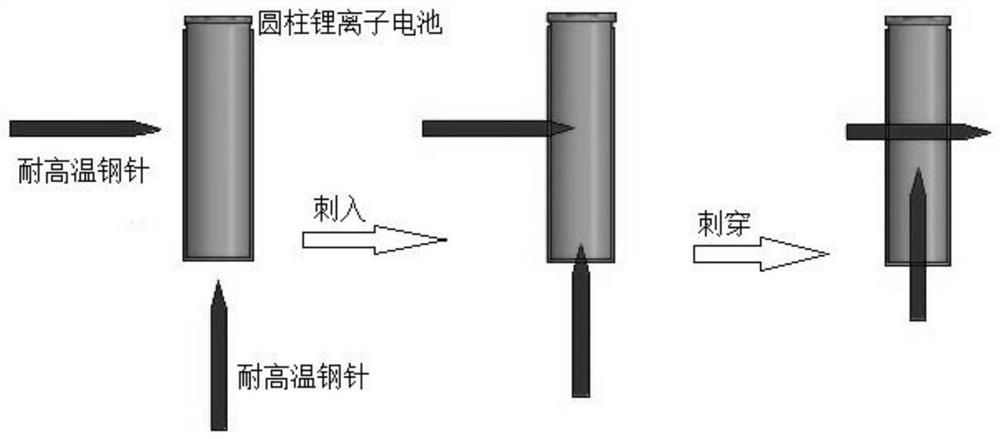

[0035] Such as figure 1 and figure 2 As shown, the high-safety cylindrical lithium-ion battery of this embodiment includes an inner shell 2 and a cylindrical lithium-ion cell 4 filled in the inner shell 2, and the outer circumferential surface and the bottom surface of the inner shell 2 are coated with an outer shell 1, And the gap formed between the inner shell 2 and the outer shell 1 is filled with a gel state flame retardant 3, a cap 5 is installed on the top surface of the inner shell 2, and the cylindrical lithium ion cell 4 is composed of a positive pole piece 4 -1. The diaphragm 4-3 and the negative pole piece 4-2 are stacked in sequence and then wound, and the cylindrical lithium-ion battery cell 4 is filled with electrolyte solution.

[0036] The composition of the gel state flame retardant 3 in the present embodiment is a chlorine flame retardant, a bromine flame retardant or a composite flame retardant, and the composite flame retardant contains phosphorus, boron ...

Embodiment 2

[0047] The manufacturing process of the high-safety cylindrical lithium-ion battery of the present embodiment includes the following steps:

[0048]Step 1, preparing a cylindrical lithium-ion cell;

[0049] Step 101, preparing the positive pole piece

[0050] Step 1011, preparation of positive electrode slurry: adding active material, conductive agent and binder to the solvent and stirring evenly with a mixer to obtain positive electrode slurry; the active material is lithium cobaltate, and the conductive agent is conductive carbon black and carbon A composite conductive agent composed of nanotubes, the binder is polyvinylidene fluoride, the solvent is N-methylpyrrolidone, and the mass ratio of active material, conductive agent, binder and solvent is 96.5:1.8:1.7:60;

[0051] Step 1012, positive electrode coating: the positive electrode slurry obtained in step 1011 is evenly coated on both sides of the positive electrode current collector aluminum foil by means of intermitten...

Embodiment 3

[0077] The manufacturing process of the high-safety cylindrical lithium-ion battery of the present embodiment includes the following steps:

[0078] Step 1, preparing a cylindrical lithium-ion cell;

[0079] Step 101, preparing the positive pole piece

[0080] Step 1011, positive electrode slurry preparation: add active material, conductive agent and binder to the solvent and use a mixer to stir evenly to obtain positive electrode slurry; the active material is nickel cobalt lithium manganese oxide material (NCM811), conductive agent It is a composite conductive agent composed of conductive carbon black and carbon nanotubes, the binder is polyvinylidene fluoride, and the solvent is N-methylpyrrolidone, and the mass ratio of active material, conductive agent, binder and solvent is 96.7: 1.8:1.5:80;

[0081] Step 1012, positive electrode coating: the positive electrode slurry obtained in step 1011 is evenly coated on both sides of the positive electrode current collector alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com