Negative modified high-safety lithium-ion battery

A lithium-ion battery, high-safety technology, applied in battery electrodes, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problems of reducing heat release, inconvenient application, not effectively reducing, etc., to achieve enhanced safety performance, Ease of use, hindering thermal runaway effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

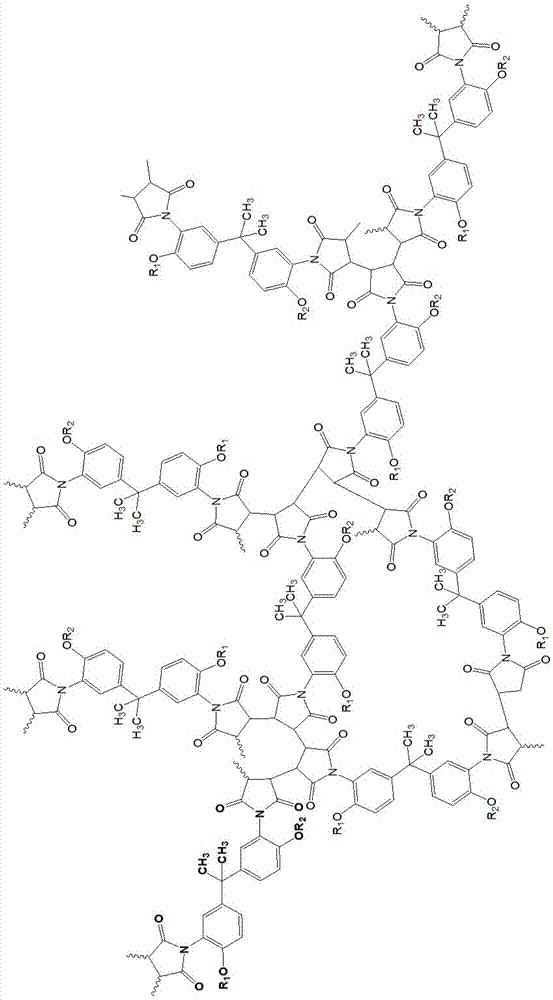

Image

Examples

Embodiment 1

[0023] Cathode material: LiFePO 4 / PVDF / VGCF=90 / 4 / 6;

[0024] Anode material: graphite / PVDF / VGCF=91 / 4 / 5;

[0025] Diaphragm: PE microporous membrane;

[0026] Electrolyte: 1M LiPF 6 , solvent EC / DMC / EMC (v / v / v=1 / 1 / 1).

[0027] Battery type: soft pack battery 10Ah.

[0028] This example serves as a comparative example for the following examples.

Embodiment 2

[0030] Cathode material: LiFePO 4 / PVDF / VGCF=80 / 10 / 10;

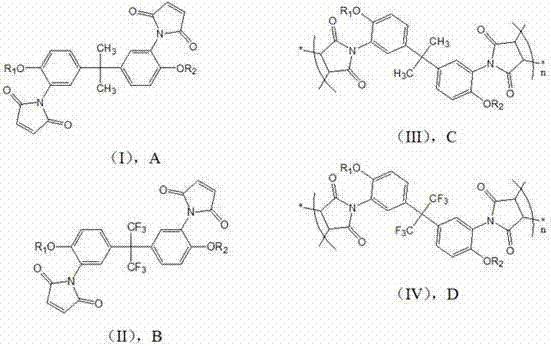

[0031] Negative electrode material: graphite / PVDF / VGCF / A=90 / 4 / 5 / 1, medium A, R 1 , R 2 for H;

[0032] Diaphragm: PE microporous membrane;

[0033] Electrolyte: 1M LiPF 6 , solvent EC / DMC / EMC (v / v / v=1 / 1 / 1).

[0034] Battery type: soft pack battery, 6Ah.

[0035] The puncture test was done simultaneously with the comparative example, and the comparative example caught fire, while the embodiment 2 did not catch fire.

Embodiment 3

[0037] Cathode material: LiNi 1 / 3 co 1 / 3 mn 1 / 3 / PVDF / VGCF=91 / 4 / 5;

[0038] Negative electrode material: graphite / PVDF / VGCF / A=70 / 10 / 10 / 10, A medium, R 1 , R 2 is phenyl (-C 6 h 5 );

[0039] Diaphragm: PE microporous membrane;

[0040] Electrolyte: 1M LiPF 6 , solvent EC / DMC / EMC (v / v / v=1 / 1 / 1).

[0041] Battery type: soft pack battery, 8Ah.

[0042] The puncture test was done simultaneously with the comparative example, the comparative example caught fire, but the embodiment 3 did not catch fire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com