Patents

Literature

44results about How to "A variety of" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed frozen food of fresh fruit and vegetable and concentrated fruit and vegetable juice and processing method thereof

InactiveCN101803671AMake full use of functional complementarityNutritional diversityFrozen sweetsQuick FreezeFruit juice

The invention relates to mixed frozen food of fresh fruits and vegetables and concentrated fruit and vegetable juice and a processing method thereof, belonging to the field of the quick-frozen fresh fruit and vegetable beverage product and the production method thereof. The method comprises the following steps: directly selecting fresh fruits and eatable vegetables collected from pollution-free planting bases as main raw materials, obtaining clean solid materials after cleaning, peeling, seed removal and slitting pretreatment, mixing with such components as concentrated fruit juice and / or concentrated vegetable juice, white granulated sugar, honey, pectin, drinking water and the like according to a proportion, vacuum packaging to form a semi-finished product, and quickly freezing, thereby obtaining the finished quick-frozen fresh fruit and vegetable mixed food which can be stored, transported and sold under low-temperature conditions. The raw materials comprise the following components by weight percentage: 55-77 percent of solid clean materials of fresh fruit or / and eatable vegetables, 7-16 percent of concentrated fruit juice or / and concentrated vegetable juice, 0.2-1 percent of pectin, 2.5-5 percent of white granulated sugar, 0.3-3 percent of honey and 20-30 percent of drinking water. Therefore, the processed product is a novel frozen fruit and vegetable mixed food product with a high solid content.

Owner:WUHAN EAST YONGTAI BEVERAGE

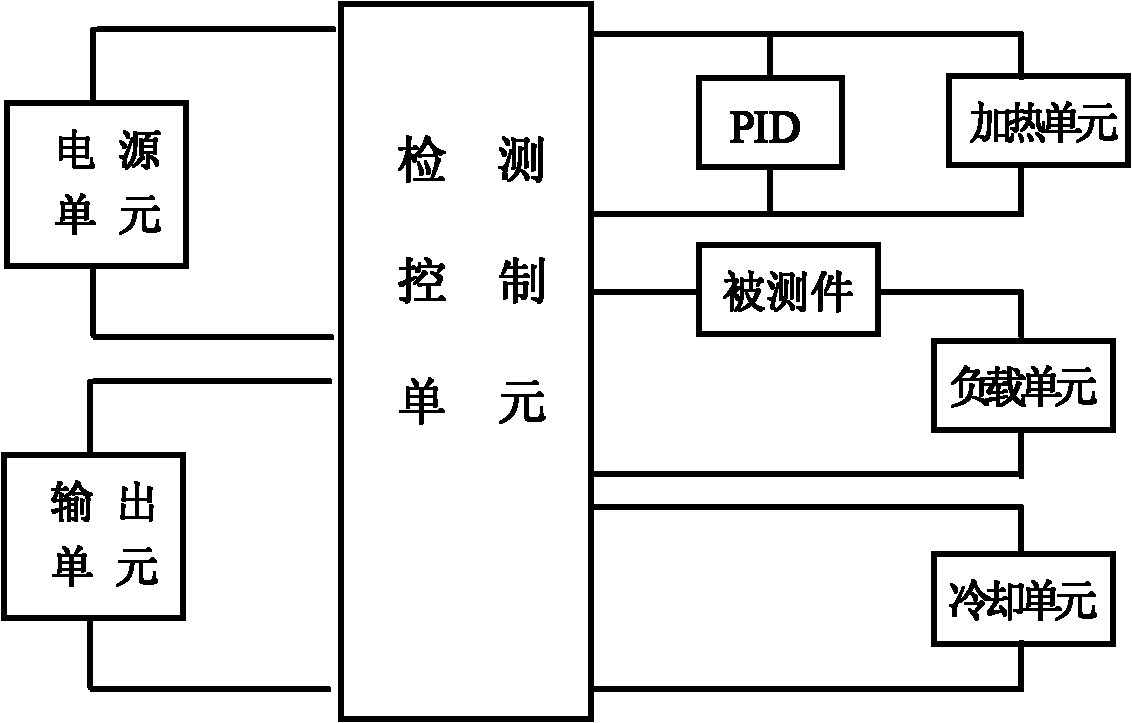

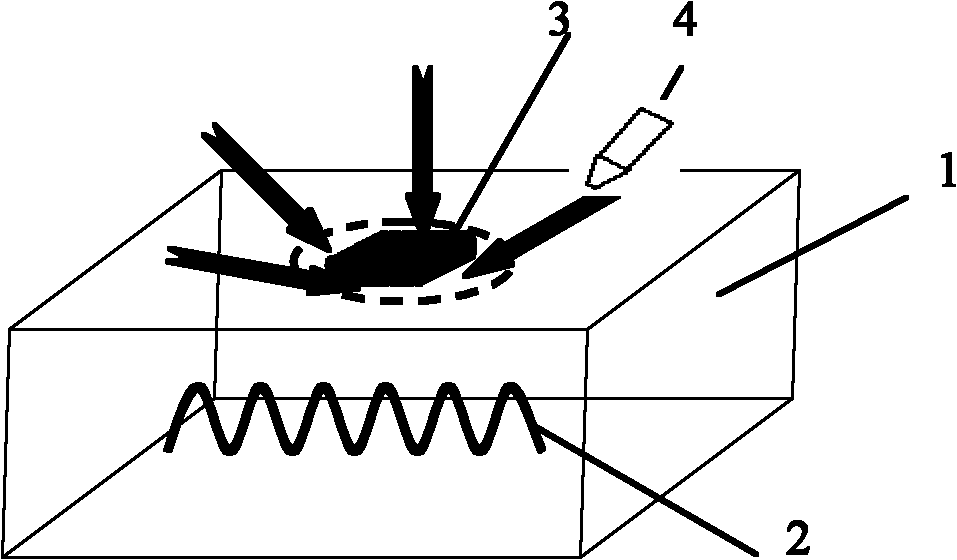

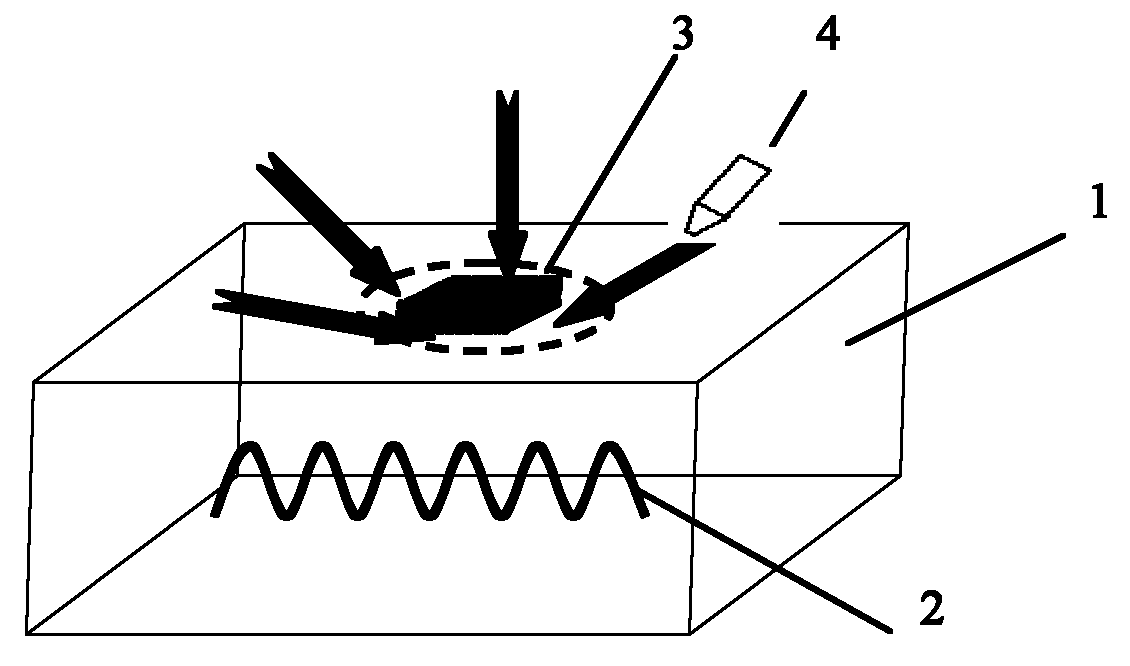

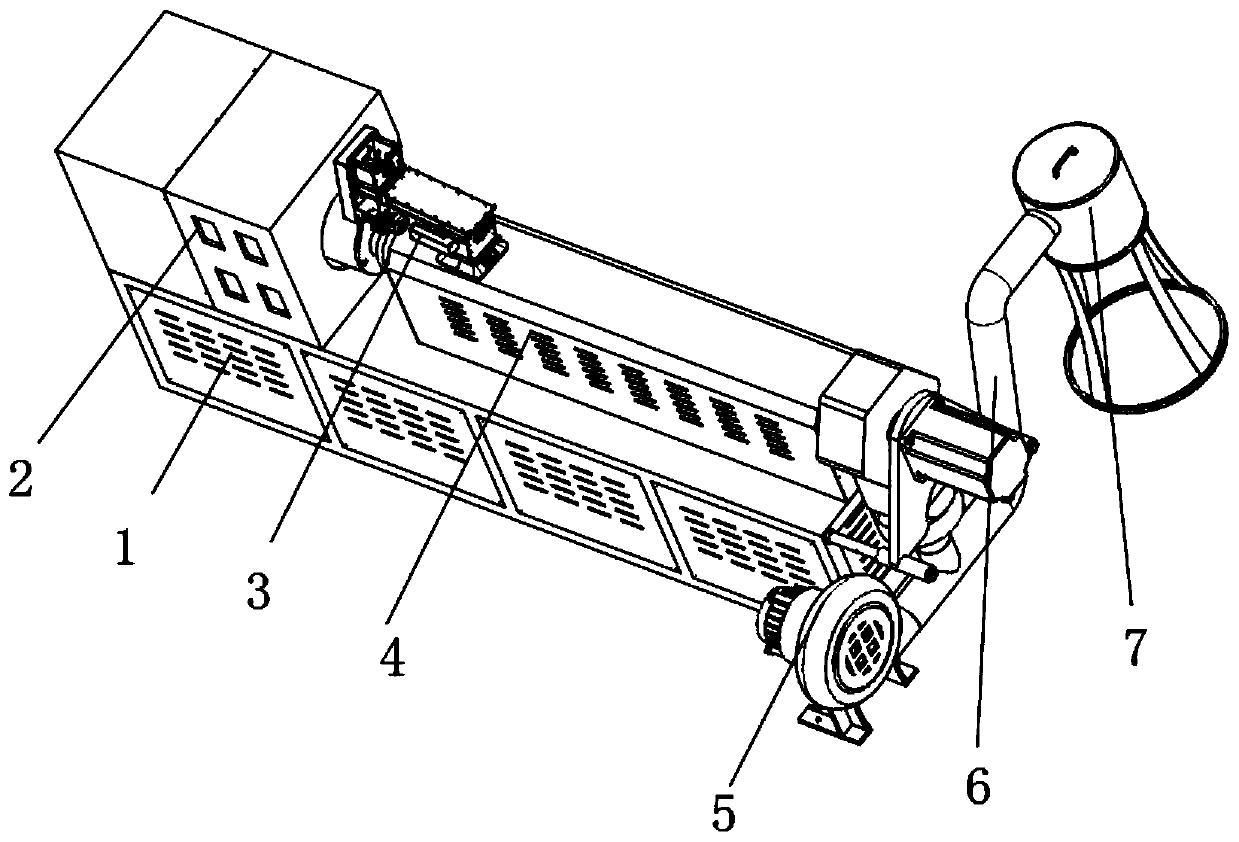

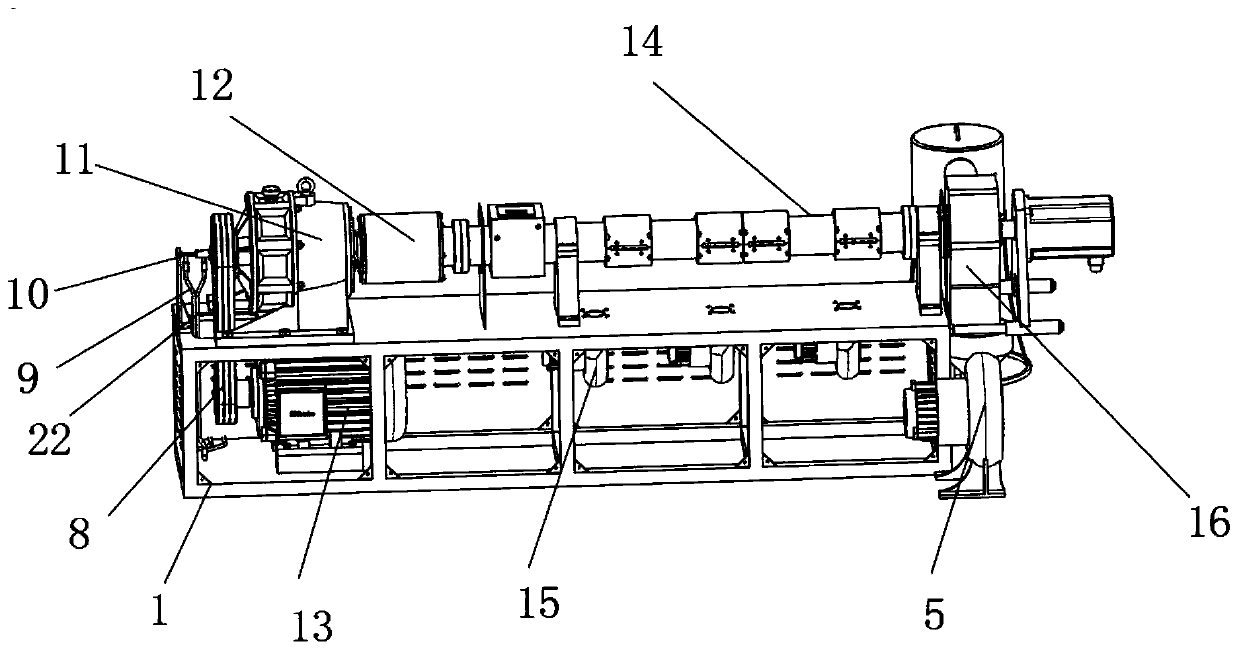

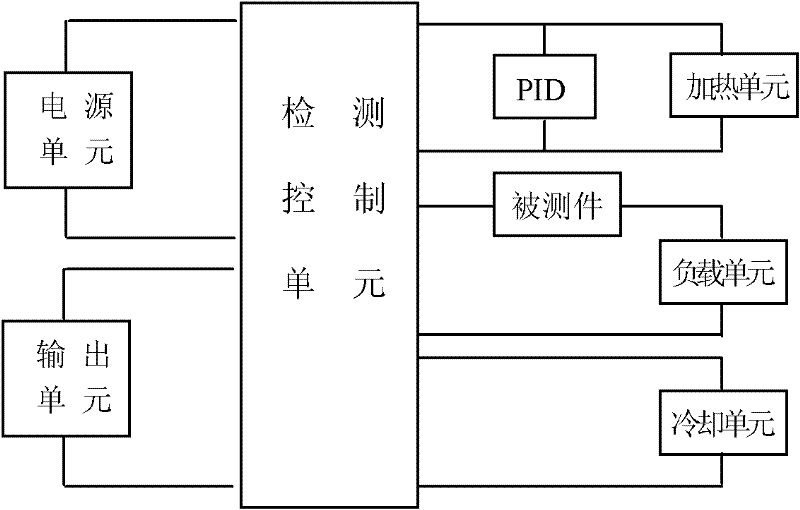

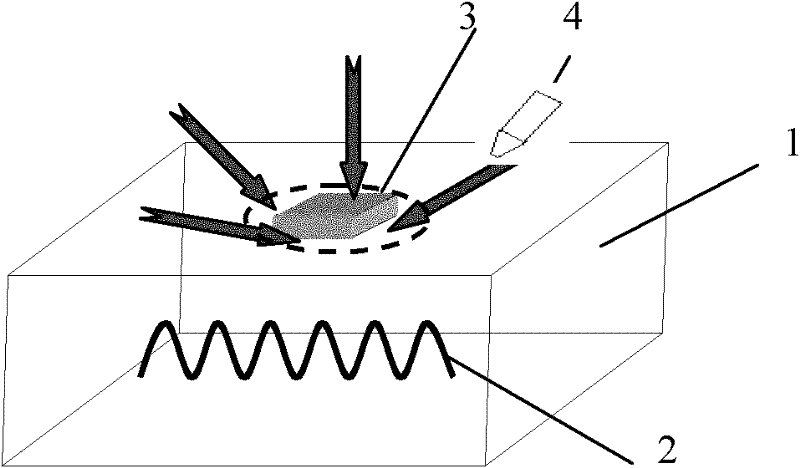

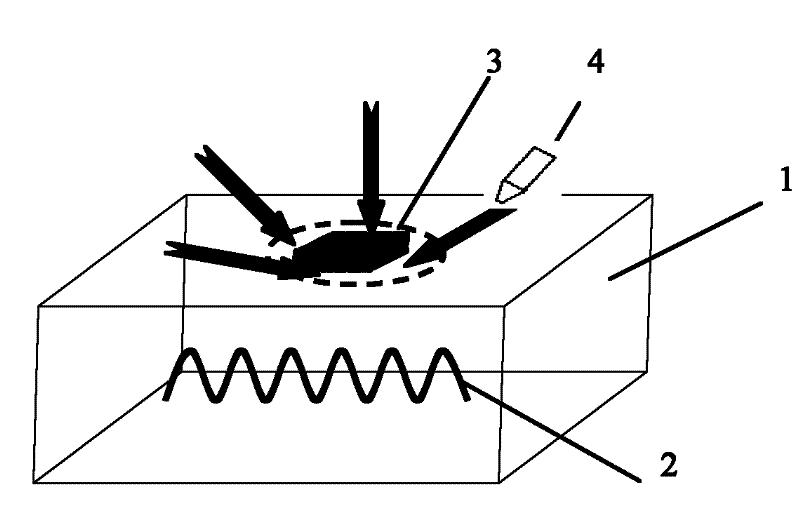

Durability tester for temperature controller

InactiveCN102122169ASmall thermal inertiaPrecise adjustment of heating temperatureTesting/monitoring control systemsAir pumpEngineering

The invention discloses a durability tester for a temperature controller, which comprises a power supply unit, a load unit, a detection control unit, an output unit, a heating unit and a cooling unit. The durability tester is characterized in that the heating unit comprises a copper block in which a heating pipe is arranged, the heating pipe is connected with the power supply unit, an upper surface of the copper block is provided with a thermoelectric couple for acquiring the temperature of the copper block in real time, the thermoelectric couple is connected with the detection control unit, and the upper surface of the copper block is further provided with an insulating heat-resistant pressure plate for fixing a temperature sensitive part of a temperature controller; the cooling unit is a cooling airflow sprayer arranged over the insulating heat-resistant pressure plate and connected with an external air pump of the tester; and the temperature controller is connected with an input end of the load unit through a lead. The durability tester has the advantages that the heating mode of the tester is small in thermal inertia, so that an adjustable range of the conduction and the disconnection of the temperature controller is large, the range of the heating temperature is large, the heating temperature and the cooling speed can be accurately controlled, accuracy of the test result can be improved, and the tester is simple in structure and low in cost.

Owner:宁波市产品质量监督检验研究院

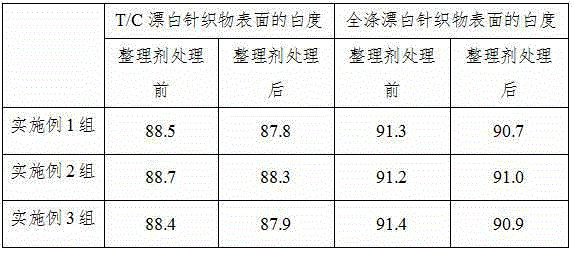

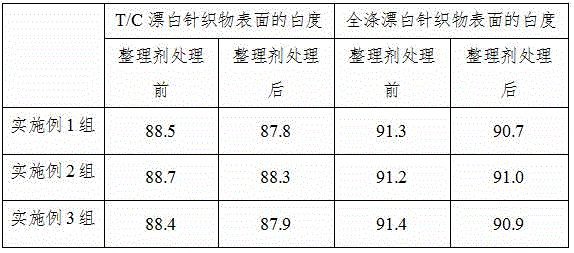

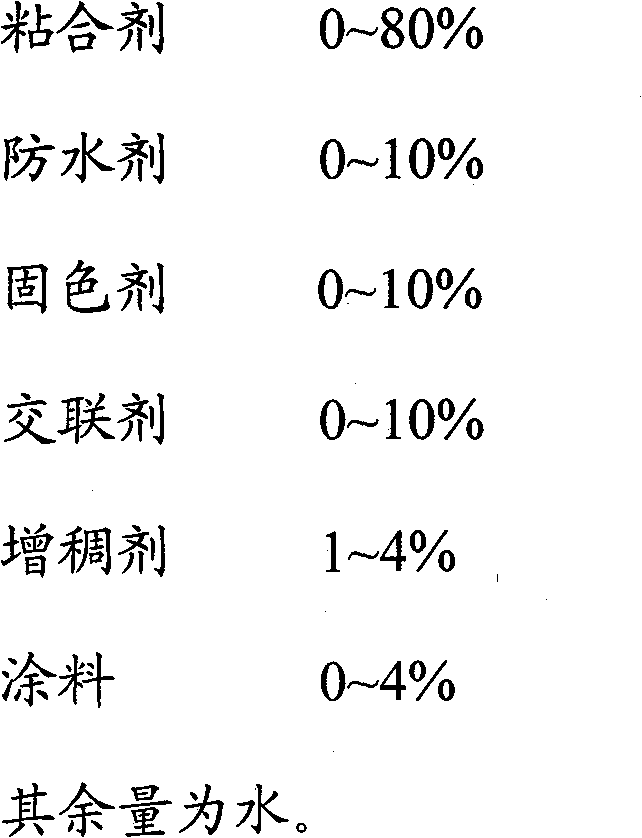

Ice feeling finishing agent and preparation method thereof

The invention belongs to the technical field of printing and dyeing auxiliaries, particularly relates to an ice feeling finishing agent and a preparation method thereof. The ice feeling finishing agent mainly comprises raw silicone oil, an emulgator, a cosolvent, glacial acetic acid and water, wherein the raw silicone oil is prepared by adding 99-99.5% of silicone oil, 0.01-0.9% of a silane coupling agent and 0.01-0.1% of a catalyst into a reaction kettle for reaction. According to the ice feeling finishing agent and the preparation method thereof, provided by the invention, primary amine or / and secondary amine is / are introduced onto the molecular chain of silicone oil, therefore the hydrophilic performance of the overall molecular structure is improved, fabric subjected to finishing of the finishing agent has air-permeating, moisture permeating, moisture-absorbing and sweat releasing functions, at the same time can maintain a certain humidity, and enables people to have a feeling of comfortableness and coldness after wearing the clothes subjected to finishing; besides, the ice feeling finishing agent has excellent stability, thoroughly overcomes the defects that the conventional amino silicon oil is prone to demulsification, floating and roll sticking, can easily produce oil spots, and is not easy to repair.

Owner:珠海华大浩宏新材料有限公司

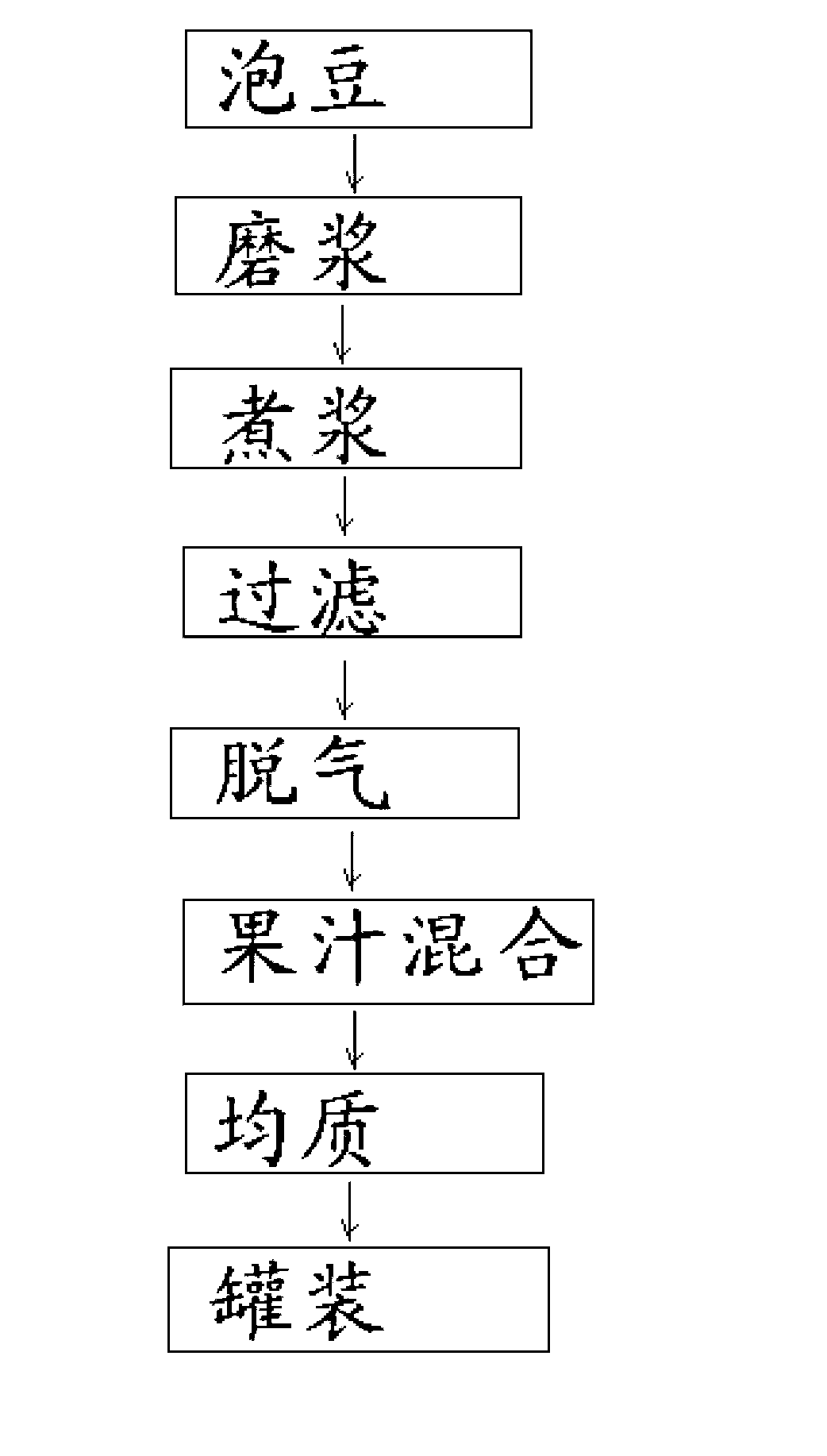

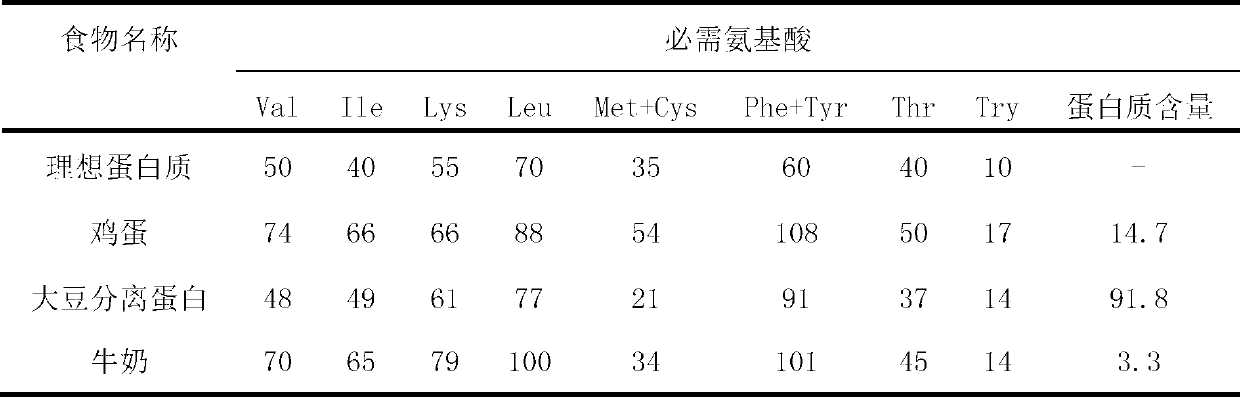

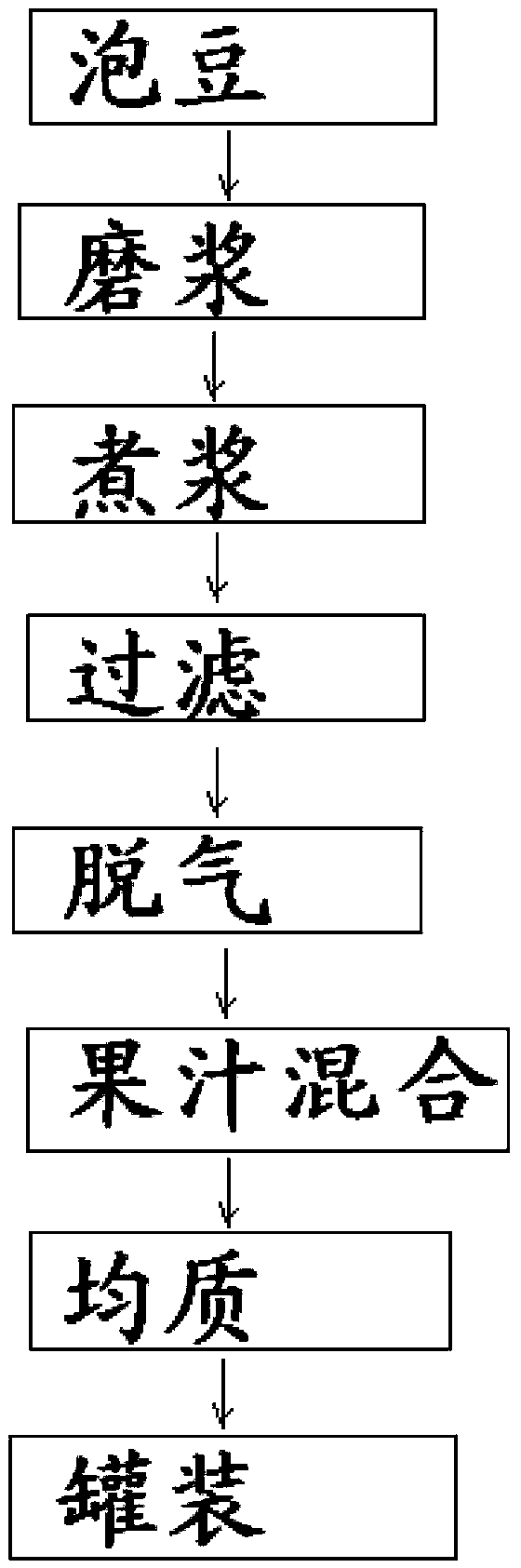

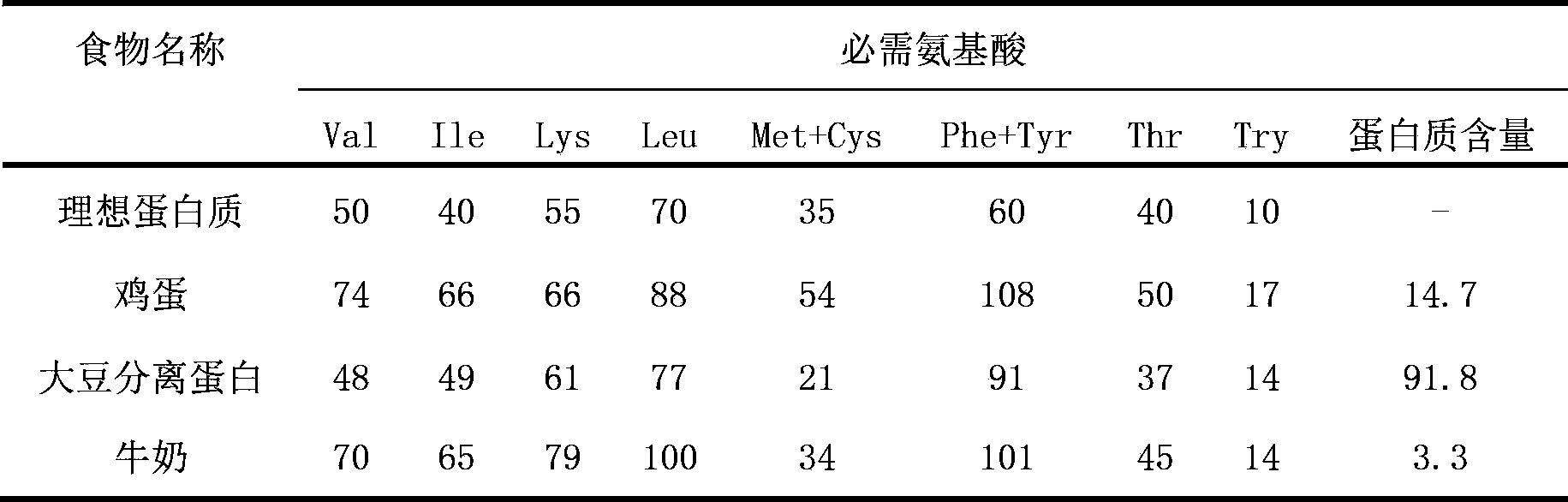

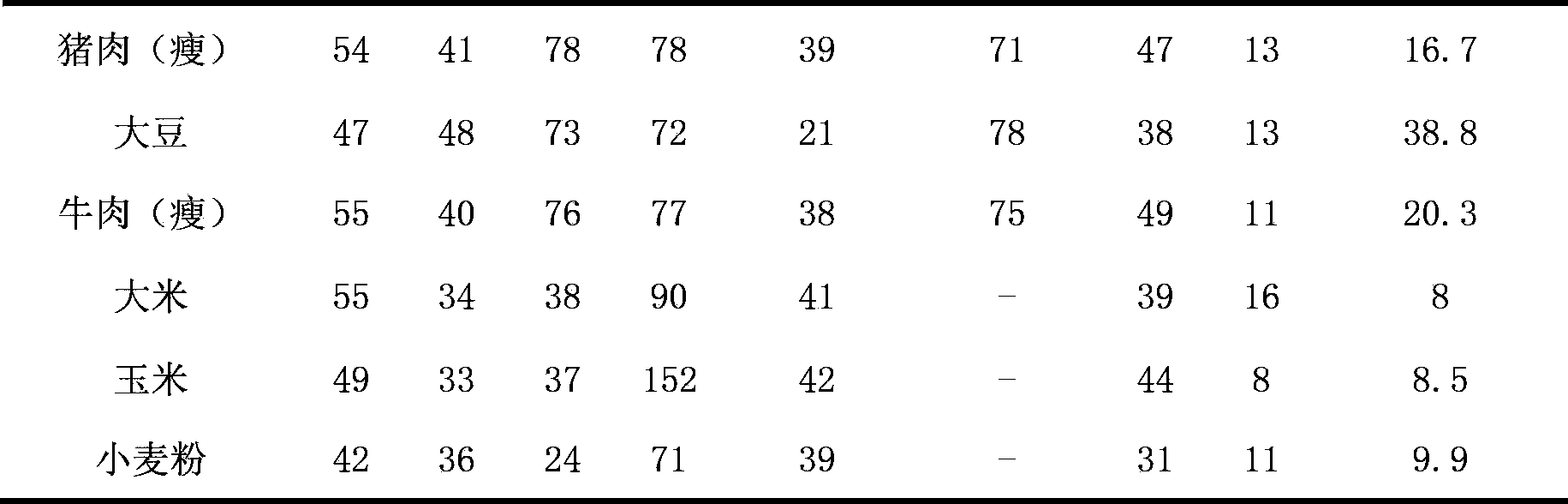

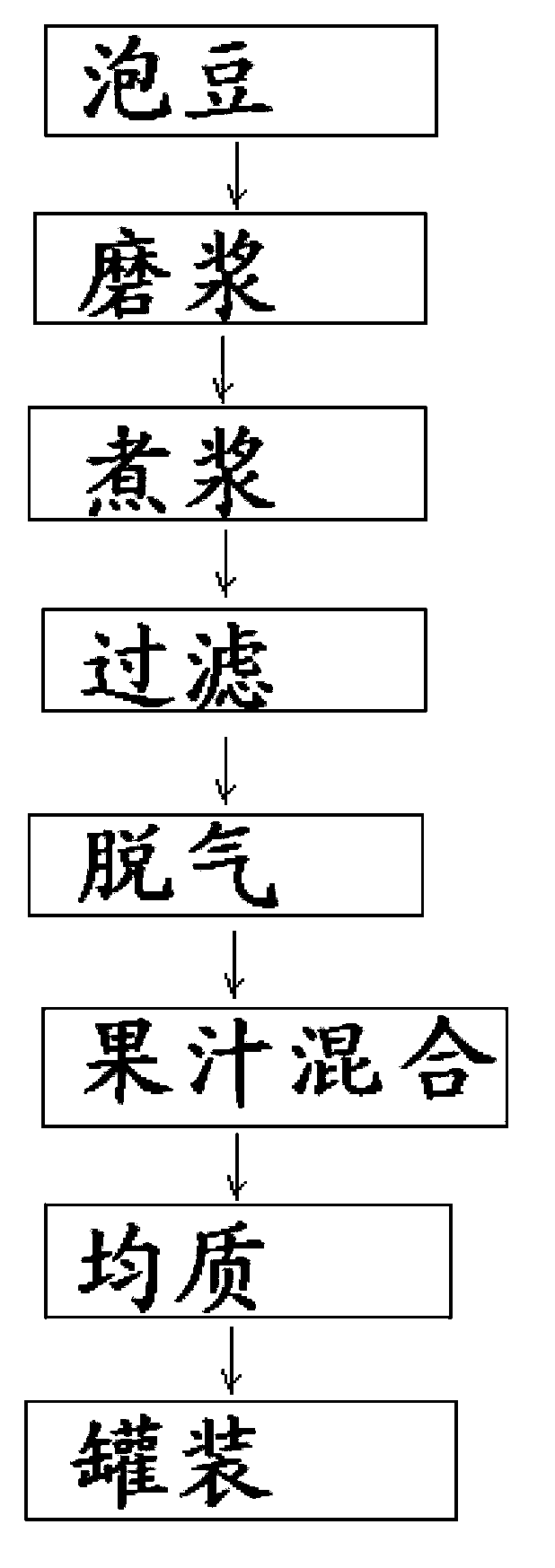

Fruity soymilk

The invention provides a fruity soymilk. The fruity soymilk comprises the following components in percentage by mass: 35% of soymilk, 10% of pure fruit juice, 7% of cane sugar, 0.1% of citric acid and 0.05% of malic acid. The soymilk also contains 0.20% of CMC (Carboxy Methylated Cellulose) as a stabilizer. The soymilk further contains emulsifiers including 0.07% of polyglycerol fatty acid ester, 0.07% of molecular distillation monoglyceride and 0.05% of sucrose fatty emulsifier SE-13. The problem that fruit juice cannot be mixed with soybean milk is thoroughly solved, the nutritional ingredients of the fruit juice and the soybean milk are mixed in the same beverage, two nutritional ingredients of two foods can be obtained by people through drinking one cup of soybean milk, and therefore, the fruity soymilk is praised by people.

Owner:SHANGHAI QINGMEI GREEN FOOD

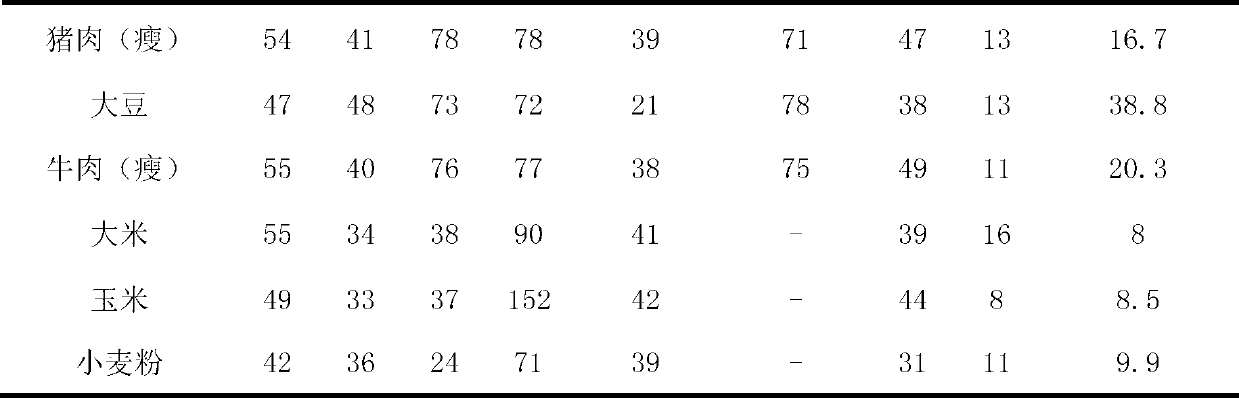

Built-in earphone

InactiveCN1929692AOvercoming technical biasUniform textureEarpiece/earphone attachmentsEngineeringSound quality

This invention discloses one ear small phone to process ear phone front and back shells, wherein, the materials is of good resistance property to absorb redundant vibration besides trumpet to make the sound quality more pure, clear; the materials quality is of good spring and tightness to absorb trumpet.

Owner:张耀国

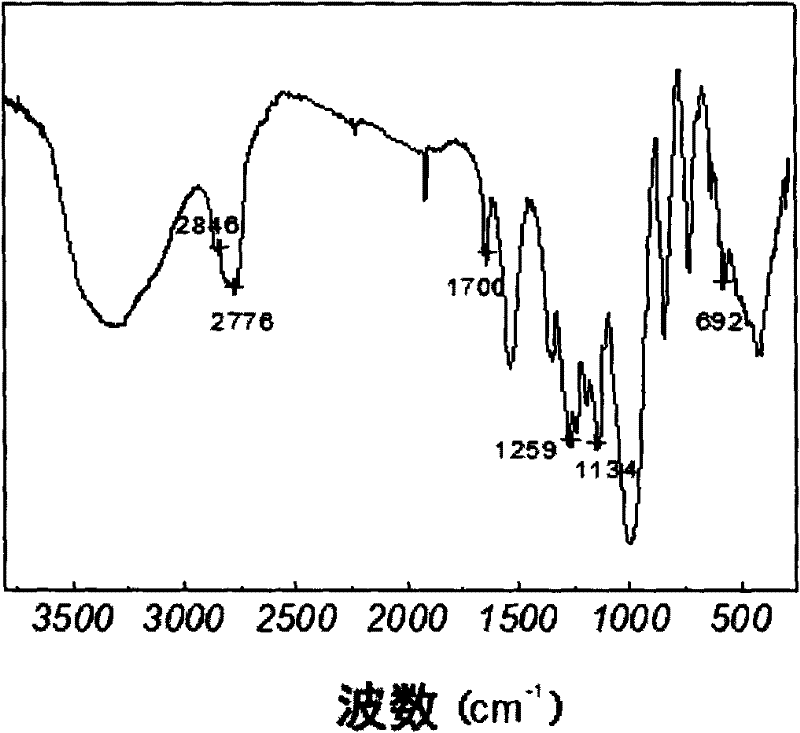

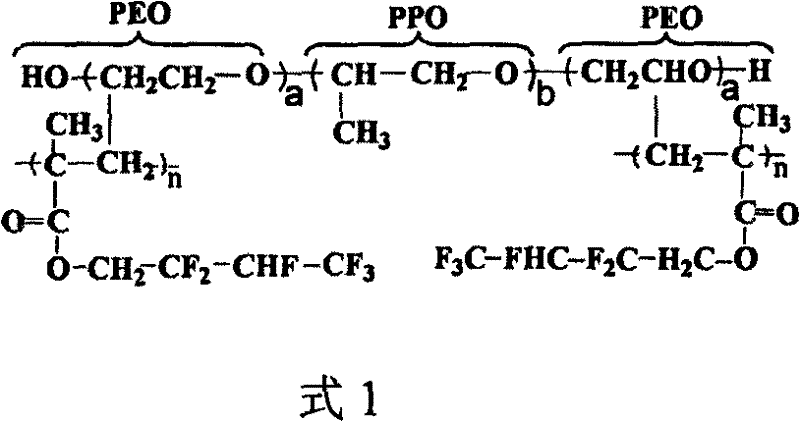

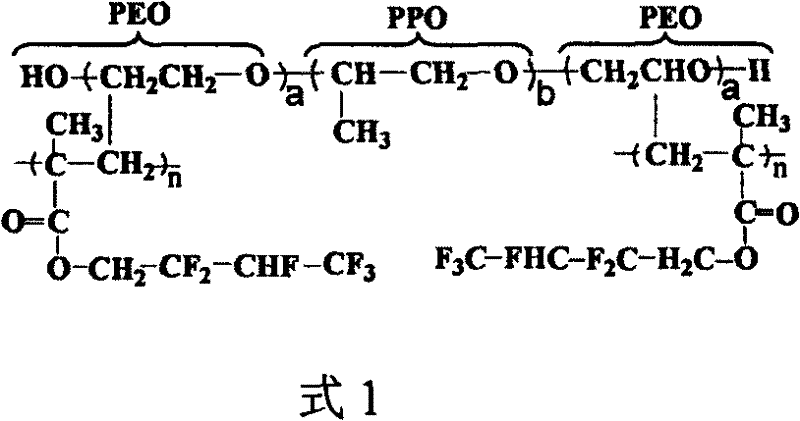

Fluorine-containing amphipathic modifying material for preparing antifouling membrane and preparation method thereof

The invention relates to a fluorine-containing amphipathic modifying material for preparing an antifouling membrane and a preparation method thereof. The fluorine-containing amphipathic modifying material has a structure formula shown in the specification. The preparation method of the fluorine-containing amphipathic modifying material comprises the following steps of: feeding a polyethylene glycol-polymethoxy propylene-polyethylene glycol segmented copolymer and methacrylic acid hexafluorobutyl according to mole ratio into deionized water to obtain an emulsified liquid; feeding ammonium ceric nitrate as an initiator under the protection of nitrogen gas, stirring and reacting to obtain a reaction solution containing a product; and carrying out water removal, impurity removal and drying on the reaction solution to obtain the fluorine-containing amphipathic modifying material. The invention has the advantages that the preparation method has mild process and conditions and is simple and feasible; and the obtained fluorine-containing amphipathic modifying material is used for preparing the antifouling membrane with excellent performances.

Owner:TIANJIN UNIV

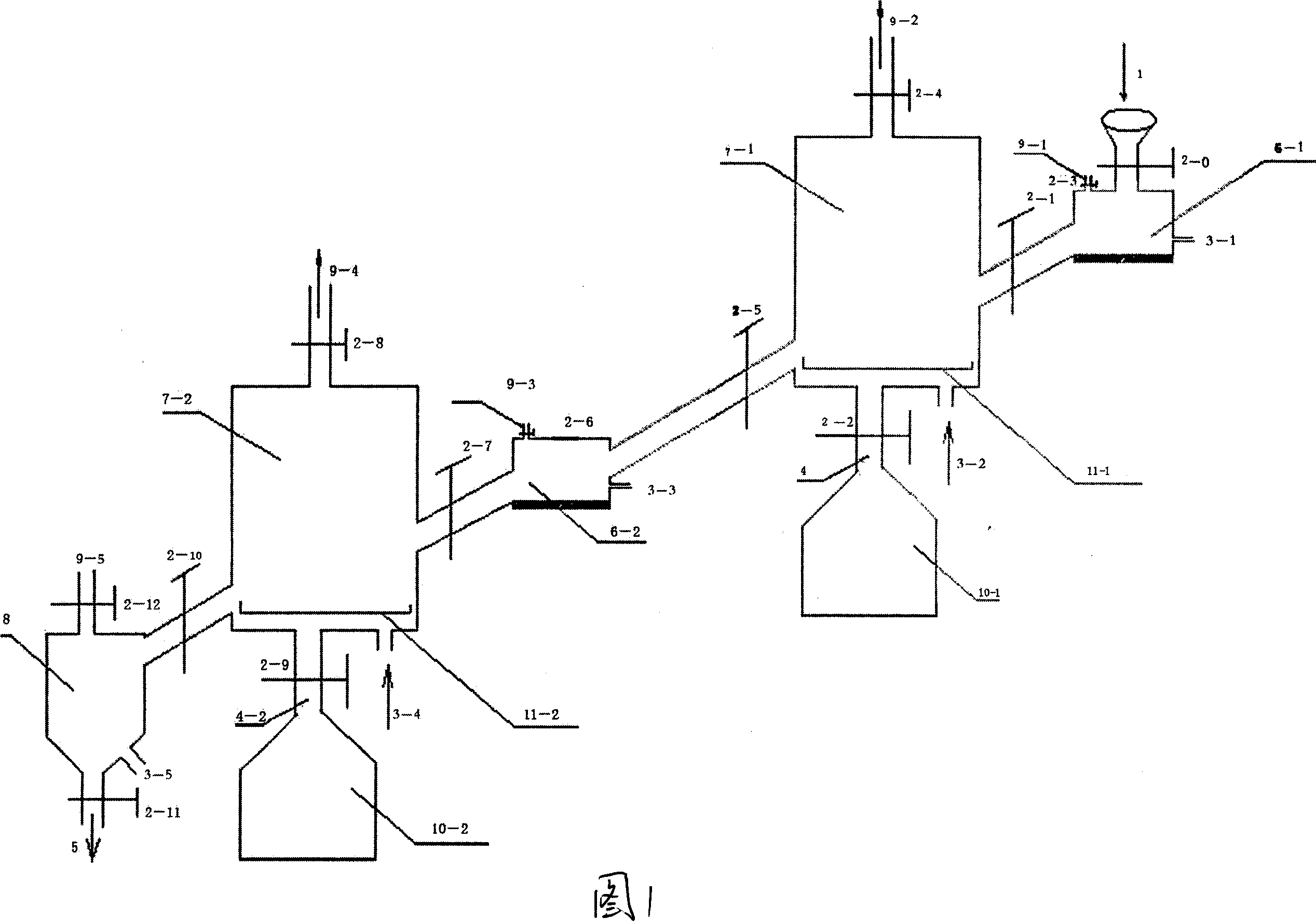

Method and device for coating non-metallic material with ferromagnetic and magnetic metal plating coat

ActiveCN101016623AExcellent performanceA variety ofChemical vapor deposition applicationHeat treatment applicationBoiling pointLower limit

The invention discloses a method of non-metallic material coating iron magnetic properties and magnetic metal coating and device, which comprises the following steps: pre-heating the non-metallic material in heating chamber (6); making the greatest lower limit of heated temperature higher than the boiling point of coating earbonyl metal complex compound; setting high limit of heated temperature according to the needed coating metal thickness of temperature bearability of the coating material and applicability of composite electromechanical material; transferring to coating chamber (7) with vibration and stirrer (11); feeding in earbonyl metal complex compound steam; coating; transferring to cooling inactive chamber (8); inactivating; cooling; discharging; or getting into the next round heated coating recirculation. This method overcomes the shortcoming of elemental metallic material and meets the need of appliance.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

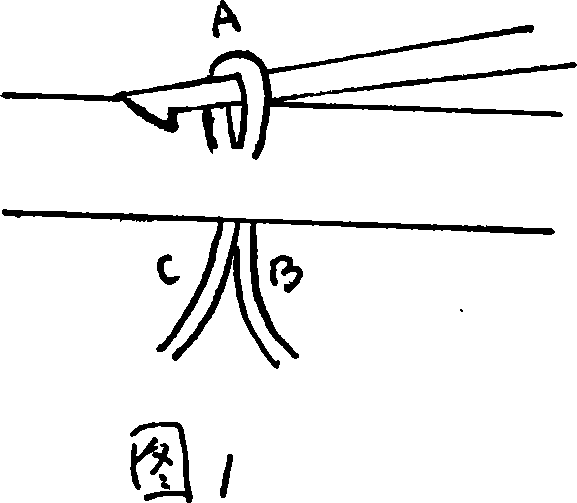

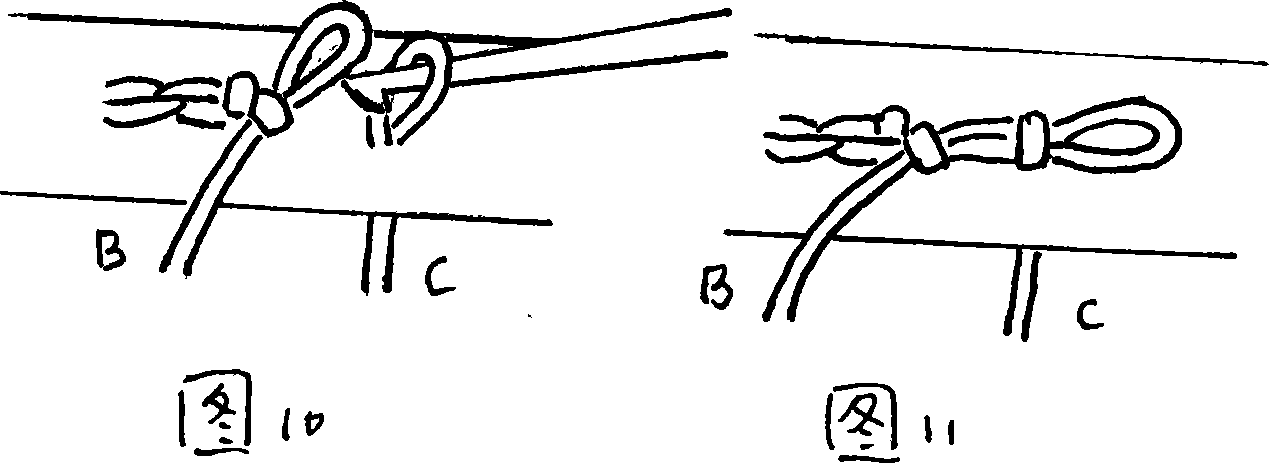

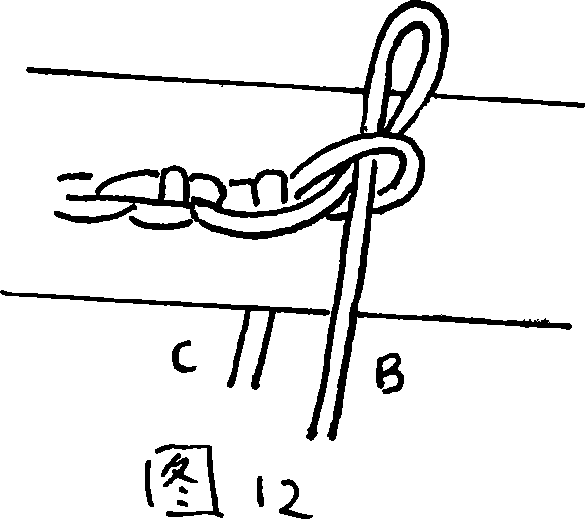

Novel embroidery technique

InactiveCN101058929ABeautiful and smooth linesColorful color block paintingCrochetingHand embroideringEngineeringHooking

The present invention discloses a new embroidery technology. It characterized by: the new embroidery technology hooks many isometric stitch on embroidery materials with barbed needle, the stitches are linked and embedded each other to form smooth lines. The effect after hooking embroidery through the method is just like the traditional line drawing in Chinese painting. The invention replaces the embroidery needle with bearded needle to embroider clothing patterns, and its hooking embroidery products can reach the effect of manual embroidery products and machine embroidery products. The traditional line drawings embroidered through the method is attractive and has elegant and smooth lines, vivid objects and colorful and gorgeous paintings. The hooking embroidery method is suitable for hooking embroidering paintings on many materials, in particular when it is applied in fashion sweaters knitting industry, its advantages are more obvious. The paintings to be hooking embroidered by the method can be more or less, and embroidered savage and wild patterns on more solid materials. That are out of the reach of thin embroidery needles.

Owner:黄良能

Wash flower process

The invention discloses a wash flower process, comprising the following steps: (1) selecting a color cloth; (2) printing a non-apparent printing type pattern through slurry on the selected color cloth; and (3) flowering and washing the color cloth. The invention skillfully combines a traditional printing technology and a washing technology, thereby processing wash flower finished products with wide varieties, different concealing and revealing levels, changeable pattern styles, rich and colorful appearance and infinite changes on the same color cloth substrate according to demands of producers and market.

Owner:王玉山

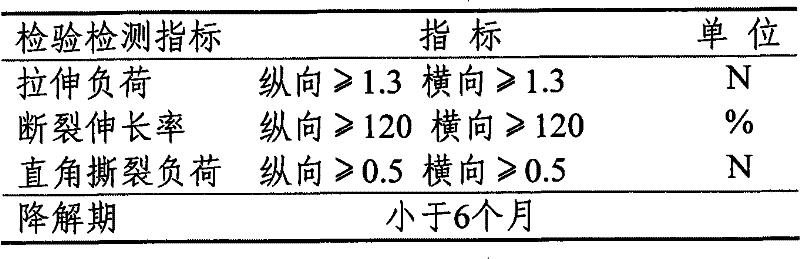

Starch base degradable plastic

InactiveCN101597414BEase of industrial productionHelps eliminate "white" pollutionPolymer scienceMolecular materials

The invention discloses a starch base degradable plastic prepared by macromolecular composition; wherein the macromolecular composition contains the following components by weight parts: 50-80 parts of starch, 5-15 parts of polyvinyl alcohol, 7-15 parts of polyalcohol, 5-10 parts of organic aldehyde compound and 0.1-0.5 part of initiator. The starch and polyvinyl alcohol used in the invention areall high molecular materials which are easy to be biologically degraded, thus being beneficial to eliminate white pollution and protect the environment; and production technology is simple, and degradation effect is obvious, thus being easy for industrialized production.

Owner:杨凌瑞丰环保科技有限公司 +1

Fruit-flavored soymilk added with emulsifier

The invention provides a fruit-flavored soymilk added with an emulsifier. The fruit-flavored soymilk comprises, by mass: 35% of soymilk, 10% of pure fruit juice, 7% of sucrose, 0.1% of citric acid, and 0.05% of malic acid. The fruit-flavored soymilk is characterized by also containing the emulsifier, which is composed of, by mass: 0.07% of tripolyglycerol fatty acid ester, 0.07% of molecular distilled monoglyceride, and 0.05% of a sucrose ester emulsifier SE-13. From the technical level, the problem that juice and soymilk cannot be mixed is completely broken, so that the nutritional ingredients of fruit juice and soymilk are fused in a beverage, and people can drink a cup of soymilk containing the nutritional ingredients of two food. Thus, the fruit-flavored soymilk added with an emulsifier involved in the invention can get the public's praise.

Owner:SHANGHAI QINGMEI GREEN FOOD

Tea beverage containing nanometer SOD and its preparation method

A health-tea tea beverage containing nano-SOD for protecting liver, preventing the diseases of respiratory tract, oral cavity, throat, intestine, etc, and improving immunity is prepared through making tea beverage, proportionally adding nano-SOD and stirring.

Owner:王成余

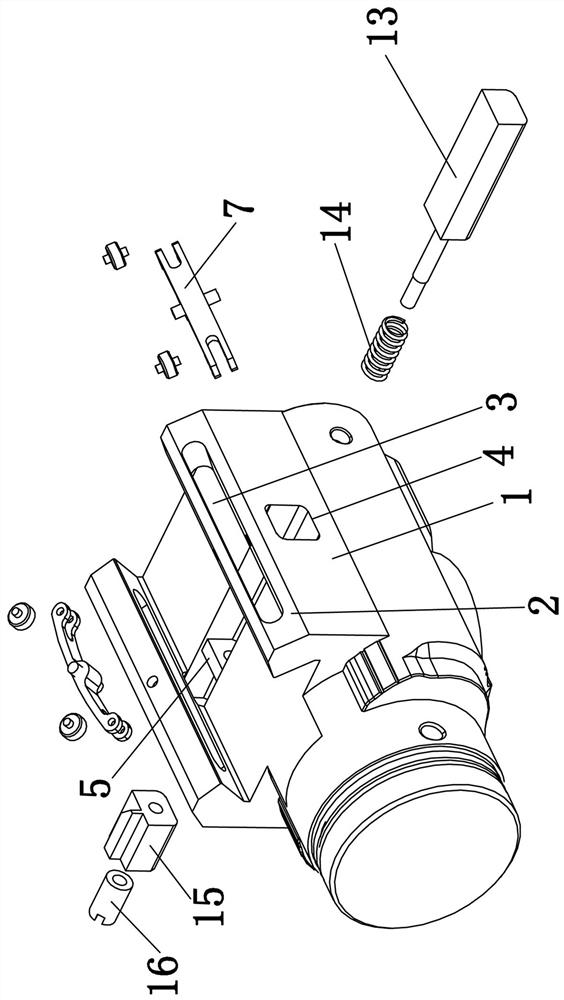

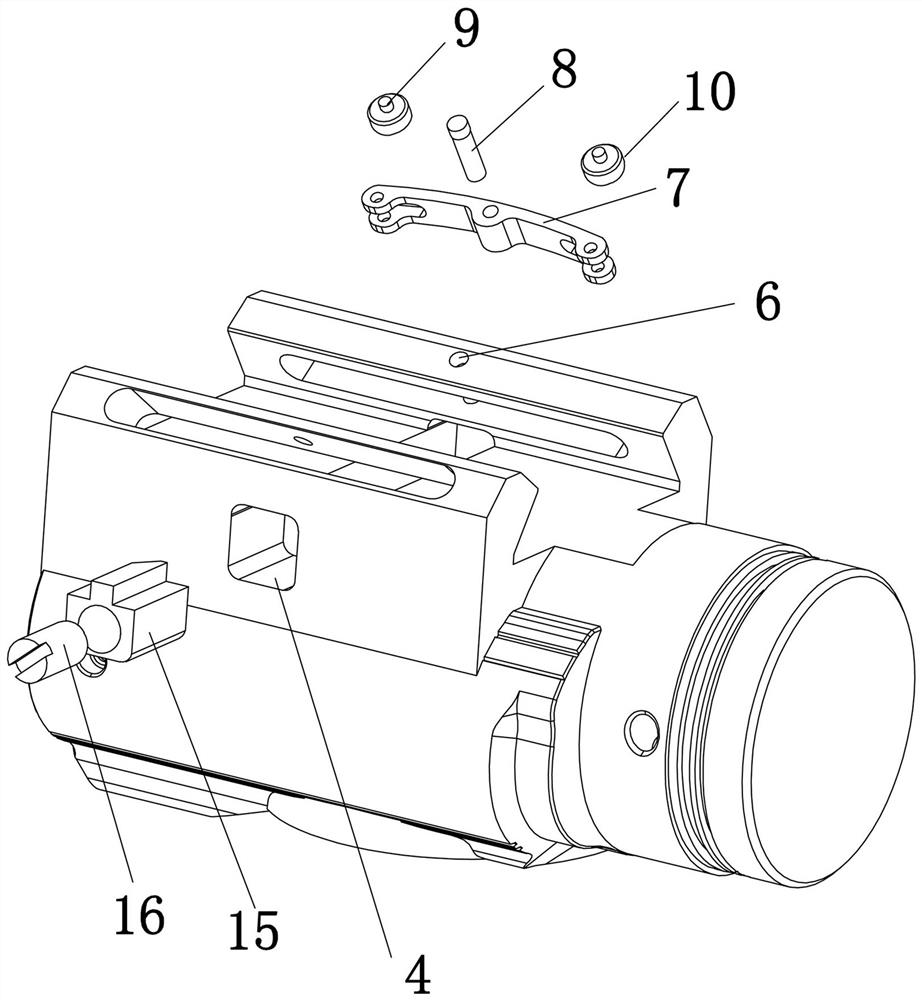

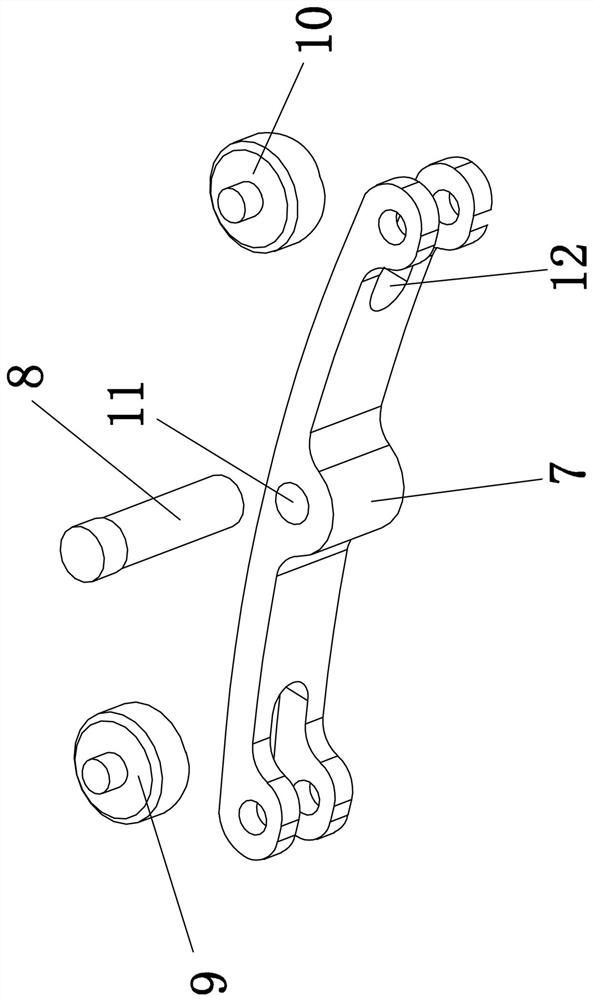

Pistol lamp rapid removal device

ActiveCN111664424AQuick loading and unloadingEasy to useLighting support devicesWeapon componentsMaterials scienceMechanical engineering

Owner:傲雷科技集团股份有限公司

A kind of starch-based degradable bioplastic and preparation method thereof

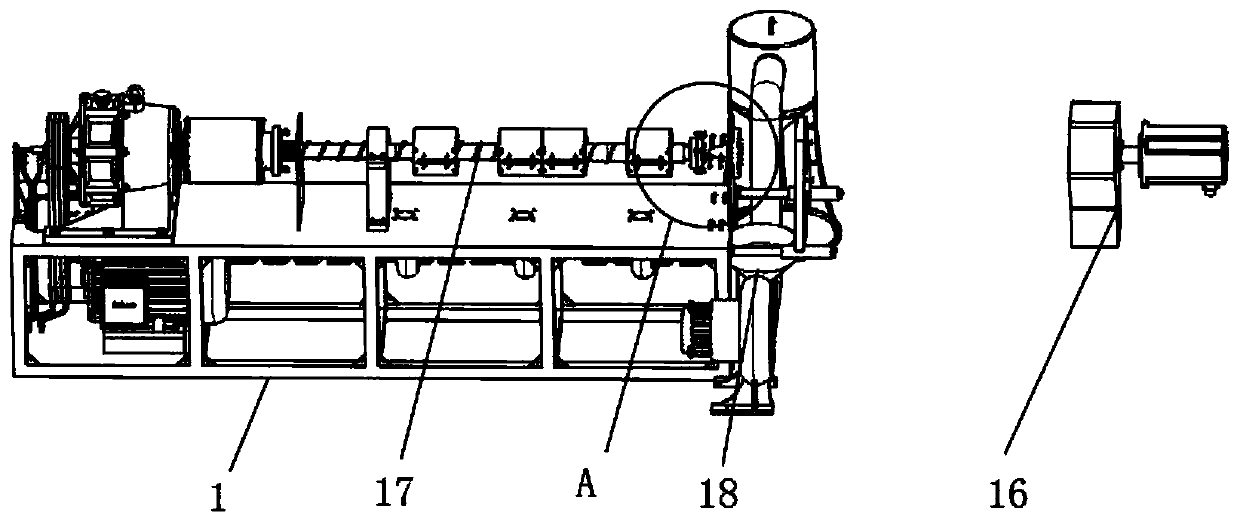

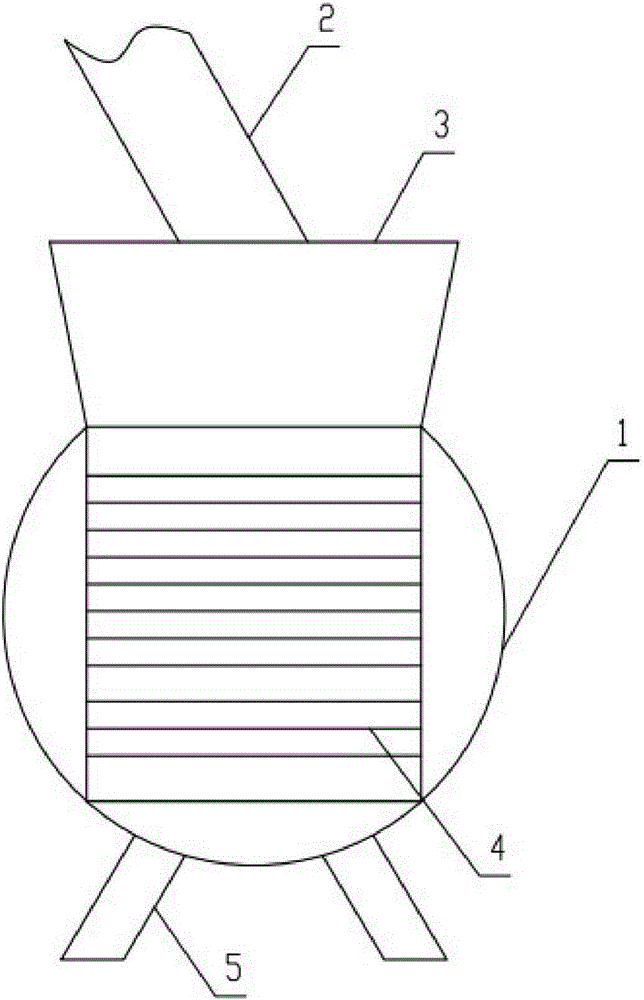

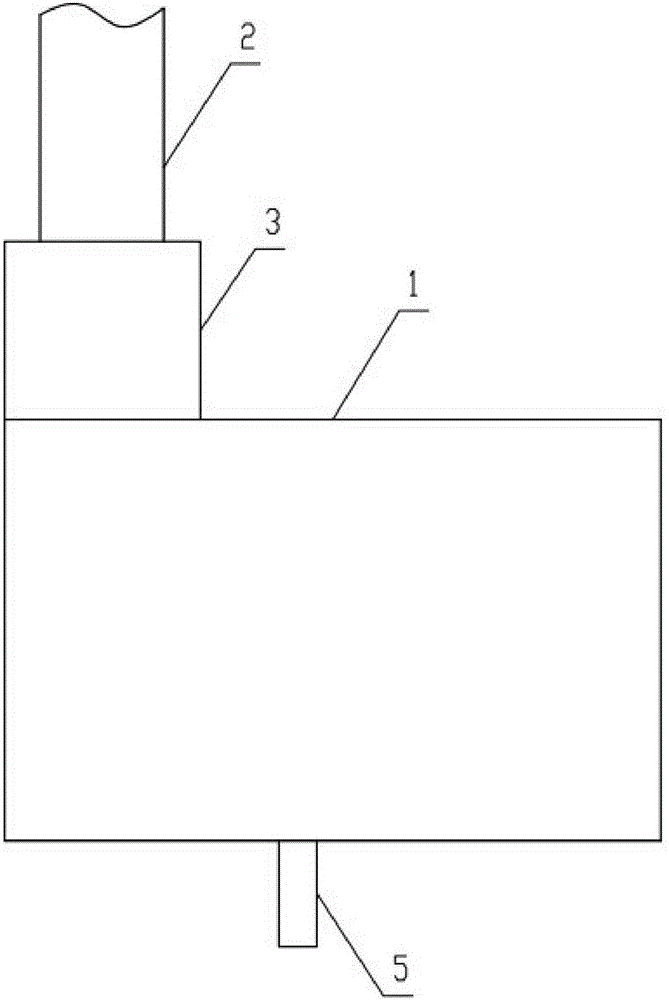

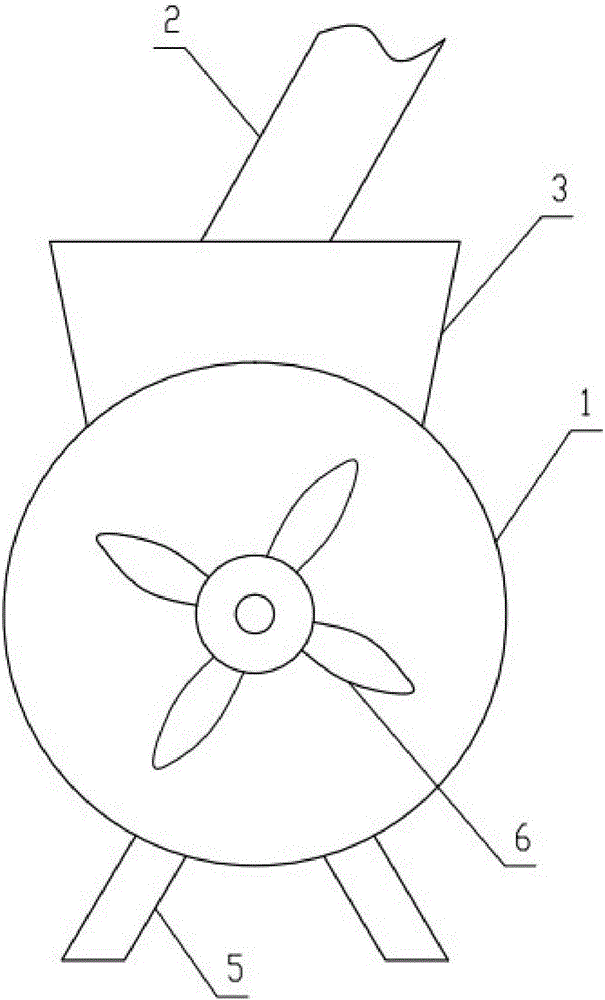

The invention relates to starch-base degradable bioplastic and a preparing method thereof, and belongs to the technical field of biodegradable materials. The starch-base degradable bioplastic is prepared from 40-85% of commodity polymer plastic, 10-50% of a high-hydrophobicity starchiness material, 0.5-5% of aliphatic polyester and 0.1-5.5% of oxidation accelerator. The preparing method of the starch-base degradable bioplastic includes the following steps that starch is treated in a hydrophobization mode to obtain the high-hydrophobicity starchiness material, the raw material components are mixed by a ratio and prepared into master batch through a twin-screw extrusion machine, and after the master batch and the commodity polymer plastic are mixed, the starch-base degradable bioplastic is prepared through injection molding, flattening, blow molding, vacuumizing and forming. The product prepared through the method can be used repeatedly on the dry condition without perpendicular sunlight incidence, the strength is kept unchanged basically, an abandoned product is completely decomposed finally in wet soil, no harmful component is generated, and the environment is not polluted.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

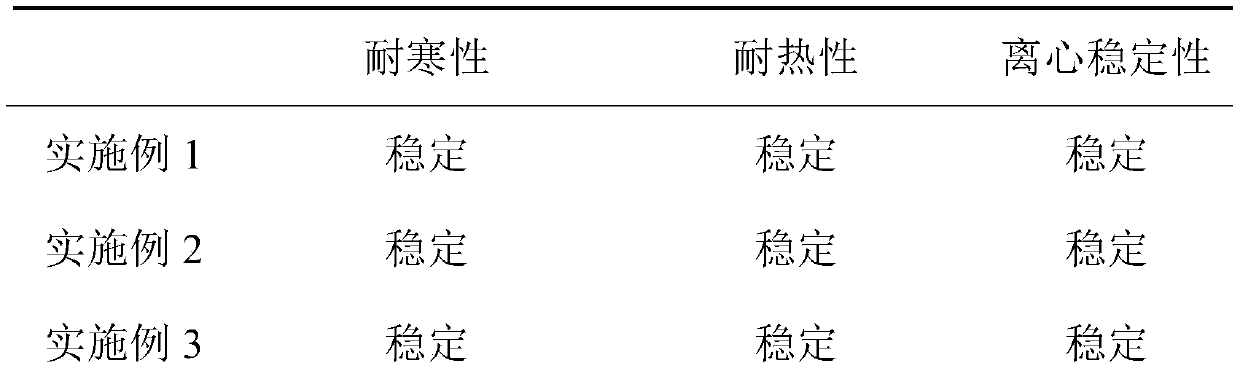

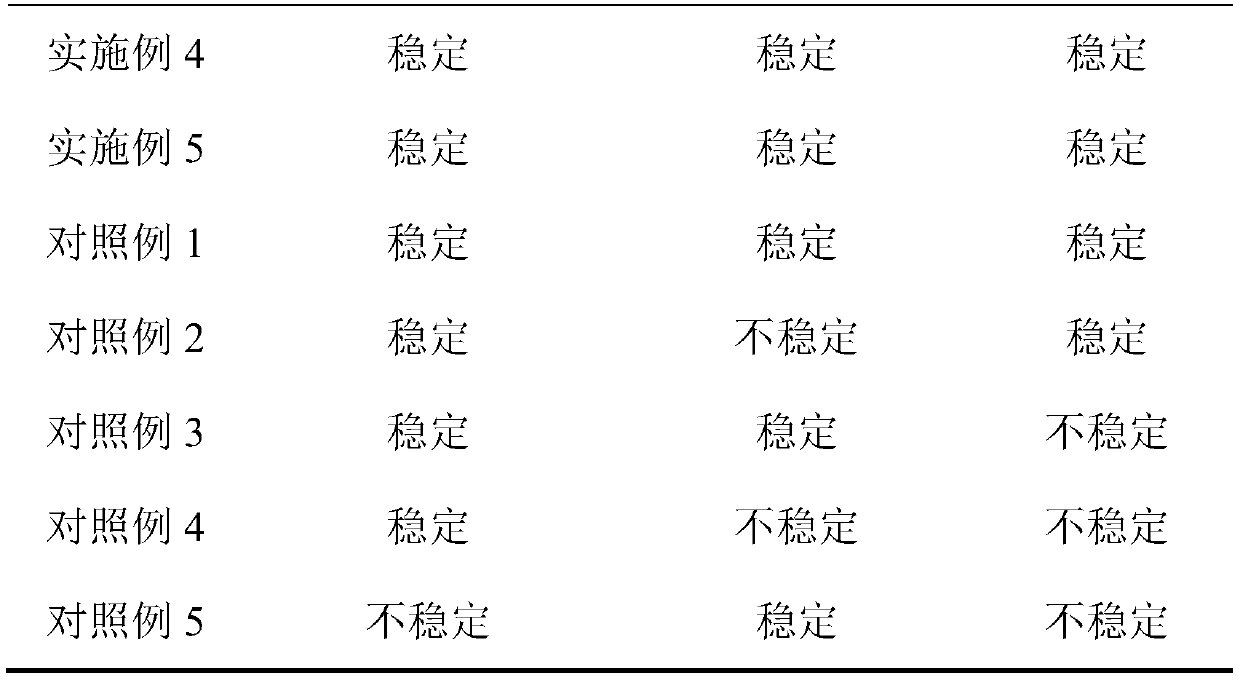

Bacteriostatic acne-removing facial mask containing soapberry ferment and borneol essential oil and preparation method thereof

ActiveCN110123699AWide variety of sourcesA variety ofCosmetic preparationsToilet preparationsGlycerolCinnamomum camphora

The invention relates to a bacteriostatic acne-removing facial mask containing a soapberry ferment and borneol essential oil and a preparation method thereof, and belongs to the field of cosmetics skin care. The adopted soapberry ferment is prepared by naturally fermenting fresh peel of soapberry, and has a high bacteriostatic ability. The adopted borneol essential oil is derived from leaves of cinnamomum camphora, and has the ability to inhibit mites and bacteria. A facial mask liquid is prepared from the following raw materials in parts by mass: 5-10 parts of glycerol, 1-5 parts of 1,3-butanediol, 4-8 parts of 1,2-propylene glycol, 20-40 parts of the soapberry ferment, 1-3 parts of sodium alginate, 0.1-0.3 part of disodium ethylenediaminetetraacetate, 0.1-0.3 part of a preservative, 0.00001-0.01 part of the borneol essential oil, and 30-40 parts of deionized water. The bacteriostatic acne-removing facial mask comprises a facial mask substrate and the facial mask solution infiltratedon the facial mask substrate. The facial mask has the characteristics of good color and uniform texture, and has good bacteriostatic and acne-removing effects in vitro.

Owner:JIANGNAN UNIV

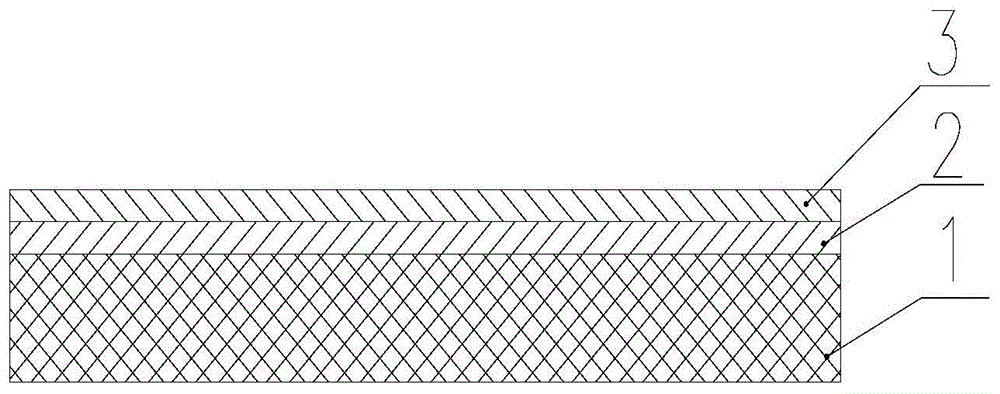

Ecological composite board and manufacturing method thereof

ActiveCN104895270AImprove performanceNo pollution in the processCovering/liningsSynthetic resin layered productsPolymer scienceVolumetric Mass Density

The invention provides an ecological composite board and a manufacturing method thereof. The ecological composite board comprises a surface acrylic board layer, a middle loofah sponge layer and a bottom density board layer. The loofah sponge layer is respectively fixed to the density board layer and the acrylic board layer through adhesive layers, the surface acrylic board layer is made of transparent acrylic boards, a plurality of loofah sponge pieces with the same specification are spliced to form the loofah sponge layer and have preset thicknesses, mutually spliced surfaces of the loofah sponge pieces are diagonal surfaces, and original ecological loofah sponge is soaked, peeled, colored, stripped, flattened, stamped and hot-pressed to form the loofah sponge pieces. The composite board is attractive and elegant, and has natural stereoscopic impression of the loofah sponge, high heat insulation and sound insulation effects and high stability.

Owner:SHIJIAZHUANG YIFA NEW MATERIALS CO LTD

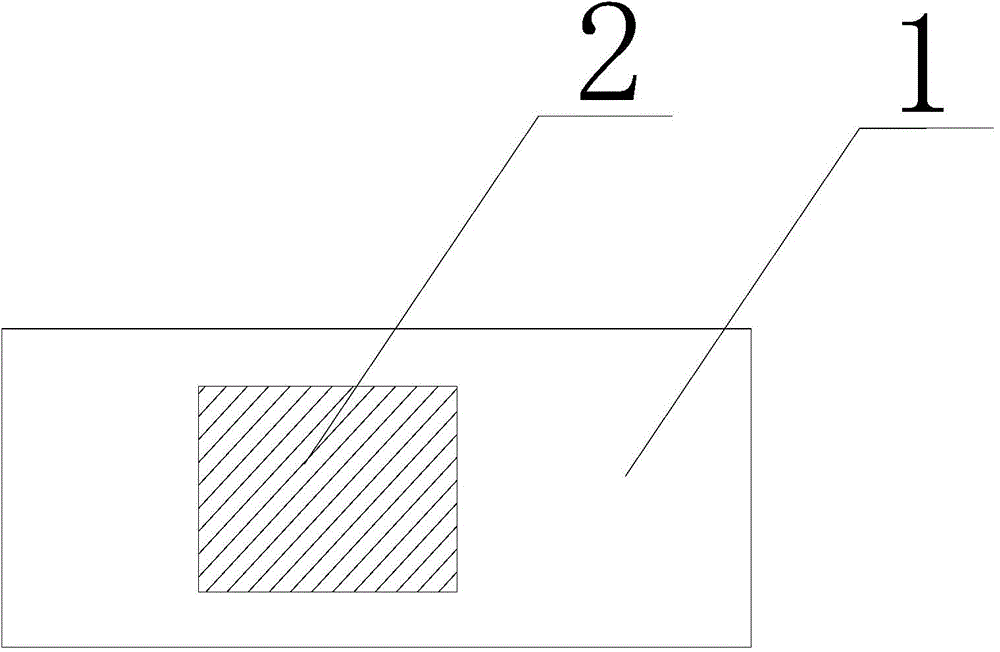

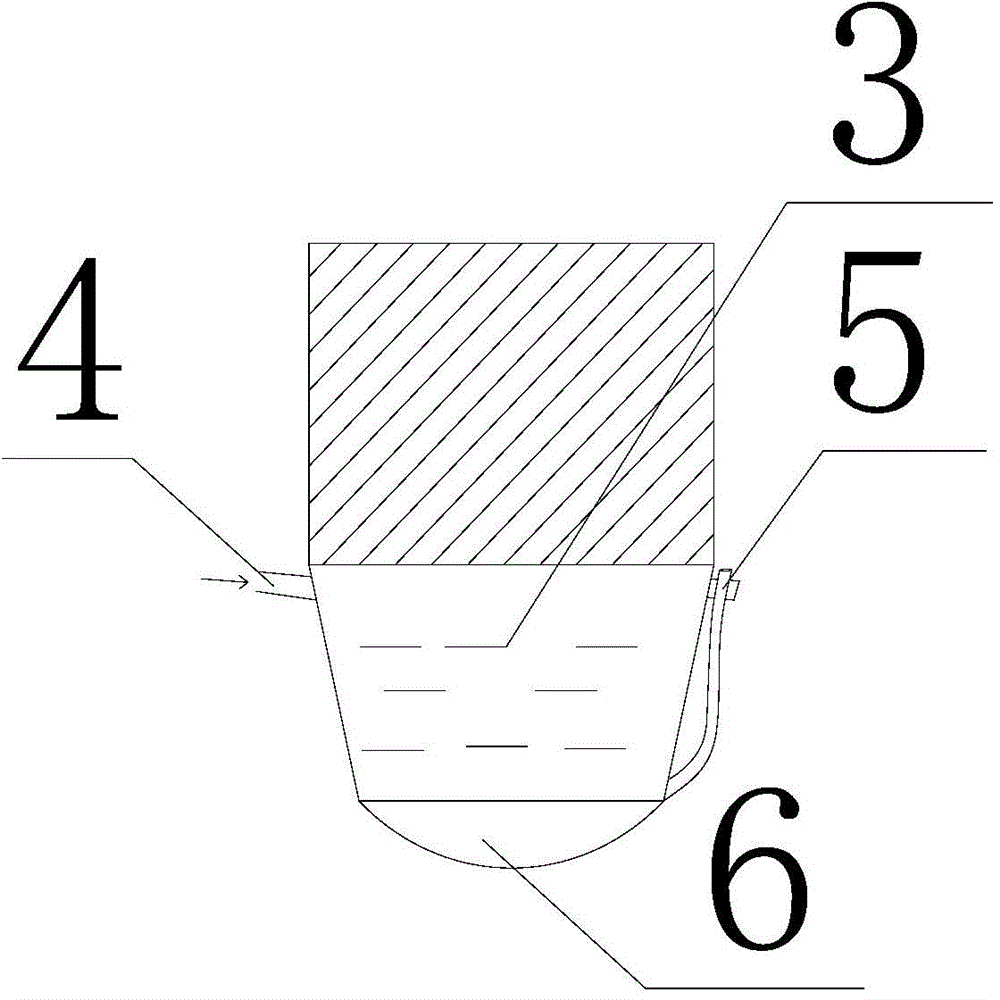

MCM (micro-Chinese medicine) molecule penetration absorption treatment for treatment of lumbar vertebra disease

InactiveCN104815390AA variety ofGood treatment effectSkeletal disorderMedical devicesVertebraTreatment effect

The invention provides an MCM (micro-Chinese medicine) molecule penetration absorption treatment for the treatment of a lumbar vertebra disease, and the bed comprises a bed body. The bed body comprises a bed plate and a supporting column. The supporting column is vertically disposed at a side of the bed plate, and the bed plate is provided with a thermal conduction plate in an embedded manner. The thermal conduction plate is covered by traditional Chinese medicine compositions for the treatment of the lumbar vertebra disease. The bottom of the bed plate is provided with a water tank, and the bottom of the water tank is provided with a heater. The bed provided by the embodiment of the invention changes a conventional treatment mode, is good in treatment effect, and has no side effect.

Owner:卫景龙

Fruit-flavored soymilk added with stabilizer

Owner:SHANGHAI QINGMEI GREEN FOOD

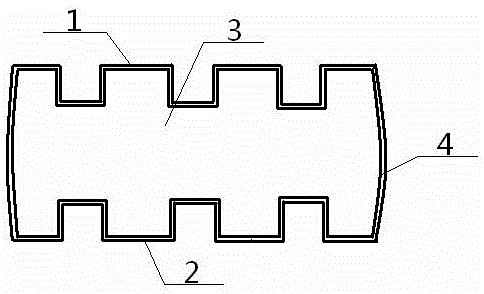

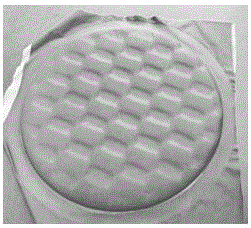

Compression-molded cushion and preparation method thereof

ActiveCN106827340AAvoid misalignmentPrevent slippingStuffed mattressesSpring mattressesHoneycombEngineering

The invention discloses a compression-molded cushion. The compression-molded cushion comprises an upper outer surface coating material, a lower outer surface coating material, and a liner manufactured by honeycomb cottons therebetween; the edges of the upper and lower outer surface coating materials are connected as cushion edge parts; the liner is a molded three-dimensional structure; the middle parts of the upper and lower outer surface coating materials are respectively connected with the top and bottom surfaces of the liner; a concave-convex three-dimensional structure of the cushion is embodied by concave-convex three-dimensional structures on the outer surface coating materials and the liner; during preparing, the outer surface coating materials and the honeycomb cottons are once molded by the mold to obtain the cushion; and the printing can be also considered. The compression-molded cushion is higher in preparation efficiency, lower in production cost, higher in combination firmness and better in environmental protecting performance, achieves the advantages of high elasticity and resilience, and is high in third dimension, excellent in support performance and excellent in beauty.

Owner:KUNSHAN TENGFEI UNDERWEAR TECH

A kind of ice feeling finishing agent and preparation method thereof

Owner:珠海华大浩宏新材料有限公司

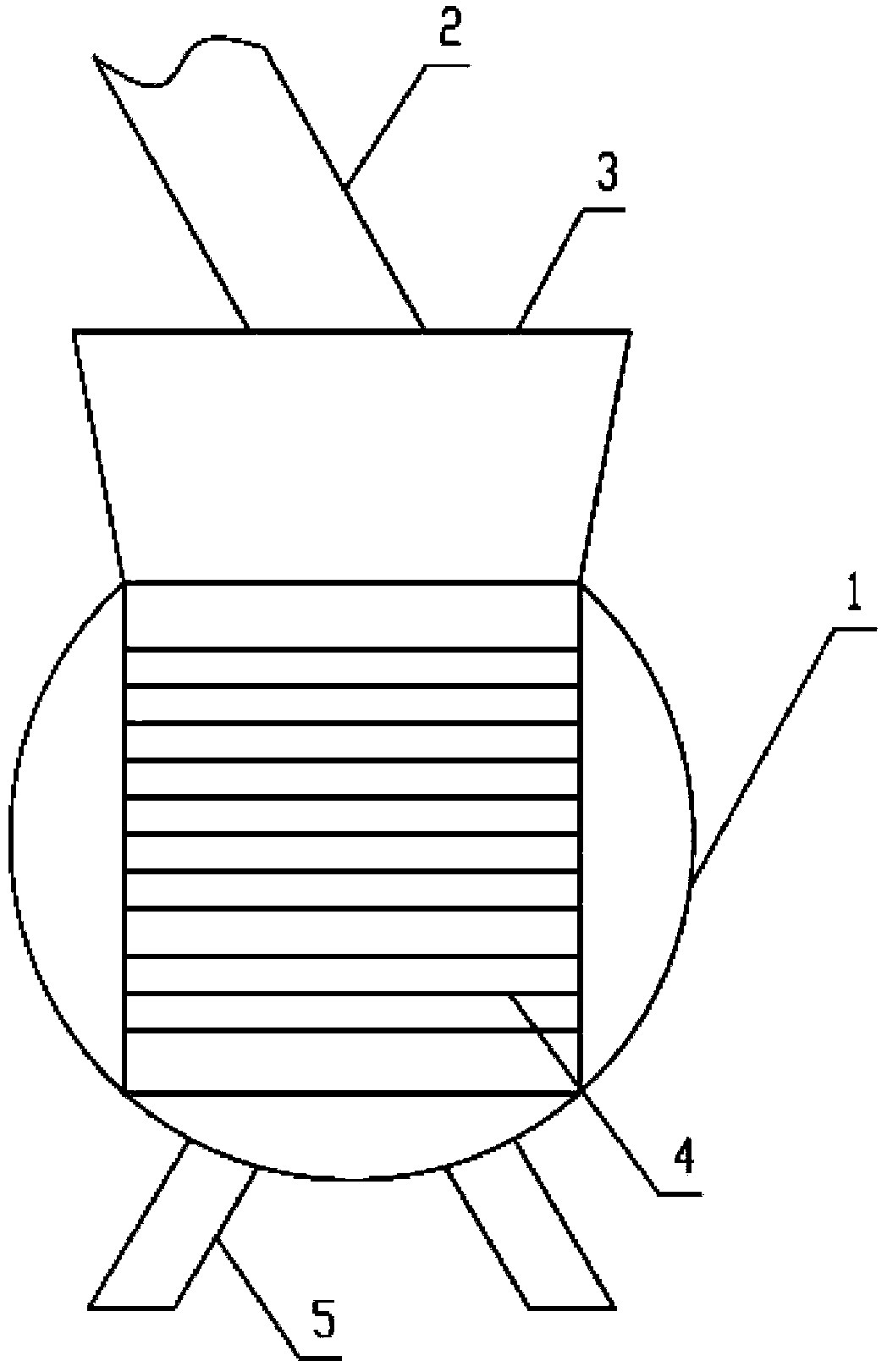

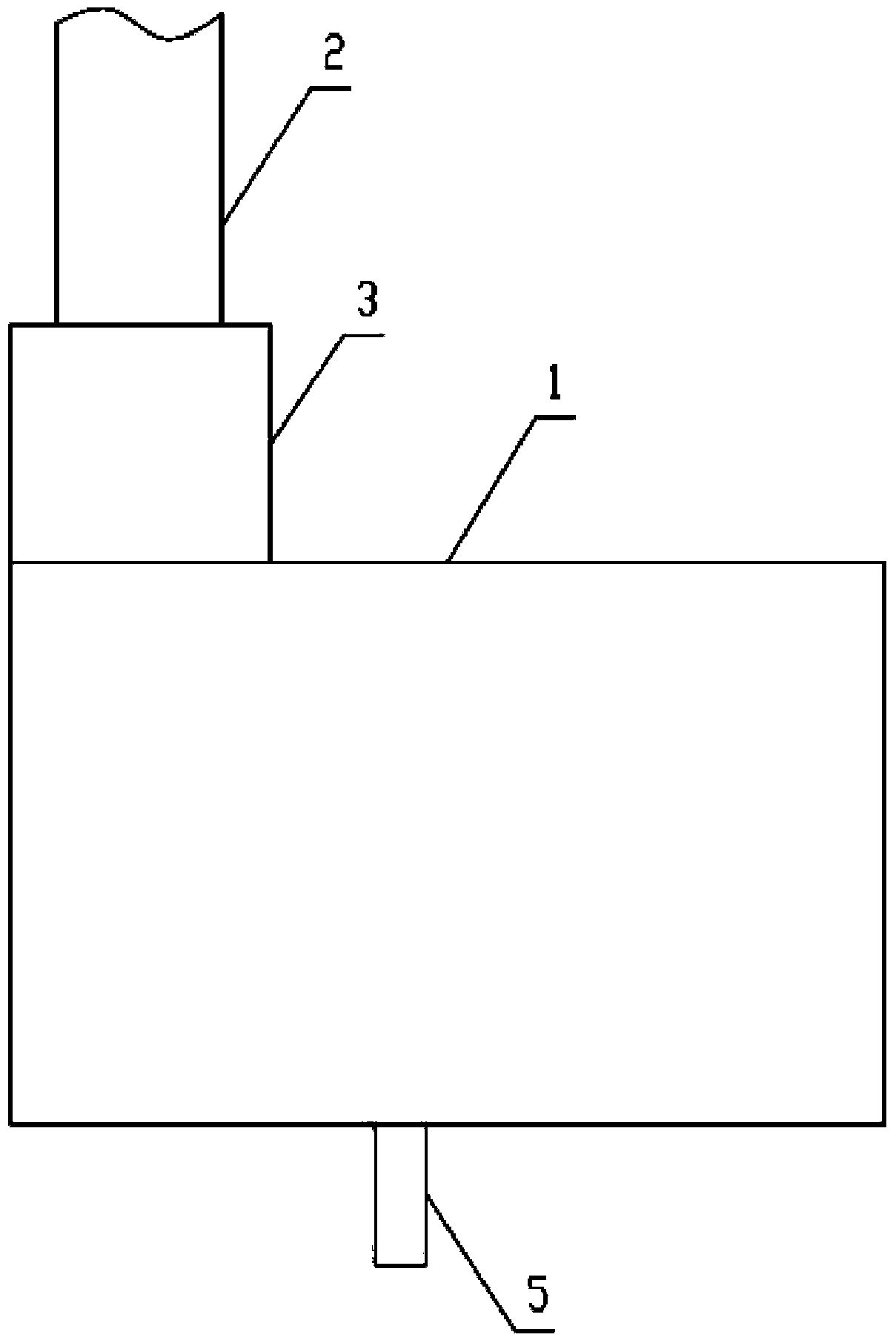

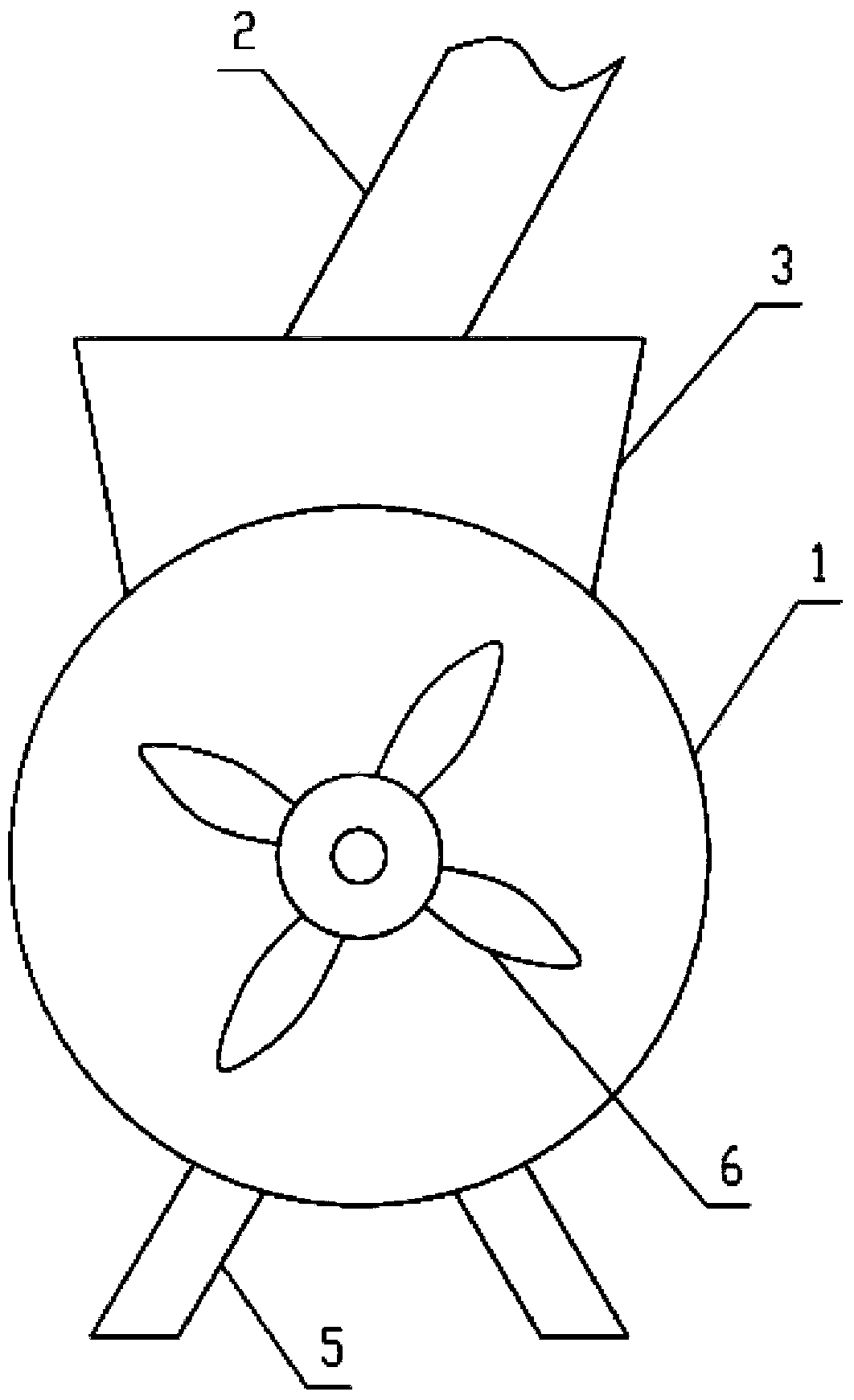

Preparation method of plastic raw material beneficial to degradation

The invention discloses a preparation method of a plastic raw material beneficial to degradation, wherein the preparation method comprises the steps: sending 30-40 parts by weight of degradable resinpowder, 10-14 parts by weight of glycerol starch ester and 35-42 parts by weight of modified starch into a kneader, and kneading for 15-20 min; then adding the kneaded raw materials into a crushing box of a mixing mill, and then sequentially adding 3-5 parts of a dispersing agent, 2-3 parts of a composite coupling agent, 4-8 parts of a plasticizer, 2-5 parts of an antioxidant, 1-3 parts of a fluorescent whitening agent, 0.5-2 parts of an ultraviolet light absorber and 2.5-8 parts of a filling agent. Starch and polyvinyl alcohol used in the preparation method are easily biodegradable high molecular materials, so elimination of white pollution is facilitated, and the environment is protected.

Owner:ANHUI HUANJIA TIANYI RENEWABLE RESOURCES

A kind of vermiculite production and processing technology

The invention provides a vermiculite production processing technology. The method of the technology comprises the following steps: grinding the vermiculite raw material; sieving and grading the ground vermiculite raw material; performing primary cleaning of the vermiculite raw material after the primary sieving by use of a sand removing machine; calcining the vermiculite raw material after the primary cleaning; performing secondary cleaning of the calcined expanded vermiculite in a winnowing machine; sieving and grading the expanded vermiculite after the winnowing by use of a flat sieve, and sieving out various types of expanded vermiculite according to the different sizes of the expanded vermiculite; and performing third-time mechanical cleaning of the types of expanded vermiculite. The vermiculite production processing technology provided by the invention has the beneficial effects that the vermiculite does not need to be spread out to be cooled after the calcination and can be packaged directly, thereby greatly improving the working efficiency and reducing the labor intensity of workers; and through the cooling and purifying technology, the production cost is greatly reduced, and the produced vermiculite product can be widely applied to the industries with relatively high requirement on the vermiculite product quality such as fireproof coatings and rubbing seal materials.

Owner:SHIJIAZHUANG JINLI MINING IND

Vermiculite production processing technology

The invention provides a vermiculite production processing technology. The method of the technology comprises the following steps: grinding the vermiculite raw material; sieving and grading the ground vermiculite raw material; performing primary cleaning of the vermiculite raw material after the primary sieving by use of a sand removing machine; calcining the vermiculite raw material after the primary cleaning; performing secondary cleaning of the calcined expanded vermiculite in a winnowing machine; sieving and grading the expanded vermiculite after the winnowing by use of a flat sieve, and sieving out various types of expanded vermiculite according to the different sizes of the expanded vermiculite; and performing third-time mechanical cleaning of the types of expanded vermiculite. The vermiculite production processing technology provided by the invention has the beneficial effects that the vermiculite does not need to be spread out to be cooled after the calcination and can be packaged directly, thereby greatly improving the working efficiency and reducing the labor intensity of workers; and through the cooling and purifying technology, the production cost is greatly reduced, and the produced vermiculite product can be widely applied to the industries with relatively high requirement on the vermiculite product quality such as fireproof coatings and rubbing seal materials.

Owner:SHIJIAZHUANG JINLI MINING IND

Wash flower process

The invention discloses a wash flower process, comprising the following steps: (1) selecting a color cloth; (2) printing a non-apparent printing type pattern through slurry on the selected color cloth; and (3) flowering and washing the color cloth. The invention skillfully combines a traditional printing technology and a washing technology, thereby processing wash flower finished products with wide varieties, different concealing and revealing levels, changeable pattern styles, rich and colorful appearance and infinite changes on the same color cloth substrate according to demands of producers and market.

Owner:王玉山

Novel road bridge beam supporting seat dustproof structure

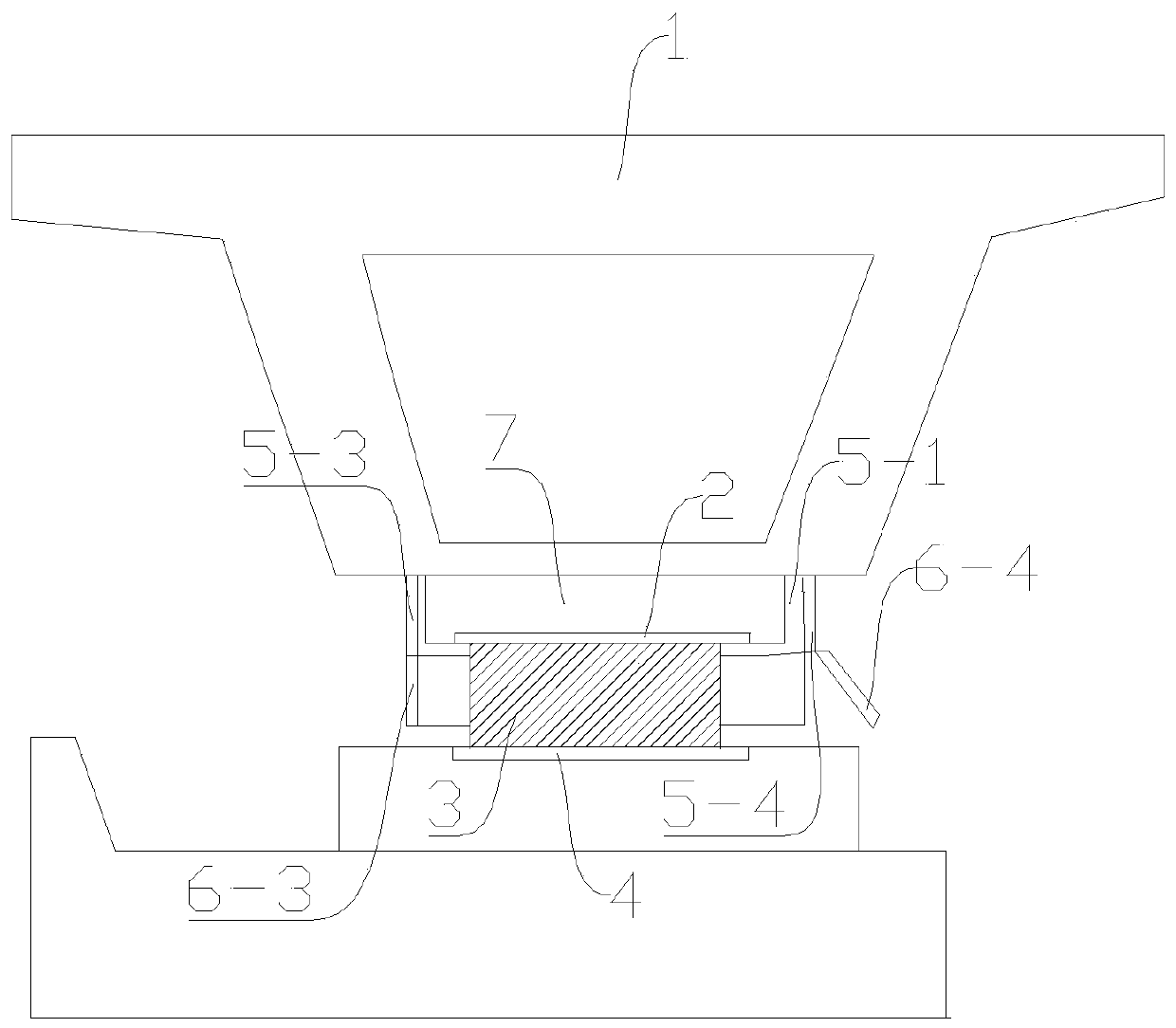

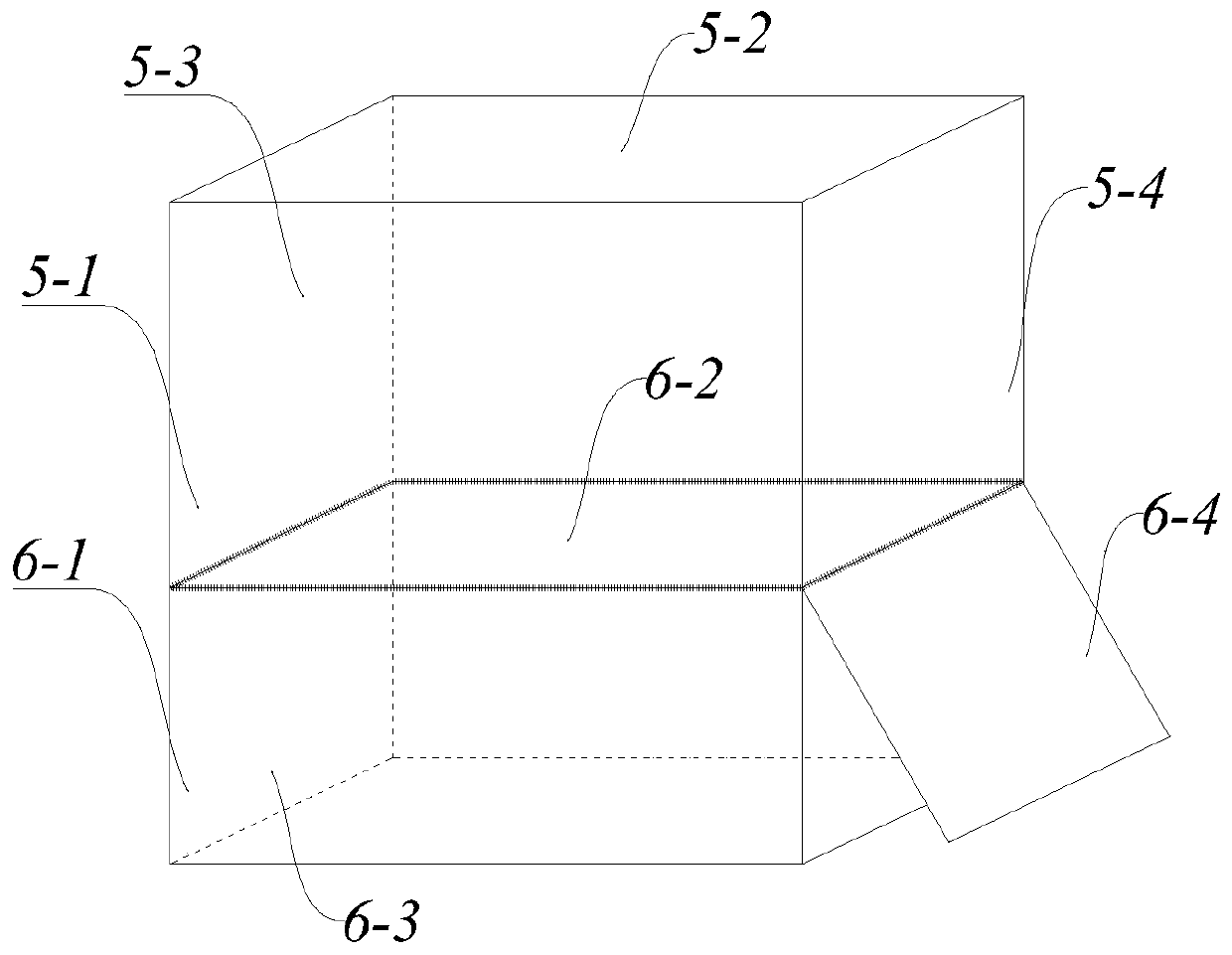

PendingCN110184905AAdaptableGood weather resistanceBridge structural detailsTest efficiencyArchitectural engineering

The invention discloses a novel road bridge beam supporting seat dustproof structure, including a beam body, an upper cushion stone and an upper steel plate located below the beam body, a supporting seat located below the upper steel plate, a fixed side plate enclosing the upper cushion stone and the upper steel plate, a movable side plate located below the fixed side plate and enclosing the supporting seat, and a lower steel plate located below the supporting seat, and the upper edge of the movable side plate is hinged to the lower edge of the fixed side plate. According to the novel road bridge beam supporting seat dustproof structure, manufacture of the fixed side plate and the movable side plate by perspex is adopted, durability is good, and the structure is not prone to aging; and corrosion of the steel plate of the bridge beam supporting seat caused by seepage of water is prevented effectively, the influence of dust on a sliding surface of the supporting seat is prevented, agingof the supporting seat is slowed, and the life of the supporting seat is prolonged. The state of the supporting seat is tested visually without the need of using other methods, testing efficiency is improved, a supporting seat maintenance operation is not hindered, a replacement operation of the supporting seat during later maintenance is convenient, and long-time benefits are obvious.

Owner:江苏京沪高速公路有限公司

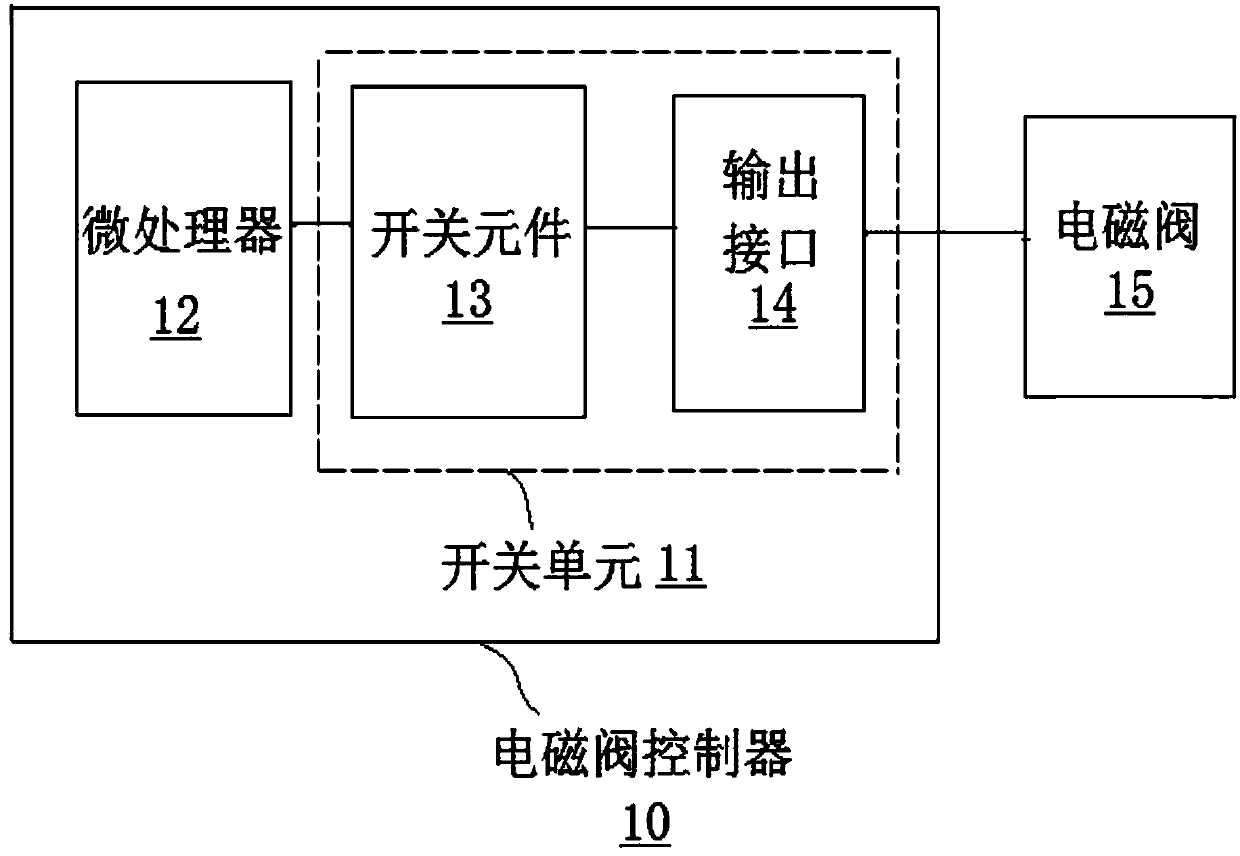

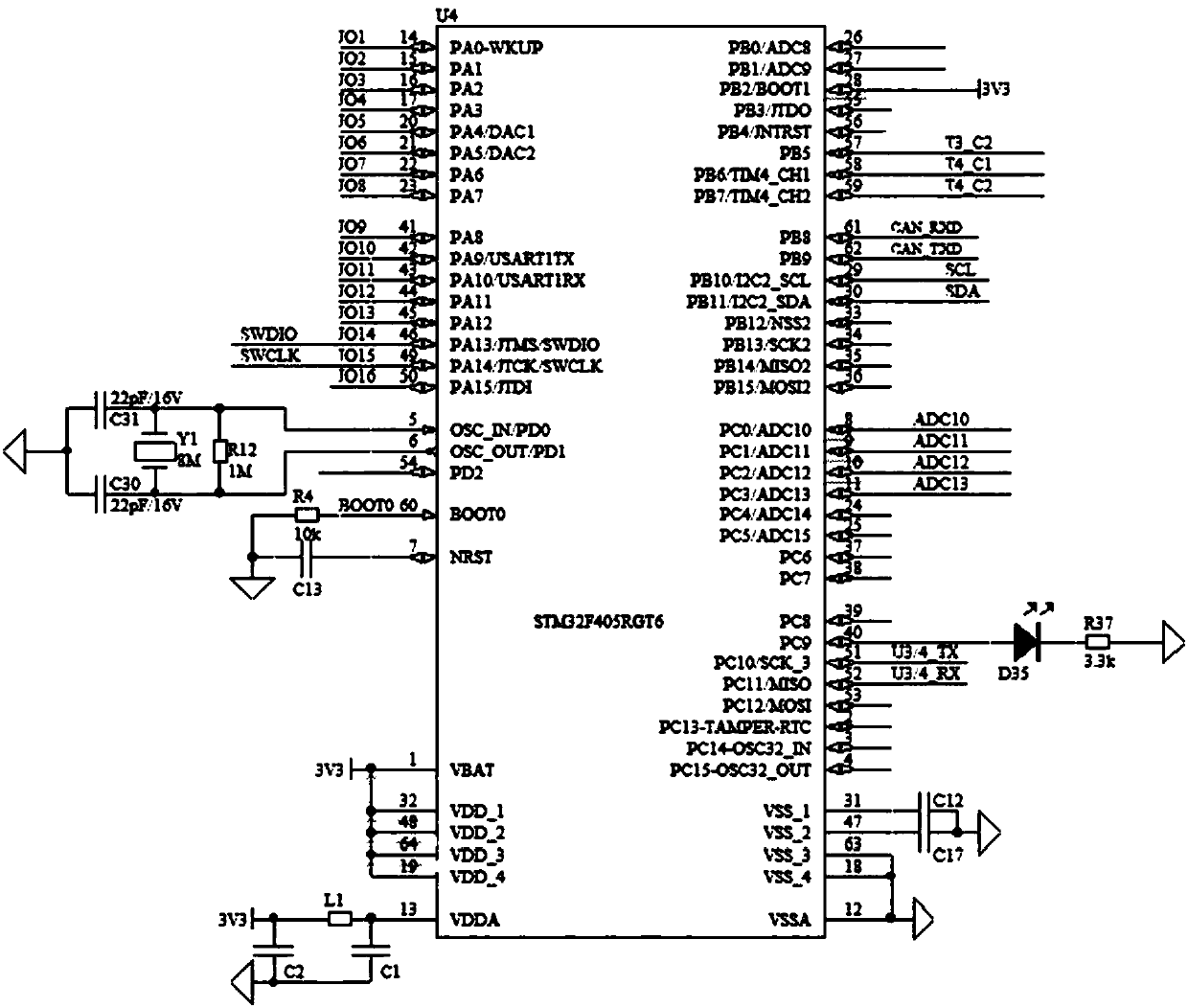

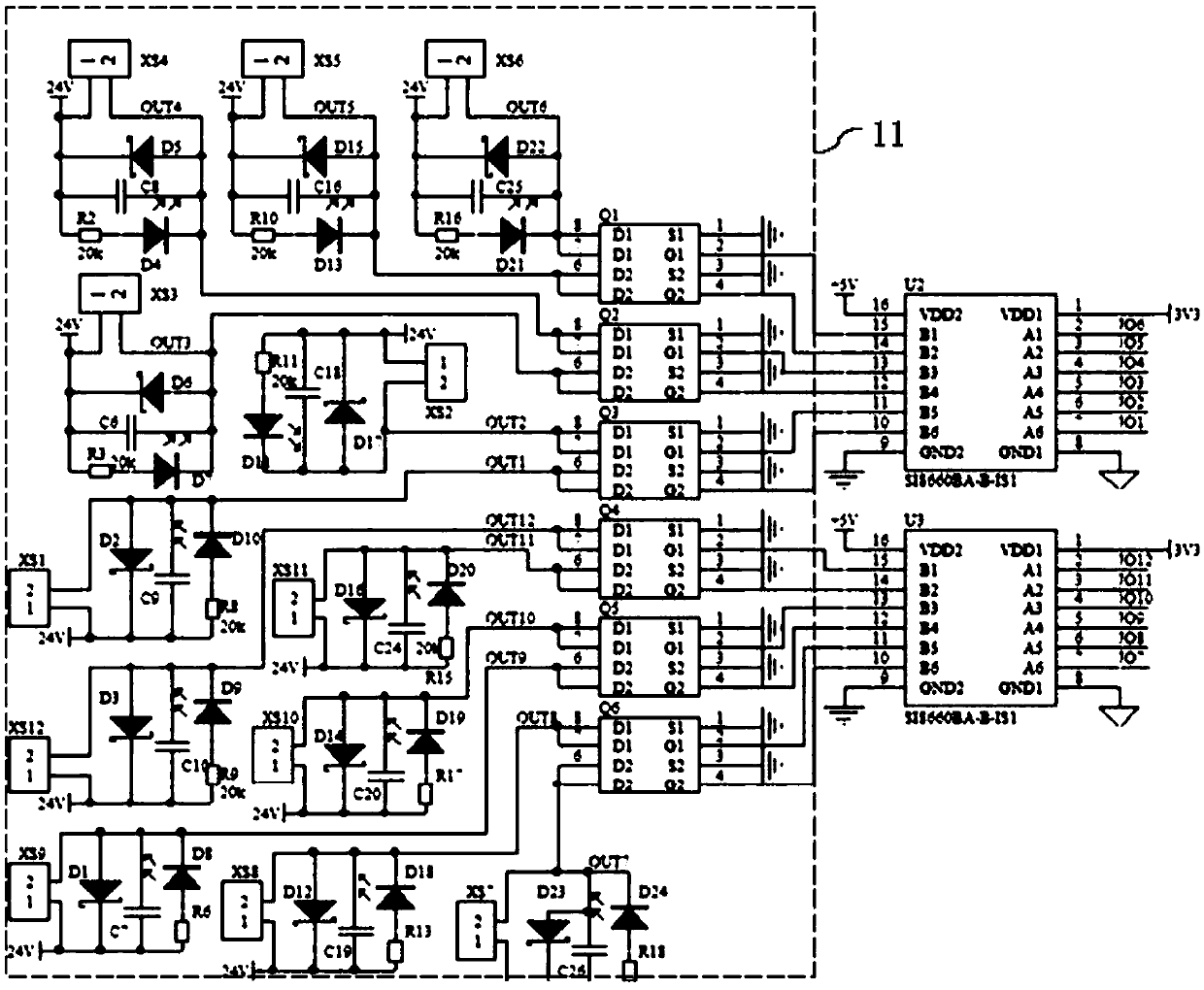

Controller of multiple electromagnetic valves, electromagnetic valve device comprising controller and control method of electromagnetic valves

InactiveCN110081221ALow calorific valueLower control costsOperating means/releasing devices for valvesControl theoryElectromagnetic valve

The invention provides a controller of multiple electromagnetic valves. The controller is used for controlling the multiple electromagnetic valves, and comprises a microprocessor and a plurality of switch units, wherein the switch units are correspondingly connected between the microprocessor and the multiple electromagnetic valves, the microprocessor controls the multiple electromagnetic valves through the plurality of switch units, the microprocessor outputs a pulse signal with a preset frequency and a preset duty cycle to the electromagnetic valves, so that the electromagnetic valves are enabled to keep in a power-on state; and the invention further provides an electromagnetic valve device, and the electromagnetic valve device comprises the controller of the multiple electromagnetic valves and the multiple electromagnetic valves.

Owner:科尼格沃斯(无锡)医学科技有限公司

Durability tester for temperature controller

InactiveCN102122169BSmall thermal inertiaPrecise adjustment of heating temperatureTesting/monitoring control systemsAir pumpEngineering

The invention discloses a durability tester for a temperature controller, which comprises a power supply unit, a load unit, a detection control unit, an output unit, a heating unit and a cooling unit. The durability tester is characterized in that the heating unit comprises a copper block in which a heating pipe is arranged, the heating pipe is connected with the power supply unit, an upper surface of the copper block is provided with a thermoelectric couple for acquiring the temperature of the copper block in real time, the thermoelectric couple is connected with the detection control unit, and the upper surface of the copper block is further provided with an insulating heat-resistant pressure plate for fixing a temperature sensitive part of a temperature controller; the cooling unit is a cooling airflow sprayer arranged over the insulating heat-resistant pressure plate and connected with an external air pump of the tester; and the temperature controller is connected with an input end of the load unit through a lead. The durability tester has the advantages that the heating mode of the tester is small in thermal inertia, so that an adjustable range of the conduction and the disconnection of the temperature controller is large, the range of the heating temperature is large, the heating temperature and the cooling speed can be accurately controlled, accuracy of the test result can be improved, and the tester is simple in structure and low in cost.

Owner:宁波市产品质量监督检验研究院

Negative modified high-safety lithium-ion battery

ActiveCN105244551BImprove securityImprove solubilityCell electrodesSecondary cells servicing/maintenanceOligomerLithium-ion battery

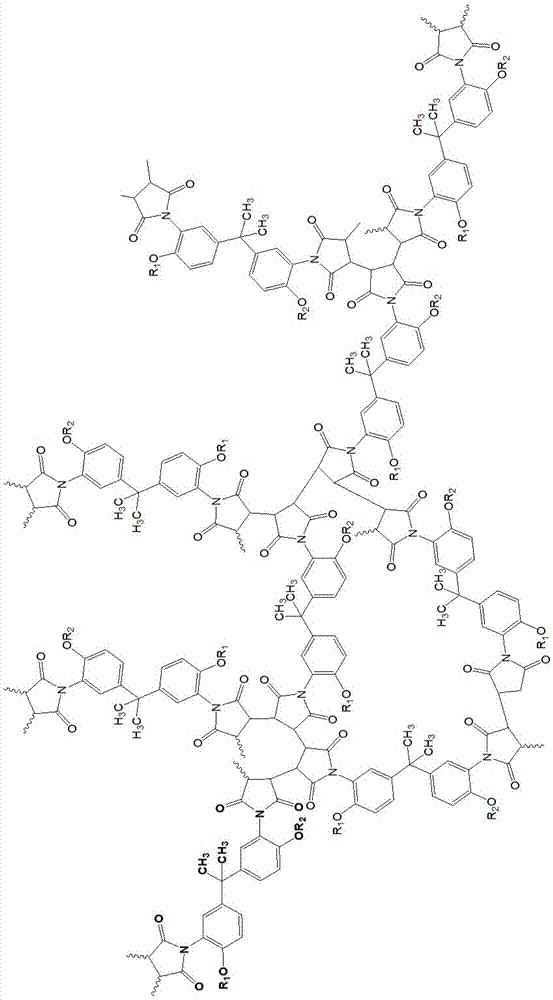

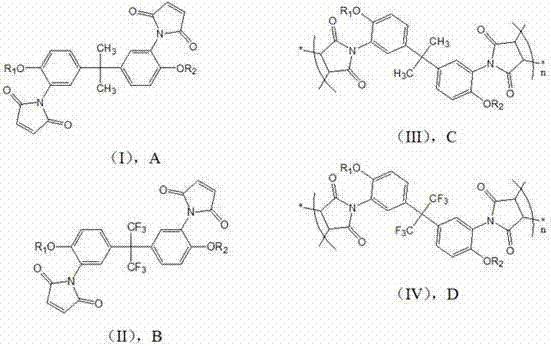

The invention relates to a cathode modified high security lithium ion battery, which is characterized in that a negative plate contains a thermal protective agent. When the battery is heated to a certain temperature, the thermal protective agent conducts crosslinking reaction to barrier thermal runaway; the thermal protective agent bismaleimide A shown in formula (I), or bismaleimide B shown in formula (II), or a bismaleimide oligomer C shown in formula (III), or bismaleimide oligomer D shown in formula (IV). The thermal protective agent can accept a variety of modifications, including alkoxy modification and acyl modification, has a large amount of varieties and is convenient for selection and usage. When being heated to a certain temperature, the thermal protective agent conducts crosslinking reaction, thus preventing thermal runaway. The battery has strengthened safety performance, and the manufacturing method is also simple.

Owner:CHINA FIRST AUTOMOBILE

Preparation method of non-fried instant wonton

The invention provides a preparation method of a non-fried instant wonton; the method comprises the following steps of: making a dough, leavening, pressurized steaming, making wonton wrappers, fillingstuff, cooking the wonton, dehydrating the cooked wonton, packaging, and the like. The invention utilizes the methods of adding wheat gluten in the preparation formulation and the like and adopts themethod of pressurized steaming to better overcome the shortcomings of poor reconstituability and bad mouth feel of the non-fried wonton wrappers; as for the formed wonton, a compound microwave-stewing heating method is used to further improve the quality and mouth feel of the wonton; and microencapsulation is conducted on the seasoning, thus being capable of developing seasonings with rich nutrition and various types.

Owner:ZHEJIANG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com