A kind of vermiculite production and processing technology

A processing technology, vermiculite technology, applied in the field of vermiculite production and processing technology, can solve the problems of slow cooling speed, high impurity content, etc., achieve the effect of various varieties, low impurity content, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

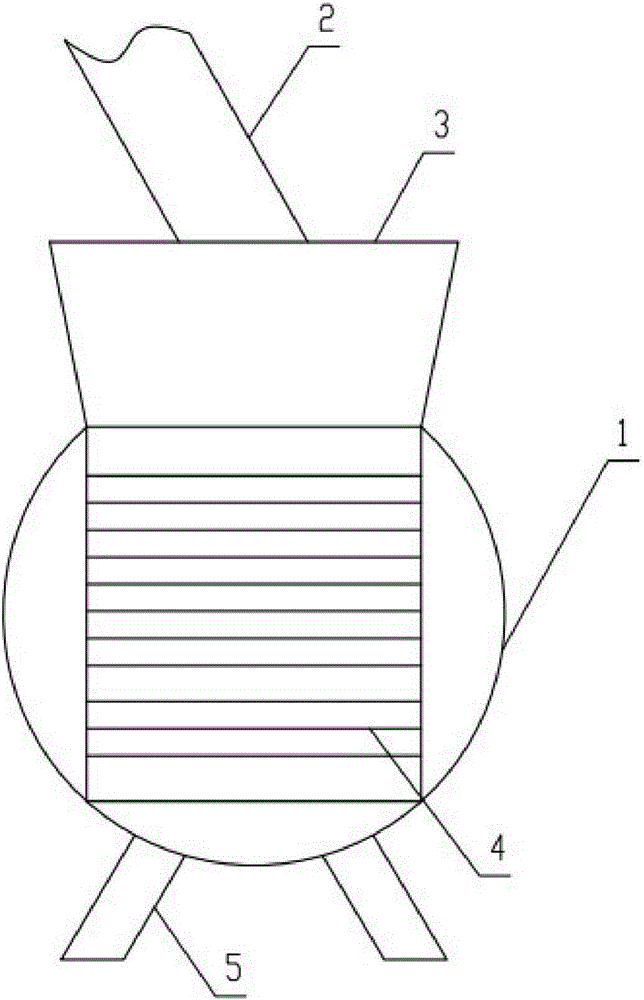

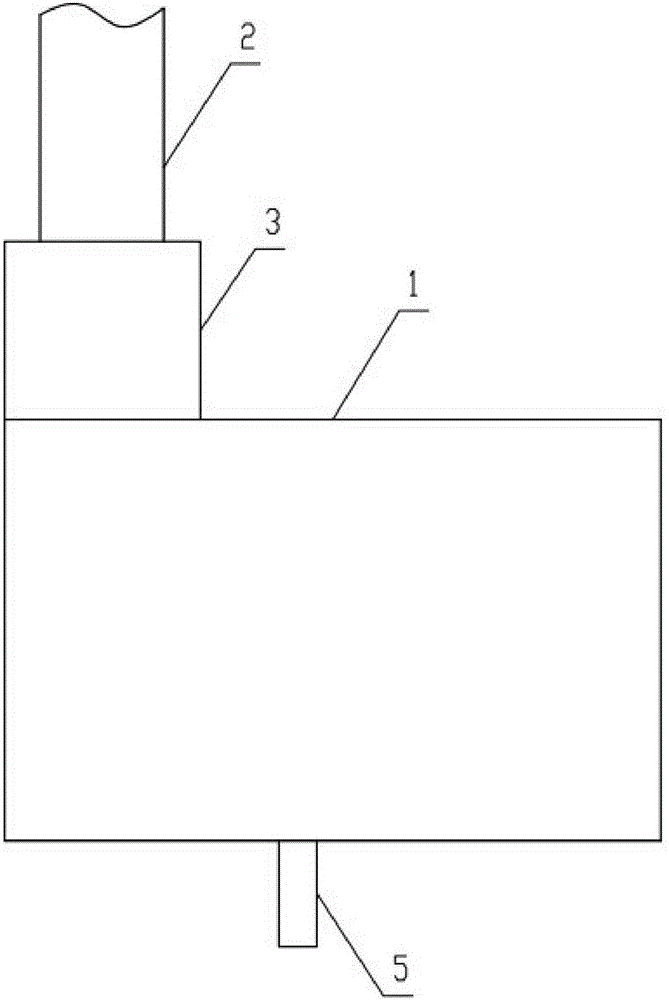

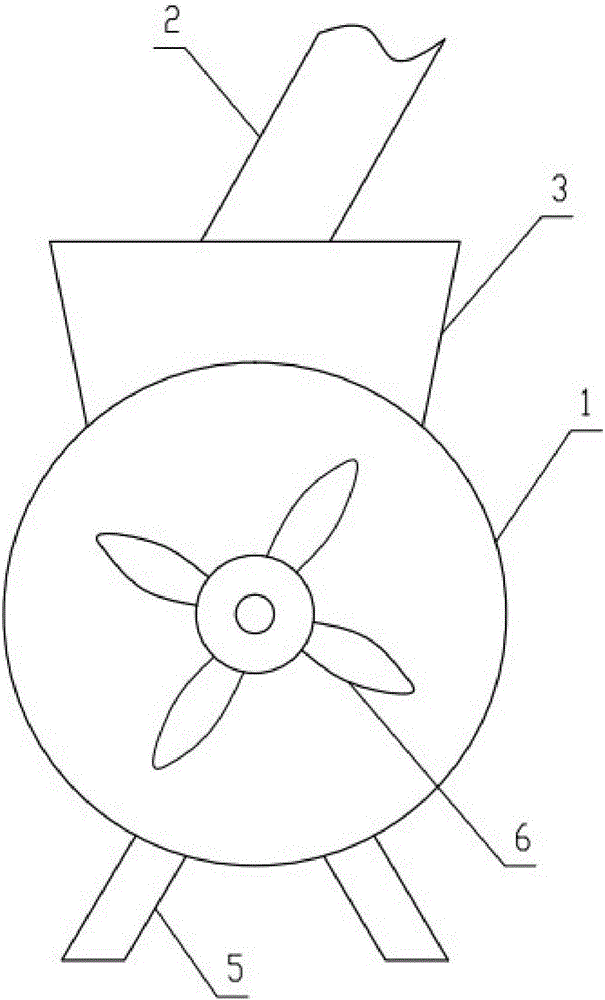

[0035] A kind of vermiculite production and processing technique, its method step is as follows:

[0036] (1) Pulverization: The vermiculite raw material is pulverized by a hammer crusher.

[0037] (2) Primary sieving: sieving and grading the pulverized vermiculite raw materials to remove larger non-vermiculite impurities.

[0038] Since vermiculite is relatively soft and brittle, other non-vermiculite impurities are relatively hard and not brittle, so it is easy to remove the larger non-vermiculite impurities after the crushed vermiculite raw material is sieved.

[0039] (3) One-time machine removal of impurities: the vermiculite raw material after primary screening is passed through a sand remover to remove a part of sandstone in the vermiculite raw material, so that the impurity content in the vermiculite raw material is reduced to 15% to 20%;

[0040] Since part of the vermiculite will be broken during the process of removing impurities by the impurity remover in step thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com