Wash flower process

A technique of crafting and washing flowers, which is applied in the fields of dyeing, textiles and papermaking, etc. It can solve the problem of not processing faintly visible printed patterns, etc., and achieve the effect of rich and colorful appearance and changeable pattern styles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Choose the base fabric for the color cloth, such as special black vulcanized dyed pure cotton cloth.

[0048] Invisible printing involves the following steps:

[0049] Net making and slurry preparation;

[0050] Printing with prepared slurry on the colored cloth;

[0051] drying the colored cloth at a temperature ranging from 100 to 120°C; and

[0052] The dried colored cloth is baked in a temperature range of 160-180° C. for setting.

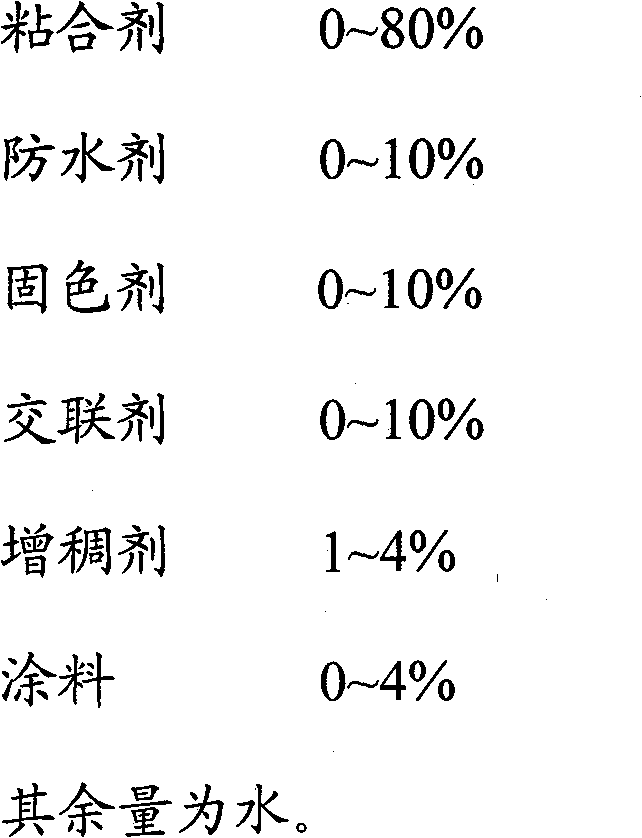

[0053] The printing paste prescription is as follows (weight ratio):

[0054] Binder 25%

[0055] Crosslinker 1.5%

[0056] Thickener 3%

[0057] Paint Black 1.8%

[0058] Paint navy blue 0.7%

[0059] Dope Scarlet 0.4%

[0060] Water X%

[0061] The blooming washing process includes:

[0062] Invisible calico sewing processing;

[0063] Dry sweeping monkey;

[0064] Ash removal;

[0065] general washing; softening;

[0066] dehydration;

[0067] drying.

Embodiment 2

[0069] The color cloth chooses the base fabric, such as light-colored reactive dyed pure cotton cloth.

[0070] Invisible printing involves the following steps:

[0071] Net making and slurry preparation;

[0072] Printing with prepared slurry on the colored cloth;

[0073] drying the colored cloth at a temperature ranging from 100 to 120°C; and

[0074] The dried colored cloth is baked in a temperature range of 160-180° C. for setting.

[0075] Described printing slurry prescription is as follows (weight ratio):

[0076] Water repellant 5%

[0077] Fixing agent 3%

[0078] Cross-linking agent 2%

[0079] Thickener 3%

[0080] Water X%

[0081] Blooming washes include:

[0082] Invisible calico sewing processing;

[0083] Dry sweeping monkey;

[0084] Ash removal;

[0085] general washing;

[0086] soften;

[0087] dehydration;

[0088] drying.

Embodiment 3

[0090] The color cloth adopts the base fabric, such as warp dyed weft yarn flashing white denim.

[0091] Net making and slurry preparation;

[0092] Printing with prepared slurry on the colored cloth;

[0093] drying the colored cloth at a temperature ranging from 100 to 120°C; and

[0094] The dried colored cloth is baked in a temperature range of 160-180° C. for setting.

[0095] Described printing slurry prescription is as follows (weight ratio):

[0096] Binder 45%

[0097] Cross-linking agent 3%

[0098] Thickener 3%

[0099] Water X%

[0100] Blooming washes include:

[0101] Invisible calico sewing processing;

[0102] Dry sweeping monkey;

[0103] Ash removal;

[0104] general washing;

[0105] soften;

[0106] dehydration;

[0107] drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com