Durability tester for temperature controller

A technology of a thermostat and a tester, applied in the field of measuring instruments, can solve the problems that the heating temperature of a hot air gun is not easy to accurately control, the on-off adjustable range of the thermostat is small, and the deviation from the working state of the thermostat can be achieved. The speed adjustable range is improved, the controllable range is large, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

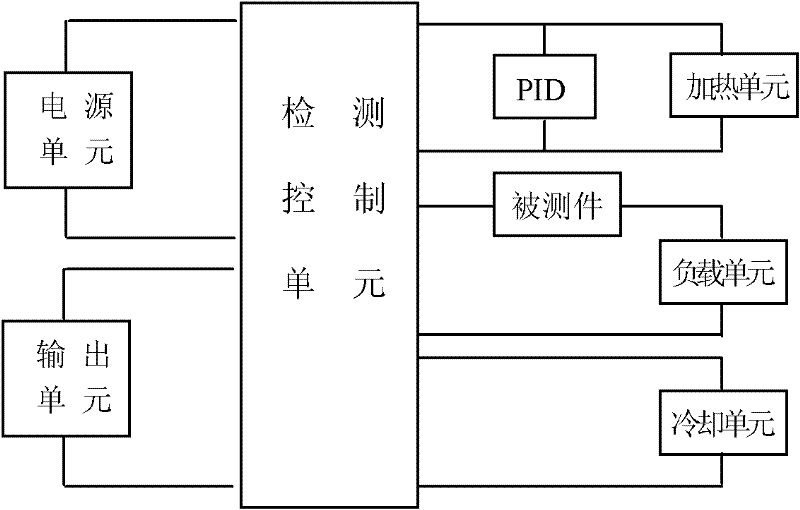

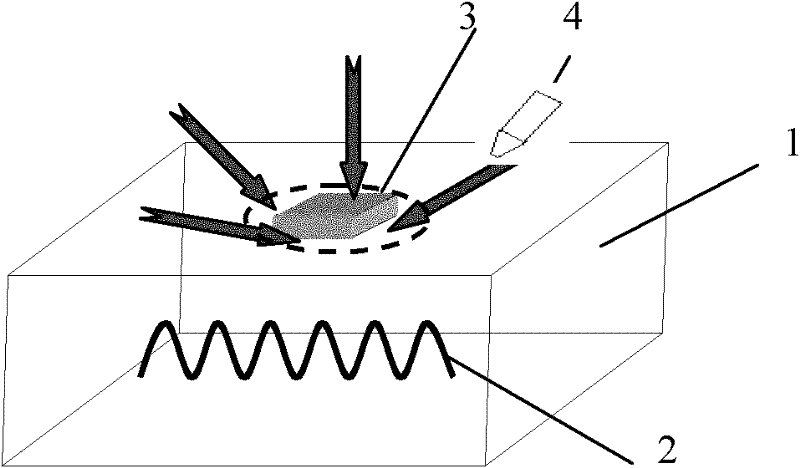

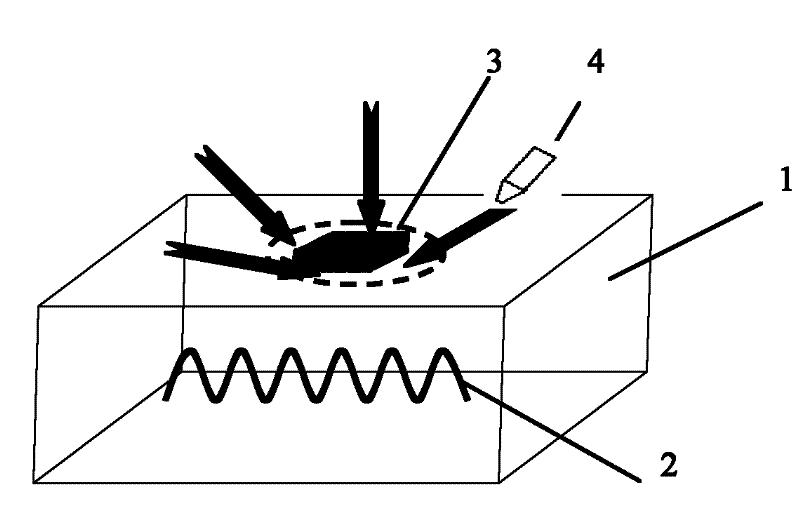

[0027] A kind of thermostat durability tester of the present invention, as figure 1 As shown, including power supply unit, load unit, detection control unit, output unit, heating unit and cooling unit, such as figure 2 As shown, the heating unit adopts a copper block 1 with a heating tube 2 inside, and the heating tube 2 is connected to the power supply unit. The upper surface of the copper block 1 is provided with a thermocouple for real-time acquisition of the temperature of the copper block 1 (not shown in the figure). The thermocouple is connected with the detection control unit, and the thermocouple collects the temperature of the copper block in real time and compares it with the preset temperature of the detection control unit, so that the entire copper block 1 reaches the preset temperature value, and the thermocouple is also connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com