Preparation method of lithium iron phosphate

A technology of lithium iron phosphate and tributyl phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of poor conductivity, impurity phase of lithium iron phosphate, influence of lithium iron phosphate cycle performance, etc. High conductivity, low internal resistance, and superior electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

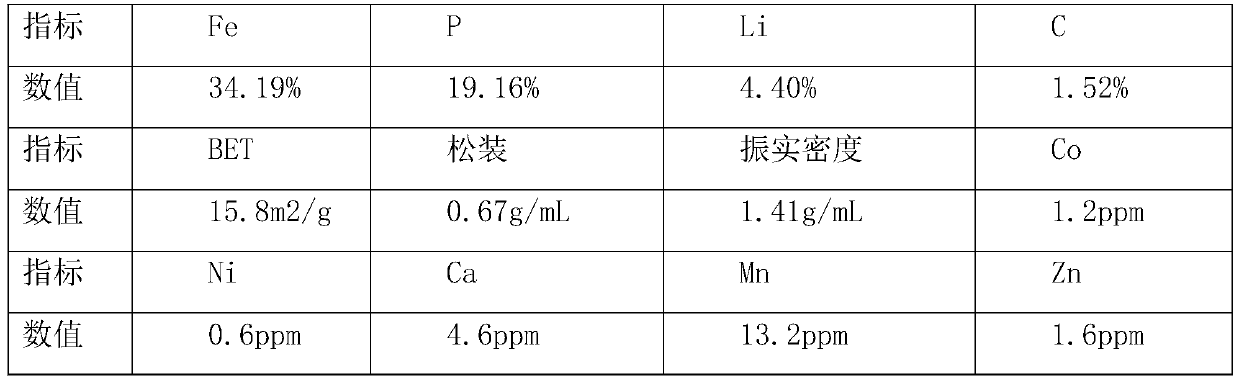

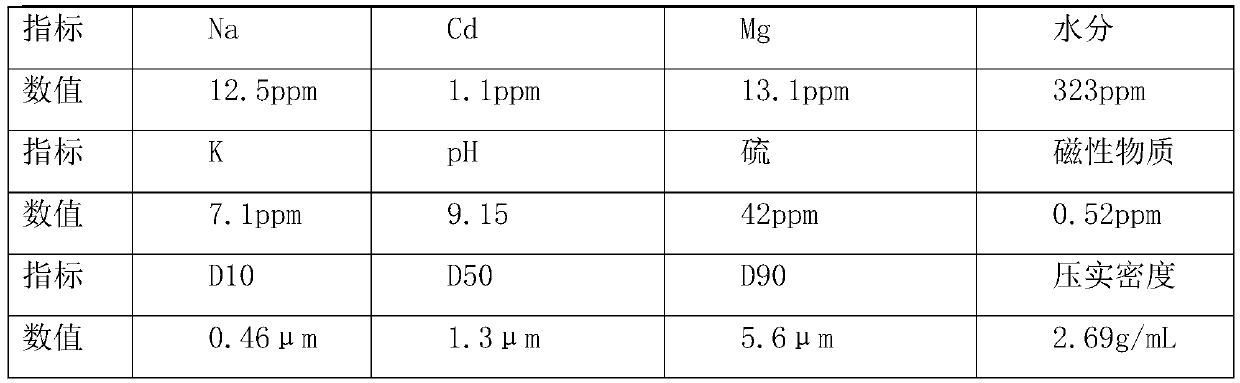

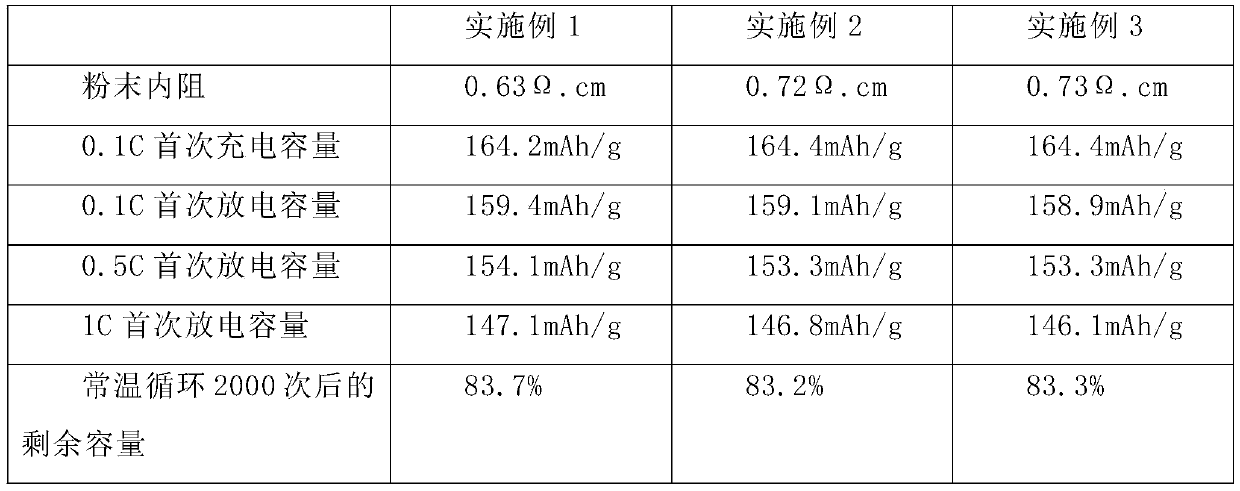

Embodiment 1

[0033] A preparation method for lithium iron phosphate, which comprises the following steps:

[0034] 1) Mix ferric chloride and lithium chloride with water at a molar ratio of 1:1.04 to obtain a mixed solution, then mix tributyl phosphate and N235 extractant at a volume ratio of 9:1 and stir evenly to obtain an extractant, and then The mixed solution and the extractant are extracted in 7 stages of countercurrent, and the phases are separated to obtain an organic phase and an aqueous phase;

[0035] 2) The organic phase is sprayed into the combustion furnace, and at the same time, air is introduced for combustion. The combustion temperature is 420 ° C, and the combustion material is obtained through dust collection;

[0036] 3) The obtained combustion material is put into a roller hearth furnace, calcined under the protection of an inert atmosphere, and the calcined material is obtained after cooling. After the calcined material is jet-pulverized, it is sieved to remove iron to ...

Embodiment 2

[0046] A preparation method for lithium iron phosphate, which comprises the following steps:

[0047] 1) Stir and mix ferric chloride and lithium chloride with water at a molar ratio of 1:1.035 to obtain a mixed solution, then mix tributyl phosphate and N235 extractant at a volume ratio of 8:1 and stir evenly to obtain an extractant, and then 8-stage countercurrent extraction of the mixed solution and the extractant, and phase separation to obtain an organic phase and an aqueous phase;

[0048] 2) The organic phase is sprayed into the combustion furnace, and at the same time, air is introduced for combustion. The combustion temperature is 380 ° C, and the combustion material is obtained through dust collection;

[0049] 3) The obtained combustion material is put into a roller hearth furnace, calcined under the protection of an inert atmosphere, and the calcined material is obtained after cooling. After the calcined material is jet-pulverized, it is sieved to remove iron to obt...

Embodiment 3

[0058] A preparation method for lithium iron phosphate, which comprises the following steps:

[0059] 1) Stir and mix ferric chloride and lithium chloride with water at a molar ratio of 1:1.045 to obtain a mixed solution, then mix tributyl phosphate and N235 extractant at a volume ratio of 8:1 and stir evenly to obtain an extractant, and then 8-stage countercurrent extraction of the mixed solution and the extractant, and phase separation to obtain an organic phase and an aqueous phase;

[0060] 2) The organic phase is sprayed into the combustion furnace, and at the same time, air is introduced for combustion. The combustion temperature is 425 ° C, and the combustion material is obtained through dust collection;

[0061] 3) The obtained combustion material is put into a roller hearth furnace, calcined under the protection of an inert atmosphere, and the calcined material is obtained after cooling. After the calcined material is jet-pulverized, it is sieved to remove iron to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com