Layered composite oxide coated positive electrode material and preparation method and application thereof

A layered composite and positive electrode material technology, applied in the field of materials, can solve the problems of industrial application requirements, there is still a certain distance, the cycle stability of lithium cobalt oxide is not helpful, and the problem of cycle stability cannot be overcome, so as to achieve obvious oxidation Reduction activity, excellent ion conductivity and electron conductivity, and the effect of reducing the generation of CEI

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the layered composite oxide-coated positive electrode material of the present invention, its main preparation steps include:

[0028] Step 110, mix the cobalt salt and the salt or oxide of M evenly in proportion, and sinter at 400°C to 700°C to obtain the bulk material precursor Co 3-x m x o 4-y x y ;

[0029] Among them, in the chemical formula, 0≤x≤0.03, 0≤y≤0.09;

[0030]M is a pre-doped metal element, including at least one of Mn, Ni, Al, Mg, Ti, Sm, Zr, and Nb;

[0031] The metal salt or oxide of M includes: at least one of the salts or oxides of Mn, Ni, Al, Mg, Ti, Sm, Zr or Nb;

[0032] X includes at least one of F, S and Cl;

[0033] The mass fraction of M in the cobalt element in the bulk material precursor is 0.05wt% to 1wt%;

[0034] Step 120, mix the bulk phase material precursor with lithium salt and additives according to the ratio, sinter at a high temperature of 800°C to 1200°C in an air atmosphere, and then pulverize to ...

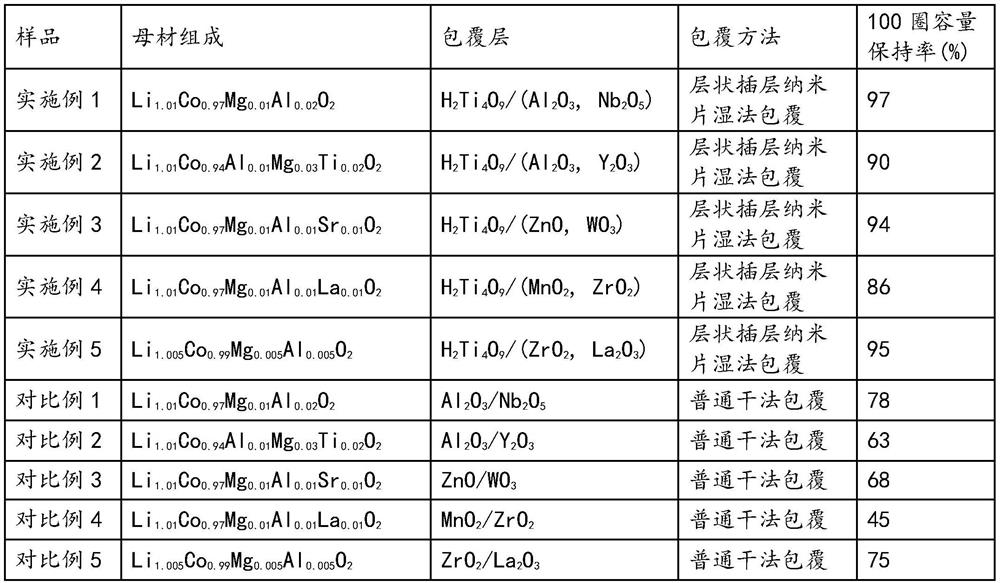

Embodiment 1

[0047] The cathode material provided in this embodiment is Li 1.01 co 0.97 Mg 0.01 Al 0.02 o 2 / H 2 Ti 4 o 9 / (Al 2 o 3 ,Nb 2 o 5 ). Among them, Li 1.01 co 0.97 Mg 0.01 Al 0.02 o 2 / H 2 Ti 4 o 9 / (Al 2 o 3 ,Nb 2 o 5 ) means Li 1.01 co 0.97 Mg 0.01 Al 0.02 o 2 As the core, the surface layer is coated with nano-H 2 Ti 4 o 9 / (Al 2 o 3 ,Nb 2 o 5 ) positive electrode material of composite oxide, brackets (Al 2 o 3 ,Nb 2 o 5 ) are oxides intercalated into layered titanates. The methods described in the following examples are the same.

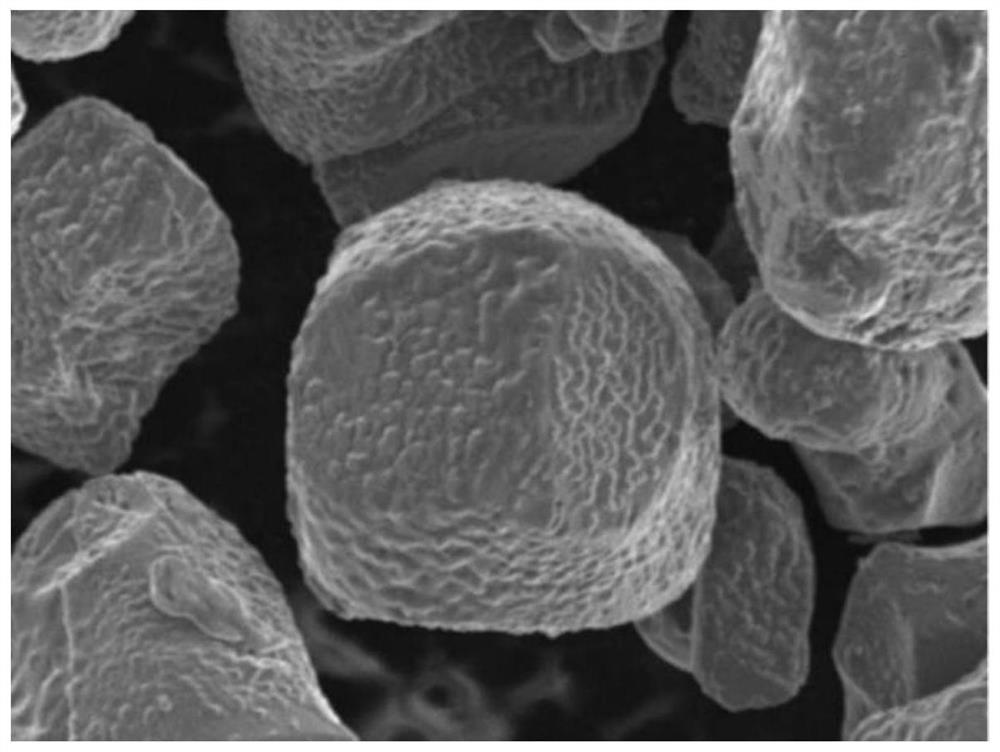

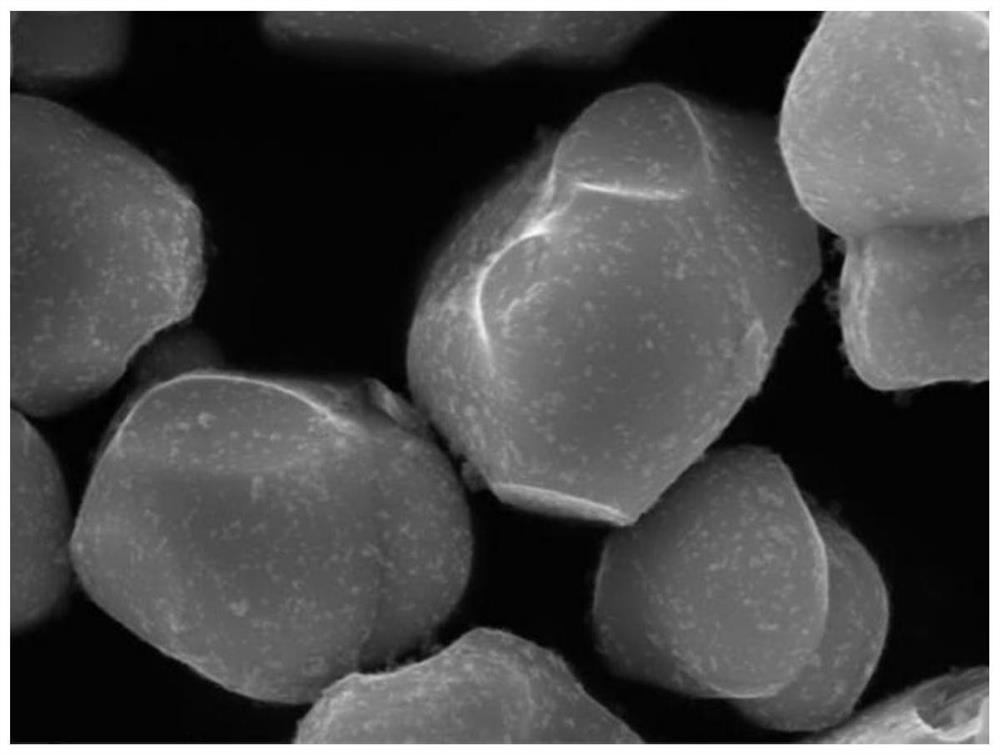

[0048] Among them, the base material Li 1.01 co 0.97 Mg 0.01 Al 0.02 o 2 The particle size is about 14.0μm, and the thickness of the surface coating layer is about 20nm.

[0049] The preparation method is as follows:

[0050] 1) Weigh a certain mass of CoCO with a D50 of 14.0 μm 3 , then press M Mg :M Co = 0.1% ratio MgO was weighed, mixed uniformly by a high-speed mixer, sintered and pulverized at 68...

Embodiment 2

[0057] Change MgO in step 1) in embodiment 1 to Al 2 o 3 , M in Example 1 Mg :M Co = M Al :M Co , Al in step 2) 2 o 3 Change to MgO+TiO 2 ,M Mg+Ti :M Co+Al =0.5%, other steps are the same to obtain the positive electrode material of this embodiment.

[0058] For the convenience of comparison, according to the traditional dry mixing and sintering method, the same material was used to prepare Comparative Example 2 for comparison with Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com