A kind of preparation method of lithium-ion battery hybrid positive electrode

A technology of lithium-ion batteries and mixed positive electrodes, which is applied in the directions of battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve the problems of large internal resistance of pole pieces and poor cycle life of batteries, so as to improve energy density and increase Stability, the effect of avoiding the increase of interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

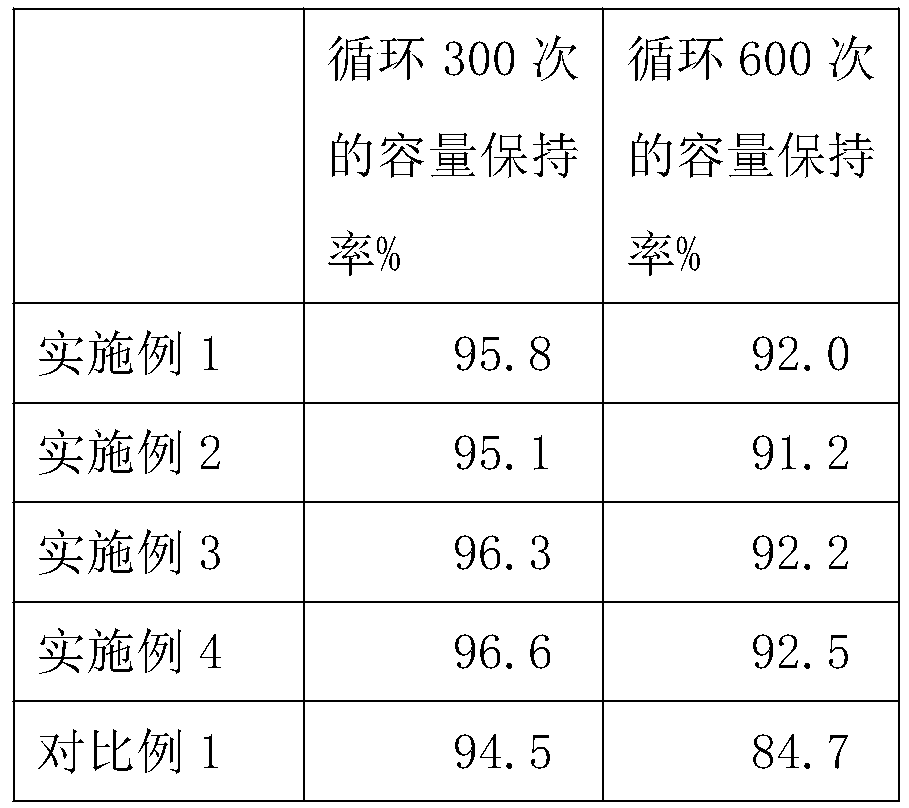

Examples

Embodiment 1

[0024] 1), providing a first active material, a second active material and a third active material, wherein the molecular formula of the first active material is LiNi 0.8 mn 0.1 co 0.1 o 2 , the molecular formula of the second active material is LiNi 0.3 mn 0.4 co 0.3 o 2 , the third active material is LiMnPO 4 ;

[0025] 2) Add NMP into the first vacuum stirred tank, add sodium carboxymethyl cellulose, PVDF, and superconducting carbon black Super P into the first vacuum stirred tank in turn, stir for 3 hours to obtain a dispersed solution, and add the average The first active material particles with a particle size of 2.5 microns and an aspect ratio of 1.5 were stirred for 4 hours at a stirring speed of 30 r / min to obtain the first slurry, wherein the mass ratio, the first active material: PVDF: sodium carboxymethylcellulose : superconducting carbon black Super P=100:2:6:3, the solid content of the first slurry is 52%;

[0026] 3), NMP was added to the second vacuum ...

Embodiment 2

[0032] 1), providing a first active material, a second active material and a third active material, wherein the molecular formula of the first active material is LiNi 0.8 mn 0.1 co 0.1 o 2 , the molecular formula of the second active material is LiNi 0.3 mn 0.4 co 0.3 o 2 , the third active material is LiMnPO 4 ;

[0033] 2), NMP was added to the first vacuum stirred tank, sodium carboxymethyl cellulose, PVDF, and superconducting carbon black Super P were added to the first vacuum stirred tank in turn, and stirred for 5 hours to obtain a dispersed solution. The first active material particles with a particle size of 4 microns and an aspect ratio of 1.8 were stirred for 6 hours at a stirring speed of 90 r / min to obtain the first slurry, wherein the mass ratio, the first active material: PVDF: sodium carboxymethylcellulose : superconducting carbon black Super P=100:4:9:5, the solid content of the first slurry is 56%;

[0034] 3), NMP was added to the second vacuum stirr...

Embodiment 3

[0040] 1), providing a first active material, a second active material and a third active material, wherein the molecular formula of the first active material is LiNi 0.8 mn 0.1 co 0.1 o 2 , the molecular formula of the second active material is LiNi 0.3 mn 0.4 co 0.3 o 2 , the third active material is LiMnPO 4 ;

[0041] 2), NMP was added to the first vacuum stirred tank, sodium carboxymethyl cellulose, PVDF, and superconducting carbon black Super P were added to the first vacuum stirred tank in turn, stirred for 4 hours to obtain a dispersed solution, and the average The first active material particles with a particle size of 3 microns and an aspect ratio of 1.6 were stirred for 5 hours at a stirring speed of 60 r / min to obtain the first slurry, wherein the mass ratio, the first active material: PVDF: sodium carboxymethylcellulose : superconducting carbon black Super P=100:3:7:4, the solid content of the first slurry is 55%;

[0042] 3), NMP was added to the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com