Coil type battery plate group and battery comprising the same

A battery pole and winding technology, which is applied to primary batteries, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of stress concentration, small curvature radius, and decrease in tensile strength, so as to reduce stress concentration and improve Tensile strength, effect of reducing compacted density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

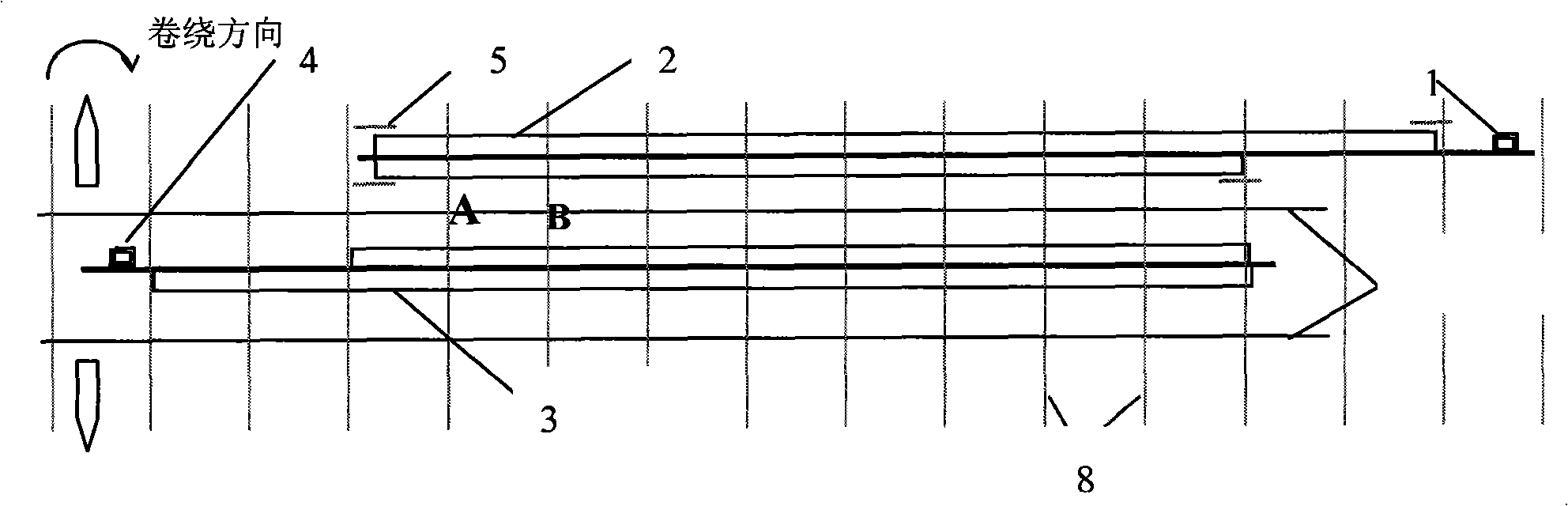

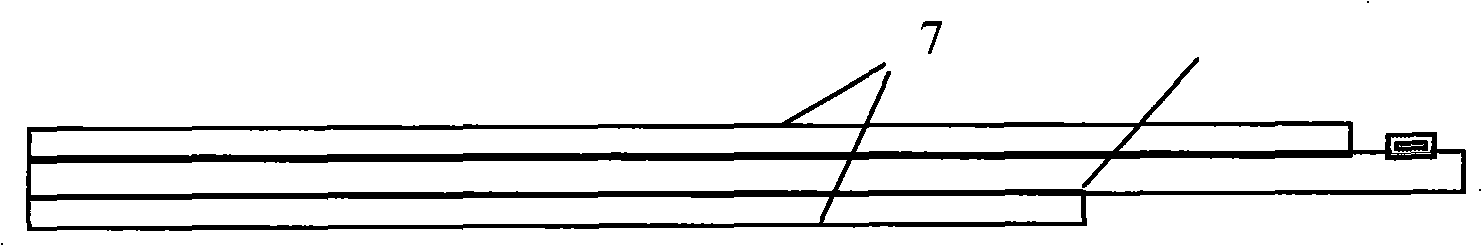

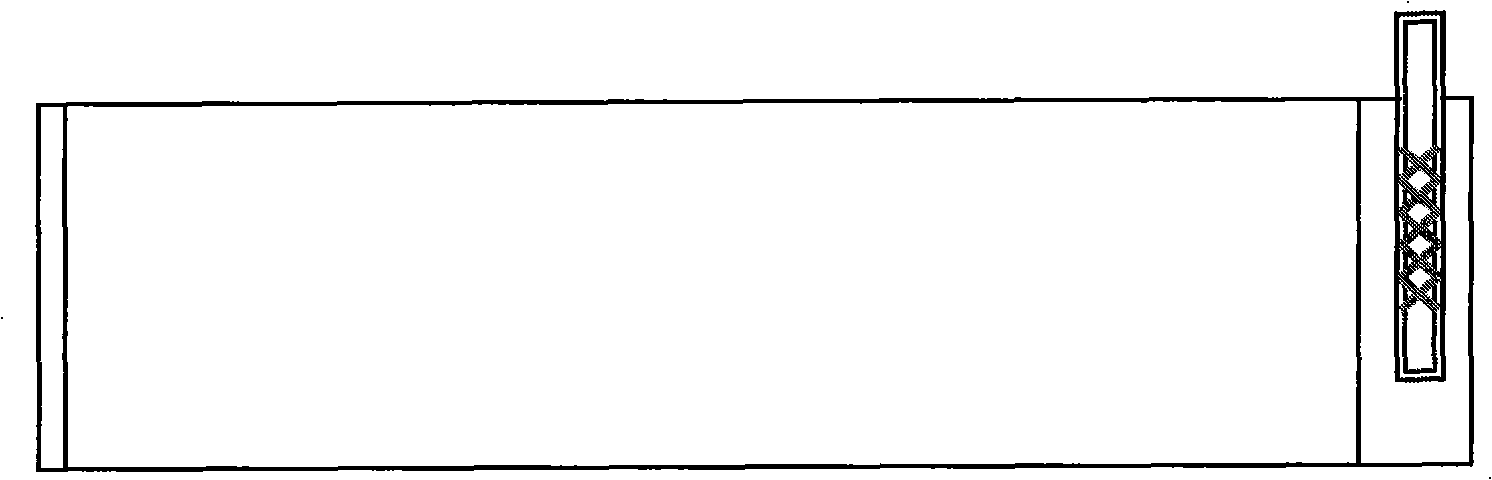

[0040] Referring to Fig. 2a-Fig. 2e, the lithium-ion battery includes a wound battery pole group, and the wound battery pole group includes a positive electrode sheet (the compacted density of the positive electrode sheet is designed by lowering the upper limit critical value by 0.05g / cm3) 2. The negative electrode sheet 3. A diaphragm 9 is provided in the middle of the positive electrode sheet 2 and the negative electrode sheet 3 and on the outside of the negative electrode sheet; the positive electrode sheet 2 and the negative electrode sheet 3 are respectively connected with the positive electrode ear 1 and the negative electrode ear 4; Adhesive paper 5; aluminum foil 10 in the middle of the positive electrode sheet 2, and attachments 7 on both sides; copper foil 6 in the middle of the negative electrode sheet 3, and attachments 7 on both sides; the positive electrode sheet 2 and the negative electrode sheet 3 are along the crease of the electrode sheet 8 coils. There is a ...

Embodiment 2

[0044] Referring to Figures 3a-3e, the lithium ion battery includes a wound battery pole group, and the wound battery pole group includes a positive electrode sheet 2 and a negative electrode sheet 3; a separator is provided in the middle of the positive electrode sheet 2 and the negative electrode sheet 3 and on the outside of the negative electrode sheet 9. The positive pole piece 2 and the negative pole piece 3 are respectively connected with the positive pole ear 1 and the negative pole pole 4; the two ends of the positive pole piece 2 are pasted with protective adhesive tape 5; the middle of the positive pole piece 2 is aluminum foil 10, and the two sides are attachments 7; The middle of the negative electrode sheet 3 is copper foil 6, and the two sides are attached materials 7; the positive electrode sheet 2 and the negative electrode sheet 3 are wound along the crease 8 of the electrode sheet.

[0045] The difference from the lithium-ion battery of Example 1 is that ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com