Method for preparing lithium ion battery mixed positive electrode

A lithium-ion battery, hybrid cathode technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc. Stability, the effect of avoiding the increase of the interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

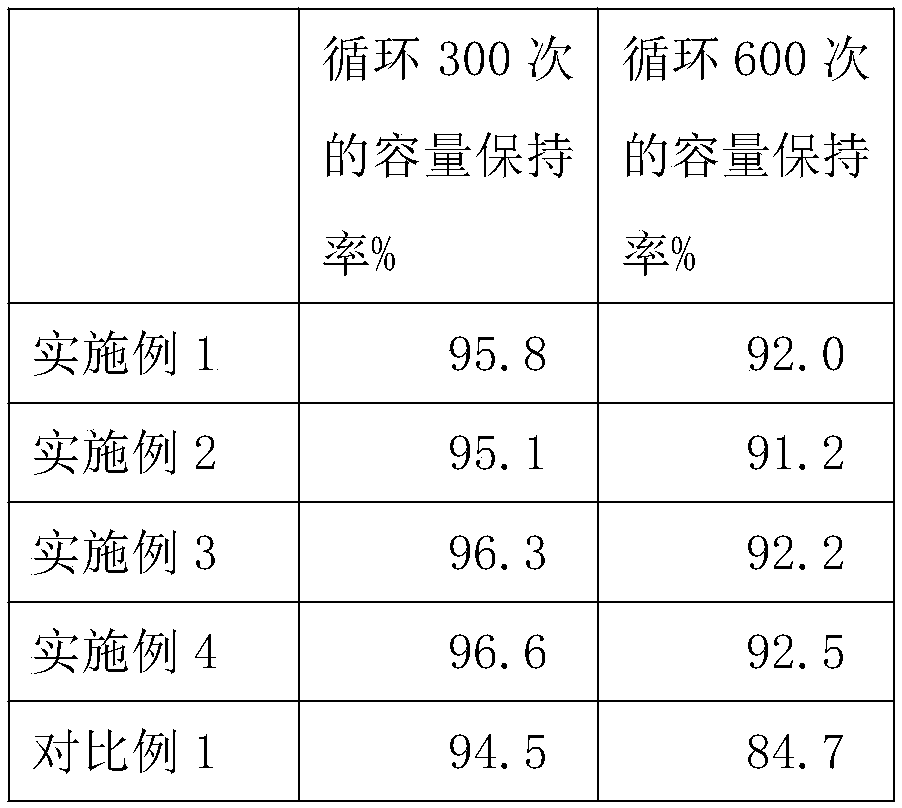

Examples

Embodiment 1

[0024] 1), providing a first active material, a second active material and a third active material, wherein the molecular formula of the first active material is LiNi 0.8 mn 0.1 co 0.1 o 2 , the molecular formula of the second active material is LiNi 0.3 mn 0.4 co 0.3 o 2 , the third active material is LiMnPO 4 ;

[0025] 2) Add NMP into the first vacuum stirred tank, add sodium carboxymethyl cellulose, PVDF, and superconducting carbon black Super P into the first vacuum stirred tank in turn, stir for 3 hours to obtain a dispersed solution, and add the average The first active material particles with a particle size of 2.5 microns and an aspect ratio of 1.5 were stirred for 4 hours at a stirring speed of 30 r / min to obtain the first slurry, wherein the mass ratio, the first active material: PVDF: sodium carboxymethylcellulose : superconducting carbon black Super P=100:2:6:3, the solid content of the first slurry is 52%;

[0026] 3), NMP was added to the second vacuum ...

Embodiment 2

[0032] 1), providing a first active material, a second active material and a third active material, wherein the molecular formula of the first active material is LiNi 0.8 mn 0.1 co 0.1 o 2 , the molecular formula of the second active material is LiNi 0.3 mn 0.4 co 0.3 o 2 , the third active material is LiMnPO 4 ;

[0033] 2), NMP was added to the first vacuum stirred tank, sodium carboxymethyl cellulose, PVDF, and superconducting carbon black Super P were added to the first vacuum stirred tank in turn, and stirred for 5 hours to obtain a dispersed solution. The first active material particles with a particle size of 4 microns and an aspect ratio of 1.8 were stirred for 6 hours at a stirring speed of 90 r / min to obtain the first slurry, wherein the mass ratio, the first active material: PVDF: sodium carboxymethylcellulose : superconducting carbon black Super P=100:4:9:5, the solid content of the first slurry is 56%;

[0034] 3), NMP was added to the second vacuum stirr...

Embodiment 3

[0040] 1), providing a first active material, a second active material and a third active material, wherein the molecular formula of the first active material is LiNi 0.8 mn 0.1 co 0.1 o 2 , the molecular formula of the second active material is LiNi 0.3 mn 0.4 co 0.3 o 2 , the third active material is LiMnPO 4 ;

[0041] 2), NMP was added to the first vacuum stirred tank, sodium carboxymethyl cellulose, PVDF, and superconducting carbon black Super P were added to the first vacuum stirred tank in turn, stirred for 4 hours to obtain a dispersed solution, and the average The first active material particles with a particle size of 3 microns and an aspect ratio of 1.6 were stirred for 5 hours at a stirring speed of 60 r / min to obtain the first slurry, wherein the mass ratio, the first active material: PVDF: sodium carboxymethylcellulose : superconducting carbon black Super P=100:3:7:4, the solid content of the first slurry is 55%;

[0042] 3), NMP was added to the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com