A kind of preparation method of high compaction high capacity lithium iron phosphate

A lithium iron phosphate, high-capacity technology, applied in chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve the problems of large particle size of lithium iron phosphate and low capacity of lithium iron phosphate, and achieve good electrical performance and simple method , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method for high-compression high-capacity lithium iron phosphate, which comprises the following steps:

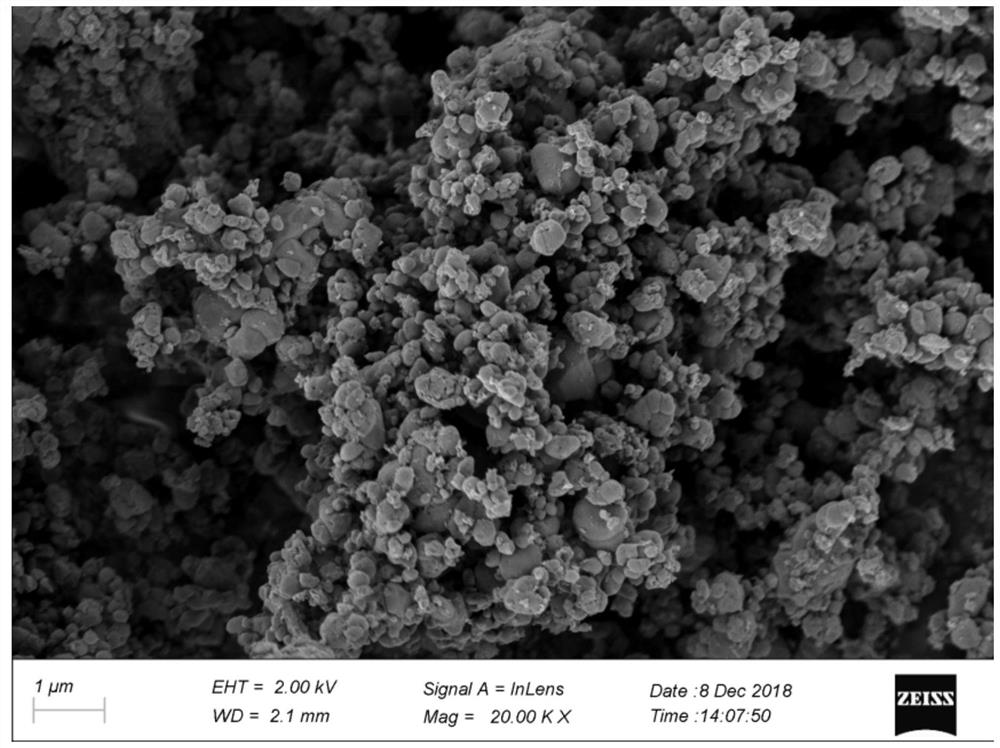

[0038] (1) Iron phosphate, lithium carbonate, polyethylene glycol and sucrose are weighed, then mixed, and alcohol is added to carry out wet grinding to obtain a particle diameter of 455nm;

[0039] (2) The slurry obtained in step (1) is spray-dried, and the dried alcohol vapor is condensed to obtain alcohol, and the spray-dried material is pulverized to a particle size of 4 μm to obtain a pulverized material;

[0040] (3) Put the pulverized material obtained in step (2) into the roller furnace for sintering. The sintering is divided into four stages, namely heating section, heat preservation section, decarburization section and cooling section, heating section and heat preservation section Nitrogen is introduced into the interior, and carbon dioxide is introduced into the decarburization section and the cooling section. The heating time of the heating ...

Embodiment 2

[0054] A preparation method for high-compression high-capacity lithium iron phosphate, which comprises the following steps:

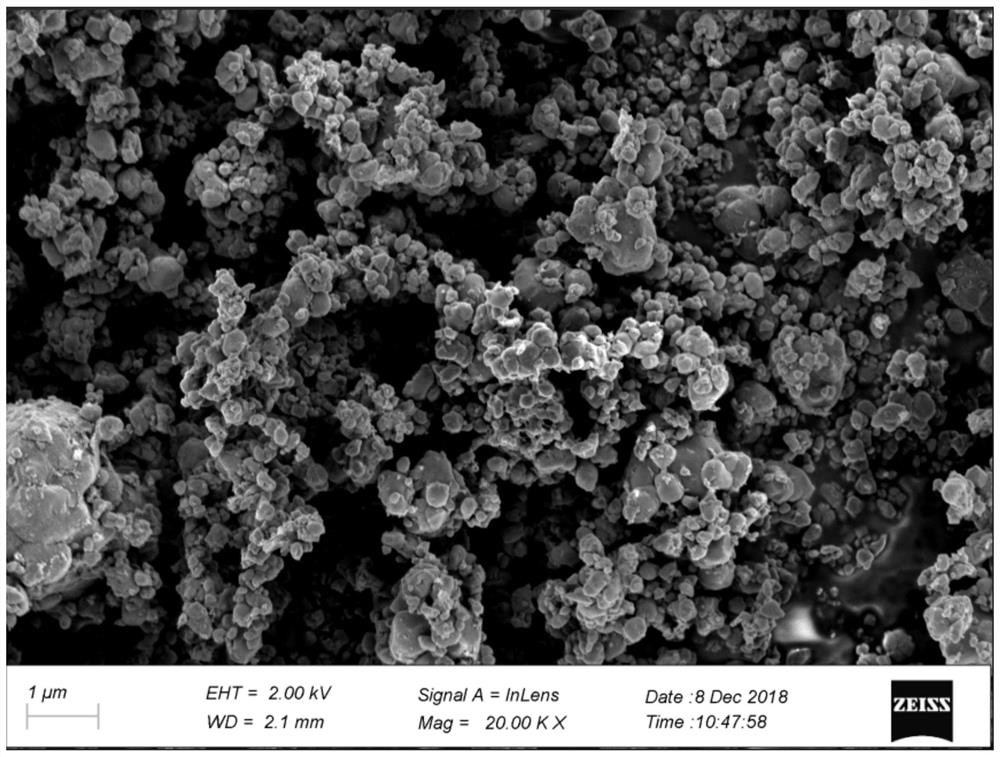

[0055] (1) Iron phosphate, lithium carbonate, polyethylene glycol and sucrose are weighed, then mixed, and alcohol is added to carry out wet grinding to obtain a particle diameter of 420nm;

[0056] (2) The slurry obtained in step (1) is spray-dried, and the dried alcohol vapor is condensed to obtain alcohol, and the spray-dried material is crushed to a particle size of 5 μm to obtain a crushed material;

[0057] (3) Put the pulverized material obtained in step (2) into the roller furnace for sintering. The sintering is divided into four stages, namely heating section, heat preservation section, decarburization section and cooling section, heating section and heat preservation section Nitrogen is introduced into the interior, and carbon dioxide is introduced into the decarburization section and the cooling section. The heating time of the heating sectio...

Embodiment 3

[0071] A preparation method for high-compression high-capacity lithium iron phosphate, which comprises the following steps:

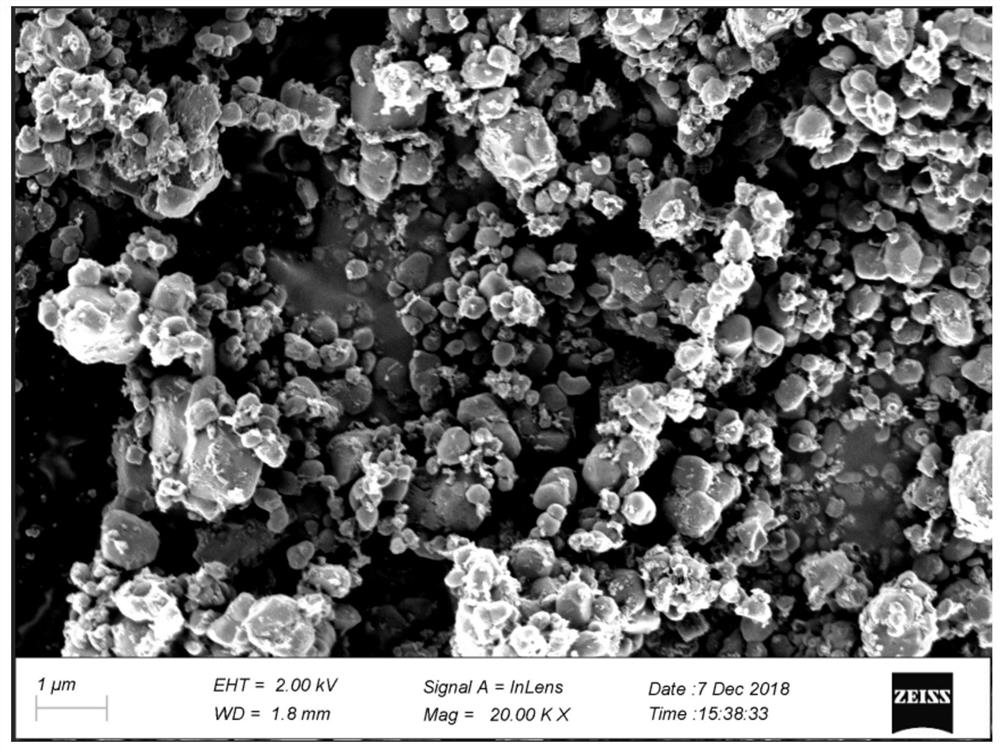

[0072] (1) Iron phosphate, lithium carbonate, polyethylene glycol and sucrose are weighed, then mixed, and alcohol is added for wet grinding to obtain a particle diameter of 445nm;

[0073] (2) The slurry obtained in step (1) is spray-dried, and the dried alcohol vapor is condensed to obtain alcohol, and the spray-dried material is crushed to a particle size of 4.2 μm to obtain a crushed material;

[0074] (3) Put the pulverized material obtained in step (2) into the roller furnace for sintering. The sintering is divided into four stages, namely heating section, heat preservation section, decarburization section and cooling section, heating section and heat preservation section Nitrogen is introduced into the interior, and carbon dioxide is introduced into the decarburization section and the cooling section. The heating time of the heating section is 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com