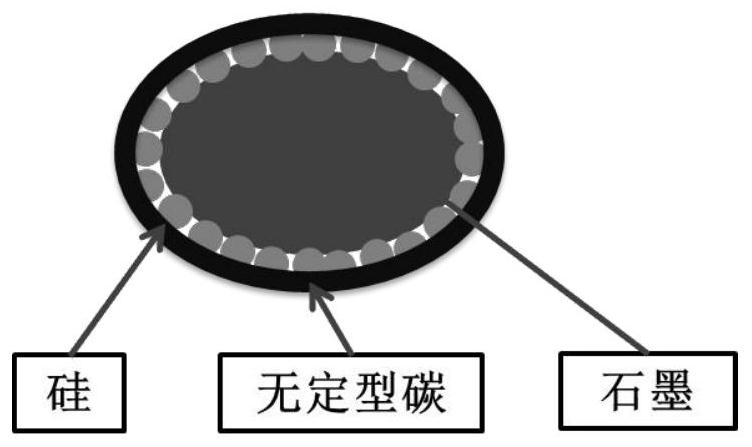

A kind of preparation method of silicon carbon negative electrode material and lithium ion battery

A negative electrode material, silicon carbon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfavorable industrial development and application, complicated steps, and poor cycle performance, and achieve excellent electrochemical cycle stability and easy industrialization The effect of simple production and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

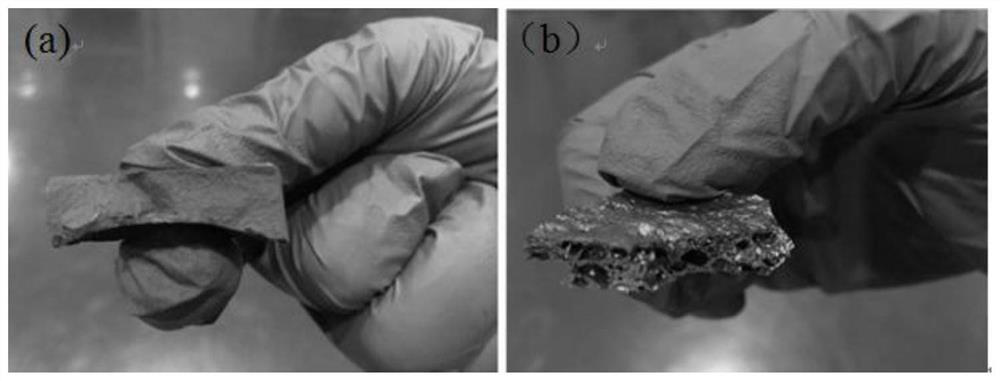

Method used

Image

Examples

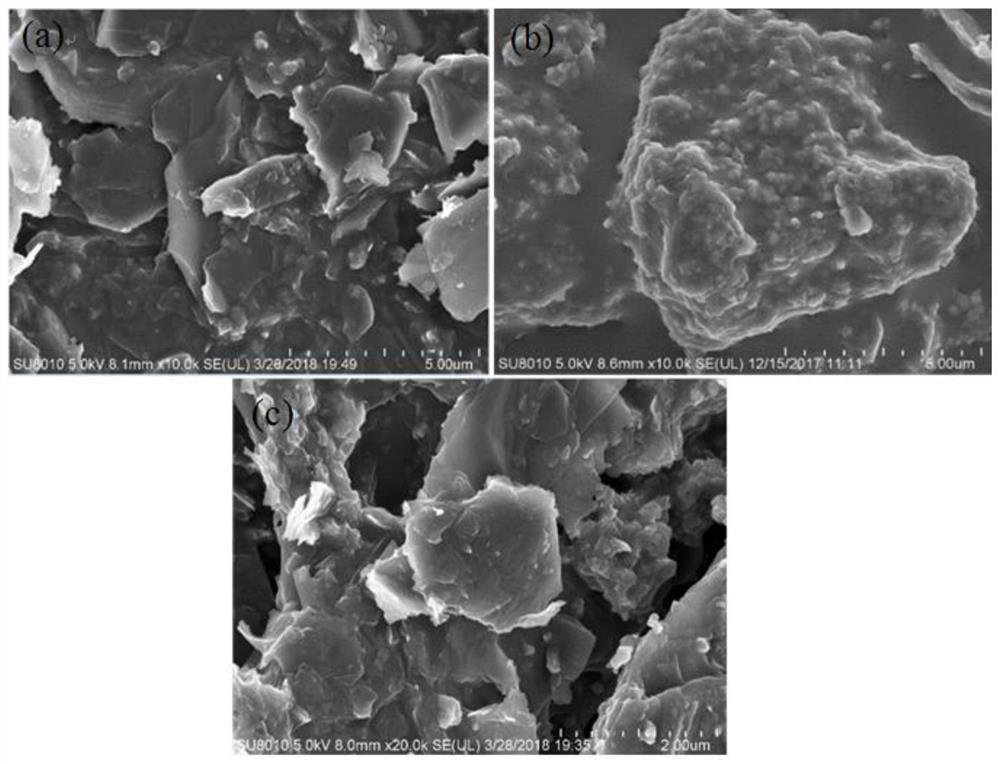

Embodiment 1

[0045] Will D 50 100nm of 2g nano-silicon and D 50 6g flake natural graphite of 8μm is mixed evenly in solid phase, vibrating and sieving, the sieve is 600 mesh, the power of vibrating sieving is 300KW, and then mixed with 2g of high-temperature asphalt in solid phase, vibrating and sieving, the sieve is 250 Mesh sieve, the power of vibrating sieving is 300KW to obtain nano-silicon / graphite / high-temperature asphalt composite material, the above-mentioned composite material is formed by vibration, the frequency of vibration forming is 500 times / min, and the time of vibration forming is 20min to obtain dense powder In an inert gas environment, raise the temperature of the obtained compact powder to 500°C at the first heating rate of 2°C / min, keep it for 4h, then raise the temperature to 950°C at the second heating rate of 3°C / min, and keep it for 4h , natural cooling, crushing and crushing to obtain the silicon carbon negative electrode material.

Embodiment 2

[0047] Will D 50 100nm of 2g nano-silicon and D 50 6g flake natural graphite of 20μm is mixed evenly in solid phase, vibrating and sieving, the sieve is 450 mesh, the power of vibrating sieving is 300KW, then mixed with 1g glucose in solid phase, vibrating and sieving, the sieve is 250 mesh Sieve, the power of vibrating sieving is 300KW to obtain nano-silicon / graphite / glucose composite material, the above-mentioned composite material is vibrated, the frequency of vibration forming is 600 times / min, the time of vibration forming is 20min, and dense powder is obtained. The obtained dense powder was heated up to 500°C at the first heating rate of 8°C / min in an inert gas environment, and kept for 5 hours, and then raised to 800°C at the second heating rate of 0.5°C / min, kept for 4 hours, and naturally Cool down, crush and pulverize to obtain silicon carbon negative electrode material.

Embodiment 3

[0049] Will D 50 100nm of 3g nano-silicon and D 50 8g flake natural graphite of 10μm is mixed evenly in solid phase, vibrating and sieving, the sieve is 350 mesh, the power of vibrating sieving is 500KW, and then mixed with 4g high-temperature asphalt in solid phase, vibrating sieving, sieving It is a 250-mesh sieve, and the power of vibrating sieving is 500KW to obtain a nano-silicon / graphite / high-temperature asphalt composite material. The composite material is vibrated and formed. The frequency of vibration forming is 20 times / min, and the time of vibration forming is 600min. For dense powder, heat the obtained dense powder to 400°C at the first heating rate of 0.5°C / min in an inert gas environment, keep it warm for 5 hours, and then raise the temperature to 1100°C at the second heating rate of 1°C / min, Keeping it warm for 5 hours, cooling down naturally, crushing and pulverizing to obtain the silicon carbon negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com