Novel geo-thermal drilling impactor

A geothermal drilling and impactor technology, applied in drilling equipment, drilling with liquid/gas jet, driving device for drilling in wellbore, etc. Reduced slippage, easy processing and installation, good erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not intended to limit the present invention.

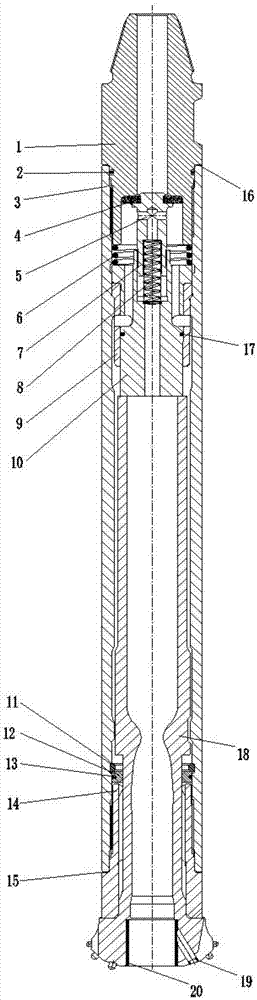

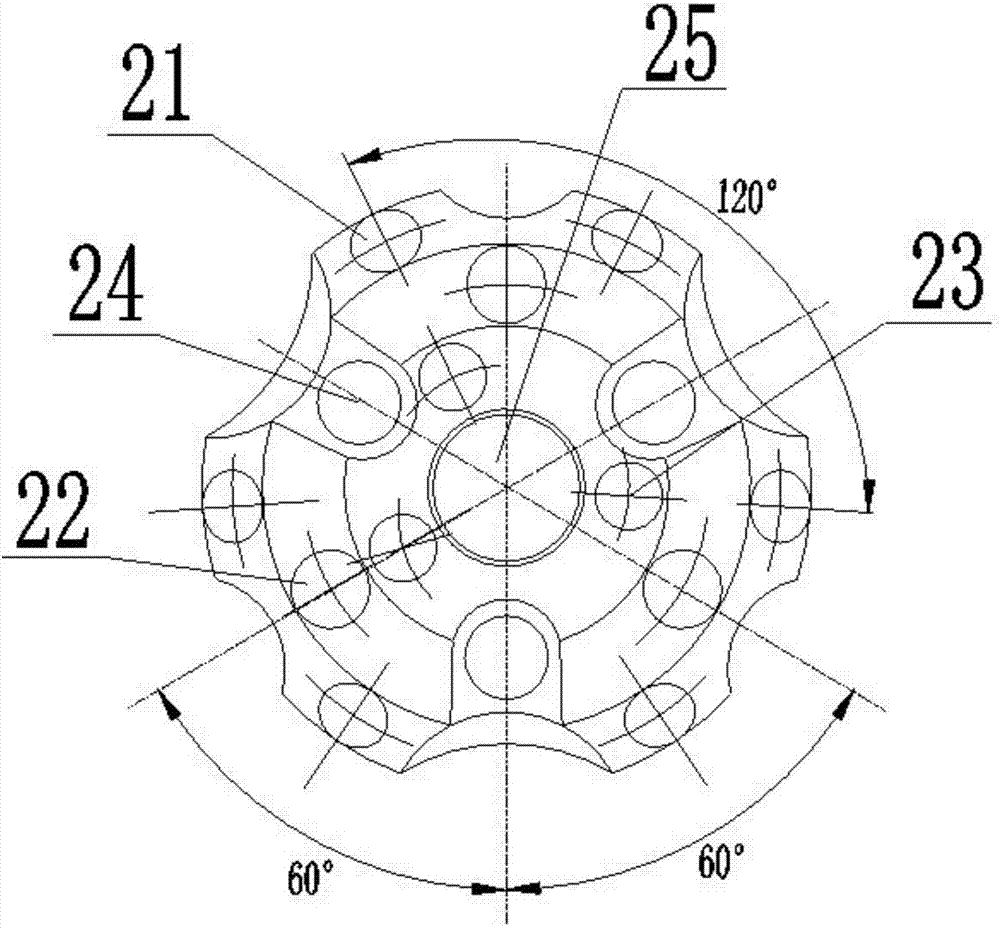

[0040] Such as figure 1 , figure 2 As shown, a new geothermal drilling impactor consists of a rear joint 1, a sealing ring I2, an outer casing 3, an alloy head 4, an airway hole 5, a spring I6, a check valve body 7, a spring II8, an air inlet sleeve 9, Air distribution seat 10, snap ring 11, retaining ring 12, sealing ring II13, front joint 14, adjusting pad 15, gasket 16, sealing ring III17, Rafael bit body 18, small nozzle 19, large nozzle 20, The inside of the rear joint 1 is drilled with reaming holes and airway holes, and the gasket 17 is installed between the joint 1 and the outer sleeve 3 to support and protect the sealing end faces of the rear joint 1 and the outer sleeve 3, and the rear joint 1 and the outer sleeve 3 It is connected by a tapered thread, and the sealing ring I2 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com